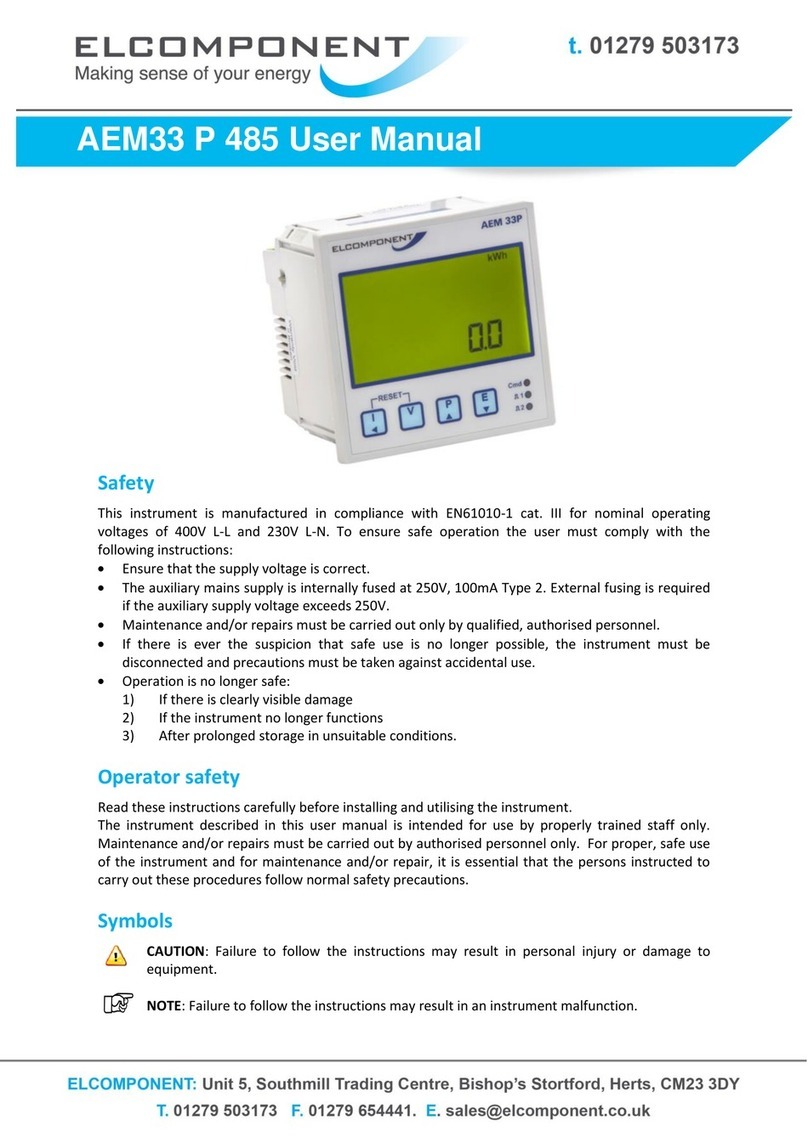

Elcomponent AEM33 P 485 User manual

AEM33 P 485

INSTRUCTIONS

This instrument is manufactured in compliance with EN61010-1

Cat III for nominal operating voltages of 400V L-L and 230V L-N,

to ensure safe operation the user must comply with the

following instructions:

Ensure that the supply voltage is correct.

The auxiliary mains supply is internally fused at 250V,

100mA Type 2. External fusing is required if the auxiliary

supply voltage exceeds 250V.

Maintenance and/or repairs must be carried out only by

qualified, authorised personnel.

If there is ever the suspicion that safe use is no longer

possible, the instrument must be disconnected and

precautions must be taken against accidental use.

Operation is no longer safe:

1) If there is clearly visible damage

2) If the instrument no longer functions

3) After prolonged storage in unsuitable conditions.

Read these instructions carefully before installing and utilising

the instrument.

The instrument described in this user manual is intended for

use by properly trained staff only. Maintenance and/or repairs

must be carried out by authorised personnel only. For proper,

safe use of the instrument and for maintenance and/or repair,

it is essential that the persons instructed to carry out these

procedures follow normal safety precautions.

CAUTION: Failure to follow the instructions may result in

personal injury or damage to equipment.

NOTE: Failure to follow the instructions may result in

an instrument malfunction.

(OPT)

(OPT)

(OPT)

CAUTION: The instrument is internally fused at 250V 100mA.

External fusing is required if the supply voltage exceeds 250V.

1 SAFETY

1.1 OPERATOR SAFETY

2 SYMBOLS

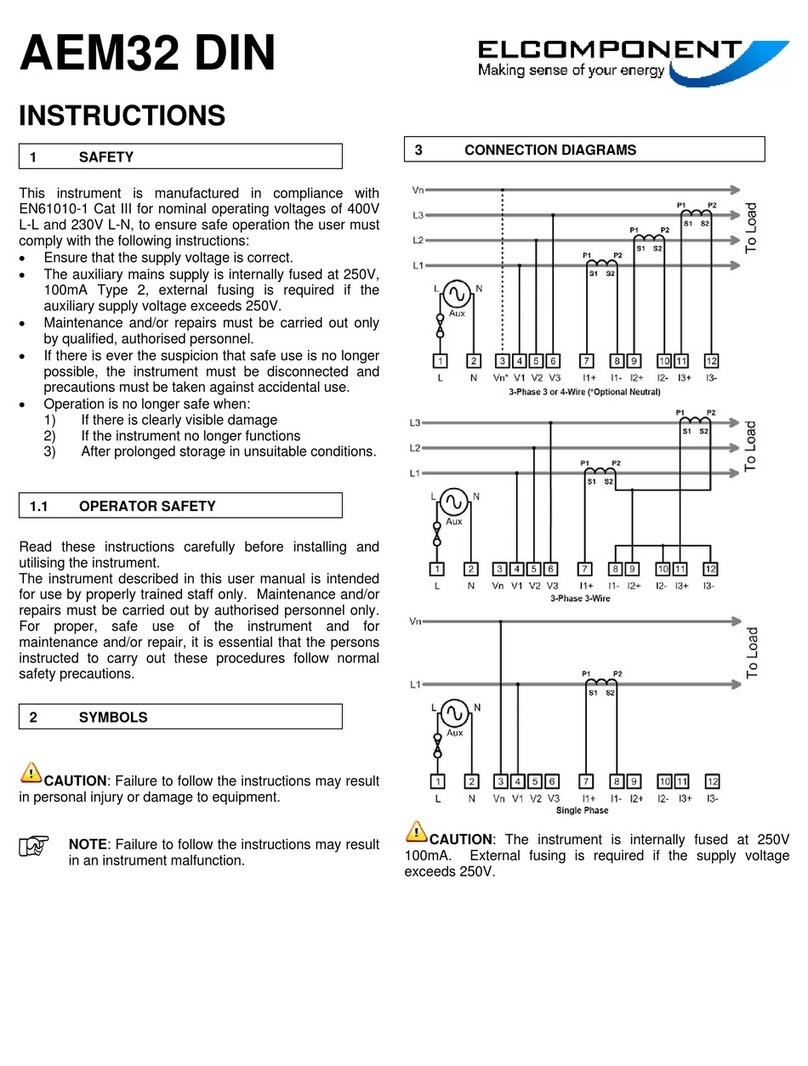

3 CONNECTION DIAGRAMS

The AEM33 is suitable for use with current transformers (CTs)

with 5A secondary output. Metering quality CTs of Class 1

accuracy with a minimum rating of 2.5VA are recommended.

Connections should be made according to the diagrams above.

CAUTION:

The pulse output contacts are rated at 100mA AC/DC, 100V

max. Under no circumstances should this rating be exceeded.

The AEM33P is fitted with a single pulse output proportional to

kWh. The output has a telltale l.e.d. on the front panel which

flashes ‘on’ to indicated that a pulse has been counted.

The pulse connections are: Terminals 13 & 14

The contacts are volt free and therefore an external power

supply must be provided.

13 14

The RS485 output consists of 3 pairs of terminals located at the

bottom left of the rear panel of the instrument. These should

be connected via the correct specification cable to the data bus.

(Refer to Elcomponent for cable recommendations.)

Terminal connections are as follows:

19 & 20 = A 21 & 22 = B 23 & 24 –0V

19 20 21 22 23 24

AB 0V

NOTE: It is essential that polarity is respected when other

units are connected to the bus.

When the instrument is powered up, the display will initially show

the internal software version, then after a few seconds will start

displaying measured values. The four buttons allow the user to

scroll through the available measurements.

ENERGY DISPLAYS

Press to select kWh, kVArh, KVAh and Hours Run pages.

The Hours Run register accumulates the total time during which the

average 3 phase load current exceeds a preset level. This is always

displayed with a resolution 0.1 hour.

The percentage level of (l1+l2+l3) at which the Hours Run register

accumulates is user programmable from 1% to 100% of full scale

current.

Press and together and hold for 2 seconds to reset the

hours run register.

3.1 CONNECTION OF THE CURRENT INPUT

3.2 PULSE OUTPUT CONNECTIONS

4 INSTRUMENT OPERATION & SET-UP

3.3 RS485 CONNECTIONS

kWh

kVArh

kVAh

Hours Run

3.1 CONNECTION OF THE CURRENT INPUT

3.2 PULSE OUTPUT CONNECTIONS

VOLTAGE DISPLAYS

Press to select from the following displays:

CURRENT DISPLAYS

Press to select from the following displays:

POWER DISPLAYS

Press to select from the following displays:

NOTE: The symbol following the VAr value = capacitive

load. A negative indicator before the VAr value indicates

exported reactive power.

NOTE: The symbol following the PF value = capacitive

load.

NOTE: The symbol following the kVAr value =

capacitive load.

Phase –N

Voltages 1-3

Line –Line

Voltages 1-3

Max Phase –N

Voltages 1-3

Average Phase –N

Voltages 1-3

Max Average

Phase –N

Voltages 1-3

Phase Current

1-3

Max Phase

Current

1-3

Average Phase

Current

1-3

Max Average

Phase Current

1-3

Phase Active Power

1-3

System Power –

Reactive, Apparent

Active

Voltages 1-3

System

Balance Current (I1+I2+I3)

Frequency (V1)

PF

Phase Apparent Power

1-3

Phase Reactive Power

1-3

NOTE: The symbol following the Cos value =

capacitive load.

INSTRUMENT SET-UP

To enter programming mode press and simultaneously

for 5 seconds. The display shows the CT settings screen. The

instrument settings are entered from this point, starting with

the CT values.

CT SET-UP

The CT primary value may then be set from the following

nominal values (secondary value must be 5A):

5, 10, 15, 20, 30, 40, 50, 60, 80, 100, 150, 200, 250, 300, 400,

500, 600, 800, 1000, 1200, 1250, 1500, 1600, 2000, 2400, 3000,

2500, 4000, 4500, 5000, 5500, 6000, 6500, 7000, 7500, 8000,

8500, 9000, 9500, 10000, 10500, 11000, 11500, 12000, 12500,

13000, 13500, 14000, 14500, 15000, 15500, 16000, 16500,

17000, 17500, 18000, 18500, 19000, 19500, 2000, 205000,

21000, 21500, 22500, 23000, 23500, 24000, 24500, 25000

Press the or key until the desired current is displayed. If

the desired CT value is not present in the above list, the ratio

may be ‘fine adjusted’ as follows: Press and hold the and

buttons simultaneously for 2 seconds to enter ‘Fine Adjust

Mode’. This is indicated by the ‘L’ symbol at the bottom left of

the display changing to ‘F’ (Fine). Find mode allows the CT

primary value to be changed in steps of 10A until the desired

ratio is displayed. Press the key to store the value and

advance the page.

VT SET-UP

The default voltage setting is 400V and this value should not be

altered unless the meter is an HV type and is connected via voltage

transformer(s). In this instance the nominal line to line voltage of

the meter must match the secondary voltage of the VT(s) and the

voltage is programmed to the primary voltage rating of the VT(s)

MD INTEGRATION PERIOD SET-UP (in Minutes)

This sets the integration period for the sliding window used for MD

calculation.

Press the or key until the desired value is displayed.

Press the key to advance the page.

CURRENT / VOLTAGE AVERAGING PERIOD SET UP

This sets the integration period (in seconds) for the sliding window

used for average current and voltage calculations. Press the or

key until the desired value is displayed.

Press the key to advance the page.

HOURS RUN SET-UP

The hours run preset level may be set to any desired kW value.

Press the or key until the desired value is displayed.

Press the key to advance the page.

PULSE SET-UP

The pulse rate value (PLr) may be set between 0.1 and 100 pulses

per unit. Press the or key until the desired pulse is displayed.

Note that the unit of energy (Wh/kWh/MWh) will automatically

change to reflect the primary values of CT & VT previously set. The

pulse value is set for both outputs during the process. Press the

key to store the value and advance the page.

The pulse duration value (PLt) may be set in increments between

100mS & 20 seconds as required.

The Pulse Output test allows the meter pulse output and connected

data collection hardware to be tested regardless of whether an

actual load is present. Press the button to start the test. The

display will show ‘run’ and the front panel led will flash to verify a

pulse is being generated. The display will verify the number of

pulses generated.

Phase PF

1-3

System Average

Demand

Rolling average of

user defined MD

period

System Max Demand

Maximum recorded

average demand

value

Press the button to stop the test.

Press and simultaneously to reset the counter.

Press the key to advance the page.

RS485 SET-UP

This allows the baud rate and MODBUS address to be set. Use

the and buttons to set the desired baud rate. Press the

key to store the value and advance the page.

Use the and buttons to set the unit address. Press the

key to store the value and save and exit from the set-up menu.

The display will show ‘storing’ to confirm this action.

Connection: 3 Phase 3 or 4 wire Unbalanced, 3 Phase

Balanced, Single Phase Load.

Inputs: Voltage: 400/230V 3 Phase 3/4 wire

Current: 5A –External CTs. Fully isolated.

Burden: <0.1VA per phase Current/Voltage

Pulse Output: Opto isolated volt free contact

Rating: 100mA ac/dc, 100V ac/dc max

Value: 1 pulse per kWh

1 pulse per 10 kWh

1 pulse per 100 kWh

1 pulse per 1000 kWh

Duration: 100ms

Isolation: 2.5kV for 1 minute

Power Supply: 230V 50/60Hz +/- 15%

Overload: Voltage x 4 for 1 hour

Current x 40 for 0.5 seconds max

Consumption: 2VA

Weight: 325g

IP Rating: Instrument = IP20 Front panel = IP40

Temp Range: -10o- +65o

Dims: 96 x 96 x 83.5

Accuracy: kWh: Class 1 EN62053-21 7 BS8431 (2%-120%

Nominal Load)

Environment: Operate -10oC > T < 65oC. RH < 75% Non-

Condensing

Storage- 25oC > T < 75oC

IP54 (IP65 with optional kit)

NOTE: Do not expose the instrument display to direct

sunlight.

Unit 5 Southmill Trading Centre, Southmill Road, Bishop’s Stortford,

Herts. CM23 3DY.

01279 503173 sales@elcomponent.co.uk

www.elcomponent.co.uk

16.04.15–Issue 5

5 TECHNICAL CHARACTERISTICS

Table of contents

Other Elcomponent Measuring Instrument manuals

Elcomponent

Elcomponent SPCMini User manual

Elcomponent

Elcomponent AEM33 User manual

Elcomponent

Elcomponent AEM33 V 485 DIN User manual

Elcomponent

Elcomponent EnergyPro EP600 User manual

Elcomponent

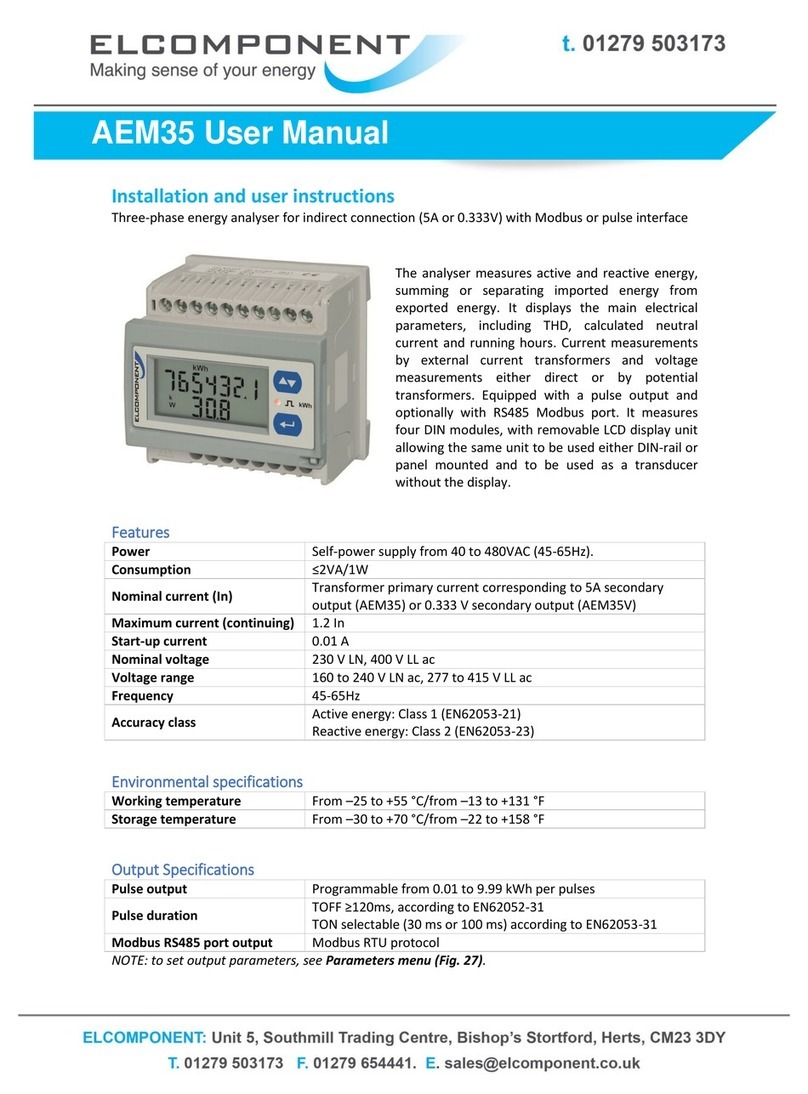

Elcomponent AEM35 User manual

Elcomponent

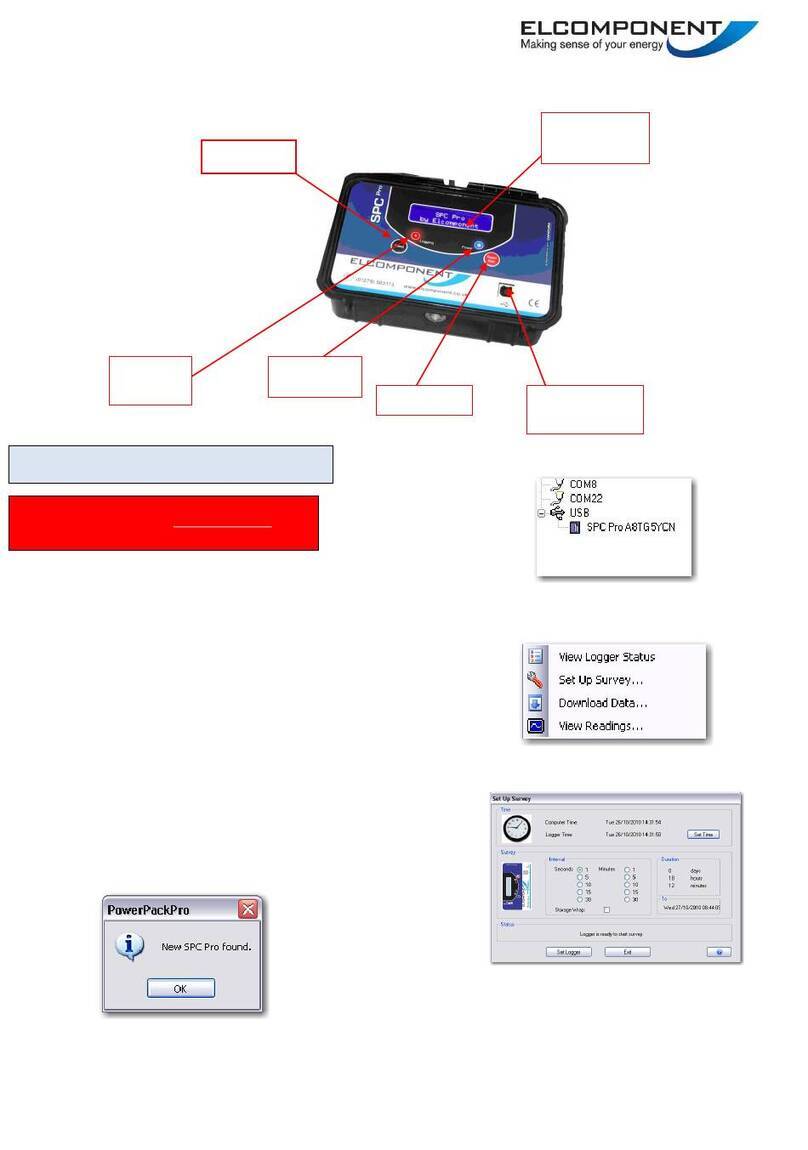

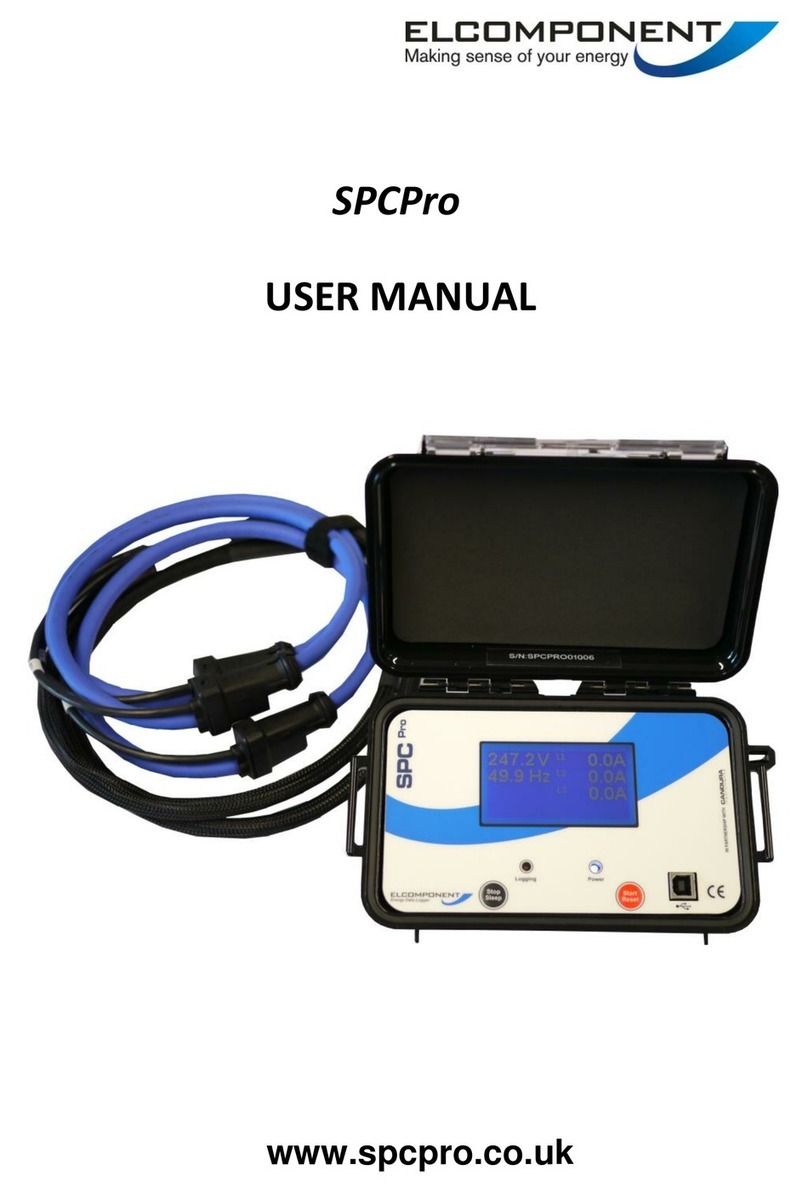

Elcomponent SPCPro User manual

Elcomponent

Elcomponent AEM33 485 DIN User manual

Elcomponent

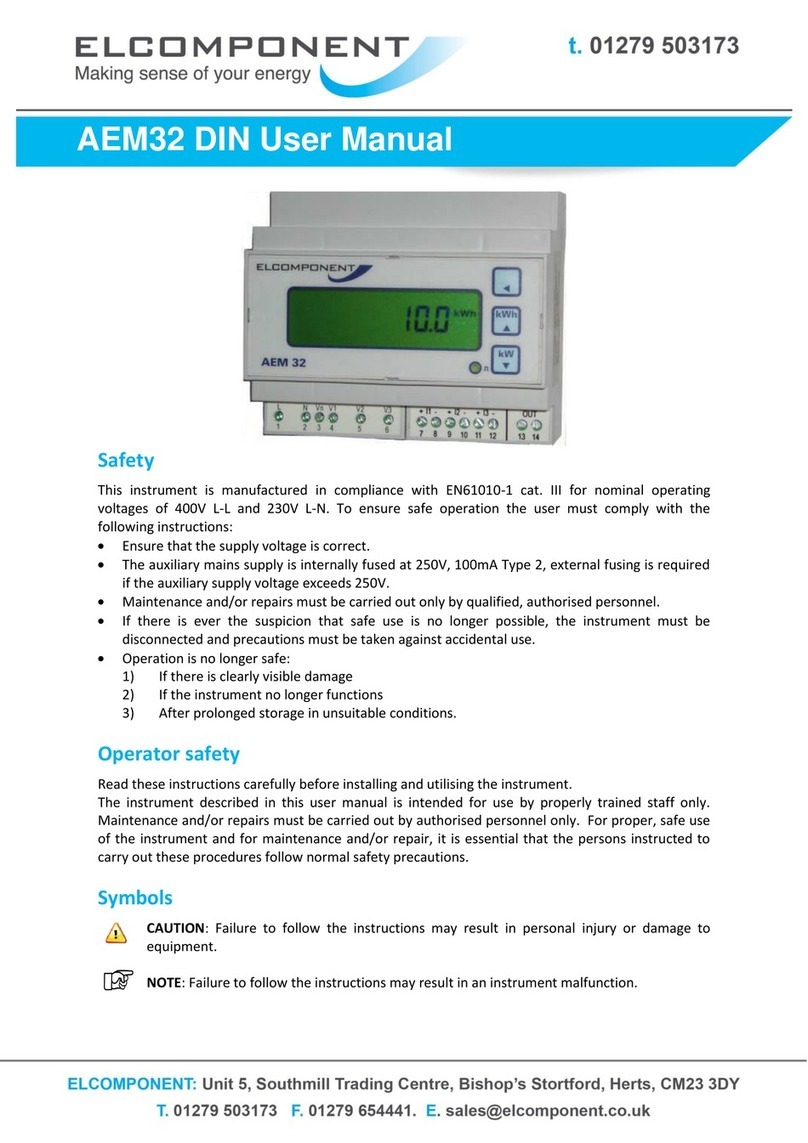

Elcomponent AEM32 User manual

Elcomponent

Elcomponent PQPro User manual

Elcomponent

Elcomponent AEM33 User manual