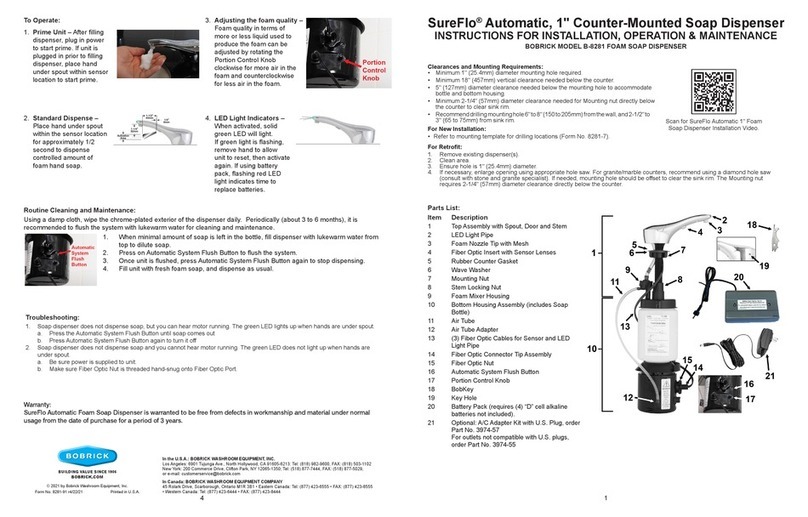

Setting up the ULTRASAVER™

Filling barrels

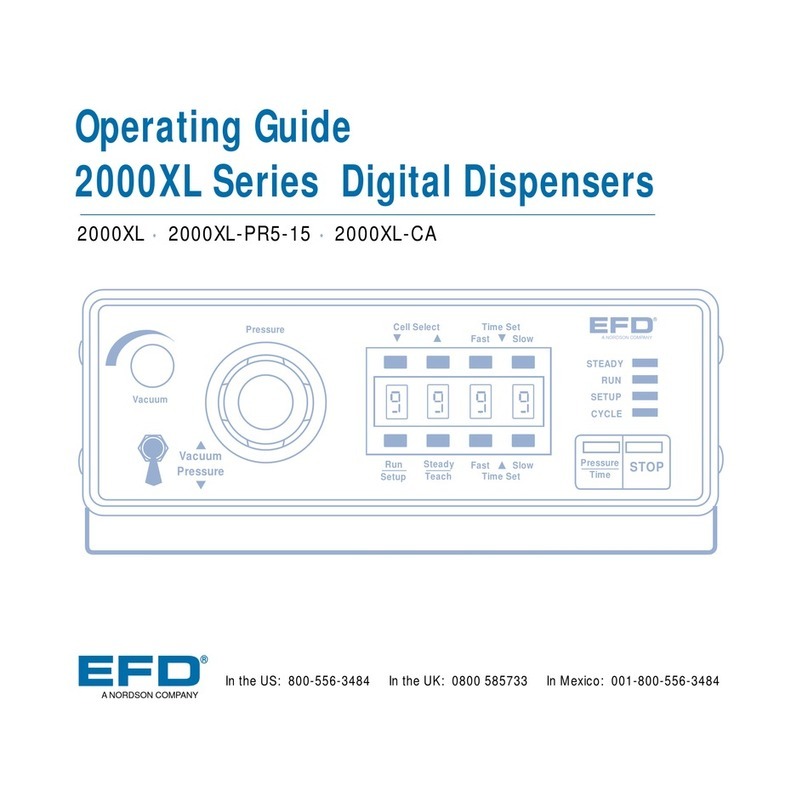

1

2

3

4

5

67

8

9

Note: Clean, dry, filtered air is required to meet warranty. If necessary,

use five-micron filter regulator (not supplied – order #2000F755).

1. Connect ULTRASAVER (or filter regulator where required) to plant

air supply.

2. If appropriate, connect ULTRASAVER to filter regulator.

Press air hose firmly into fittings to connect.

3. Set plant air supply (or filter regulator) within 80 to 100 psi

(5.4 to 7.0 bar).

4. Plug in the foot pedal.

5. Set voltage selector switch to the proper value.

6. Connect power cord.

7. Attach the hose support to desired side of the ULTRASAVER.

8. Position barrel adapter hose in the support and connect to

the ULTRASAVER’s output.

9. Turn power switch on (rear panel).

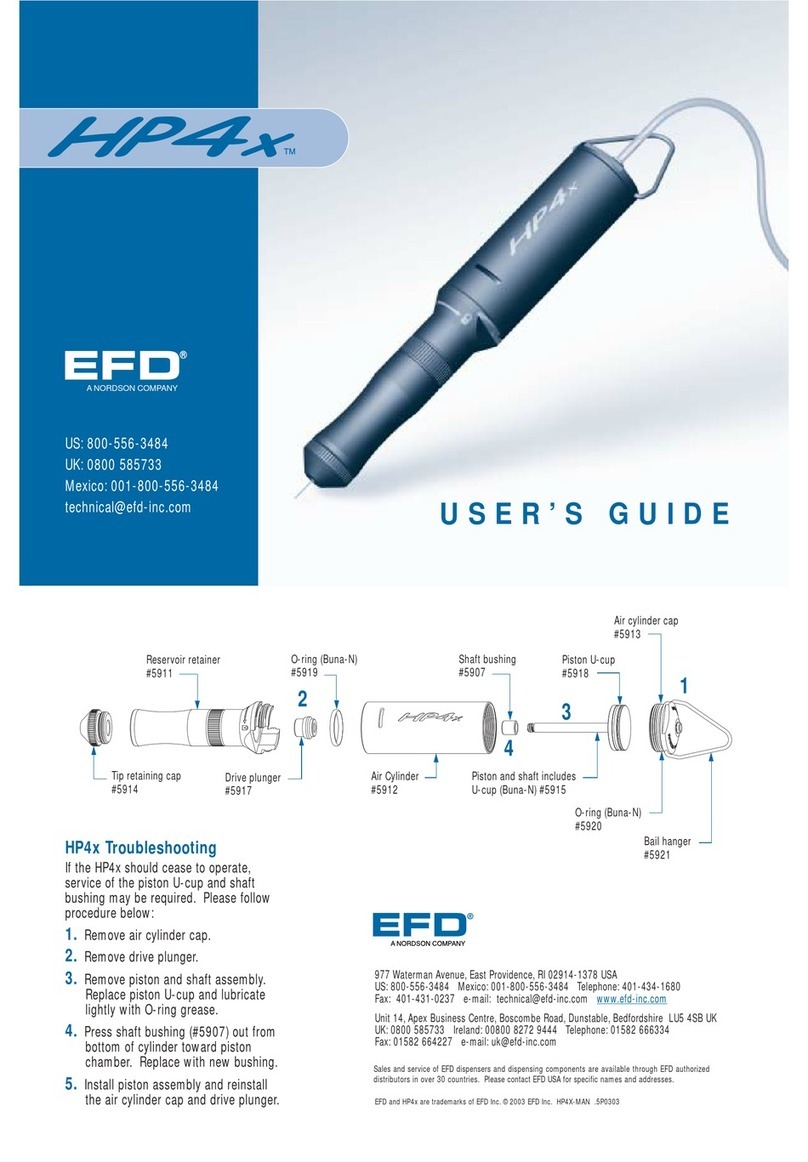

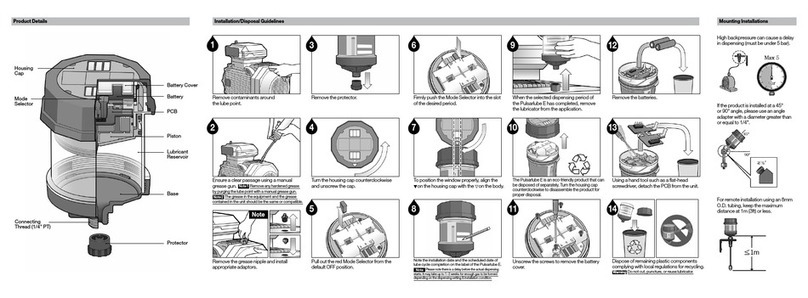

Thin, pourable fluids

Twist on a tip cap and pour fluid in.

If appropriate, insert the SmoothFlow™ piston.

Carefully press the piston down (use a pen or pencil)

until it contacts the fluid.

Attach barrel to barrel adapter assembly.

Invert barrel, replace tip cap with selected dispense tip.

Thick or non-leveling materials

Same procedure as with thin, pourable fluids EXCEPT:

Spoon fluid into the barrel with a spatula. (If packed

in a 1/10 gallon cartridge, try loading the barrel with a

caulking gun.)

Note: Move the fluid toward the bottom of the barrel

by pressing the SmoothFlow™ piston. Squeeze barrel

sides slightly to allow trapped air to escape.

Solvents,

cyanoacrylates

or anaerobics

Same procedure as with thin,

pourable fluids EXCEPT:

Use the blue LV Barrier™.

Place barrier in the TOP of the

barrel reservoir.

Allow air between barrier and

fluid. (Do not contact the blue

barrier to the fluid.)

1/2 max. fill

Air gap

LV Barrier™

Caulking gun

or spatula

2/3

max.

fill

2/3

max.

fill