EFD 1000XL User manual

Operating Guide

1000 Series Dispensers

®

A NORDSON COMPANY

In the US: 800-556-3484 In the UK: 0800 585733 In Mexico: 001-800-556-3484

1000XL 1000D

•

The 1000 Series dispensers provide years of trouble-free, produc-

tive service. This Operating Guide will help you maximize the

usefulness of your new dispenser.

Pleasespendafewminutestobecomefamiliarwiththecontrolsand

features of your new dispenser. Follow our recommended testing

procedures. Reviewthehelpfulinformationwehaveincludedbased

on over 30 years of industrial dispensing experience.

Most questions you will have are answered in this Guide. However,

ifyouneedassistance,pleasedonothesitatetocontactEFDoryour

authorized EFD distributor.

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

Introduction

The EFD Pledge

We pledge that you will be completely satisfied with our products.

We endeavor to ensure that every EFD product is produced to our

no-compromise quality standards.

If you feel that you are not receiving all the support you require,

orifyouhaveanyquestionsorcomments,Iinviteyoutowriteorcall

me personally.

Our goal is to build not only the finest equipment and components,

but also to build long-term customer relationships founded on

superb quality, service, value and trust. John Carter, President

☎

Getting Started ............................................................................. 4

Specifications

First Steps .................................................................................... 5

Unpacking the Dispenser and Activating your Ten Year No-fault Warranty

1000XL - Hookup ...................................................................... 6-7

1000XL - Setup for Testing ....................................................... 8-9

1000D - Hookup .................................................................... 10-11

1000D - Setup for Testing ..................................................... 12-13

Testing the 1000 Series Dispensers ..................................... 14-15

Making Timed Deposits

Changing Deposit Size

Drawing Stripes

ULTRA Dispensing System................................................... 16-17

How to Use the Vacuum Control........................................... 18-19

1000XL only

Loading the Barrel Reservoirs............................................... 20-21

Now, Test Your Fluid.................................................................. 22

Troubleshooting ......................................................................... 23

1000XL and 1000D Schematic & Parts...................................... 24

1000 Series Programmable Timer ............................................. 25

Suggestions & Reminders.......................................................... 26

Components Reorder................................................................. 27

Ten Year No-fault Warranty ....................................................... 28

Meets applicable CSA and CE requirements.

Reference CSA LR File Number 84105

Contents

This manual is for the express and sole use of EFD

dispenserpurchasers and users,andnoportionof this

manual may be reproduced in any form.

EFD, ULTRA System, LV Barrier, SmoothFlow,

ZeroDraft, SafetyLok, SnapLok and DispenStand are

trademarks of EFD Inc. ©2004 EFD Inc.

We have organized this Guide to provide setup and testing proce-

dures for the 1000XL and 1000D dispensers.

If you have the 1000XL, first review pages 6 - 9 which illustrate how

to hook up the dispenser and what the controls do.

For the 1000D, review pages 10 - 13.

Next, pages 14 - 15 show how to dispense the thick, paste-like test

material included in the Test Kit. These instructions are common to

both 1000 Series dispensers.

Finally, pages 18 - 19 illustrate how to dispense low-viscosity liquid

using the vacuum control provided on the 1000XL.

The rest of the information in this Guide applies to both of the 1000

Series dispensers.

1000 Series Specifications

Input voltage: Selectable

100/120/220 VAC

50/60 Hz 16/13 VA

Internal voltage: 24 VDC

Foot-pedal voltage: 9 VDC

Air input: 80 to 100 psi

(5.5 to 6.9 bar)

Air output: 0 to 100 psi

(0 to 6.9 bar)

Cycle rate: > 600/minute

Time repeat: ±0.1%

Initiation: maintained or momentary

TimeRange: programmable(seconds)

0.005 to 0.04 sec.

0.01 to 1.0 sec.

0.1 to 10 sec.

0.2 to 20 sec.

0.3 to 31 sec.

1000XL

10⅜x 8½x 2⅝ 5 lb 12 oz

26.4 x 21.6 x 6.7 cm 2.63 kg

1000D

8⅝x 8½x 2⅝ 4 lb 12 oz

21.9 x 21.6 x 6.7 cm 2.18 kg

Getting Started

First: Unpackanduse the checklist enclosed with the Dispenser Kit

to identify all items. If there is any discrepancy, please call us

immediately.

Second: Powerandcompressedplantairshouldbeavailablewhere

thedispenseristobesetup. Airpressureshouldbebetween80and

100 psi (5.5 to 6.9 bar). (Bottled nitrogen can be used.) If you are

notusing an EFD five-micronfilterregulator #2000F755, be certain

your plant air is properly filtered and dry.

Check voltage label to be certain it agrees with the available power.

Third: Now is a good time to ACTIVATE your extended Ten Year

No-fault Warranty. Please fill in and return the postage-paid

Warrantycard. Or,ifyouprefer,calltheappropriatetoll-freenumber

listed below, provide the serial number of your dispenser and

respond to a few short questions.

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

☎

First Steps

❻

❶

❺

Check voltage label

on dispenser

Plant air, 125 psi maximum to

regulator. Output from regulator

should be a minimum of 80 psi,

maximum of 100 psi.

❷

❸

❹

Blue

test fluid Male quick-connect,

insert and twist to lock

❼

Power

cord

Air input

hose

Foot pedal

assembly

Adapter

assembly 1000XL

1000XL

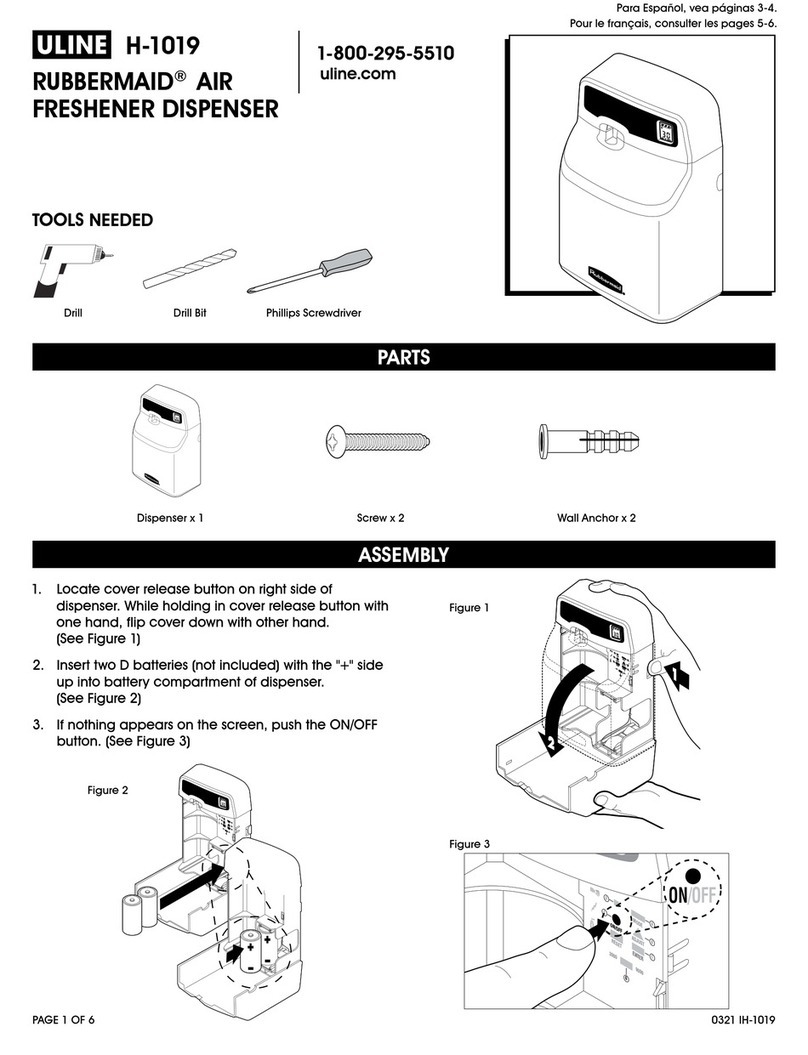

1000XL -- Hookup

❶Connecttheairinputhosetoaplantairsource. Setplantairsupply

within 80 to 100 psi (5.5 to 6.9 bar). Where required, use an EFD

five-micron filter regulator #2000F755 (see Warranty).

❷Attachtheairinputhosecouplingtothedispenser. Pullbackmetal

ring to attach to dispenser.

❸Plug in the polarized foot pedal connector.

❹Checkthevoltagelabelontheinputvoltageselectorcartridge. To

change the voltage, remove the voltage selector from the car-

tridge,rotateitandpositionthecorrectvoltagetoshowthroughthe

cartridge window. Replace the cartridge into the power cord

receptacle and insure that both sides snap securely into position.

Install the power cord.

❺Attach the 10cc barrel pre-filled with blue, nontoxic test fluid

(included with the dispenser) to the 10cc adapter head.

❻Takethe10ccadapterassembly(#5150ontheadapterhead)and

inserttheblack,malequick-connectintotheairoutputfittingonthe

frontpanelandturnclockwisetolock. Placethebarrelinthebarrel

stand.

❼Duringtheinitialtesting,youwillnotusethevacuumcontrol. Keep

this control shut off (turned completely clockwise—do not force).

220

120

100

Spare fuse

Voltage value

Cartridge window

(check voltage indicated)

CONTROLS and CONNECTIONS

5

4

Voltage selector and

fuse cartridge

Air input

Vacuum transducer

air exhaust port

Cover screw

Power input

receptacle

Barrel

vacuum control Vacuum gauge

Air output

quick-connect Power

switch

21

Air pressure

regulator

3

6

Timer

bypass

7

Time

controlAir gauge Cycle LED

220

1000XL

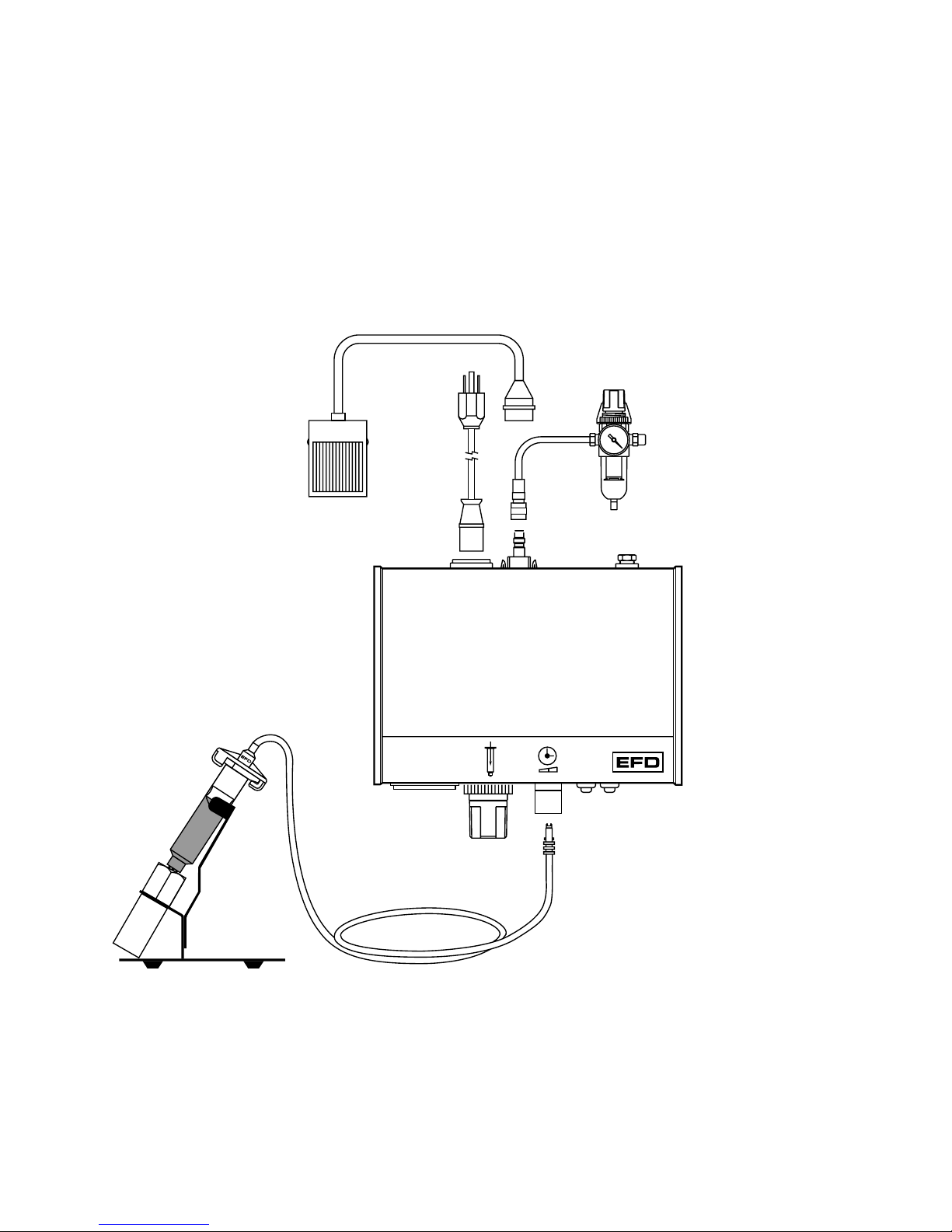

1000XL -- Setup for Testing

Power switch 6should be off.

The amount of material dispensed each cycle depends on the

combination of air pressure, time of air pulse, viscosity of material

and dispensing tip size.

Thefirststepistoremovethetipcapfromthepre-filledbarrelofblue

test material (twist and pull). Replace it with an 18 gage (green)

tapered dispensing tip. Press the tip on and twist clockwise to lock.

Pulloutairpressureregulatorknob1untilit"clicks"intotheunlocked

position. Turnclockwisetoadjusttheairpressureto30psi(2.1bar)

for the initial tests.

Always set the pressure desired by turning the air regulator knob 1

clockwise. To reduce the pressure, turn the knob counterclockwise

until the air gauge 2reads a lower pressure than desired. Then

increase and stop at desired pressure. Push knob in to lock.

Set the time control 3to #7. Dispense cycle time increases from

0.01 second minimum to 1.0 second as knob is turned clockwise.

Be sure vacuum control 4is shut off. In the initial tests, the vacuum

pressure gauge 5will indicate zero pressure. You may notice the

needle on this gauge (when turned off) will jump slightly after each

cycle. This is normal.

Press power switch 6to turn on the dispenser. It will light green.

Press timer bypass switch 7. It will light yellow. In this operation

mode, the timer will be bypassed to fill the dispensing tip before you

begintesting. Acontinuousflowofmaterialwilloccuraslongasthe

foot pedal is pressed.

Please continue to page 14 for test procedures.

❶

Plant air, 125 psi maximum to

regulator. Output from regulator

should be a minimum of 80 psi,

maximum of 100 psi.

❷

❺

Check voltage label

on dispenser

❸

❻

Blue

test fluid

❹

Male quick-connect,

insert and twist to lock

Power

cord

Air input

hose

Foot pedal

assembly

Adapter

assembly

1000D

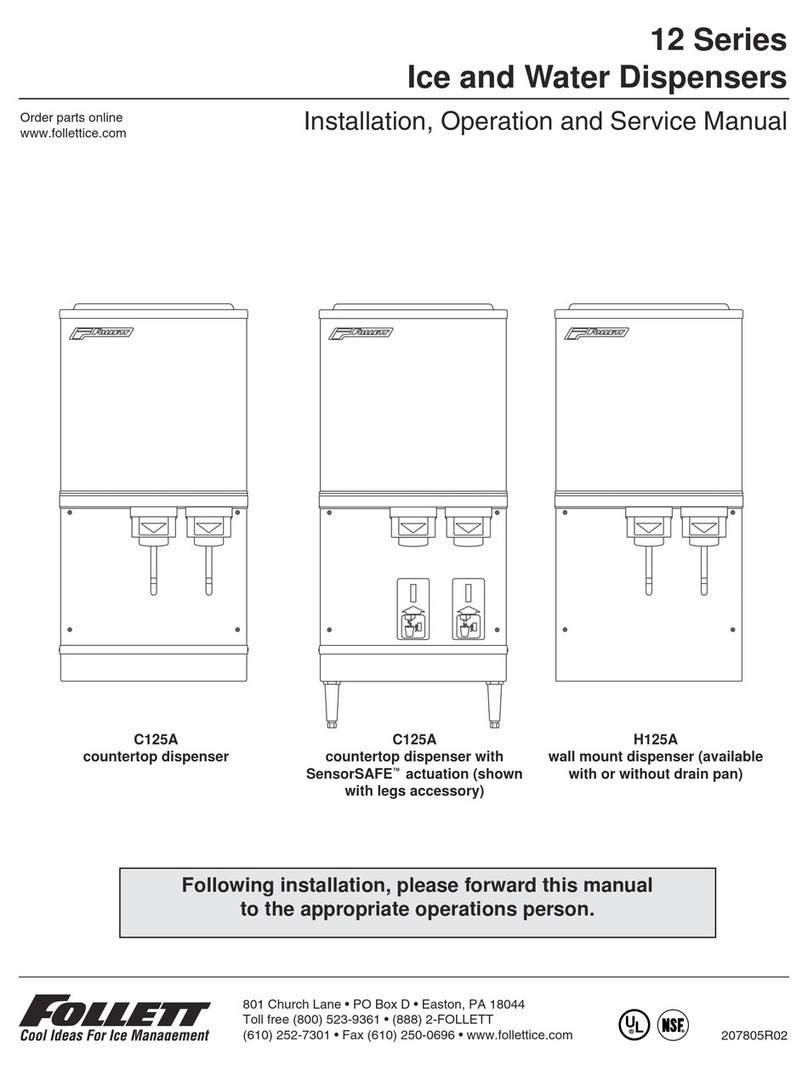

1000D -- Hookup

❶Connecttheairinputhosetoaplantairsource. Setplantairsupply

within 80 to 100 psi (5.5 to 6.9 bar). Where required, use an EFD

five-micron filter regulator #2000F755 (see Warranty).

❷Attachtheairinputhosecouplingtothedispenser. Pullbackmetal

ring to attach to dispenser.

❸Plug in the polarized foot pedal connector.

❹Checkthevoltagelabelontheinputvoltageselectorcartridge. To

change the voltage, remove the voltage selector from the car-

tridge,rotateitandpositionthecorrectvoltagetoshowthroughthe

cartridge window. Replace the cartridge into the power cord

receptacle and insure that both sides snap securely into position.

Install the power cord.

❺Attach the 10cc barrel pre-filled with blue, nontoxic test fluid

(included with the dispenser) to the 10cc adapter head.

❻Takethe10ccadapterassembly(#5150ontheadapterhead)and

inserttheblack,malequick-connectintotheairoutputfittingonthe

frontpanelandturnclockwisetolock. Placethebarrelinthebarrel

stand.

1000D

220

120

100

Spare fuse

Voltage value

Cartridge window

(check voltage indicated)

CONTROLS and CONNECTIONS

Cover screw

Air output

quick-connect Power

switch

21

Air pressure

regulator

3

4

Timer bypass

5

Time

controlAir gauge Cycle

LED

220

Air input

Solenoid Power input

receptacle

Foot pedal

receptacle Voltage selector

and fuse cartridge

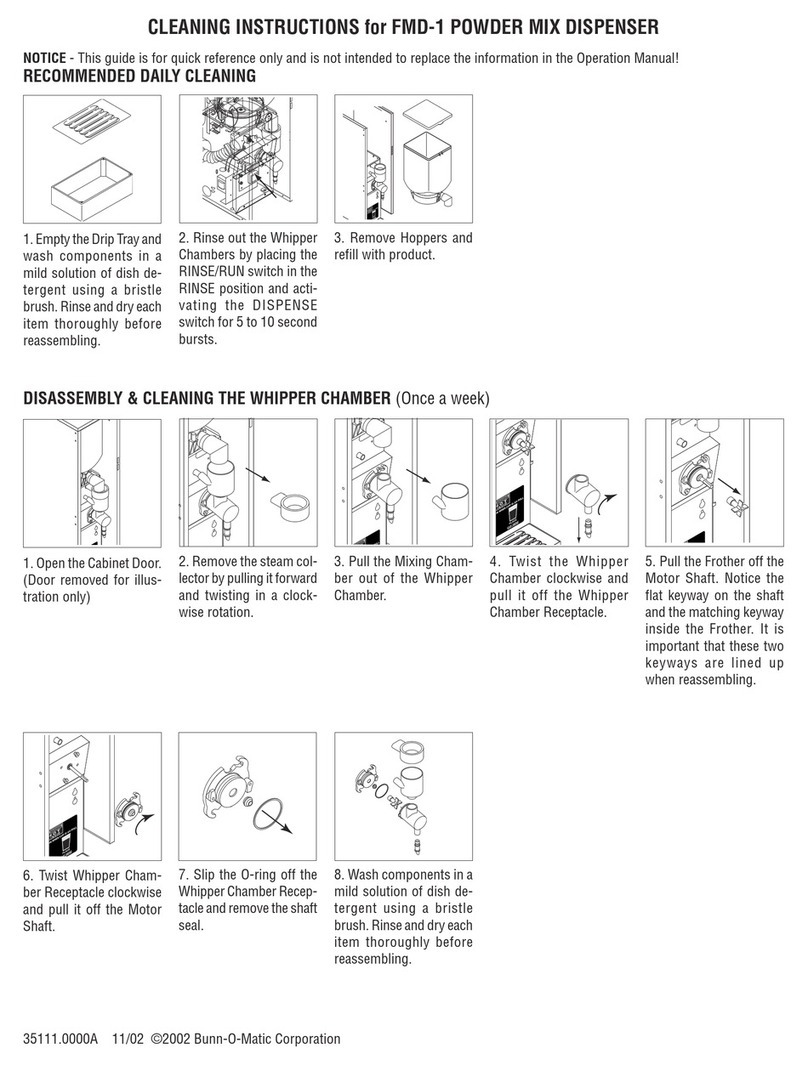

Power switch 4should be off.

The amount of material dispensed each cycle depends on the

combination of air pressure, time of air pulse, viscosity of material

and dispensing tip size.

Thefirststepistoremovethetipcapfromthepre-filledbarrelofblue

test material (twist and pull). Replace it with the 18 gage (green)

tapered dispensing tip. Press the tip on and twist to lock.

Pulloutairpressureregulatorknob1untilit"clicks"intotheunlocked

position. Turnclockwisetoadjusttheairpressureto30psi(2.1bar)

for the initial tests.

Always set the pressure desired by turning the air regulator knob 1

clockwise. To reduce the pressure, turn the knob counterclockwise

until the air gauge 2reads a lower pressure than desired. Then

increase and stop at desired pressure. Push knob in to lock.

Setthetimecontrol 3to#7. Dispensecycletimeincreasesfrom0.01

second minimum to 1.0 second as knob is turned clockwise.

Press power switch 4to turn on the dispenser. It will light green.

Press timer bypass switch 5. It will light yellow. In this operation

mode, the timer will be bypassed to fill the dispensing tip before you

begintesting. Acontinuousflowofmaterialwilloccuraslongasthe

foot pedal is pressed.

Please continue to page 14 for test procedures.

1000D -- Setup for Testing

1000D

Making Timed Deposits

Youarenowreadytotestthepre-filled,nontoxic,bluetestfluid. This

material is representative of thick, non-leveling fluids like sealants,

pastes or greases.

Check your initial settings:

A) Air gauge reads 30 psi

B) Timer is set at #7

C) Green tapered tip is on the test barrel

D) Power and timer bypass switches are on.

Holding the barrel as shown, rest the tip on a piece of paper. Press

the foot pedal until the tip fills and some fluid is pushed out onto the

paper. Repeat this whenever you change to a new tip.

With the tip filled, turn the timer bypass switch off (yellow light out).

UsetheDotTestsheetsupplied,andpressthefootpedaltoactivate

the timer. Check the dot size. Press the foot pedal again and note

the size consistency.

Remember—When the yellow timer bypass switch is on, a continu-

ous flow of material will occur as long as the foot pedal is pressed.

The yellow light must be off to make timed deposits.

Trydifferentpressuresettings. Continuetoexperimentbyreplacing

the green tip with the blue (22 gage) tapered tip included in the Dot

Test Kit. Note the effects of air pressure and tip size on the deposit.

Correct angle for consistent deposits.

Remember-alwaysbringthetipin

contact with the work surface at

the illustrated angle. After the tip

isin position, pressthefootpedal.

Release pedal and remove tip by

lifting straight up.

Testing the 1000 Series Dispensers

Timer

Pressure

2

30

7

6

8

45°

80°

Changing Deposit Size, Drawing Stripes

The dot size is determined by the tip diameter, the air pressure

output setting and the pulse time. For large dots, use a large tip,

higher pressure and more time. Normally, you want to use as short

a time pulse as possible. To increase the dot size, slightly increase

the air pressure output, or increase the tip size, or both.

Use the convenient Dot Test sheet included.

Dot Test with Green Tapered Tip

First, follow the settings illustrated on the left, and you will get dots

about the sizes shown. Try other times and pressures to see how

easy it is to get just the dot size you want.

Dot Test with Blue Tapered Tip

These tests show the effect of using a smaller diameter tip.

Replacethegreentipwiththeblue(22 gage) tapered tip. Now, turn

on the timer bypass switch and press the foot pedal to fill the tip.

Then,turnoffthetimerbypassswitch(yellowlightout)andpressthe

foot pedal.

Making Stripes

Keep the settings at Test G (shown to the left) and turn on the timer

bypass switch (yellow light on). With the tip in contact with the test

sheet, press and hold down the foot pedal while drawing a line for

beading or striping.

Blue Tip Settings

Test Pressure Time Dot Size

F 30 psi #6

G 20 psi #6

H 20 psi #3

I 15 psi #3

J 10 psi #3

Green Tip Settings

Test Pressure Time Dot Size

A 30 psi #7

B 20 psi #7

C 20 psi #3

D 15 psi #3

E 10 psi #3

Ifyoudispensethickfluids,severalproblemsmay

occur. First, the repetitive air cycles can bore

tunnels through non-leveling fluids, causing

spitting and inconsistent deposits. Second, thick

fluids contain trapped air that leads to drooling

and oozing.

These problems are eliminated by using the

SmoothFlow™piston. That's because the white

pistonspreventtunnelingbyprovidingabarrierto

the pulsed-air cycles, and prevent oozing by

responding to the pressure of trapped air with a

slight suck-back movement after the dispense

cycle.

The white piston is used for most fluids.

However, if you are applying RTV silicone and

findthatthepistonbouncesandcausesstringing,

switch to the orange, flat wall piston.

The SmoothFlow™pistons make barrel filling

easier, too. As you load the fluid in, air is trapped

in the bottom and throughout the fluid. Simply

insert a SmoothFlow™piston and gently press

down on the fluid as far as possible. This action

forcesoutmostoftheairandresultsinconsistent

deposits.

Advanced Dispensing System

For Thick Fluids

Air Pressure

OFF

Air Pressure

ON

No drip

or ooze.

TM

For Thin Fluids

Fumes

cannot

escape.

SmoothFlow™piston

prevents fluid backflow.

For Watery-thin Fluids

Blue LV Barrier™for

improved control of

very low viscosity

fluids.

Note: If you choose not to use the piston,

please refer to page 19 for instructions.

Ifyouuselowtomediumviscosityfluids,thewhite

SmoothFlow™piston has several advantages.

First, vacuum adjustment is much less sensitive.

Second, the piston prevents fumes from the fluid

beingexhaustedintotheworkenvironment. Third,

the piston prevents fluid backflow into the dis-

penser if the barrel is inadvertently turned upside

down. Fourth,usingthepiston makesiteasy and

safe to change tips without dripping.

Note: Ifyouusewatery-thinfluidssuchassolvents,

cyanoacrylatesandanaerobics,specifytheULTRA

System™withtheblueLVBarrier™

. Availableonly

in 10cc size.

How to Use the Vacuum Control (1000XL only)

Insert

SmoothFlow™

piston.

Remove

orange

end cap.

Remove

tip cap.

The vacuum control allows low viscosity fluids, even water, to be

consistentlydispensedwithoutdrippingbetweencycles. Thevacuum

exerts a negative pressure on the fluid in the barrel and prevents

dripping.

For these tests, you will use the test barrel with the clear fluid.

1. Whileholdingthebarreluprightinonehand,removetheorange

end cap and insert the white SmoothFlow™piston. Carefully

press the piston down to contact the liquid.

Be sure to push it far enough to remove all air, but not into the

fluid,sincethiswillforcethefluidupalongthesidesofthepiston.

2. Attachthebarreltothe10ccadapter. Snapthesafetycliptightly

closed to prevent any dripping or bubbling. Remove the tip cap

and attach the 25 gage (red) tip.

3. Setairpressureat 5psiandtimerto#5,thenturnontimerbypass.

4. With the barrel pointing downward over a container, press the

foot pedal to fill the tip.

5. Turn off the timer bypass switch (yellow light out).

6. If a drop begins to form at the end of the tip, slowly turn the

vacuum control knob counterclockwise to stop the drop from

growing. Wipethetipandslowlyadjustvacuum. Normally,only

1 to 2 psi of vacuum pressure is necessary.

7. Takethebarrelandplacethetiponthetestsheet. Pressthefoot

pedalandrelease. Check thedeposit. Increase ordecreaseby

adjusting pressure or time.

If you choose not to use the piston, please follow these instruc-

tions carefully:

1. While holding the barrel upright in one hand, twist on an

orange tip cap. Using the small funnel supplied, fill about

2/3 full with your liquid.

2. Openthesafetyclipandattachthebarreltothe10ccadapter.

3. Close the safety clip as tight as possible.

4. Increase vacuum by turning vacuum control knob counter-

clockwise and set to 1.5 on the vacuum pressure gauge.

5. Then, without tipping the barrel upside down, remove the tip

cap and attach the 25 gage (red) tip.

6. Open the safety clip. Your material may begin to bubble.

Reduce vacuum by turning vacuum control knob clockwise.

7. If a drop begins to form at the end of the tip, slowly turn the

vacuumcontrol knob counterclockwise to stop the drop from

growing. Wipe the tip and adjust vacuum as necessary.

Now the fluid is in proper balance. It does not bubble or drip.

Repeat tests as before, keeping the air pressure low and adjust-

ing the time for different deposit sizes. Contact EFD if you have

any questions.

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

☎

Do not tip the barrel upside down

or lay flat. This will cause the

liquid to run into the dispenser.

When changing tips

or attaching a tip cap,

snap the safety clip

completely closed to

prevent any dripping

or bubbling.

Three things to remember

If you do not use the piston when

dispensing thin fluids:

Use an EFD filter trap (#1000FLT-Y).

This filter trap will impede the flow

should the low viscosity liquid be

sucked back towards the dispenser.

Open

Closed

Loading the Barrel Reservoirs

Caution:Donotcompletelyfillbarrels.Theoptimumfillisamaximum

2/3 of the barrel capacity and 1/2 of the barrel capacity when using

the LV Barrier™

.

If the fluid you are dispensing is pourable, take the barrel, twist on a

tipcap andpour yourfluidin. Ifappropriate, inserttheSmoothFlow™

piston(seepage13). Carefullypressthepistondownuntilitcontacts

the fluid. The barrel is now ready for use.

If you are dispensing solvents, cyanoacrylates or anaerobics, use

theLVBarrier™

. Placebarrierinthetopofthebarrelreservoir. Allow

air between barrier and fluid. Do not contact the barrier to the fluid.

If your fluid is thick or non-leveling, you can spoon it into the barrel

withaspatula. Or,ifthefluidcomespackedina1/10galloncartridge,

try loading the barrel with a caulking gun. Then, press in the

SmoothFlow™pistontomovethefluidtothebottomofthebarreland

to remove trapped air.

2/3

Maximum

Fill

White

SmoothFlow™

piston.

LV Barrier™

Fill procedure for

watery-thin fluids.

1/2 maximum fill

Fill procedure with

caulking gun. Air

Fill procedure for

pourable fluids.

This manual suits for next models

1

Table of contents

Other EFD Dispenser manuals

Popular Dispenser manuals by other brands

Follett

Follett C125A Installation, operation and service manual

Bunn

Bunn FMD-1 Cleaning instructions

Hampton Research

Hampton Research HR8-170 user guide

Franke

Franke RODX625 Installation and operating instructions

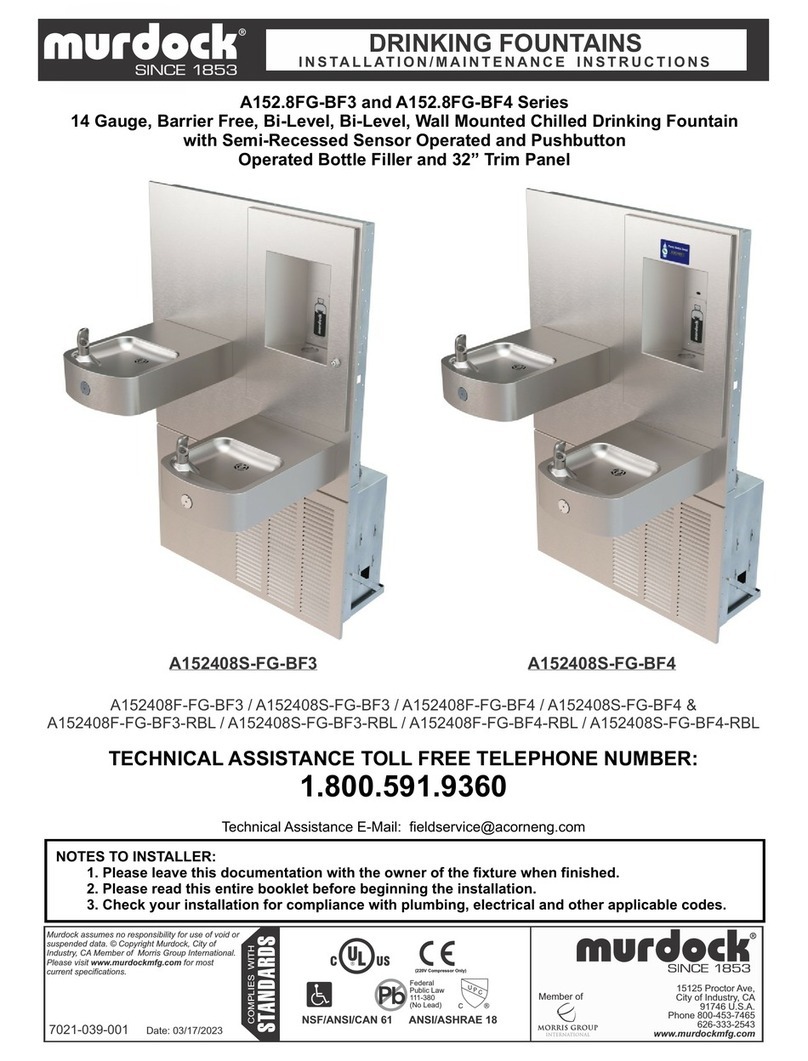

Murdock

Murdock A152.8FG-BF3 Series Installation & maintenance instructions

Tach-It

Tach-It SH-402TR user manual

Bunn

Bunn BUNN-O-MATIC ULTRA-1 Installation & operating guide

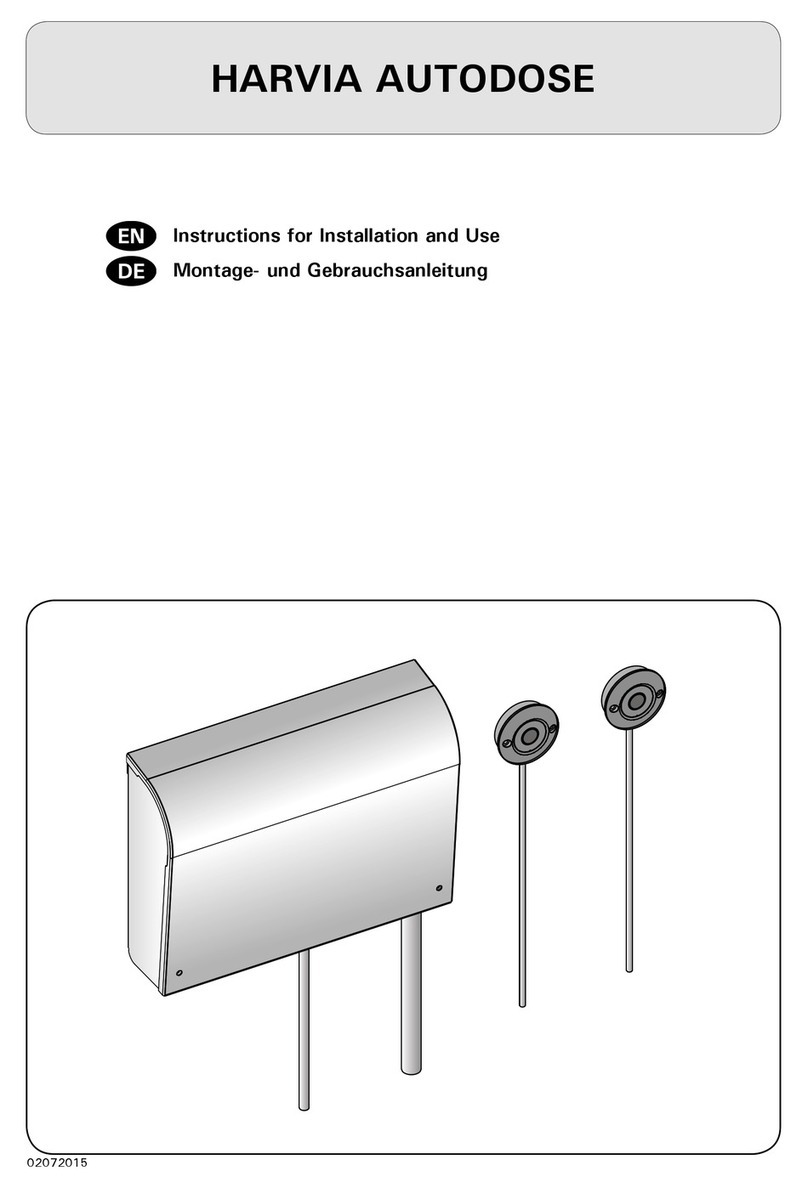

Harvia

Harvia AUTODOSE Instructions for installation and use

BOWMAN

BOWMAN BD216-0012 manual

MT

MT columbia aqua FC-750-SOBREMESA-RO Service manual

Sartorius

Sartorius rLine 5-200ul LS Technical user's manual

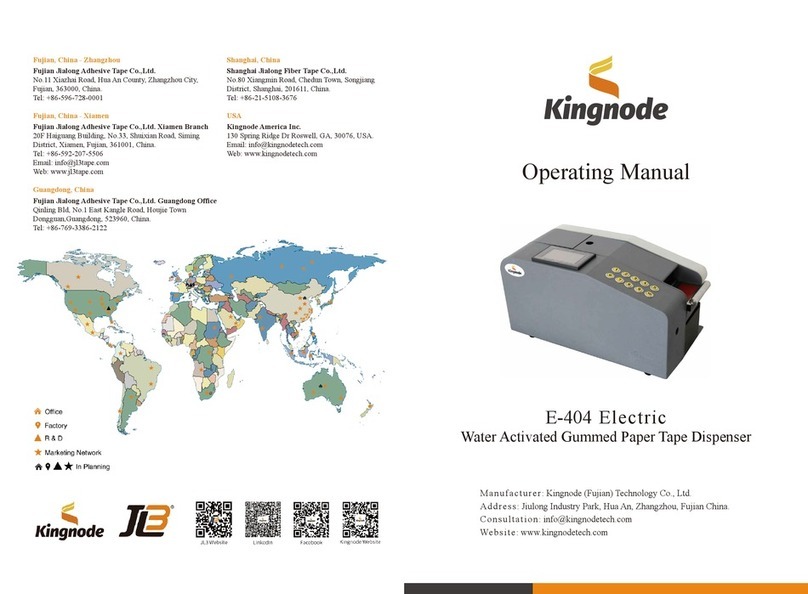

Kingnode

Kingnode E-404 Series operating manual