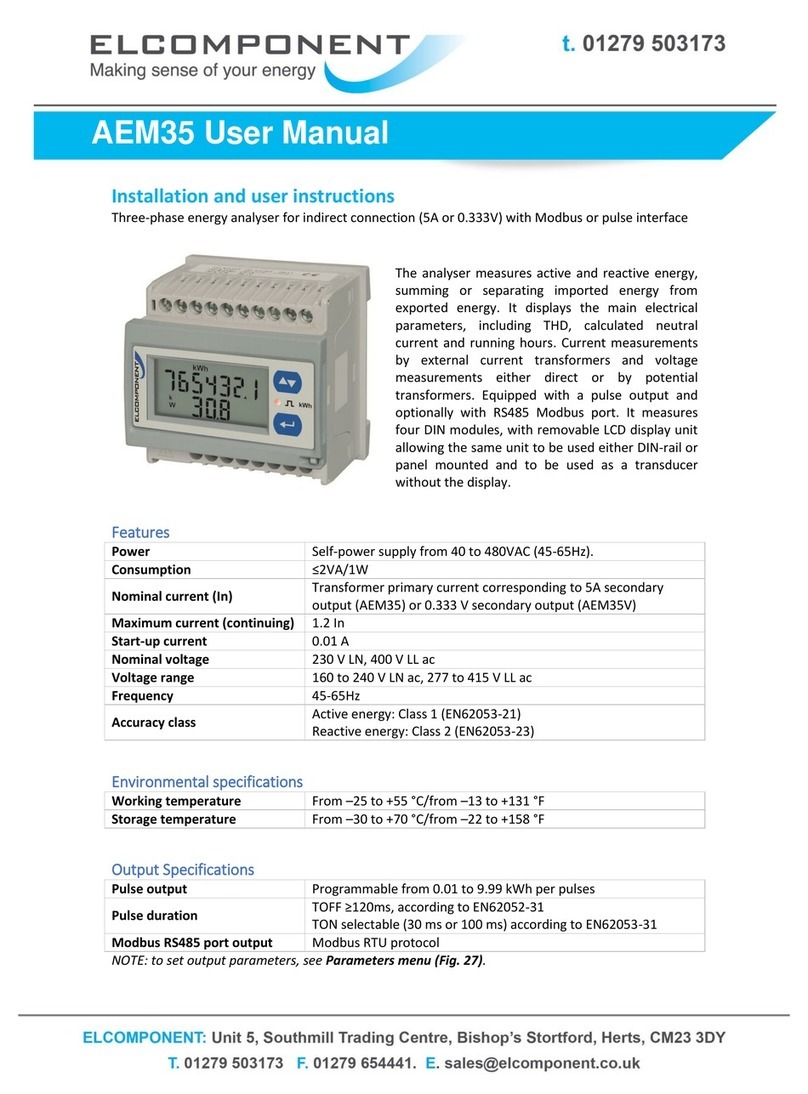

VOLTAGE DISPLAYS

Press to select from the following displays:

CURRENT DISPLAYS

Press to select the following display

:

POWER DISPLAYS

Press to select from the following displays:

NOTE: The values for phase power factor may be used to

verify correct CT position & orientation.

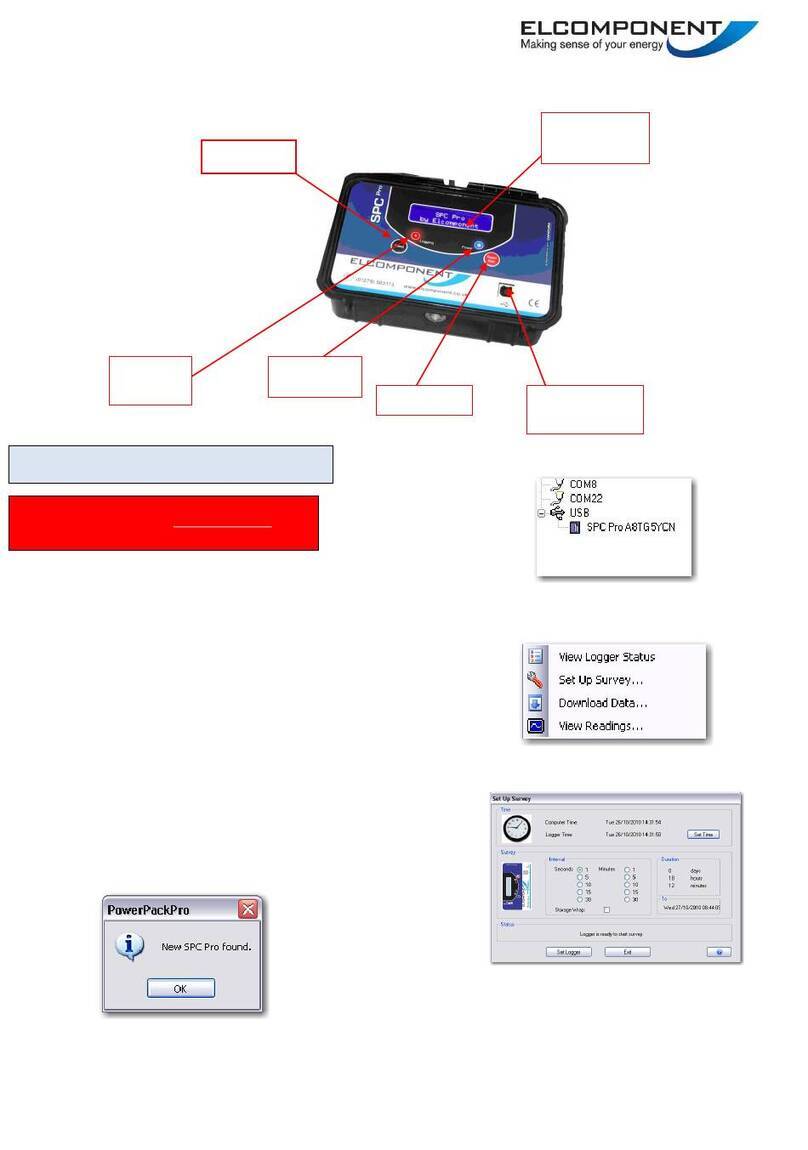

INSTRUMENT SET-UP

The display shows the CT set-up screen. The instrument settings

are entered from this point, starting with the CT values.

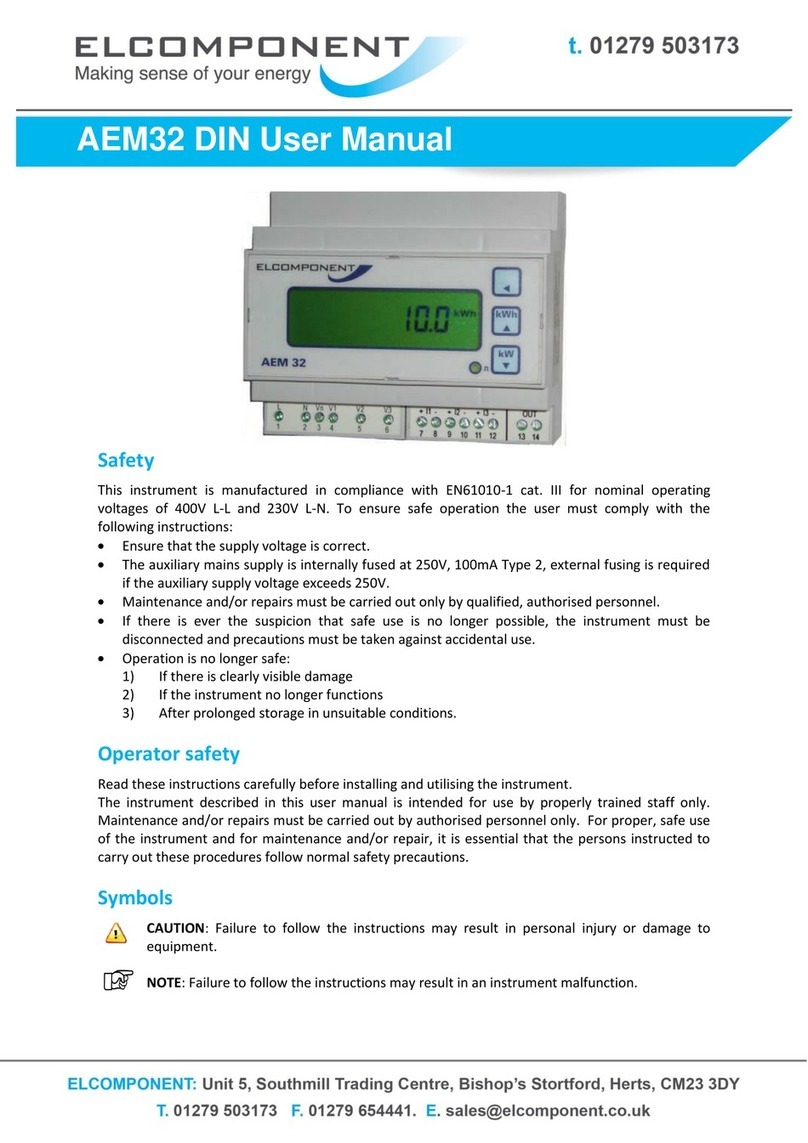

CT SET-UP

To enter programming mode press and simultaneously

for 5 seconds. The CT primary value may then be set from the

following nominal values (secondary value must be 5A):

5, 10, 15, 20, 30, 40, 50, 60, 80, 100, 150, 200, 250, 300, 400, 500,

600, 800, 1000, 1200, 1250, 1500, 1600, 2000, 2400, 3000, 2500,

4000, 4500, 5000, 5500, 6000, 6500, 7000, 7500, 8000, 8500,

9000, 9500, 10000, 10500, 11000, 11500, 12000, 12500, 13000,

13500, 14000, 14500, 15000, 15500, 16000, 16500, 17000, 17500,

18000, 18500, 19000, 19500, 20000, 205000, 21000, 21500,

22500, 23000, 23500, 24000, 24500, 25000

Press the p or q key until the desired current is displayed. If the

desired CT value is not present in the above list, the ratio may be

‘fine adjusted’ as follows: Press and hold the t and p buttons

simultaneously for 2 seconds to enter ‘Fine Adjust Mode’. This is

indicated by a decimal point displayed immediately to the right of

the defined parameter viz: “Ct.” this enables the CT primary value

to be changed in 10A steps until the desired ratio is displayed.

Press the t key to store the value and advance the page.

VT SET-UP

The default voltage setting is 400V and this value should not be

altered unless the meter is an HV type and is connected via

voltage transformer(s). In this instance the nominal line to line

voltage of the meter must match the secondary voltage of the

VT(s) and the voltage is programmed to the primary voltage rating

of the VT(s)

PULSE SET-UP

The pulse rate value (PLr) may be set between 0.1 and 100 pulses

per unit. Press the p or q key until the desired pulse is

displayed. Note that the unit of energy (Wh/kWh/MWh) will

automatically change to reflect the primary values of CT & VT

previously set. The pulse value is set for both outputs during the

process. Press the t key to store the value and advance the

page.

The pulse duration value (PLt) may be set in increments between

100mS & 20 seconds as required.

The Pulse Output Test (Pto) allows the meter pulse output and

connected data collection hardware to be tested, regardless of

whether an actual load is present. Press the p button to start the

test. The display will show “Ptr” and both outputs will pulse

simultaneously. This is verified by the front panel l.e.d.s. Press

the p and q together to stop the test and reset the test

counter.

HOURS RUN SET-UP

The hours run preset level may be set between 1% and 100% of

the full scale current. Press the p or q key until the desired

value is displayed. Press the t key to store the value and

advance the page.