Application Manual

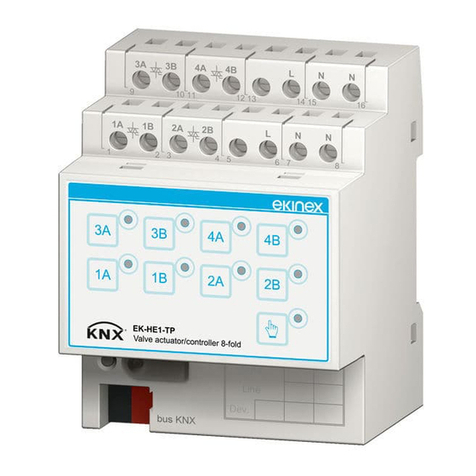

EK-HH1-TP mixing group controller

Release 1.01 - Updating: 12/05/2018 Application Manual

© EKINEX S.p.A. – All rights reserved Pag. 2

Summary

1Scope of the document..................................................................................................................................5

2Product description ........................................................................................................................................6

2.1 General characteristics ..........................................................................................................................6

2.2 Electrical characteristics ........................................................................................................................8

3Switching, display and connection elements.................................................................................................9

4Configuration ............................................................................................................................................... 11

5Programming and commissioning ...............................................................................................................11

6Function description ....................................................................................................................................12

6.1 Switching on.........................................................................................................................................12

6.2 Offline operation...................................................................................................................................12

6.2.1 Operation with bus power only.....................................................................................................12

6.2.2 Operation with load power supply only ........................................................................................12

6.3 Manual operation .................................................................................................................................12

6.3.1 Output status when mode changes .............................................................................................12

6.3.2 Manual mode activation ...............................................................................................................13

6.4 Online operation...................................................................................................................................13

6.4.1 Software working cycle ................................................................................................................13

6.4.2 State variables (communication objects) .....................................................................................13

6.5 Applications..........................................................................................................................................13

6.6 Mixing group management ..................................................................................................................14

6.6.1 Components .................................................................................................................................14

6.6.2 Activation/deactivation sequence.................................................................................................14

6.6.3 Activation......................................................................................................................................14

6.6.4 Heating/cooling changeover.........................................................................................................15

6.6.5 Types of supported servomotors..................................................................................................15

6.6.6 PI (proportional-integral) regulator ...............................................................................................16

6.6.7 Circulator protection function .......................................................................................................16

6.6.8 Anticondensation protection function ...........................................................................................16

6.6.9 Alarms ..........................................................................................................................................17

6.7 Physical inputs .....................................................................................................................................20

6.8 Physical outputs...................................................................................................................................20

6.9 Control modes......................................................................................................................................21

6.9.1 Heating: fixed point ......................................................................................................................21

6.9.2 Heating: climatic compensation ...................................................................................................21

6.9.3 Heating: recalibration based on return temperature ....................................................................22

6.9.4 Heating: recalibration based on internal conditions .....................................................................23

6.9.5 Heating: climatic compensation and recalibration based on internal conditions .........................24

6.9.6 Heating: connecting communication objects of KNX sensors .....................................................25

6.9.7 Cooling: fixed point.......................................................................................................................27

6.9.8 Cooling: climatic compensation....................................................................................................27

6.9.9 Cooling: recalibration based on internal thermohygrometric conditions ......................................28

6.9.10 Cooling: clim. Comp. and recalibration based on internal thermohygrometric conditions ...........28

6.9.11 Cooling: connecting communication objects of KNX sensors......................................................29

7Display .........................................................................................................................................................32

7.1 Navigation buttons ...............................................................................................................................32