EFI VUTEk 3r Series Operating manual

Maintenance Guide

VUTEk 3r & 5r Series

Digital Inkjet Printer

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide ii

Copyright © 2002-2020 Electronics for Imaging, Inc. All rights reserved.

Document ID: OMM-00144-L

All trademarks, registered trademarks, and product names used in this document are the property of their respective owners.

The information contained in this document is confidential and proprietary to Electronics for Imaging, Inc (EFI). This information is provided

only to authorized representatives of EFI and EFI customers solely for the purpose of facilitating the use of EFI’s products. No information

contained herein may be disclosed to any unauthorized person for any purpose whatsoever without the prior written consent of EFI.

EFI makes no representations or warranties with respect to the contents of this document. Further, EFI reserves the right to revise or

change this publication and the products it describes without notice.

English is the original language of this document.

This product may be covered by one or more of the following U.S. Patents

5,109,241, 5,150,454, 5,170,182, 5,212,546, 5,260,878, 5,276,490, 5,278,599, 5,335,040, 5,343,311, 5,398,107, 5,424,754, 5,442,429,

5,459,560, 5,467,446, 5,506,946, 5,517,334, 5,537,516, 5,543,940, 5,553,200, 5,563,689, 5,565,960, 5,583,623, 5,596,416, 5,615,314,

5,619,624, 5,625,712, 5,640,228, 5,666,436, 5,682,421, 5,729,665, 5,745,657, 5,760,913, 5,799,232, 5,818,645, 5,835,788, 5,859,711,

5,867,179, 5,937,153, 5,940,186, 5,959,867, 5,970,174, 5,982,937, 5,995,724, 6,002,795, 6,025,922, 6,035,103, 6,041,200, 6,065,041,

6,081,281, 6,112,665, 6,116,707, 6,122,407, 6,134,018, 6,141,120, 6,166,821, 6,173,286, 6,185,335, 6,201,614, 6,209,010, 6,215,562,

6,219,155, 6,219,659, 6,222,641, 6,224,048, 6,225,974, 6,226,419, 6,238,105, 6,239,895, 6,256,108, 6,269,190, 6,271,937, 6,278,901,

6,279,009, 6,289,122, 6,292,270, 6,299,063, 6,310,697, 6,321,133, 6,327,047, 6,327,050, 6,327,052, 6,330,071, 6,330,363, 6,331,899,

6,337,746, 6,340,975, 6,341,017, 6,341,018, 6,341,307, 6,347,256, 6,348,978, 6,356,359, 6,366,918, 6,369,895, 6,381,036, 6,400,443,

6,429,949, 6,449,393, 6,457,823, 6,476,927, 6,487,568, 6,490,696, 6,501,565, 6,519,053, 6,539,323, 6,543,871, 6,546,364, 6,549,294,

6,549,300, 6,550,991, 6,552,815, 6,559,958, 6,572,293, 6,590,676, 6,599,325, 6,606,165, 6,616,355, 6,618,157, 6,633,396, 6,636,326,

6,637,958, 6,643,317, 6,647,149, 6,657,741, 6,660,103, 6,662,199, 6,678,068, 6,679,640, 6,687,016, 6,707,563, 6,741,262, 6,748,471,

6,753,845, 6,757,436, 6,757,440, 6,778,700, 6,781,596, 6,786,578, 6,816,276, 6,825,943, 6,832,865, 6,836,342, 6,850,335, 6,856,428,

6,857,803, 6,859,832, 6,866,434, 6,874,860, 6,879,409, 6,885,477, 6,888,644, 6,905,189, 6,930,795, 6,950,110, 6,956,966, 6,962,449,

6,967,728, 6,974,269, 6,977,752, 6,978,299, 6,992,792, 7,002,700, 7,023,570, 7,027,187, 7,027,655, 7,031,015, 7,046,391, 7,054,015,

7,058,231, 7,064,153, 7,073,901, 7,081,969, 7,090,327, 7,093,046, 7,095,518, 7,095,528, 7,097,369, 7,099,027, 7,105,585, 7,116,444,

7,177,045, 7,177,049, 7,177,472, 7,204,484, 7,206,082, 7,212,312, 7,229,225, 7,233,397, 7,233,409, 7,239,403, 7,245,400, 7,248,752,

7,259,768, 7,259,893, 7,280,090, 7,296,157, 7,301,665, 7,301,667, 7,301,671, 7,302,095, 7,302,103, 7,304,753, 7,307,761, 7,342,686,

7,343,438, 7,349,124, 7,365,105, 7,367,060, 7,367,559, 7,389,452, 7,396,119, 7,396,864, 7,397,583, 7,397,961, 7,426,033, 7,431,436,

7,433,078, 7,453,596, 7,460,265, 7,460,721, 7,461,377, 7,463,374, 7,466,441, RE36,947, RE38,732, D341,131, D406,117, D416,550,

D417,864, D419,185, D426,206, D426,206, D439,851, D444,793.

This document is published on-line at http://inkjet.support.efi.com.

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide iii

Revision History

Ver. Date Description Request #

A 01/10/2018 First revision.

B 01/11/2018 Added Grease Gun, PRESSOL part number to Printer Maintenance Log; changed wiping LED

glass to every eight hours; added chiller fluid level check; updated air quality check and

requirements.

C 01/19/2018 Changed Nylon Brush and added part number; reformatted document for flow and usability.

D 02/09/2018 Re-arranged Maintenance Task intervals; changed Semi-Annual filter maintenance to an Oper-

ator task; updated Common Maintenance Items in the Printer Maintenance Log; added addi-

tional procedures.

E 07/23/2018 • Corrected section 2.1 and Maintenance Log to clean Print Head plate with Jet Surface Cleaner

(part# 45119466) and not IPA.

• Small text edits to pgs. 37 and 38.

• DR 5165

• DR 5119

F 08/13/2018 Changes to 4hr routines and Print Head Cleaning routine. Added additional Common Mainte-

nance Items.

DR 5194

G 10/04/2018 Added printer model to top of Maintenance Log. Removed contact table and instruction text

from Log.

DR 5304

H 02/14/2019 • Added “Apply print head cleaning solution to the wipe and then” at start of step 6 for 3.2 Clean

print heads. in 4 Hour Maintenance.

• Changed IPA to roll conditioner to step 2 for 2. Clean the T (Tension) rubber roller. in 40 Hour

Maintenance

• DR 5517

• DR 5518

I 05/21/2019 Added section 8.2 Create a printer backup. to Quarterly Maintenance DR 5687

J 10/03/2019 Updated style and added video links. Added/edited notes on pgs. 33 and 36. DR 5849

K 05/26/2020 Added section 7.5 Clean the carriage home sensor. DR 6296

L 06/25/2020 Updated Preferences window image in Figure 5-2 DR 6327

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide iv

1.0 INTRODUCTION 6

1.1 Welcome 6

1.2 Before You Begin 6

1.3 Safety 7

1.4 Using Retaining Pins 8

1.5 Maintenance Videos 9

1.6 Customer Support 10

1.7 Performing Maintenance 11

1.8 Printer Maintenance Log 11

1.9 Safety Labels - Printer Beam 11

1.10 Fluid Emergency 11

1.11 First Aid - Inks and Solvents 12

2.0 SCHEDULED MAINTENANCE 14

2.1 Importance of Maintenance 14

2.2 8 Hour Daily Production 14

3.0 EVERY FOUR HOURS 16

3.1 Clean around the print head area. 16

3.2 Clean print heads. 17

3.3 Clean printer carriage components. 21

4.0 EVERY EIGHT HOURS 23

4.1 Check facility air compressor and air filter systems. 23

4.2 Clean the print platen. 24

4.3 Clean the measure media sensor. 26

4.4 Clean the ink sink. 27

4.5 Clean the LED lamp glass. 29

4.6 Clean the ionizer bars. 31

4.7 Clean the carriage crash sensors sides. 32

4.8 Perform print head care. 33

5.0 ONCE DAILY MAINTENANCE 35

5.1 Perform white ink maintenance. 35

6.0 EVERY 40 HOURS 38

6.1 Clean the free-fall rollers. 38

6.2 Clean the T (Tension) rubber roller. 39

6.3 Clean the Y (Shaft) rubber roller. 40

6.4 Clean metal input feed, press, and collector rollers. 41

6.5 Lubricate the carriage bearings. 43

6.6 Check/empty waste container. 45

6.7 Clean carriage rail ends. 47

6.8 Check the chiller fluid level. 48

6.9 Check last chance air and water filters. 49

7.0 MONTHLY MAINTENANCE 51

7.1 Clean the printer exterior covers. 51

7.2 Clean cable carrier and shelf. 53

7.3 Clean three main exhaust vents. 54

7.4 Wipe linear encoder strip. 55

7.5 Clean the carriage home sensor. 56

8.0 QUARTERLY MAINTENANCE 58

8.1 Inspect/replace white ink degasser tubes. 58

8.2 Create a printer backup. 60

9.0 SEMI-ANNUAL MAINTENANCE 62

9.1 Replace primary ink filters. 62

10.0 REQUIRED ITEMS LIST 66

VUTEK 3R & 5R SERIES MAINTENANCE LOG 68

Table of Contents

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 6

The guide provides instruction for certified operators to perform the required routine maintenance tasks. Download the latest version

of this document at https://inkjet.support.efi.com.

Welcome to the EFI Printer Maintenance Guide. Please take the time to get well acquainted with your printer by reading

this document and the corresponding Operations Guide. The more you know and understand about your printer, the

greater safety and production value you will derive from it.

Additional information is available in separate documents, which can be found here: https://inkjet.support.efi.com

For more information on EFI and it’s products, visit: www.efi.com

Before performing any scheduled maintenance procedure, operators are required to complete Operator Certification

Training. For more information, visit: https://inkjet.support.efi.com/training/

Ensure all required items are on-hand before beginning any maintenance procedure. Required items can be found in the

Required Items List section of this document.

NOTE: You must read and understand the following documents prior to operating or servicing this printer.

•Inkjet Solutions Printer Safety Guide - http://inkjet.support.efi.com/doc.php?doc=683

•VUTEk 3r & 5r Operations Guide - http://inkjet.support.efi.com/doc.php?doc=3941

•VUTEk 3r & 5r Maintenance Guide

These documents are available at http://inkjet.support.efi.com.

1.0 Introduction

1.1 Welcome

1.2 Before You Begin

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 7

Use caution when performing maintenance tasks on your printer. Adhere to all safety precautions described in the Inkjet

Printer Safety Guide. Make sure nothing gets caught in moving parts. Do not perform maintenance procedures while the

printer is in production. Keep all open flames and other burning materials (such as cigarettes) away from the printer.

Safety comments and instructions should be read and observed to avoid personal injury and/or printer damage. These

comments are highlighted as follows:

WARNING:

• Comments in a red highlighted box with triangle symbol

• Used when failure to follow will result in operator injury or printer damage

Example:

CAUTION:

• Comments in a yellow highlighted box

• Used when failure to follow could result in operator injury or printer damage

Example:

NOTE:

• Comments in italics

• Used when failure to follow could result in printer errors

• Used when describing helpful tips

Example:

NOTE: The second wiping must be with a dry wipe to prevent print head cleaning fluid from potentially entering

the print head.

1.3 Safety

Warning: Contact between the moving carriage and a foreign object can

cause injury and damage.

Caution: Do not apply excessive pressure. Do not try to insert the corners of

the wipes into the print head nozzles.

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 8

Two retaining pins are provided with the printer kit. Operators must install the retaining pins when the printer hood is

open and the operator is performing printer maintenance tasks. Pin installation locations are at the left (LH) and right (RH)

sides of the printer and are installed to prevent the printer hood pistons from closing.

How-to Video:

1. The LH pin installation location is shown in Figure 1-1.

2. Open the printer hood and insert the retaining pins into the LH and RH pin sockets.

3. Ensure the retaining pins are inserted fully into the sockets, and proceed with any required maintenance tasks.

4. Remove the retaining pins after completing tasks.

1.4 Using Retaining Pins

Warning: The Printer Hood represents a CRUSHING hazard when open. To prevent Operator injury, always

install the Retaining Pins when the Printer Hood is open while performing printer maintenance

tasks. The Retaining Pins are intended for the personal safety of the printer operator to prevent

the Printer Hood from lowering due to operator error or system failure.

CLICK TO PLAY

Figure 1-1 Hood Open, (Left), Installing Pin, (Middle) and Pin Installed, (Right)

Figure 1-2 : Retaining Pin

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 9

A series of Maintenance Videos is available for users to review prior to completing any maintenance procedure. Each

procedure contains a link to review the related maintenance video.

1.5 Maintenance Videos

CLICK TO PLAY

Figure 1-3 Example video link

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 10

1.6 Customer Support

North & South Americas Europe, Middle East, Africa Asian Pacific (APAC)

Customer Care

U.S 855-EFI-4HLP

(855-334-4457)

+31 20 658 8070 +1 650 357 4790

EuroInk@efi.com

Canada

Mexico

South America

+1 650 357 4790

Technical Support https://inkjet.support.efi.com

US

Canada

855-EFI-4HLP

(855-334-4457)

+32 2 749 94 50 +65 6221 2765

Mexico

South America

+1 412 690 4321 DE +49 2102 745 4500

NL +31 20 658 8080/8069

UK +44 12462 98085

Order Parts

US Inkjet.Orders@efi.com EuroParts@efi.com InternationalOrders@efi.com

Canada

Mexico

South America

InternationalOrders@efi.com

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 11

Most efficient maintenance routine:

• Read each maintenance task fully before starting.

• Verify that you have all the materials required to complete each maintenance procedure.

• Perform all maintenance tasks as scheduled in the maintenance log.

• Perform maintenance activities either before or after printing production shifts.

The VUTEk 3r & 5r Series Maintenance Log is at the end of this document.

The Printer Maintenance Log lists the maintenance tasks, as well as the means for tracking the completion of each item.

Print the first side once per week for daily and weekly tasks, and print the second page once per year for less frequent

maintenance. When filling out the Maintenance Log, record the current date and time (if applicable), and write your

initials in the space provided. Please retain copies of the Maintenance Log. Field Engineers will often ask to review your

maintenance records during service visits.

The Printer Beam contains powerful magnets that assist the carriage movement. Persons with implanted medical devices

must take extreme caution to avoid being within or contacting these magnets. Operators and Technicians must take

extreme caution when using tools or other metal objects within 24" (61 cm) of the Printer Beam Magnets.

If an emergency situation involving inks or maintenance fluids arises, contact local emergency services, download any

SDS (Safety Data Sheets) and make them available to emergency service personnel. SDS are available on the Inkjet

Support Site, https://inkjet.support.efi.com/main.php under Documents > SDS (Safety Data Sheets).

1.7 Performing Maintenance

1.8 Printer Maintenance Log

1.9 Safety Labels - Printer Beam

1.10 Fluid Emergency

Introduction

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 12

Follow first aid directions based on these situations.

Eye contact

• Immediately flush with cool water (≥15 minutes)

• Seek medical attention

Ingestion

• Do not induce vomiting; drink two glasses of water

• Seek medical attention

Skin contact

• Remove contaminated clothing

• Flush with plenty of cool water and non-abrasive soap

• Seek medical attention if irritation develops

Inhalation

• Move person to fresh air

• Seek medical attention if symptoms develop

1.11 First Aid - Inks and Solvents

Scheduled Maintenance

Document ID: OMM-00144-L VUTEk 35 & 5r Series Maintenance Guide 14

Scheduled maintenance is essential to promoting greater printer reliability, increased print quality, and greater

production results. Use only recommended fluids, lubricants and parts, as described in EFI documents.

Routine maintenance can help to:

• Maintain printer up time

• Maximize productivity

• Maintain peak image quality

To help you service your printer, we provide a Maintenance Log which makes tracking routine maintenance easy. The

Maintenance Log provides you with a list of preventative maintenance tasks, as well as the means for tracking the

completion of each task. Please keep your maintenance log up to date. Your EFI Service Engineer will review your

maintenance log during scheduled visits.

The maintenance guidelines are based on an eight hour print production schedule, five days per week. Adjust your

maintenance intervals if your operating shifts are longer than eight hours, five days per week.

2.0 Scheduled Maintenance

2.1 Importance of Maintenance

2.2 8 Hour Daily Production

Every 4 Hours

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 16

The following maintenance tasks must be performed every 4 hours of production.

PPE Items: GLOVES NITRILE DISPOSABLE BOX LARGE

SAFETY GLASSES

Required Items: WIPES 9X9 CLEAN ROOM

PRINT HEAD CLEANING FLUID

How-to Video:

Directions:

NOTE: Before wiping the print heads, clean any accumulated ink residue around the print head area and the

bottom of the carriage (print head plate). This procedure should be carried out daily, at minimum, or if

needed, every 4 hours of production.

1. Raise the carriage to its highest position.

2. Open the printer hood and insert the retaining pins into the LH and RH pin sockets.

3. Wipe the print head plate with print head surface cleaner.

3.0 Every Four Hours

3.1 Clean around the print head area.

CLICK TO PLAY

Every 4 Hours

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 17

PPE Items: GLOVES NITRILE DISPOSABLE BOX LARGE

SAFETY GLASSES

Required Items: WIPES 9X9 CLEAN ROOM

PRINT HEAD CLEANING FLUID

How-to Video:

Directions:

1. Ensure the printer is in the Printer Ready status.

NOTE: Print head wiping should not proceed until ink system is completely warmed.

2. From the printer Front End in Print Heads Maintenance pane, set the Duration to 3 seconds.

3. Click the Purge button to perform a three second Ink Purge, Figure 3-1.

3.2 Clean print heads.

CLICK TO PLAY

Figure 3-1 Print Heads Maintenance, Purge options, 3 second duration

A Purge button

A

Every 4 Hours

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 18

4. Open the printer hood and insert the retaining pins into the LH and RH pin sockets.

5. Fold a lint-free wipe in half, and in half again, Figure 3-2.

6. Apply print head cleaning solution to the wipe and then position the

wipe between your fingers, Figure 3-3, and place wipe parallel to the

print head plate at the carriage rear, Figure 3-4.

7. Wipe the print head faces of one color in one motion toward the

carriage front. Take care to wipe only one color at a time; do not

allow the wipe to contact the adjacent print heads or contamination

may occur.

Caution: Do not apply excessive pressure. Do not try to insert the corners of the wipes into the print

head nozzles.

Figure 3-2 Three stages of folding wipes

Figure 3-3 Holding wipe between fingers

Figure 3-4 : Wiping print heads

Every 4 Hours

Document ID: OMM-00144-L VUTEk 3r & 5r Series Maintenance Guide 19

8. Pull the used portion of wipe through your fingers as ink accumulates on the wipe. When no clean portion remains, discard the

wipe.

9. Repeat steps 5. through 8. for the remaining colors.

10. From the printer Front End in Print Heads Maintenance pane, set the Duration to 3 seconds.

11. Click the Purge button to perform a three second ink purge, Figure 3-1.

12. Fold a DRY, lint-free wipe in half, and half again as described earlier, Figure 3-2.

13. Dry-wipe the print head faces in the same way as described earlier.

14. From the printer front end, print a Nozzle Test and analyze, Figure 3-7.

• If Nozzle Test is acceptable, the procedure is complete. Proceed to step

• If Nozzle Test is not acceptable, proceed to Perform print head care., focusing on those color channels indicating nozzle out

or nozzle misdirects, Figure 3-6.

EXAMPLE: The magenta and cyan channels both displayed Nozzle Out conditions in Figure 3-7. The operator cleared the white,

yellow, and black channels to purge only the magenta and cyan print heads, Figure 3-6, and used a wet wipe.

Figure 3-5 Advancing to clean portion of wipe, Left, and discarded wipe, Right

Figure 3-6 Purge section, only Magenta and Cyan channels selected

This manual suits for next models

1

Other EFI Printer manuals

EFI

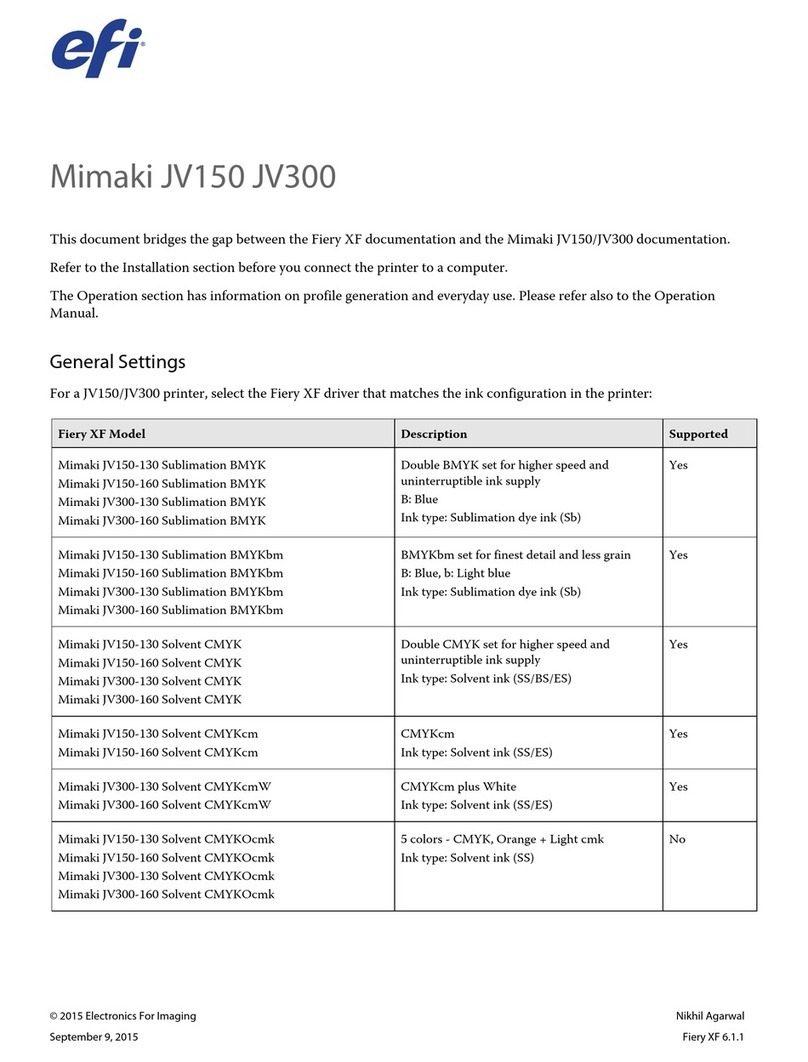

EFI Mimaki JV150 User manual

EFI

EFI Pro 32r User manual

EFI

EFI Fiery X3eTY2 Quick guide

EFI

EFI Pro 16h User manual

EFI

EFI Kyocera 17 Quick guide

EFI

EFI IQ-501 Operating instructions

EFI

EFI Pro 30f User manual

EFI

EFI Pro 24f User manual

EFI

EFI Vutek QS2000 Manual

EFI

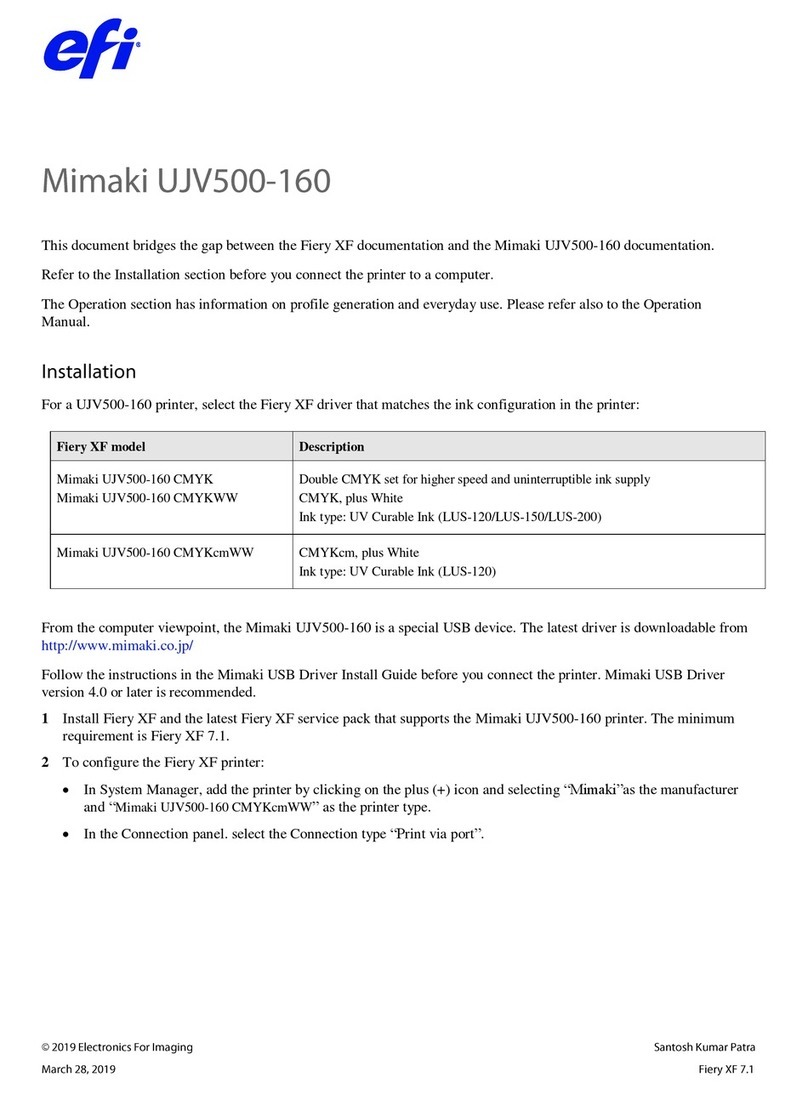

EFI Mimaki UJV500-160 Series User manual