2

Connection of the KNX bus line

The connection of the KNX bus line (g. a) is made with

the terminal block (black/red) included in delivery and in-

serted into the slot of the housing.

Characteristics of the KNX terminal block

• spring clamping of conductors

• 4 seats for conductors for each polarity

• terminal suitable for KNX bus cable with single-wire

conductors and diameter between 0.6 and 0.8 mm

• recommended wire stripping approx. 5 mm

• color codication: red = + (positive) bus conductor,

black = – (negative) bus conductor

at the top.

For the installation of the device on the rail proceed as

follows:

• with the aid of a tool bring the locking device in the

fully lowered position (1);

• place the upper edge of the rear inner prole on the

upper edge of the rail (2);

• rotate the device towards the rail (3);

• push the locking device upward until it stops (4).

Before removing the device, be sure the inputs have been

disconnected and the bus terminal has been extracted

from its slot. Use a screwdriver to slide down the locking

device and remove the device from the rail.

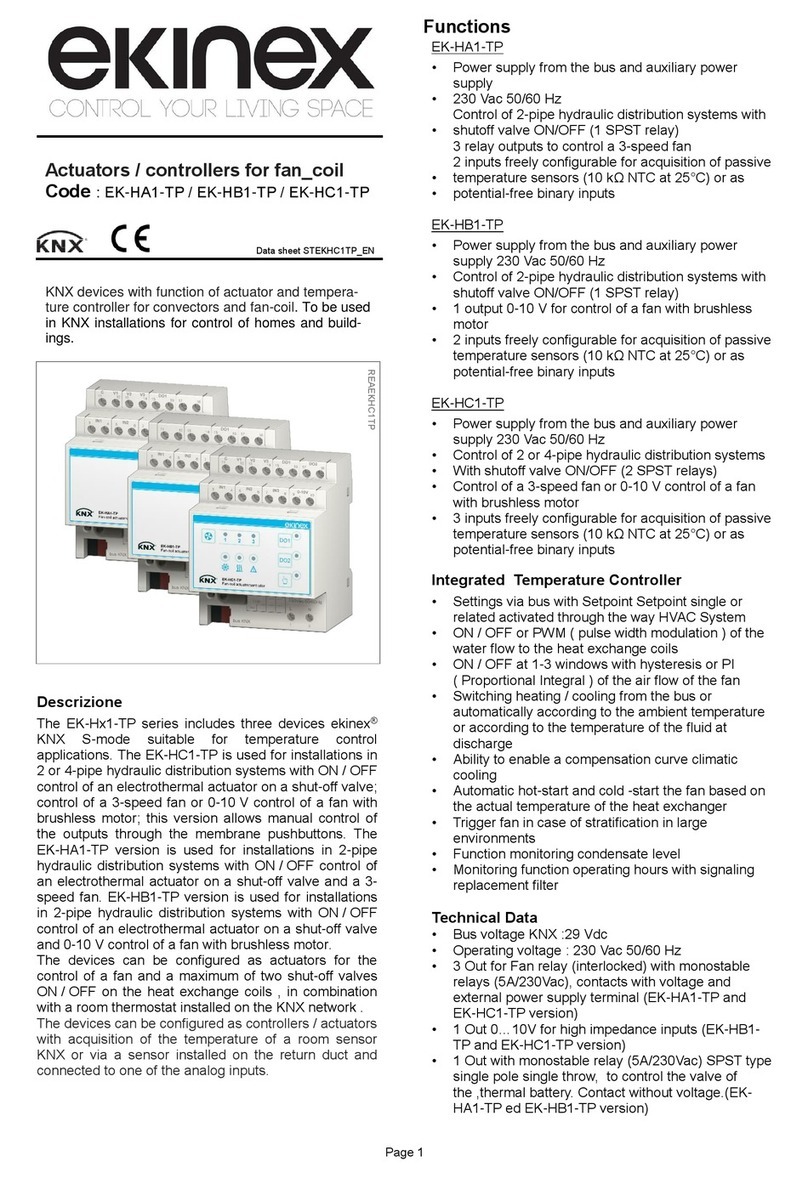

Switching, display and connection elements

The device is equipped with a programming pushbutton

and a programming LED, membrane pushbuttons, LED

for status indication and terminals for connecting the KNX

bus line, the 100-230 Vac power supply and the outputs.

Switching elements

• Pushbutton (3) for switching between the normal and

programming operating mode

• Pushbutton (7) for switching between the operating

modes: forced (pushbuttons on the front panel: active)

or automatic (pushbuttons on the front panel: not

active)

• Pushbuttons (2) for forced operation of the output

channels

Display elements

• Red LED (4) for displaying the active operating mode

of the device (on = programming, off = normal opera-

tion)

• Green LEDs (9) for displaying the switching status of

the output channels (on = closed contact, off = opened

contact)

• Red LED (8) for displaying the operating mode (on =

forced operation, off = automatic operation)

Mounting

The device has degree of protection IP20, and is there-

fore suitable for use in dry interior rooms. The housing is

made for rail mounting according to EN 60715 in boards

or cabinets for electrical distribution. The installation is in

horizontal position, the correct position is when the KNX

bus terminal and the 100-230 Vac terminals are located at

the bottom and the terminals for the outputs are located

• Rated voltage (Un): 100-230 Vac 50 / 60Hz

• Rated current (In): max 16 (10) A (both @ 100Vac and

@ 230Vac)

• Max switched power: max 4000 VA @ 250Vac

• Inrush current: 88 A 20 ms

Environmental conditions

• Operating temperature: - 5 ... + 45°C

• Storage temperature: - 25 ... + 55°C

• Transport temperature: - 25 ... + 70°C

• Relative humidity: 95% not condensing

1 2

43

EKINSTGUIDAEKAB1TP

Warning! In order to supply the KNX bus lines use

only KNX bus power supplies (e.g. ekinex EK-AB1-

TP or EK-AG1-TP). The use of different power sup-

pliy units can compromise the communication and

damage the devices connected to the bus.

!

Note. It is recommended that the installation of the

device always ensure the full accessibility of the

front side to allow the operation of the pushbuttons.

i

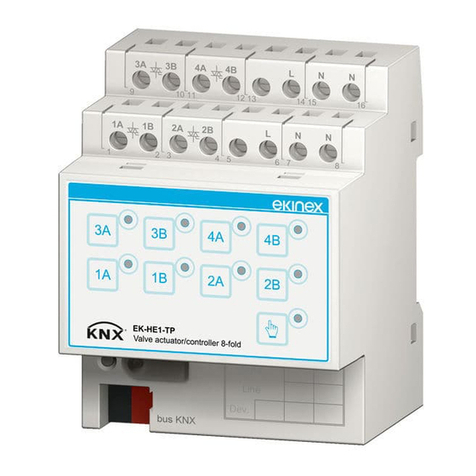

1B 2B 3B 4B

1A 2A 3A 4A

EK-FE1-TP

8xD.O. 16(10)A/230Vac ~50/60 Hz

4xBlind 16(10)A/230Vac ~50/60 Hz

34

1A

A B 56

2A

A B 78

3A

A B 910

4A

A B

11 12

1B 13 14

2B 15 16

3B 17 18

4B

1 2

L N230V~ 50/60Hz

bus KNX

1) Terminal blocks for output channels

2) Pushbuttons for forced operation of the outputs

3) Programming pushbutton

4) Programming LED

5) Terminal block for KNX bus line

6) Terminal blocks for 230 Vac 50/60 Hz power supply

7) Pushbutton for switching between manual and automatic operation

8) LED for indication forced / automatic operation mode

9) LED for status indication of the outputs

1

2

4

5

8

7

6

3

9

DCEKFE1TP

Connection of the 100-230 Vac power supply

The connection of the 100-230 Vac power supply (g. a)

is made with the screw terminals located on the lower

front of the device.

Characteristics of the terminals

• screw clamping of conductors

• maximum cross section of conductor 2.5 mm²

• ecommended wire stripping approx. 6 mm

• torque max 0.5 Nm