ELABO 90-4F User manual

Operating manual

PE conductor tester

90-4F

DIN EN ISO 9001

certified

Calibration at ELABO factory

Calibration at customer premises

Test units on loan

Hotline ++49 7951/307-0

ELABO GmbH

D-74564 Crailsheim

LGA

ELABO after sale service:

2

PE-Conductor Tester 90-4F

Description

&RQWHQWV

A DESCRIPTION OF FRONT PANEL CONTROLS ...................................3

1. INTRODUCTION......................................................................................5

1.1 GENERAL INFORMATION .....................................................................5

1.2 ABBREVIATIONS AND SYMBOLS ........................................................6

1.3 SHORT DESCRIPTION OF THE PE CONDUCTOR TESTER ................ 6

1.4 GENERAL DATA..................................................................................... 7

1.5 NAME PLATES .......................................................................................7

2. SAFETY REGULATIONS ........................................................................8

2.1 SIGNS OF SAFETY AND WARNING REGULATIONS ...........................8

2.2 WARRANTY ............................................................................................ 8

2.3 USE AS PER SPECIFICATIONS AND EXCLUSION OF LIABILITY ...... 8

2.4 GENERAL RULES OF CONDUCT AND SAFETY REGULATIONS ....... 9

2.5 PARTICULAR REFERENCES TO THE PE CONDUCTOR.......................

TESTER....................................................................................... 10

3. PUTTING INTO OPERATION................................................................ 11

3.1 TRANSPORT AND INSTALLATION ..................................................... 11

3.2 CONNECTION ....................................................................................... 11

3.3 SETTING THE TEST UNIT PARAMETERS .......................................... 12

4. OPERATING MODES............................................................................ 14

4.1 MEASURING PRINCIPLE ..................................................................... 14

4.2 PROTECTIVE CONDUCTOR TEST WITHOUT SAFETY PLUG........... 15

4.3 TEST with SAFETY PLUG.................................................................... 16

4.4 TEST WITH TEST PROBE .................................................................... 17

4.5 OPERATION IN COMBINATION WITH AN INSULATION

TESTER....................................................................................... 18

5. OPERATION VIA INTERFACE.............................................................. 19

5.1 PIN ASSIGNMENT OF INTERFACE TERMINAL STRIP (X7)............... 19

5.2 TERMINAL ASSIGNMENT OF THE 11-PIN VG CONNECTOR (X1) .... 20

5.3 TERMINAL ASSIGNMENT OF THE TERMINAL BLOCK (X6) ............. 21

6. FAULT INDICATIONS ........................................................................... 22

7. MAINTENANCE AND ATTENDANCE .................................................. 23

7.1 EXCHANGE OF FUSES ........................................................................ 23

7.2 SERVICE OF THE HOUSING................................................................ 24

8. TECHNICAL DATA ............................................................................... 25

9. APPENDIX............................................................................................. 26

9.1 COMPONENT LOCATION ILLUSTRATION OF SUBASSEMBLY

PE200 / PE300............................................................................. 27

9.2 COMPONENT LOCATION ILLUSTRATION OF SUBASSEMBLY

PEIS200 ....................................................................................... 28

9.3 WIRING DIAGRAM................................................................................ 30

3

PE-Conductor Tester 90-4F

Description

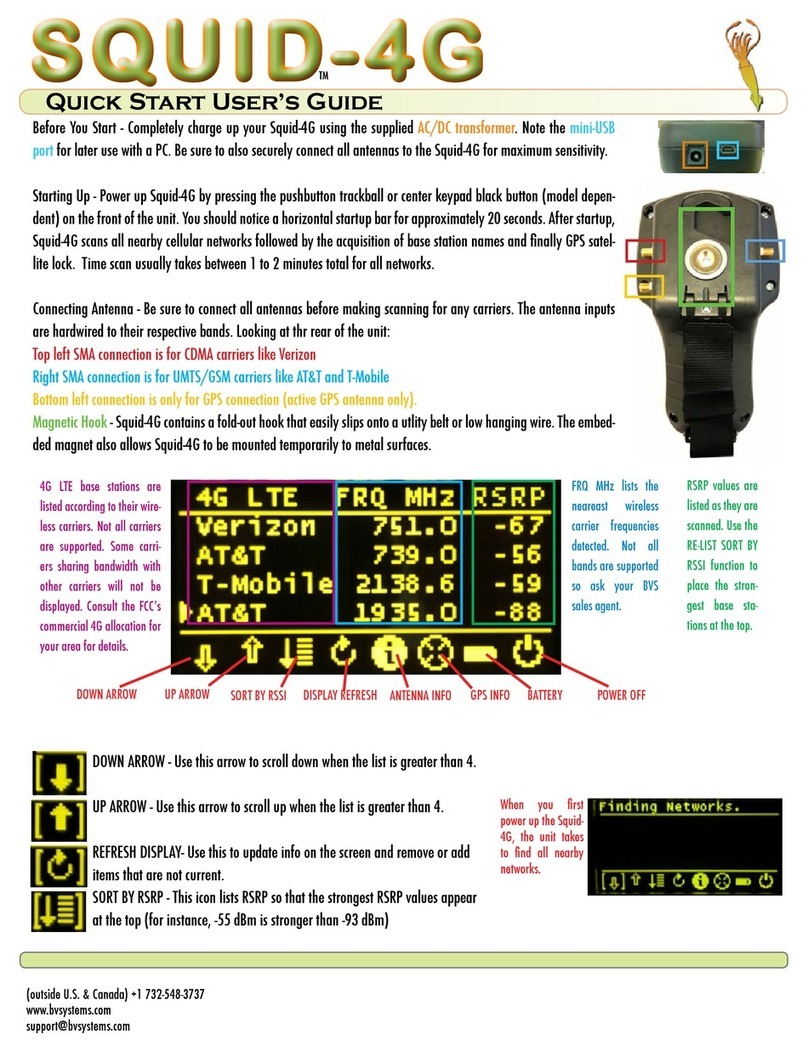

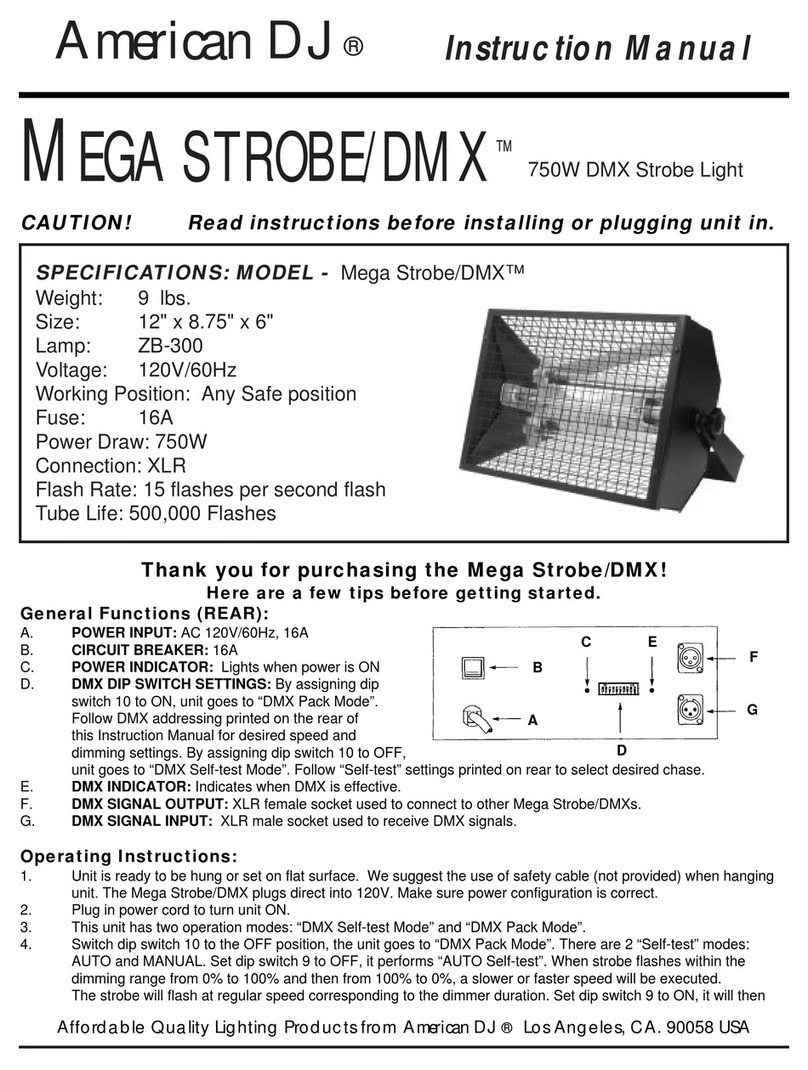

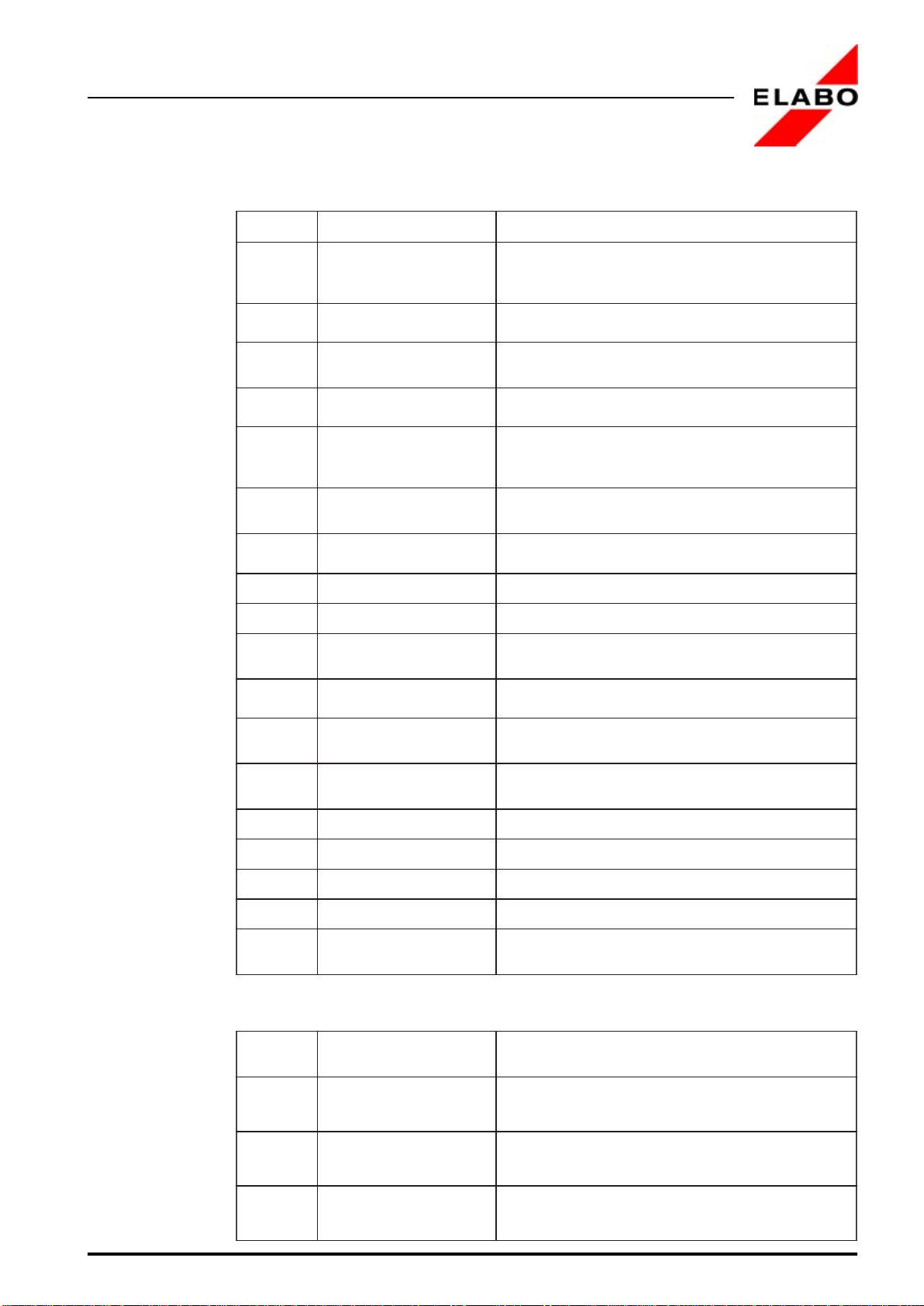

X2 X3.2 X4.2 X4.1 X3.1 S1/H1

A3 S2 S4 R2 S3 R1

V3

V4

V5

V2

V1

X5

X1 X6-3 X6-1 X7

A DESCRIPTON OF FRONT PANEL CONTROLS

Front panel

Rear side

contact 1 / 3

4

PE-Conductor Tester 90-4F

Description

A DESCRIPTON OF FRONT PANEL CONTROLS

.oN.oN .oN .oN.oNtnempiqEtnempiqE tnempiqE tnempiqEtnempiqEnoitarepOnoitarepO noitarepO noitarepOnoitarepO

3AtnerrucdnaecnatsiseR

tnemurtsnignirusaem

tigid2/13

egnaryalpsiD

mhOm053...0ecnatsiser

A52...0tnerruc

1RretemoitnetoPRfognitsujdA

xam

)desserpsi3Snottub-hsupgnidivorp(

2RretemoitnetoPIfognitsujdA

mon

tnemerusamgnidivorp(A52....0morf

)desserpsi4Snottub-hsupehtdnavitcasinoitarepo

1H/1ShctiwsrekcordetanimullI yalpsidedomgnihctiwshtiwgnihctiwsFFO/NO

2SnottubhsuP.tnemerusaemfotrats-TRATS

yalpsideht4S/2Snottub-hsupfognisserpylsuoenatlumistA

.3Anodeveihcasitnerructsetehtfo

3SnottubhsuP dna1RtadetsujdaebnacxamR-detareposi3SfI

3Anodeyalpsid

4SnottubhsuP 3Anodeyalpsidsitnerruclanimoneht-detareposi4SfI

1VwolleyDELnoitareponisitset-EPeht-NUR

2VneergDEL I>IdnaxamR<eulavgnirusaem-TPECCA

nim

"dessaP"

3VderDELR>R

xam

xamRehtnahtrehgihecnatsiserretcudnocEP-

"tluaF"

4VderDELI<I

nim

Inahtrewoltnerructset-

nim

)%01-I(

5VderDEL tontratstseT.erutarepmetrevoretsoob-DAOLREVO

.elbissop

2XteltuodnuorG

)okuhcS(dradnatsnamreG

tcejbotsetehtfonoitcennoC

1.3XskcaJ S4-49eborptsetEPehtforotcejbotsetehtfonoitcennoC

2.3XskcaJtcejbotsetehtfonoitcennoC

1.4XlanimretbalytefaS )1.3Xgnidrager(sdaelrosnesehtfonoitcennoC

2.4XlanimretbalytefaS )2.3Xgnidrager(sdaelrosnesehtfonoitcennoC

5X.lop-5tekcosedoiD tnerructset(S4-49eborptsetEPehtfonoitcennoC

)1.3Xgnidrager

1X

)edisraer(

rotcennocGVnip-11ylppussniaM

1-6X

)edisraer(

lanimretbalytefaS =1-6X.retsetehtfoedisraernotcejbotsetfonoitcennoC

.tnorfno1.3X

3-6X

)edisraer(

lanimretbalytefaS =3-6X.retsetehtfoedisraernotcejbotsetfonoitcennoC

tnorfno2.3X

7X

)edisraer(

rotcennocGVnip-46

)ecafretni-AD(

dnatupnisuoiravfolortnoclanretxerofrotcennocecafretnI

slangistuptuo

5

PE-Conductor Tester 90-4F

1. Indroduction

1. INTRODUCTION

The security of all persons coming into contact with the test unit is decisively

dependent upon the mastery of the unit. Therefore:

Read the operating instructions before

the first putting into operation!

1.1 GENERAL INFORMATION

The operating instructions enable the user to become familiar with the

tester and its application possibilities and to use it as per the specifications

before the first operation. They contain important information which

guarantee a functional, economic and safe operation and have to be

available always at the operational place of the tester.

The operating instructions are not only an indispensable lead-in for

operators who have to be instructed from the very beginning but they also

contain useful tips, information and suggestions for the skilled operator.

They are a necessary reference book for all operators. By reading the

operating instructions

•dangers are avoided

•sequences of operations are optimized and accelerated

•cost of repair and times of standstill are minimized

•reliability and service life are increased

The operating instructions should also be attentively read by the unit owner

and the person responsible for the operation. Particularly with regard to

transport and installation as well as warranty questions.

In chapter 2 important information regarding security and risks are given

which prepare you for danger situations that may arise. During operation

it is unfortunately too late to read again. In addition to this please, note the

following rule:

Cautious and careful working is the

best protection from accidents!

The testing quality of the unit is decisively dependent on maintenance

and attendance. Regular activities concerning maintenance and

attendance are described in these operating instructions. We have pleasure

in supporting you in case of necessary repairs and supply you with the

original spare parts.

If you have any questions after reading the operating instructions the

ELABO Hot -line (Telephone 07951/307-0) is at your disposal for further

details.

For better use of the operating instructions the cover page can be opened

out. Through this the illustration of the front or rear panel of the unit is

always visible for the user while reading the operating instructions.

6

PE-Conductor Tester 90-4F

1. Indroduction

•1

•

SO

ä

1.2 ABBREVIATIONS AND SYMBOLS

Special option, does not belong to the standard delivery extent

Enumeration, the recommended sequence is to be observed herewith

Enumeration

ATTENTION ELECTRIC VOLTAGE !

Danger spot to users and third persons! - Chap. 2.1

Danger to the instrument ! - Chap.2.1

Reference for the effective and economic mode of operation - Chap. 2.1

1.3 SHORT DESCRIPTION OF THE PE CONDUCTOR TESTER

The measuring instrument 2GA27 90-4F serves for the testing of the

efficacy of the PE conductor connection, for

electrical devices for measurement, controlling and laboratory

according EN61010 (DIN VDE 0411),

electrical devices of the household, according EN60335 (DIN VDE

0700),

equipment of information technology and office machines,

according EN60954 (DIN VDE 0805).

The test current is stepless adjustable between 10 to 25 A. Through the

employed test method the resistance value will be calculated from current

and voltage with high precision.

The resistance is displayed during the entire testing time by means of an

3 1/2 digit digital display.

The test object can be connected alternatively to a socket outlet or via

two terminals.

At the test device a maximum permissible resistance can be adjusted

individually. If the preset resistance R max is exceeded during a

measurement, a visual error is displayed (LED R > Rmax).

The device includes a watch-dog function for monitoring the test current.

If the test current underruns the adjusted test current at 10 %, a visual

error is displayed (LED I > Imin).

In order to achieve a non-destructive test the test current is switched on

only after operating the push-button START resp. after pressing the tip of

the test probe in.

The test device is set up as subdrawer with 36 pitches and conceives

already in the standard design for program-controlled application. The

connection is conducted via a multiple connector according to DIN 41612.

7

PE-Conductor Tester 90-4F

1. Indroduction

1.4 GENERALDATA

Type of test: reference EN 61010 (VDE0411),

EN60335 (VDE0700),

EN60950 (VDE 0805)

Duty cycle: 10 %, max. operating time 1.5 min.

Output voltage: max. 10 V AC

Test current : 10 to 25 A

Measuring range: 0 to 350 mOhm

Working temperature: 10oC to 50oC

Atmospheric humidity: 25 - 75% rel. air humidity

Power supply: 230 V +10% -5%/ 49 to 61 Hz

Dimensions: Euro-Subdrawer 3 HU/36 pitches. Depth 196 mm

Weight: 6 kg

1.5NAMEPLATES

ELABO PE-Conductor Tester 90-4F.

Fig. 1.1: ELABO name plate

SN. 0000042483

ELABO GmbH

Rossfelder Str. 56

D-74564 Crailsheim

Telefon: +49 7951 307-0

Telefax: +49 7951 307-65

Nennspg. V

~

Nennstrom A

Typ

Baujahr

230 V ; 49 - 61 Hz

1.2 A

90-4F

2004

8

PE-Conductor Tester 90-4F

2. Safety regulations

2. SAFETY REGULATIONS

Before working with the device the operating instructions and all enclosures

must have been attentively read and understood by all persons operating

the tester. The tester may be operated by trained and skilled staff only.

ELABO has equipped the unit with all necessary safety devices when

using them as per the specifications in order to protect the operator from

appearing risks. Pay attention:

CAUTIOUS AND CAREFUL WORKING IS THE

BEST PROTECTION FROM ACCIDENTS !

2.1 SIGNS OF SAFETY AND WARNING REGULATIONS

Danger Area! Electric Voltage - Danger to life !

IN DEALING WITH ELECTRIC VOLTAGE THERE IS DANGER TO LIFE!

This sign warns of a danger area through electric voltage. It is situated at

all working cycles where life of the operator and other persons is

endangered. It is situated at working and operating procedures which

have to be observed accurately in order to prevent endangering of persons

or the tester by electric voltage.

Caution !

This sign signifies danger to the tester in case of non-observance of in-

struction.

Information !

This sign signifies that a more effective and more economic use of the

tester is possible.

2.2 WARRANTY

Claims for warranty can only be asserted when the terms of warranty

included in the general terms of sale and delivery are observed.

Furthermore, the terms of the operating instructions have to be observed.

2.3 USE AS PER SPECIFICATIONS AND EXCLUSION OF

LIABILITY

The device has to be used as per the specifications only for the intended

tests. Every use beyond is considered as not according to the

specifications. ELABO does not accept any liability for damages resulting

from this, the operator exclusively carries the risk. It is also necessary for

the use as per the specifications that the information given in these

operating instructions is observed.

The device and its components have been developed and constructed

9

PE-Conductor Tester 90-4F

2. Safety regulations

for the application in the industrial field. According to DIN EN 55022 ITE

this unit represents a system of class A. Neither the device as a whole or

the single components of it may be employed in another environment. In

case of non-observance of this information ELABO does not accept any

liability for appearing malfunctions and damages resulting from this.

These operating instructions and all enclosures must have been attentively

read and understood by all operators before working with the device. The

device has to be operated by trained and skilled staff only.

The unit may not be changed regarding construction and safety technology.

Every alteration needs the particular approval of ELABO.

Unauthorized modifications at the device as well as the use of spare parts,

accessories and extra equipments which have not been controlled and

released by ELABO can have a negative influence on the function and

features of the device. ELABO does not accept any liability for damages

resulting from this.

ELABO does not accept any liability for damages arising by non-

observance of the operating instructions or by negligence of duty of care

during the transport, installation, handling, operation, attendance and

maintenance or during repair of the unit even if these duties of care are

not particularly pointed to in the operating instructions.

2.4 GENERAL RULES OF CONDUCT AND SAFETY

REGULATIONS

The device was built according to the state of art and approved safety

regulations. Nevertheless, there might arise danger to life of the operator

or third persons respectively damages at the tester or other material goods.

The device has to be operated in workmanlike condition only and according

to the specifications under observance of the operating instructions. Faults

impairing the safety have to be cleared immediately.

The person responsible for the operation has to attend to that the staff

charged with work at the device must have read and understood the

operating instructions before commencement of work. The person

responsible for the device operation is obliged to always operate the device

in perfect condition only and to instruct the service staff to use the unit as

per the specifications.

The operating instructions have to be always available at the operational

place of the device. Incomplete or illegible operating instructions have to

be replaced immediately. Of course, we are pleased to be of help to you

in this respect.

In addition to the operating instructions legal, generally valid and other

obligatory regulations for accident prevention and environmental protection

have to be observed.

10

PE-Conductor Tester 90-4F

2. Safety regulations

2.5 PARTICULAR REFERENCES TO THE PE CONDUCTOR

TESTER

Before opening the unit pull out power supply plug!

Switching off by means of rocker switch (S1/H1) is insufficient!

The PE contact of the safety socket outlet is not connected to PE

conductor potential!

The safety socket outlet at the front panel of the test unit is not a power

supply socket outlet for consumer articles but exclusively a measuring

socket outlet for the connecting of item on tests with earth safety plugs.

The PE conductor tester is for short-term measurements only, as usual

for PE conductor measurements. Continuous operation of the instrument

can lead to damages.

11

PE-Conductor Tester 90-4F

3. Putting into operation

3. PUTTING INTO OPERATION

3.1 TRANSPORT AND INSTALLATION

The PE conductor tester is delivered completely packed and may only be

taken out of package directly at the operational place.

The unit is designed to be operated in a suitable rack. As an option is a

housing available for application as stand-alone-unit (ELABO-accessory:

Catalogue-No. 2GA27 30-6M). The unit must not be operated outside a

rack or housing.

The operational surface has to suit the weight of the tester (6 kg!) and

provide a safe support for the unit at any time.

The environment of the testing unit must be clean, dry and dust-free.

When installing the tester pay attention that the information and safety

signs at the unit are not covered.

3.2 CONNECTION

The tester can be connected to the mains supply via a 11 pole multiple

connector (X1) located on the rear of the unit.

When inserting into the rack, the mains supply connector at the rear side

of the unit will be connected to the mains supply connector installed in the

rack. Thus, the unit is automatically connected to the power supply.

After inserting the unit into the rack it must be tightly fitted by means of the

two screws located on the front panel.

The operation with a loosely inserted

test unit is not permissible!

12

PE-Conductor Tester 90-4F

3. Putting into operation

3.3 SETTING THE TEST UNIT PARAMETERS

Before the unit is put into operation some parameters must be adjusted.

Switch on unit with illuminated rocker switch (S1/H1). The pilot lamp (S1/

H1) lights up.

Setting of Rmax

Press push-button S3 and set the trimming potentiometer R1 to the maxi-

mal permissible resistance value in the range from 0 to 350 mOhm. The

set value is displayed at the display A3.

Setting of the test current

The test current is adjustable between 10 to 25 A.

In order to adjust the test current, the measuring circuit must be closed by

making a short circuit of the measuring leads.

When using a test probe (SO) the tip of the probe must be pressed onto

the terminal jack X3.2.

Press push button START (S2) and push button I act (S4) simultaneously

and adjust the required test current with trimming potentiometer R2 in the

range of 10 to 25 A. The test current is displayed on instrument A3.

Press push-button S3 and set the trimming potentiometer R1 to the maxi-

mal permissible resistance value in the range from 0 to 350 mOhm. The

set value is displayed at the display A3.

If the lower limit value of the test current is undershot, a red LED V4

(I < Imin) lights up. Nevertheless the test can be carried out. It should be

noted that the accuracy indicated is no longer guaranteed if the test current

falls below I - 10 %. There is no „Accept“ indication by LED V2.

Setting the alarm buzzer.

The buzzer can be set inside the test unit to different modes by setting

jumpers on the subassembly PEIS200.

Work inside the test unit are to be carried out by

an electrical specialist only!

The unit has to be disconnected from the mains if

work is to be carried out inside the unit!

The presetting at works is marked with an #.

13

PE-Conductor Tester 90-4F

3. Putting into operation

Buzzers as GO - or FAULT - signal.

B1: Jumper 1-2 > FAULT-signal

2-3 > Go-signal #

Buzzer ON or OFF.

B2: Jumper 1-2 > ON #

open > OFF

Buzzer for timer mode or Go/Fault evaluation

B5 Jumper 1-2 > Timer mode

2-3 > Fault evaluation #

The Fig. 3.1 shows the location of the jumper on the subassembly.

For more information see the component location illustration of PEIS200

(Chapt. 9.2).

subassembly PEIS 200

Fig. 3.1: Subassebly PEIS200 - buzzer setup

14

PE-Conductor Tester 90-4F

4 Operating modes

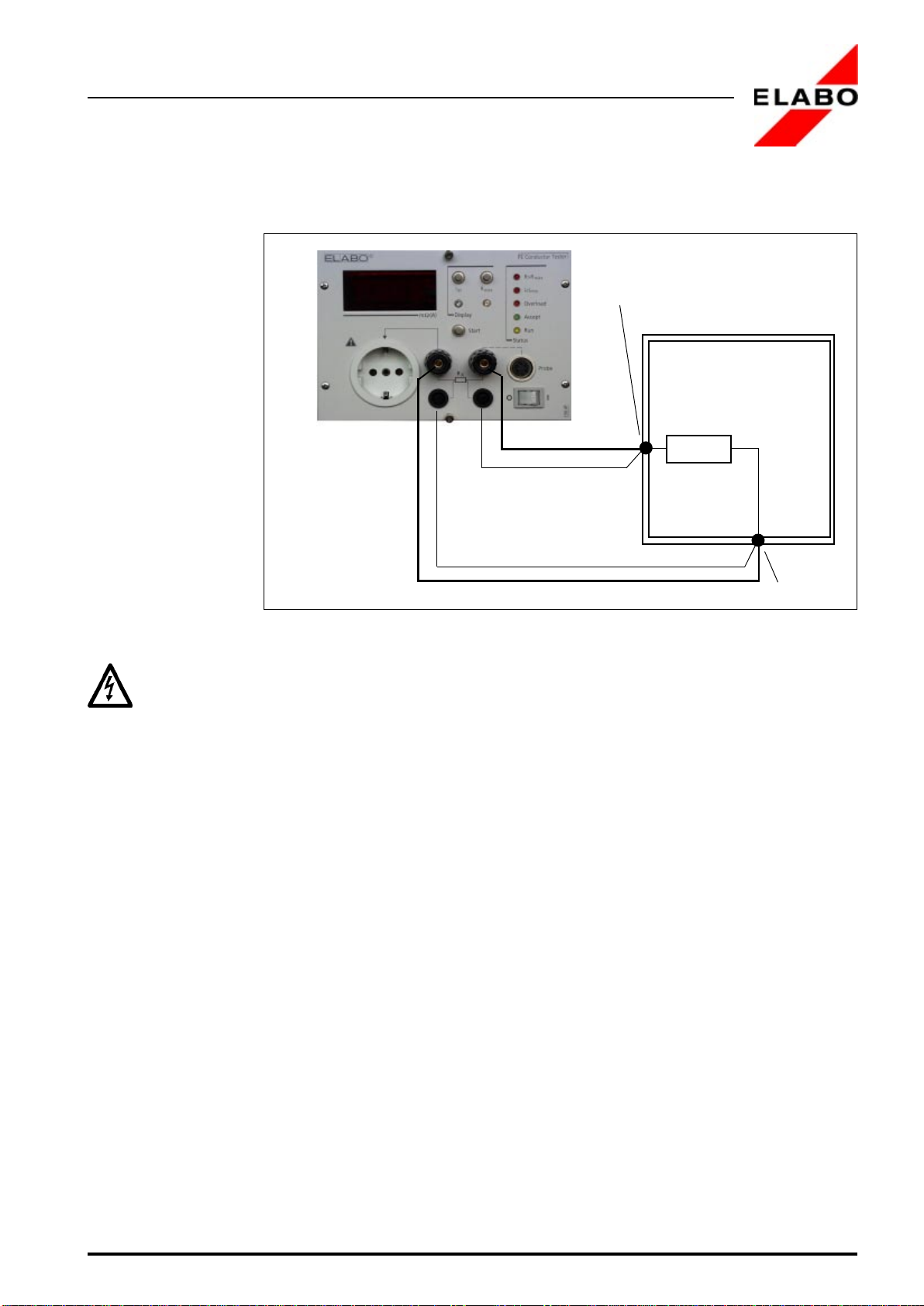

Fig. 4.1: Measurement principle of the PE conductor tester

PE-contact test point

10V

current

Sensor

Rx

4. OPERATING MODES

Before starting of the measuring operation the adjustments must be carried

out according to Chap. 3.3.

4.1 MEASURING PRINCIPLE

Illustration 4.1 shows the measuring principle of the PE conductor tester.

For the measurement a test current is taken from an AC source with a no-

load voltage of 10 V. The amount of the test current conforms with the

valid VDE-standards.

The current is applied between the PE-terminal and every touchable metal

part in turn. The resistance is then calculate from the current and the

voltage measured between the PE -terminal an the touchable metal parts.

The test current and the open circuit voltage are electronically stabilized.

Therefore it is not necessary to readjust the test current after changing

the item under test.

The instrument can be used for tests with or without safety plug socket as

well as for tests with a test probe.

Use exclusively safety checked leads for the connection of the test

object to the measuring instrument !

Use never damaged or defective leads or power supply cable for

the connection of the test object !

Check the condition of the leads before each measurement !

The result of the protective conductor test will be displayed via the LED

V2, V3 and V4. The green LED V2 signals a faultless test, while the red

LED V3 and V4 will display a fault. The buzzer supports the display

according to the setting (Chap. 3.3).

15

PE-Conductor Tester 90-4F

4 Operating modes

Rx

4.2

PROTECTIVECONDUCTORTESTWITHOUTSAFETYPLUG

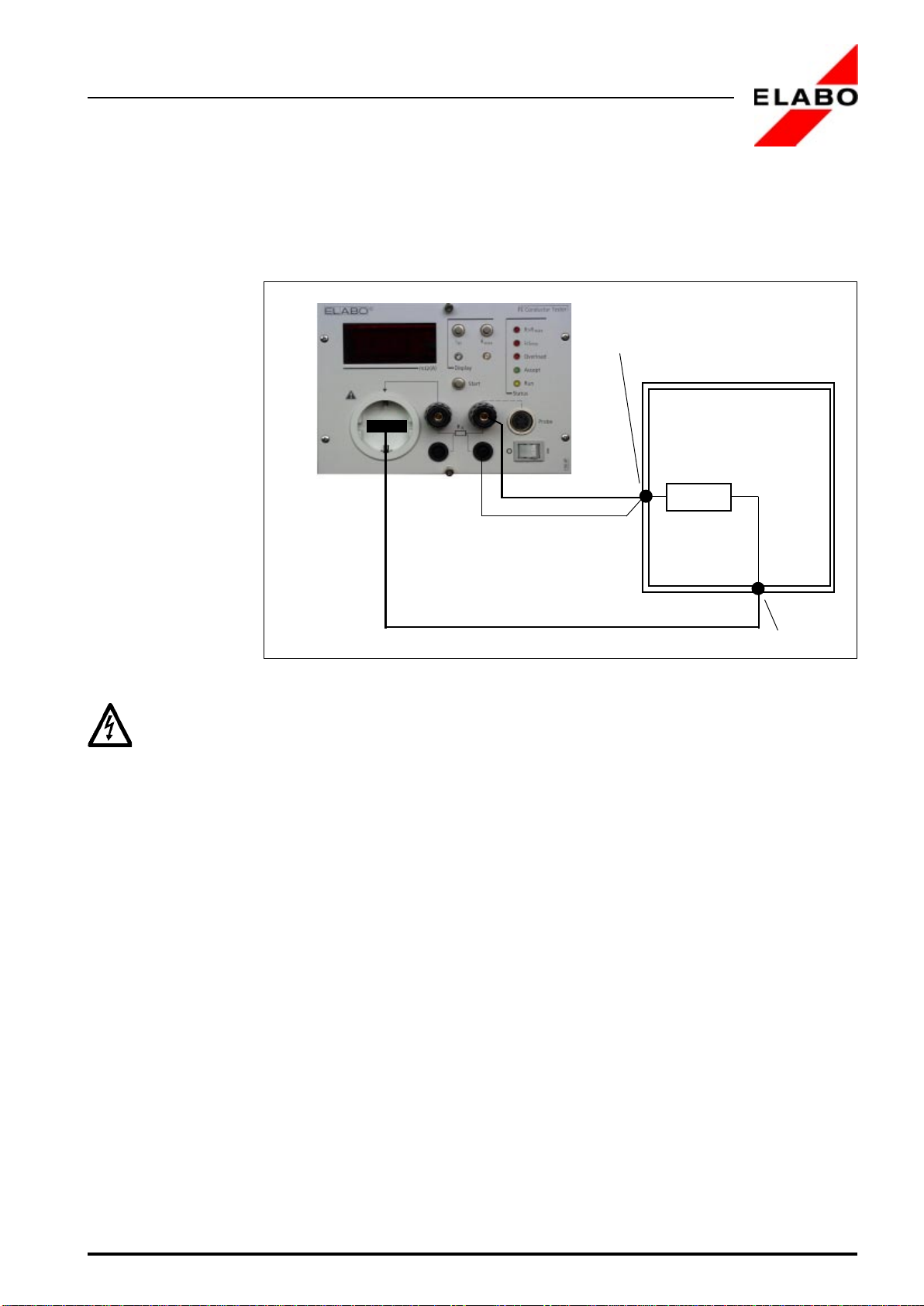

Ills. 4.2 shows the test arrangement for this operating mode.

For the connection of the item on test to the terminals of the instrument

use connecting leads with a cable cross-section of at least 2.5 mm² !

Connect the PE conductor of the test object with the connecting terminal

(X3.2) and the safety lab terminal (sensor) (X4.2). Connect the cable from

connecting terminal (X3.1) to the test point. Connect a sensor cable from

the safety lab terminal (X1.1) to the test point.

Start the measurement by means of the start push-button (S2) or via

interface start.

test object

PE-contact

test point

Fig. 4.2: Test arrangement for measurements without safety plug

16

PE-Conductor Tester 90-4F

4 Operating modes

Rx

test object

PE-contact

test point

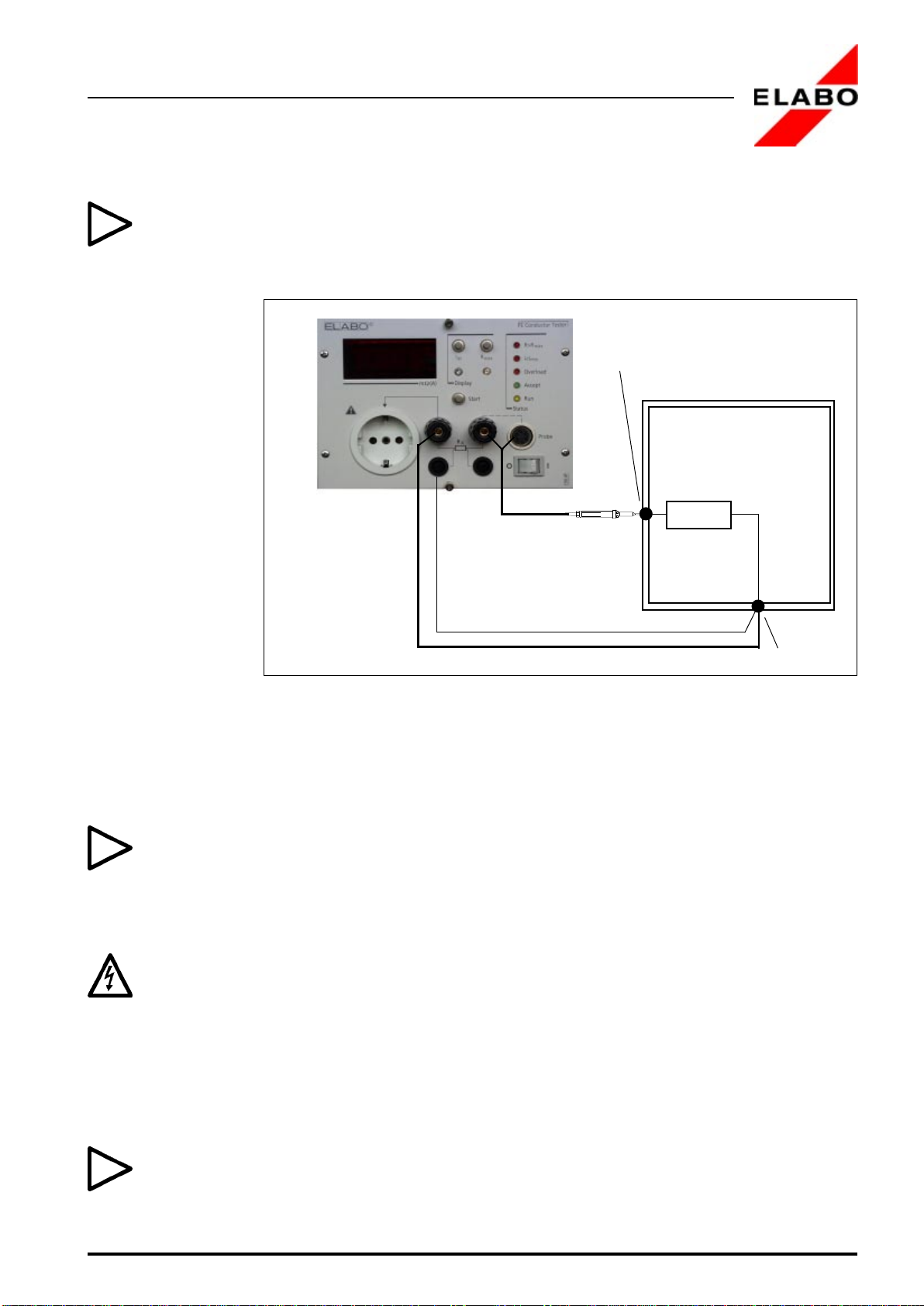

4.3 TEST WITH SAFETY PLUG

Fig. 4.3 shows the test arrangement for the measurement with a safety

plug.

Use a power supply cable with a cable cross-section of at least 1 mm² for

the connection of the item on test to the socket outlet of the instrument!

Put the power supply cable of the item on test into the socket outlet (X2).

Connect the cable from the connecting terminal (X3.1) to the test object.

Connect sensor cable from safety lab terminal (X4.1) to the test point.

Start the measurement via the start push-button (S2).

Fig. 4.3: Test arrangement for measurements with safety plug

17

PE-Conductor Tester 90-4F

4 Operating modes

Rx

test object

PE-contact

test point

4.4 TEST WITH TEST PROBE

For a simpler operation the measuring instrument can be operated with a

test probe. (ELABO - accessory: Catalogue-No. 2GA27 94-4S).

Fig. 4.4 shows the test arrangement with a test probe and without a three

wire plug.

Put the 5 pole diode plug of the test probe into the diode socket (X5) and

secure by means of screwing against unintentional loosening.

Put the 4 mm plug of the test probe into the socket X3.1.

For operation with a test probe the adjustment of the test current can be

achieved by pressing the tip of the test probe against the PE-conductor

terminal of the test socket outlet or the socket X3.2 and simultaneously

operating of the Iact -push-button (S4).

With the test probe are measurements with and without safety plugs

possible, as described under Chap. 4.2 and 4.3.

Consider, when connecting, the references mentioned in Chap. 4.2 and

4.3.

Connect the test specimen to the socket outlet (X2) or to the terminals

(X3.1) and (X3.2).

The tip of the test probe must be pushed-in completely at the test point of

the item under test.

To prevent contacts and measuring points of the specimen from charring,

the test current will not be applied before the spring-loaded tip of the test

probe is pushed-in completely.

Fig. 4.4: Test arrangement for measurements with test probe

18

PE-Conductor Tester 90-4F

4 Operating modes

4.5 OPERATION IN COMBINATION WITH AN INSULATION

TESTER

Together with the ELABO-Insulation tester (Catalog-No. 2GA27 90-2E) a

simultaneous measurement of PE conductor and insulation resistance is

possible.

Consider for the connection of the item on test absolutely

the references given in Chap. 4.1 - 4.4 !

For the combination measurement the item on test must be contacted

always at the PE conductor tester. Otherwise the insulation tester can be

damaged.

The actuation of the start push-button at the PE conductor tester

triggers the protective conductor and insulation resistance

measurement. An actuation of the start push-button at the insulation tester,

triggers the insulation test only.

If the protective conductor test proceeds faultlessly, the insulation test is

started automatically. A fault at the protective conductor test will give a

„Fault“ alarm at the PE conductor tester, the insulation test is not started.

The buzzer in the PE conductor tester must be in position „OFF“ during

the combination operation (see appendix). If possible, the interface should

be operated floating.

19

PE-Conductor Tester 90-4F

5 Interface

5. OPERATION VIA INTERFACE

The PE conductor tester disposes of an interface which enables the

external control and evaluation.

The signal level of the input should be between 5 V and 24 V. The

connections a and c of 64 pole terminal strip (X7) are linked.

The operating and display elements on the front panel have the external

control during their full function.

The connections of the test current and the sensor cable are in parallel to

the front panel terminals during operation via the external interface. It is

recommended to operate the interface control floating, since the ground

potential of the interface is not electrical isolated from the test signal.

5.1 PIN ASSIGNMENT OF INTERFACE TERMINAL STRIP (X7)

In the following, the pin assignment of the 64 pole terminal strip (X8) is

described. The terminal strip corresponds to DIN 41612, Type C).

Attention: The control Inputs/Outputs (Pin 2, 4, 6, 9, 10, 14) as well as

the analog outputs (Pin 27) at the 64-pole interface (X8) have a fixed

potential to the test current.

If for instance, the control is carried out by a grounded PLC via the before

mentioned Pins then the current source which generates the test current

is also grounded. Thus, a falsification of the test results becomes possible.

Pin 2 Good/Fault.

Open collector of transistor BD 675 for

„Good/Fault“ identification:

Transistor conductive = GOOD

Transistor blocking = FAULT

Pin 9 and 14 GND

Reference potential of all inputs and outputs.

Pin 4 GNDR

Reference potential of the floating input "Start H".

For more information see Chapt. 9.2 Appendix.

Pin 6 Start L.

Connection of Pin 6 to GND acts like operating key

„Start“ (S2).

If possible use floating contacts.

20

PE-Conductor Tester 90-4F

5 Interface

Pin 8 Measuring H.

Applying of an external DC of 5 V to 24 V, acts like

operating key „Start“ (S2).

For more information see Chapt. 9.2 Appendix.

Pin 16, 18 Fault I

Floating relay output for identifying off-limit test

currents.

No connection between pins 16 and 18 in the event of a

fault (contact open).

For more information see Chapt. 9.2 Appendix.

Pin 20, 22 Fault R

Floating relay output for identifying over-ranging

resistance values.

No connection between pins 20 and 22 in the event of a

fault (contact open).

For more information see Chapt. 9.2 Appendix.

Pin 27 Rnom (Rist)

Analog DC signal as a function of the resistance:

0. . .350 mOhm = 0 to 10 V DC, measured against

GND.

Maximum loading capacity 5 mA.

Pin 29 Sensor left.

Sensor lead, parallel to left-hand sensor jack (X4.2).

Pin 31 Sensor right.

Sensor lead, parallel to right-hand sensor jack (X4.1).

Table of contents

Other ELABO Test Equipment manuals