EFD 2000XL User manual

STEADY

RUN

SETUP

CYCLE

STOP

Cell Select

Run

Setup Fast Slow

Time Set

Steady

Teach Pressure

Time

Fast Slow

Time Set

Pressure

Vacuum

Vacuum

Pressure

®

A NORDSON COMPANY

Operating Guide

2000XL Series Digital Dispensers

®

A NORDSON COMPANY

In the US: 800-556-3484 In the UK: 0800 585733 In Mexico: 001-800-556-3484

2000XL 2000XL-PR5-15 2000XL-CA

••

☎

The EFD Pledge

We pledge that you will be completely satisfied with our products.

We endeavor to ensure that every EFD product is produced to our

no-compromise quality standards.

If you feel that you are not receiving all the support you require, or if

youhaveanyquestionsorcomments,Iinviteyoutowriteorcallme

personally.

Our goal is to build not only the finest equipment and components,

but also to build long-term customer relationships founded on

superb quality, service, value and trust.

Introduction

The 2000XL Series dispensers provide years of trouble-free,

productiveservice. ThisOperatingGuidewillhelpyoumaximizethe

usefulness of your new dispenser.

Pleasespendafewminutestobecomefamiliarwiththecontrolsand

features of your new dispenser. Follow our recommended testing

procedures. Reviewthehelpfulinformationwehaveincludedbased

on over 30 years of industrial dispensing experience.

Most questions you will have are answered in this guide. However,

ifyouneedassistance,pleasedonothesitatetocontactEFDoryour

authorized EFD distributor.

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

Randall Richardson, President

Getting Started .............................................................................4

Specifications

First Steps ....................................................................................5

Unpacking the dispenser & Activating your Ten Year No-fault Warranty

Features and Controls.............................................................. 6-7

Indicator Lamps ....................... 7

Setup..................................................................................... 8-10

Setup procedures..................8-9

Diagram .................................10

Final checklist ........................ 10

Testing the 2000XL .............................................................. 11-12

Programming deposit size ..... 12

Operational Features .................................................................13

ULTRA Dispensing System.................................................. 14-15

How to Use the Vacuum Control.......................................... 16-17

Loading the Barrel Reservoirs.............................................. 18-19

Memory Function ................................................................. 20-21

Input and Output Connection Instructions................................. 22

Schematic and Replacement Parts List .....................................23

Troubleshooting .........................................................................24

Suggestions and Reminders ......................................................25

Reordering Components ............................................................26

Ten Year No-fault Warranty .......................................................27

Meets applicable CSA and CE requirements.

This manual is for the express and sole use of EFD

dispenser purchasers and users, and no portion of

this manual may be reproduced in any form.

EFD, ULTRA System, LV Barrier and SmoothFlow

are trademarks of EFD Inc. ©2002 EFD Inc.

Contents

STOP

Steady

Run

Setup Fast Slow

Time Set Pressure

Time

Time Set

Fast Slow

STEADYSTEADY

RUN

SETUP

CYCLE

7.470"

19.0 cm

5.570"

14.1 cm

2.700"

6.9 cm

3.380"

8.6 cm

Pressure

Vacuum

Cell Select

Vacuum

Pressure

Teach

A NORDSON COMPANY 2000XL

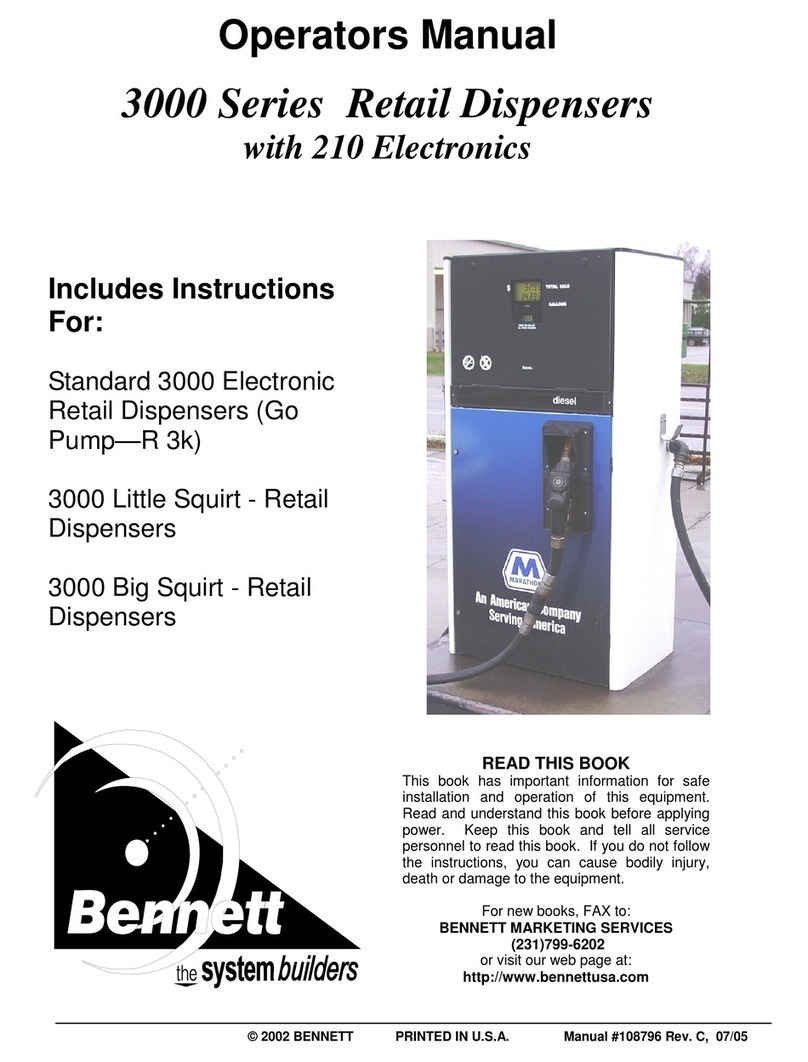

The 2000XL Series automatic fluid dispensers are designed to

provide complete process control using advanced microprocessor

circuitry. Allmicroprocessorfunctionsareaccessedbypushbutton.

Microprocessor features include:

• Push-button time setting input or one-touch time programming.

• Floatingdecimal,providingdispensetimerangesof0.001to9.999

and 00.01 to 99.99 seconds.

• Backlit LCD displays time settings, dispensing pressure and

vacuum pressure.

• Dispensingpressure display is programmable for either psi or bar

scale.

• Memory with storage for up to eight separate time settings.

Intelligent technology makes the 2000XL Series easy to set up and

use. With one-touch setup, just press the pedal to determine the

proper amount. The microprocessor remembers the time and

repeatsthis amount with eachcycleuntil you are readytochange it.

From microdeposits to volumetric filling, the 2000XL provides the

ultimate in control and versatility for time/pressure-based fluid

dispensing.

Note: Specifications and technical

details are subject to engineering

changes without prior notification.

Specifications

Cabinet size: Weight

7.470 x 5.570 x 2.700" 3 lb 3 oz

(19.0 x 14.1 x 6.9 cm) 1.44 kg

Input voltage:

Selectable 100/120/220 VAC

50/60 Hz 10/9 VA

End-of-cycle feedback circuits:

5 to 24 VDC N.C. solid-state switch

250mA maximum (details page 23)

Initiate circuit: Foot pedal or

5 to 24 VDC signal

Air consumption: Approximately 1.5

SCFM at 400 cycles per minute

Cycle rate: Exceeds 600 per minute

Timerange: Programmable 0.001to

9.999, or 00.01 to 99.99 seconds

2000XL

air input:

80 to 100 psi (5.5 bar to 6.9 bar)

air output:

0 to 100 psi (0 to 6.9 bar)

2000XL-PR5

air input:

10 to 50 psi (0.7 bar to 3.4 bar)

air output:

0 to 5 psi (0 to .34 bar)

2000XL-CA

air input:

80 to 100 psi (5.5 bar to 6.9 bar)

air output:

0 to 15 psi (0 to 1.0 bar)

Getting Started

First: Unpackandusethechecklist enclosedwith theDispenser Kit

to identify all items. If there is any discrepancy, please call us

immediately.

Second: Powerandcompressedplantairshouldbeavailablewhere

thedispenseristobesetup. Inputairshouldbesetbetween80and

100 psi (5.5 and 6.9 bar). For model 2000XL-PR5, input air should

be set between 10 and 50 psi (0.7 and 3.4 bar). If you are not using

an EFD five-micron filter regulator #2000F755, be certain your

plant air is properly filtered and dry and a regulated, constant

air pressure is supplied to the dispenser.

Note: Model 2000XL-CA is supplied with an EFD five-micron filter

regulator with coalescing filter (#2000F756).

Bottled nitrogen can be used.

Warning: If high pressure bottled air or nitrogen is used, a high

pressure regulator must be installed on the bottle and set at 100 psi

maximum. The 2000F755 filter regulator is not required.

Check the voltage label to be certain it is set to the available power.

Third: Now is a good time to ACTIVATE your extended Ten Year

No-fault Warranty. Please fill in and return the postage paid

Warrantycard. Orifyouprefer,calltheappropriatetoll-freenumber

listed below, provide the serial number of your dispenser and

respond to a few short questions.

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

First Steps

☎

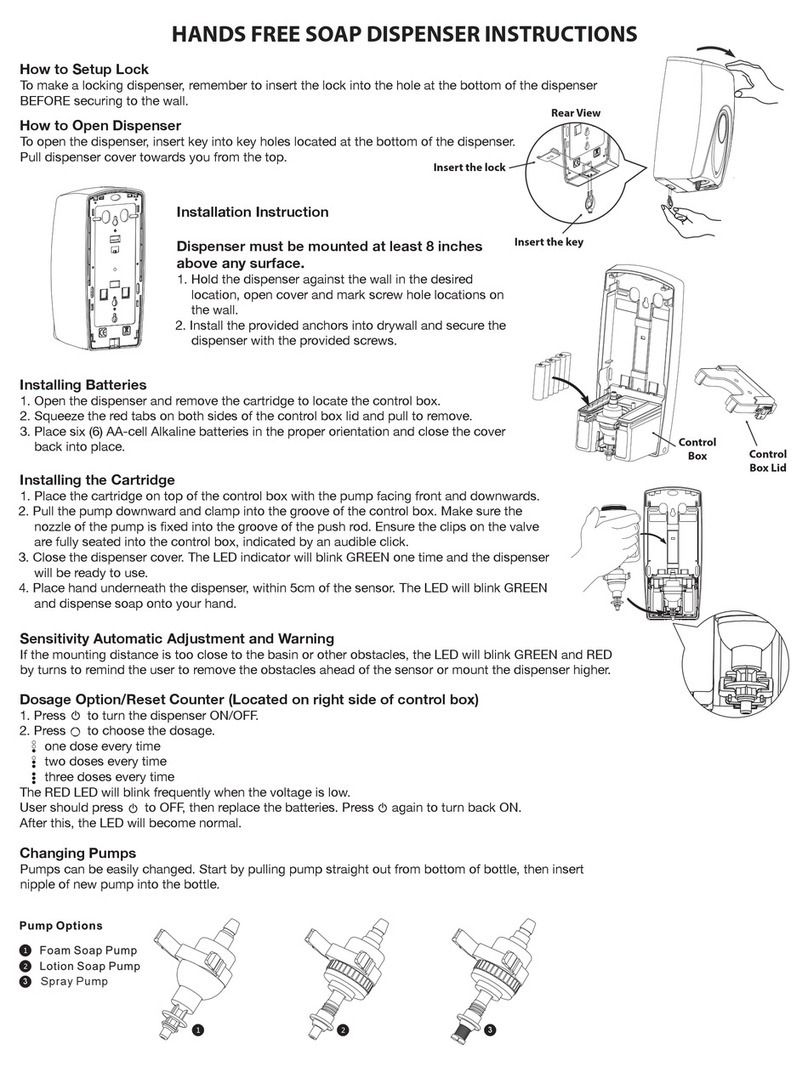

Digital Time, Air Pressure and

Vacuum Pressure LCD Display

•Programmablefloatingdecimalprovidestimerange

readout from 0.001 to 99.99 seconds.

•Air pressure readout can be programmed in either

psi or bar.

•Vacuum pressure readout is displayed by holding

the vacuum toggle switch in the "up" position.

Memory

Can store up to eight Time settings. (See page 20.)

Run/Setup

1. The RUN mode allows access to all eight cells. Cell

numbers are displayed as CEL1, CEL2....CEL8. Chang-

ing the cell number will change the time setting corre-

sponding to that cell.

The SETUP mode provides access to selected cell

TEACH andTIME SET functions. Only in the SETUP mode

can cell time values be viewed, cleared, or changed.

2. In the RUN mode, the functions are inoperative.

Steady/Teach

In SETUP mode, pressing STEADY/TEACH will clear

the currently displayed cell setting, reset the cell

display to blinking "0000", and place the dispenser

in a TEACH mode (refer to page 12 for TEACH

procedures).

In RUN mode, pressing STEADY/TEACH will override the

timer and dispense for as long as the foot pedal is

pressed. The dispenser display will read "----" in the

STEADY mode.

Time Set ▼ (down) ▲(up)

In SETUP mode, use the TIME SET buttons to change

time settings. Left buttons scroll digits quickly; right

buttons scroll digits slowly.

Pressure/Time

PresstochangedisplayvaluesfromTIMEtoPRESSURE

or PRESSURE back to TIME.

In SETUP mode, pressure readings may be changed

from PSI to BAR and BAR to PSI by pressing and

holding the PRESSURE/TIME button for four seconds.

STOP

This button stops the dispenser immediately.

Barrel Vacuum Control

Refer to page 16 for operation.

Air Pressure Regulator

Refer to page 11 for operating instructions.

STEADY

RUN

SETUP

CYCLE

STOP

Run

Setup Fast Slow

Time Set Pressure

Time

Fast Slow

Time Set

Pressure

Vacuum

Steady

Teach

Cell Select

EL1C

V

acuum

Pressure

®

A NORDSON COMPANY

2000XL

Function

Indicator

Lamps

Air pressure

regulator

Barrel vacuum

control

Vacuum

toggle switch

Features and Controls

STEADY

RUN

SETUP

CYCLE

STOP

Slow

tPressure

Time

Slow

t

®

A NORDSON COMPANY

2000XL

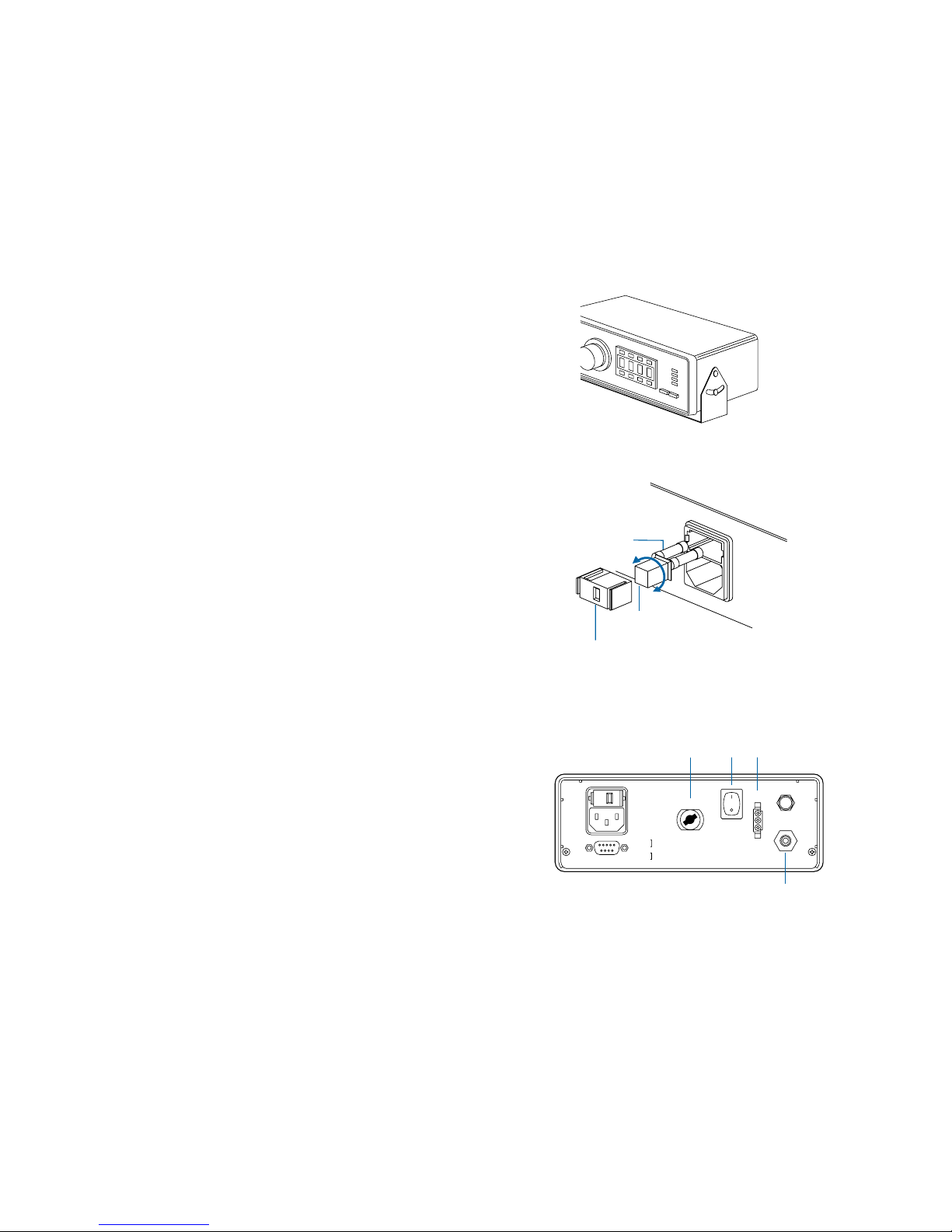

Power Input Receptacle with Voltage Selector and Fuse Cartridge

Threeinputvoltagescan be used: 100 VAC, 120 VAC and 220 VAC. To

change input voltage, remove fuse cartridge and position the selected

voltage marked on the cartridge so that it shows through the window.

(Details on page 8.)

Input/Output 9 Pin Interface Connector

Theinput/outputfeaturesareusedwhenthedispenser isinterfaced with

external control circuits.

•AnEnd-of-Cyclesignal,intheformofasolid-stateswitch,closesupon

completion of the dispense cycle. Maximum load is 250mA from 5 to

24 VDC.

•The 2000XL can be initiated using a 5 to 24 VDC signal.

•Contact Closure.

(For more details, refer to page 22.)

In the upper right corner of the

front panel are four indicator

lamps. These lamps indicate

the mode of operation.

STEADY - Indicates that the

timing feature has been

overridden and that the output

is controlled by the length of

time the foot pedal is pressed.

RUN -Indicates that the

dispenser is in the RUN mode

ready to be initiated through a

dispense cycle. In this mode,

time settings cannot be

changed.

SETUP -Indicates that the

dispenser is in the SETUP

mode. In this mode, time

settings can be changed.

CYCLE - This lamp is on during

the dispense cycle.

Indicator Lamps

Fuse T 125mA 250V

100/120/220VAC

50/60Hz 10/9VA

Air

Input

Foot

Pedal

7

.

Contact Closure

5. Contact Closure

6. Chassis Ground

8. Not Used

9. Not Used

1. Initiate

+

2. Initiate

-

3. Output

+

4. Output

-

5-24 VDC

5-24 VDC

250mA

Exhaust

Air

Output

I/O 9 pin interface

connector Air input

Voltage selector

and fuse cartridge Exhaust

Foot pedal

receptacle

Power input

receptacle

Power

switch

Air output

quick-connect

Fuse T 125mA 250V

100/120/220VAC

50/60Hz 10/9VA

Air

Input

Foot

Pedal

7

.

Contact Closure

5. Contact Closure

6. Chassis Ground

8. Not Used

9. Not Used

1. Initiate

+

2. Initiate

-

3. Output

+

4. Output

-

5-24 VDC

5-24 VDC

250mA

Exhaust

Air

Output

Power switch should be off.

❶Mounting

Included is a universal mounting bracket. Mounting

hardware is installed into the four 10-32 mounting

holesonthe sidesofthe cabinet. Thebracket canbe

mounted either over or under the cabinet and will

allow the dispenser to pivot up or down 30°from a

horizontalposition. The bracket may be permanently

mounted, or attach the rubber feet included and use

thebracketas abench-toptiltstand.Four rubberfeet

ontheconsoleareprovidedifthebracketisnotused.

❷Input power

Check the input power cord receptacle. To change

voltage, remove the voltage selector from the car-

tridge, rotate it and position the correct voltage to

show through the cartridge window. Replace the

cartridge into the power cord receptacle and insure

that both sides snap securely into position.

Install the power cord.

❸Initiate connection

The2000XLisnormallyoperatedusingthefootpedal

supplied. Plug the foot pedal into the connector

located on the rear panel. An alternate method is to

apply a 5 to 24 VDC pulse to terminals 1 and 2.

❹Air input connection

A6ft.air inputhosekitissupplied. Connecttheinput

hosetofiltered,dryplantair. Formodels2000XL and

2000XL-CA, set plant air supply within 80 to 100 psi

(5.5 to 6.9 bar). For model 2000XL-PR5, input air

should be set within 10 to 50 psi (0.7 to 3.4 bar).

Attach the air input hose coupling to the dispenser.

Pull back metal ring to attach to dispenser.

❶

Setup

❷

❸

Spare fuse

Voltage value

Cartridge window

Note: Check voltage indicated

❺

Note:If filtered, dry air is not available, order an

EFD five-micron filter regulator #2000F755.

(2000XL-CA units are supplied with a five-micron

coalescing filter regulator.)

❻

❹

220

120

100

❺Power on/off

PressthePower Switchlocatedon therearpanel

to the "ON" position. The dispenser will power up

in the RUN, STEADY, or PRESSURE mode and indi-

cate which cell was selected last. (Dispenser is

shipped with

CEL1

selected in RUN mode).

❻Air output

Pushin andtwistlock the10cc adapter assembly

(part#1000Y5150). Thenumber5150is molded

on the side of the yellow head.

❼Setting the decimal

The dispenser is shipped with the decimal set at

hundredthsofasecond(00.00). Thedecimalcan

bemovedtoshowthousandthsofasecond(0.000)

as follows:

PressRUN/SETUP toplacethe dispenserin SETUP

mode.

To move the decimal, press and hold the STOP

button. After approximately 4.0 seconds, the

decimalwillmovetothethousandthsposition. To

return to the hundredths position, press and hold

the STOP button again.

Note: Changing the decimal place changes the

currenttimesettingbyafactorof10. Forexample,

5.35 seconds becomes 53.50; 15.00 seconds

becomes 1.50.

❽Setting the pressure readout

The dispenser is shipped with pressure display

programmed in psi.

Note: On models with 5 psi and 15 psi regulators,

the pressure is adjustable in 0.1 psi increments.

If bar is desired, change as follows:

PressRUN/SETUPandplacethedispenserintothe

SETUP mode. Press and hold the PRESSURE/TIME

button for 4.0 seconds. The display will change

from psi to bar. To change back to psi, press and

hold PRESSURE/TIME for 4.0 seconds.

❾Vacuum control

Vacuum is turned off (clockwise) during testing

procedures. (Refer to page 16 for operation.)

❿Vacuum toggle switch

To read vacuum pressure, hold toggle switch in

the "up" position. Readout will appear on the

digital display pad, then return to air pressure

readout when toggle is released.

Continue to page 11 for test procedures.

STEADY

RUN

SETUP

CYCLE

STOP

Steady

Run

Setup Fast Slow

Time Set

Teach Pressure

Time

Fast Slow

Time Set

Pressure

Vacuum

Vacuum

Pressure

Cell Select

EL1

C

®

A NORDSON COMPANY

2000XL

❼

❽

❿

❾

STOP

Run

Setup Fast Slow

Time Set Pressure

Time

Time Set

Fast Slow

STEADYSTEADY

RUN

SETUP

CYCLE

Pressure

Vacuum

Steady

Teach

Cell Select

Vacuum

Pressure

®

A NORDSON COMPANY 2000XL

Note: Plantair,125psi maximumtoregulator.Outputfrom

regulatorshouldbeaminimumof80psi,maximum100psi.

For model 2000XL-PR5, output from regulator should be

set at 30 psi.

❸

Check voltage label

on dispenser.

Male

quick-connect,

insert and twist

to lock.

Barrel

adapter

assembly

Air input hose

Power cord

Foot pedal

assembly

❹

❺

Note: For hookup purposes,

the connections for the 2000XL,

2000XL-PR5 and 2000XL-CA

models are identical.

❻

❶❷

Setup for Testing

Deposit size is controlled by TIME, PRESSURE and

TIP SIZE.

Please follow these instructions in order to test

each function. Use the convenient Dot Test

sheet included in your Test Kit.

Setup for Testing

Press RUN/SETUP ❶to set the dispenser into the

RUN mode (RUN indicator light on).

Press PRESSURE/TIME ❷and set display to

pressure.

Pull out air pressure regulator knob ❸until it

"clicks" into the unlocked position. Turn clock-

wise to adjust the pressure to 20 psi (1.4 bar).

Note: Dispensers with 5 psi or 15 psi gauges

should be tested with the clear test fluid, using a

lavender30gagetipandairpressuresetat5psi.

Refer to "How to Use the Vacuum Control" on

page 16.

Alwayssetthepressuredesiredbyturningtheair

regulator knob clockwise. To reduce the pres-

sure, turn the knob counterclockwise until the air

gauge reads a lower pressure than desired.

Then increase and stop at desired pressure.

Push knob in to lock.

Dispenserswith airpressure gaugeshigherthan

15 psi are tested using the nontoxic blue fluid

suppliedintheDotTestkit. Thisfluidisrepresen-

tative of thick, non-leveling fluids such as

sealants, pastes and greases and is used to

demonstrate the different control settings.

Attachthebarrelcontainingthetestmaterialtothe

adapter assembly ❹as shown.

Remove the orange tip cap from the end of the

dispensing barrel and attach the green 18 gage

tapered tip ❺found in the Dot Test Kit. Place the

barrel in the barrel stand.

Press STEADY/ TEACH ❻to place the 2000XL into

STEADY mode. (STEADY indicator light on.)

Rest the dispensing tip on the Dot Test sheet.

Press and hold the foot pedal until the tip fills with

test material.

Go into TIME mode by pressing STEADY/ TEACH ❻

again(STEADY indicatorlight goes out) and time is

displayed.

Press RUN/SETUP ❶to place the 2000XL into the

SETUP mode (SETUP indicator light on). Press

STEADY/ TEACH ❻to zero the display.

Continue to page 12 for tests which will demon-

strate the ease at which deposit sizes can be

established using the foot pedal or TIME SET

feature.

Program (TEACH) the Deposit Time with the Foot Pedal

When a specific time value is not known, as when first

dispensinganamount,thetimemaybeprogrammedusingthe

foot pedal.

Press RUN/SETUP to set the dispenser into RUN mode (RUN

indicatorlighton).Selectthememorycellyouwishtoprogram,

e.g.

CEL1

,

CEL2

....

CEL8

.

ReturnthedispensertoSETUPmodeandclearcellmemoryby

pressing STEADY/TEACH. The dispenser displays a blinking

"0000" to indicate that it is in TEACH mode and ready for

programming.

Holdingthebarrelasshown,restthetipontheDotTestsheet.

Press the foot pedal for about one second. Notice that the

display now shows the length of time the foot pedal was

pressed.

Keeping the tip in the same place, press the pedal again for

abouttwosecondsandaddtothefirstdeposit.Nowthedisplay

shows the total time for both deposits.

Youcanbuilduptothedesiredamountbysimplypressingthe

footpedalrepetitivelyuntilthedepositisthepropersize. Ifthe

deposit becomes too large, press STEADY/TEACH and start

again. Press RUN/SETUP to save the setting and return to the

RUN mode.

ProgramtheDepositTimewithaSpecifiedTimeSetting

Set the dispense time when the desired time SET buttons

below the display to scroll up and TIME SET buttons above the

display to scroll down. The button on the right scrolls slowly

for single digit setting; the one to the left scrolls fast.

Press STEADY/TEACH, then set the time to 1.15 seconds using

the TIME SET buttons. Press RUN/SETUP to return to the RUN

mode. Press the pedal and make a 1.15 second deposit.

Testing (continued)

Correct angle for consistent deposits.

Remember-alwaysbringthetipin

contact with the work surface at

theillustratedangle. Afterthetip

isinposition,pressthefootpedal.

Releasepedalandremovetipby

lifting straight up.

If you have any questions at this point, please call us now.

In the US, call 800-556-3484

(Between 8:30 am and 6:00 pm eastern time.)

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

☎

Don’t Forget!

✓Changes to the time settings can be

made only when the mode of operation

is SETUP.

✓RUNmodelocksoutTIMESETandTEACH

control buttons. Use this to protect the

setup from inadvertent changes.

✓Pressing STEADY/TEACH in SETUP mode

will clear all time settings within cell.

✓STOP immediatelyterminates the current

dispense cycle.

✓Use only dry, clean, filtered air.

Note: The pedal needs only to be pressed mo-

mentarily. The complete time cycle will run once

the dispenser is initiated.

Press RUN/SETUP and toggle back to the SETUP

mode. Press the TIME SET buttons and change

the time to 2.30 seconds. Go back to RUN, press

the foot pedal, and the dispenser will make a

deposit approximatelytwicethesizeofthefirstone.

Pressure—changes deposit size.

The dispenser should be in the RUN mode, the

TIME setting should be 2.30 seconds and the

dispensing pressure should be 20 psi (1.4 bar).

Increasingthepressurewillresultinlargerdepos-

its, decreasing the pressure will result in smaller

deposits. Try this now and observe the results.

Tip Size—changes deposit size.

Tipsizealsoaffectsdepositsize. Withoutchang-

ingtheTIMEorPRESSURE setting,trydifferenttips

and observe the results.

Advanced Dispensing System

Ifyoudispensethickfluids,severalproblemsmay

occur. First, the repetitive air cycles can bore

tunnels through non-leveling fluids, causing

spitting and inconsistent deposits. Second, thick

fluids contain trapped air that leads to drooling

and oozing.

These problems are eliminated by using the

SmoothFlow™piston. That's because the white

pistonspreventtunnelingbyprovidingabarrierto

the pulsed-air cycles, and prevent oozing by

responding to the pressure of trapped air with a

slight suck-back movement after the dispense

cycle.

The white piston is used for most fluids.

However, if you are applying RTV silicone and

findthatthepistonbouncesandcausesstringing,

switch to the orange, flat wall piston.

The SmoothFlow™pistons make barrel filling

easier, too. As you load the fluid in, air is trapped

in the bottom and throughout the fluid. Simply

insert a SmoothFlow™piston and gently press

down on the fluid as far as possible. This action

forcesoutmostoftheairandresultsinconsistent

deposits.

For Thick Fluids

Air Pressure

OFF

Air Pressure

ON

No drip

or ooze.

TM

For Thinner Fluids

Fumes cannot escape.

SmoothFlow™piston

prevents fluid backflow.

For Cyanoacrylates

or Watery-thin Fluids

Note: If you choose not to use the piston,

please refer to page 17 for instructions.

No air gap when using the

SmoothFlow™piston.

Blue LV Barrier™for improved

control of very low viscosity fluids.

Note: The LV Barrier ™works best

with an air gap between the barrier

and fluid.

Maximum

1/2 fill

Ifyouuselowtomediumviscosityfluids,thewhite

SmoothFlow™piston has several advantages.

First, vacuum adjustment is much less sensitive.

Second, the piston prevents fumes from the fluid

beingexhaustedintotheworkenvironment. Third,

the piston prevents fluid backflow into the dis-

penser if the barrel is inadvertently turned upside

down. Fourth,using the piston makesit easy and

safe to change tips without dripping.

Note: Ifyouusewatery-thinfluidssuchassolvents,

cyanoacrylatesandanaerobics,specifytheULTRA

System™with the blue LV Barrier™

. Available in

3cc and 10cc sizes.

The vacuum control allows low viscosity fluids, even water, to be

consistentlydispensedwithoutdrippingbetweencycles. Thevacuum

exerts a negative pressure on the liquid in the barrel and prevents

dripping.

For these tests, you will use the test barrel with the clear fluid.

1. Whileholdingthebarreluprightinonehand,removetheorange

end cap and insert the blue LV Barrier™. Allow an air gap as

shown.

2. Attachthebarreltothe10ccadapter. Snapthesafetycliptightly

closedtoprevent any dripping or bubbling. Remove the tip cap

and attach the 30 gage (lavender) tip.

3. Set air pressure at 5 psi.

4. Press RUN/SETUP to go into SETUP mode and set TIME for 00.05

seconds. Press RUN/SETUP to return to RUN mode.

5. Press STEADY/TEACH (STEADY indicator light on).

6. Withthebarrelpointingdownwardoveracontainer,unsnapthe

safety clip and press the foot pedal to fill the tip.

7. If a drop begins to form at the end of the tip, slowly turn the

vacuum control knob counterclockwise to stop the drop from

growing. Wipe the tip and adjust vacuum as necessary.

8. Toreadvacuumpressure,pressPRESSURE/TIMEsothatsystem

airpressure is displayed. Holdtoggleswitch in the "up"position

to view vacuum pressure. Release toggle to return display to

system air pressure readout.

9. Press STEADY/TEACH (STEADY indicator light off).

10. Takethebarrelandplacethetiponthetestsheet. Pressthefoot

pedalandrelease. Checkthedotsize. Increaseordecreaseby

adjusting pressure or time.

Remove

orange

end cap.

Insert

blue LV

Barrier™

How to use the Vacuum Control

Remove

tip cap.

If you choose not

+to use the piston, please follow these instructions carefully:

1. While holding the barrel upright in one hand, twist on an orange

tip cap. Using the small funnel, fill about 2/3 full with your fluid.

2. Open the safety clip and attach the barrel to the 10cc adapter.

3. Close the safety clip as tight as possible.

4. Slightly increase vacuum by turning vacuum control knob

counterclockwise.

5. Then, without tipping the barrel upside down, remove the tip cap

and attach the 30 gage (lavender) tip.

6. Openthesafetyclip.Yourmaterialmaybegintobubble. Reduce

vacuum by turning vacuum control knob clockwise.

7. Ifadropbeginstoformattheendofthetip,slowlyturnthevacuum

control knob counterclockwise to stop the drop from growing.

Wipe the tip and adjust vacuum as necessary.

Now the fluid is in proper balance. It does not bubble or drip.

Repeat tests as before, keeping the air pressure low and adjusting

the time for different deposit sizes.

Do not tip the barrel upside down

or lay flat. This will cause the

liquid to run into the dispenser.

When changing tips

or attaching a tip cap,

snap the safety clip

completely closed to

prevent any dripping

or bubbling.

Three things to remember

If you do not use the piston when

dispensing thin fluids:

Use an EFD filter trap

(#1000FLT-Y). This

filter trap will impede

the flow should the

low viscosity liquid be

sucked back towards

the dispenser.

Open

Closed

☎

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

Loading the Barrel Reservoirs

Caution: Donotcompletelyfillbarrels.Theoptimumfillisamaximum

2/3 of the barrel capacity and 1/2 of the barrel capacity when using

the LV Barrier™

.

If the fluid you are dispensing is pourable, take the barrel, twist on a

tip cap and pour your fluid in. If appropriate, insert the SmoothFlow™

piston(seepage14). Carefullypressthepistondownuntilitcontacts

the fluid. The barrel is now ready for use.

Ifyouaredispensingwaterysolvents,cyanoacrylatesoranaerobics,

use the LV Barrier™

. Place barrier in the top of the barrel reservoir.

Allow air between barrier and fluid. Do not contact the barrier to the

fluid.

Ifyourfluidisthickornon-leveling,youcanspoonitintothebarrelwith

aspatula. Or, if thefluid comes packedina 1/10 galloncartridge, try

loadingthebarrelwithacaulkinggun.Then,pressintheSmoothFlow™

piston to move the fluid to the bottom of the barrel and to remove

trapped air.

2/3

maximum

fill

Fill procedure for

pourable fluids

White

SmoothFlow™

piston

Fill procedure for thick fluids

(shown: caulking gun)

2/3

maximum

fill Fill procedure for cyanoacrylates

or watery-thin fluids

LV Barrier™

Air gap

1/2 maximum fill

Filling the cartridge

for the barrel loader.

EFDoffersproductivealternativestotraditionalbarrelloadingmeth-

ods. Here are a few suggestions that can help keep your work area

clean,save time and reduce the chance of entrapped air in the fluid.

1. YoucouldusetheEFD#920BLbarrelloader. Packthefluidinto

the 12 ounce cartridge as shown. Then place the prefilled

cartridge into the barrel loader. Using air pressure, the barrel

loader fills the barrel (with piston) from the bottom up.

Ifthefluidcomes packedina1/10gallon(300ml.) caulkingtype

cartridge, use the EFD #940BL barrel loader.

2. If you receive frozen epoxies or other fluids in medical type

syringes with a manual plunger, request our luer-to-luer fitting

#2160 to transfer the material.

Please call an EFD Fluid Application Specialist

for additional assistance.

EFD #920BL Barrel Loader

(Specify #940BL for prefilled 1/10 gallon caulking tubes)

Barrel Rack

#905BR for 3cc and 5cc barrels

#910BR for 10cc, 30cc and 55cc barrels

2/3

Maximum

Fill

#2160 Luer-to-luer fitting

3. 2 5

EL3C

The memory feature enables storage of up to eight different time

settings that can be recalled and used at the push of a button. Time

settings are saved even with power removed and will remain in

storage unless changed or erased intentionally. Memory cells are

identified as

CEL1

through

CEL8

.

Viewing MEMORY cells

Beforesavingatimesettinginmemory,viewthememorycellstosee

which cells are empty or, if all cells are used, which time can be

replaced.

To prevent accidental data loss, review the contents of each cell

before selecting and storing a new time setting into memory.

1. Press RUN/SETUP to place the dispenser in RUN mode (RUN

indicatorlighton).Thecurrentcellnumberwillbedisplayed.e.g.,

CEL3

. (Figure 1)

2. Press CELL SELECT (up) (down) to select the cell you wish to use.

3. Press RUN/SETUP again to return the dispenser to SETUP mode

(SETUP indicator light on). The time setting stored in the selected

cell will be displayed. (Figure 2)

NOTE: To avoid unintentional loss of stored settings, do not press

STEADY/TEACH in SETUP mode (doing so will clear the previously

stored cell setting). Always return the dispenser to RUN mode after

viewing or changing contents.

Memory

Figure 1

Figure 2

This manual suits for next models

2

Table of contents

Other EFD Dispenser manuals