4

Document

This datasheet refers to the release A1.0 of the ekinex®

device EK-HH1-TP, and is available for download at www.

ekinex.com as a PDF (Portable Data Format) le.

Warning

• Installation, electrical connection, conguration and

commissioning of the device can only be carried out

by qualied personnel in compliance with the appli-

cable technical standards and laws of the respective

countries

• Opening the housing of the device causes the imme-

diate end of the warranty period

• In case of tampering, the compliance with the essen-

tial requirements of the applicable directives, for which

the device has been certied, is no longer guaranteed

ekinex®defective devices must be returned to the

manufacturer at the following address: EKINEX S.p.A.

Via Novara 37, I-28010 Vaprio d’Agogna (NO) Italy

Other informations

• The instruction sheet must be delivered to the end

customer with the project documentation

• For further information on the product, please contact

the ekinex®technical support at the e-mail address:

com

• Each ekinex®device has a unique serial number on

the label. The serial number can be used by installers

or system integrators for documentation purposes and

has to be added in each communication addressed to

the EKINEX technical support in case of malfunctio-

ning of the device

• KNX®and ETS®are registered trademarks of KNX

Association cvba, Brussels

© EKINEX S.p.A. The company reserves the right to make changes to this

documentation without notice.

Filename Device release Updating

STEKHH1TP_IT.pdf A1.0 03 / 2017

Note. The conguration and commissioning of KNX

devices require specialized skills. To acquire these

skills, you should attend the workshops at KNX cer-

tied training centers.

i

Characteristics of the terminals

• screw clamping of conductors

• maximum cross section of conductor 2.5 mm² (single-

wire) or 1.5 mm² (multi-wire)

• recommended wire stripping approx. 6 mm

• torque max 0.8 Nm

Conguration and commissioning

Conguration and commissioning of the device require

the use of the ETS® (Engineering Tool Software) program

V4 or later releases. These activities must be carried out

according to the design of the building automation system

done by a qualied planner.

Conguration

For the conguration of the device parameters the corre-

sponding application program or the whole ekinex®pro-

duct database must be loaded in the ETS program. For

detailed information on conguration options, refer to the

application manual of the device available on the website

www.ekinex.com.

Product

code

Application

program

(## = release)

Communica-

tion objects

(max nr.)

Group

adressses

(max nr.)

EK-HH1-TP

APEKHH1TP##.knxprod

185 254

Commissioning

For commissioning the device the following activities are

required:

• make the electrical connections as described above;

• turn on the bus power supply;

• switch the device operation to the programming mode

by pressing the programming pushbutton located on

the front side of the housing. In this mode of operation,

the programming LED is turned on;

• download into the device the physical address and the

conguration with the ETS®program.

At the end of the download the operation of the device

automatically returns to normal mode; in this mode the

programming LED is turned o. Now the bus device is

programmed and ready for use.

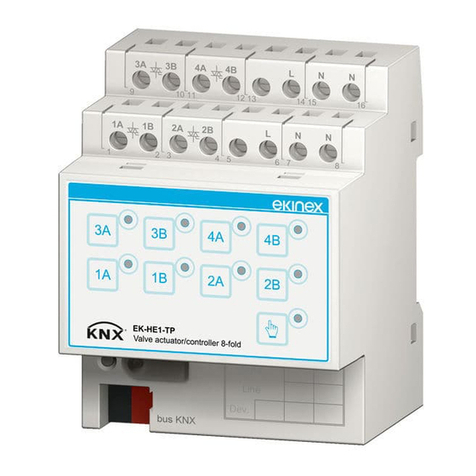

Dimensions [mm]

144 5 25 20 20

70

90

45

15 16

POWER AUX

34

IN1 56

IN2 78

IN3

20 21

DO1 22 23

DO2 24 25

DO3

910

IN4 11 12

IN5 13 14

AO1

17 18 19

OPENCLOSE COM

1 2

L N

bus KNX

EK-HH1-TP

Mixing group controller

OK

ESC

+-

Dev.

Line

Area

Marks

• KNX

• CE: the device complies with the Low Voltage Directi-

ve (2014/35/EC) and the Electromagnetic Compatibili-

ty Directive (2014/30/EC). Tests carried out according

Disposal

At the end of its useful life the product

described in this datasheet is classied

as waste from electronic equipment

and cannot be disposed together with

the municipal undierentiated solid

waste.

Warning! Incorrect disposal of this product may

cause serious damage to the environment and hu-

man health. Please be informed about the correct

disposal procedures for waste collecting and pro-

cessing provided by local authorities.

!

to EN 50491-2:2010, EN 50491-3:2009, EN 50491-4-

1:2012, EN 50491-5-1:2010, EN 50491-5-2:2010, EN

50428:2005 +A1:2007 + A2:2009

Maintenance

The device is maintenance-free. To clean use a dry cloth.

It must be avoided the use of solvents or other aggressive

substances.