Elcomponent AEM35 User manual

AEM35 User Manual

Installation and user instructions

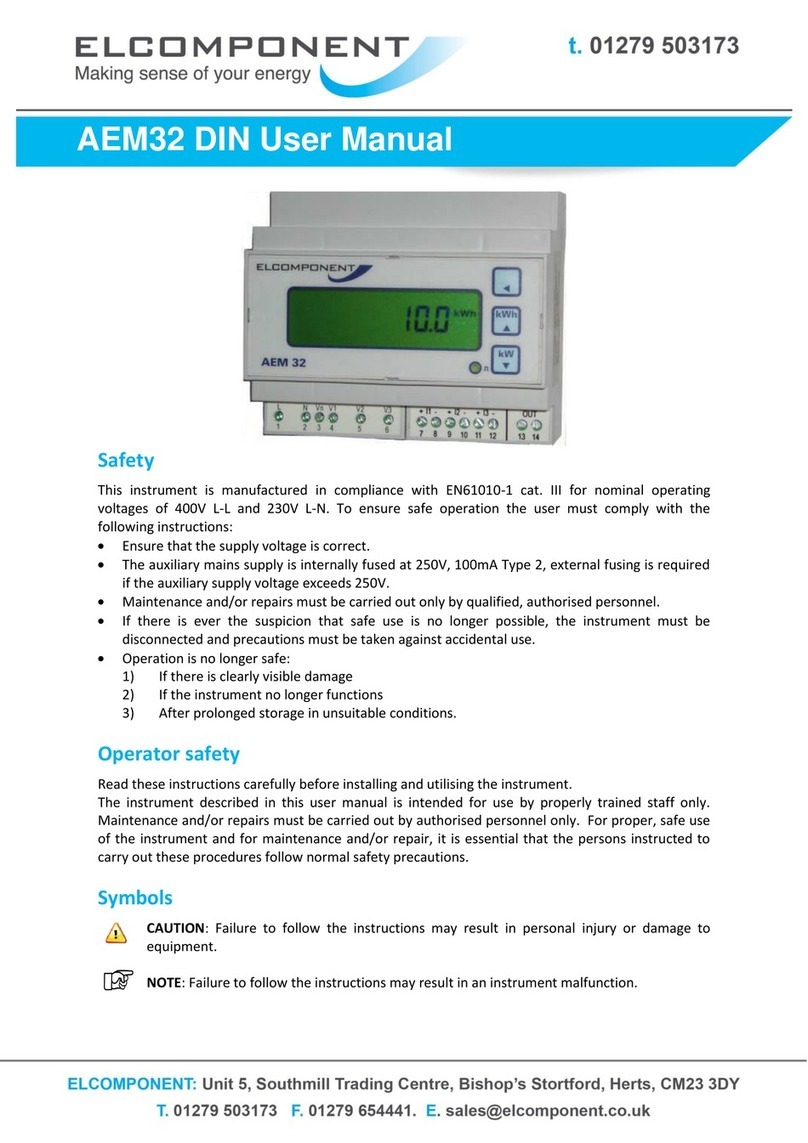

Three-phase energy analyser for indirect connection (5A or 0.333V) with Modbus or pulse interface

The analyser measures active and reactive energy,

summing or separating imported energy from

exported energy. It displays the main electrical

parameters, including THD, calculated neutral

current and running hours. Current measurements

by external current transformers and voltage

measurements either direct or by potential

transformers. Equipped with a pulse output and

optionally with RS485 Modbus port. It measures

four DIN modules, with removable LCD display unit

allowing the same unit to be used either DIN-rail or

panel mounted and to be used as a transducer

without the display.

Features

Power

Self-power supply from 40 to 480VAC (45-65Hz).

Consumption

≤2VA/1W

Nominal current (In)

Transformer primary current corresponding to 5A secondary

output (AEM35) or 0.333 V secondary output (AEM35V)

Maximum current (continuing)

1.2 In

Start-up current

0.01 A

Nominal voltage

230 V LN, 400 V LL ac

Voltage range

160 to 240 V LN ac, 277 to 415 V LL ac

Frequency

45-65Hz

Accuracy class

Active energy: Class 1 (EN62053-21)

Reactive energy: Class 2 (EN62053-23)

Environmental specifications

Working temperature

From –25 to +55 °C/from –13 to +131 °F

Storage temperature

From –30 to +70 °C/from –22 to +158 °F

Output Specifications

Pulse output

Programmable from 0.01 to 9.99 kWh per pulses

Pulse duration

TOFF ≥120ms, according to EN62052-31

TON selectable (30 ms or 100 ms) according to EN62053-31

Modbus RS485 port output

Modbus RTU protocol

NOTE: to set output parameters, see Parameters menu (Fig. 27).

AEM35 User Manual

LED specifications

Pulse weight

Proportionate to the result of CT/Primary current and VT ratios:

Weight (kWh/pulse)

CT * VT

(AEM35)

Primary current * VT

(AEM35V)

0.001

< 7

< 35.0

0.01

≥ 7.0 < 70

≥ 35.0 and <350.0

0.1

≥ 70 < 700

350.0 and <3500.0

1

≥ 700.0

≥ 3500.0

Max Frequency

16Hz

Colour

Red

General features

Terminals

2.4 x 3.5 mm, Min./Max. screws tightening torque: 0.4 Nm / 0.8 Nm

Protection degree

Front: IP40, terminals: IP20

Dimensions

See Fig. 28.

Cleaning

Use a slightly dampened cloth to clean the instrument display; do not use abrasives or solvents.

Service and warranty

In the event of malfunction, fault or for information on the warranty, contact ELCOMPONENT Ltd.

General warnings

DANGER! Live parts. Heart attack, burns and other injuries. Disconnect the power supply and load

before installing the analyser. The energy analyser should only be installed by qualified/authorised

personnel.

Intended use: measurement of electrical parameters, indoor use. Use it in installations with

overvoltage cat. III or lower.

These instructions are an integral part of the product. They should be consulted for all situations tied

to installation and use. They should be kept within easy reach of operators, in a clean place and in

good conditions.

Pay attention when removing the

instrument from the DIN rail in order to

avoid breakage of the support.

Excessive rotation of the instrument to

remove it, might break the support as

shown in the figure. We suggest extracting

downwards.

AEM35 User Manual

Product (Fig.1)

Area

Description

A

Green LED:

• steady: the instrument is power

supplied

• blinking: the instrument is power

supplied and is communicating by

serial port.

B

Current, voltage, output and

communication connection

terminals

C

Command keys

D

Red LED:

• blinking: pulses proportional to

energy being measured

(pulse weight: see Features).

E

LCD display (no backlight)

Note: In separate package, cap seals for terminals

Display (Fig.2)

Area

Description

A

Unit of measure area

B

Signal area:

In case of wrong phase sequence

Phase to phase voltage L1-2, L2-3, L3-1

System values

AEM35 User Manual

Procedure for adapting the mounting (Fig. 3)

It is possible to convert the type of instrument installation, from DIN to Panel (72x72) or vice versa,

thanks to the special removable front panel. The instrument without the front panel will have the

function of a transducer.

The table below advises the conversion process:

Step

Action

1

Unclip, using a screwdriver of appropriate size, the spring tabs (total of two) A pushing them

from the slots B.

2

Pull out the display unit

3

Insert the display unit into the side desired, according to the type of montage:

C- DIN rail

D- panel 72x72

Note: the package includes two mounting brackets for panel mounting of the instrument

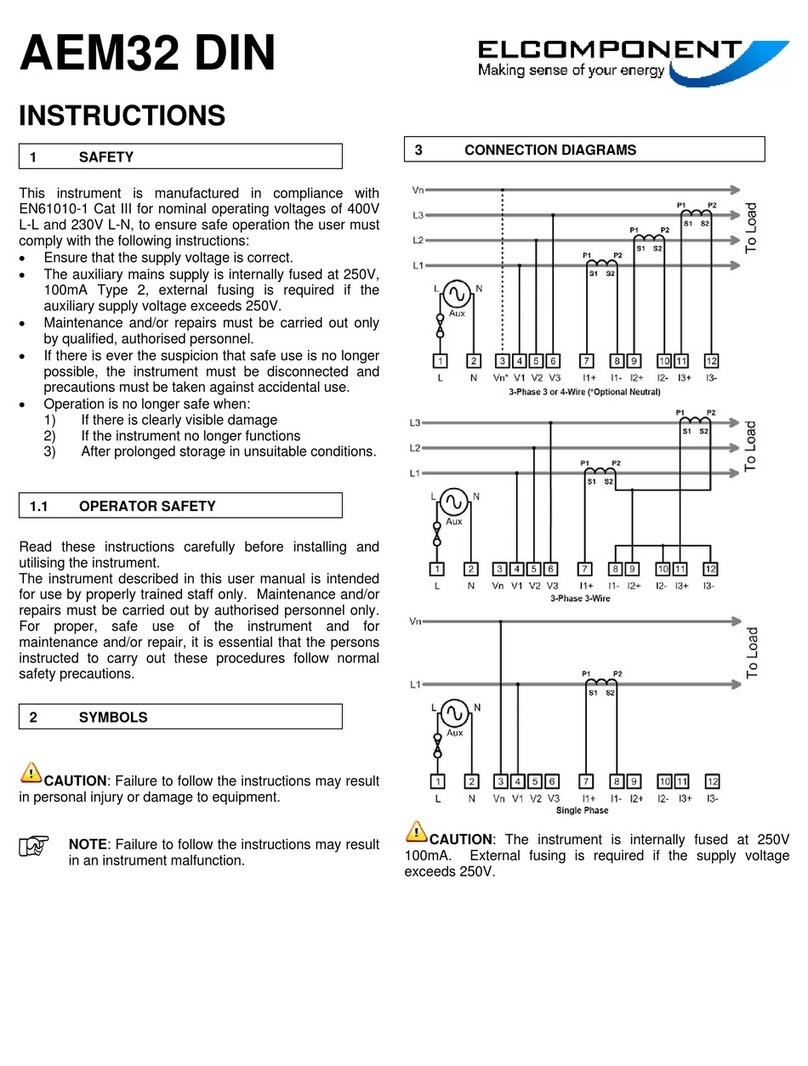

ARON connection diagrams, AEM35 only.

Diagram

Description

SyS selection (Fig. 26)

Fig. 4

3-ph, 3-wire, unbalanced load, 2-CT connections. F=315 mA

3P

Fig. 5

3-ph, 3-wire, unbalanced load, 3-VT/PT and 2-CT connections

3P

AEM35 User Manual

Connection diagrams, all models.

Diagram

Description

SyS selection (Fig. 26)

Fig. 6

3-ph, 4-wire, unbalanced load, 3-CT connection. F=315 mA

3P.n

Fig. 7

3-ph, 4-wire, unbalanced load, 3-CT and 3-VT/PT connections

3P.n

Fig. 8

3-ph, 3-wire, unbalanced load, 3-CT connection. F=315 mA

3P

Fig. 9

3-ph, 3-wire, unbalanced load, 3-CT and 2-VT/PT connections

3P

Fig. 10

3-ph, 3 or 4-wire, balanced load, 1-CT connection. F=315 mA

3P.1

Fig. 11

3-ph, 3-wire, balanced load, 1-CT and 2-VT/PT connection

3P.1

Fig. 12

2-ph, 3-wire, 2-CT connection. F=315 mA

2P

Fig. 13

2-ph, 3-wire, 2-CT and 2-VT/PT connections

2P

Fig. 14

1-ph, 2-wire, 1-CT connection. F=315 mA

1P

Fig. 15

1-ph, 2-wire, 1-CT and 1-VT/PT connection

1P

AEM35 User Manual

Connection diagrams, all models.

Diagram

Description

Fig. 16

Opto-mosfet static output

Fig. 17

RS485 Modbus with Master

Note: additional instruments with RS485 are connected in parallel. The serial output

must only be terminated on the last network device connecting terminals B+ and T. For

connections longer than 1000 m or networks with more than 160 instruments, use a

signal repeater.

Fig. 18

REMEMBER: in case of use of Current Sensors with the secondary output of 0,333V use

AEM35V models only connected as shown in figure 18.

Fig. 19

REMEMBER: in case of use of Rogowski Current Sensors, use AEM35V models only

connected as shown in figure.

AEM35 User Manual

Menu map (Fig. 23)

Area

Function

A

Measurement menu. Measurements displayed by default when turned on. Pages are

characterised by the reference unit of measure.

B

Parameter menu. Parameter settings pages. Require login password.

C

Information menu. The pages display information and set parameters without having to

enter a password.

AEM35 User Manual

Commands (Fig. from 20 to 22)

Navigation

Parameter settings

Operation

Command

Operation

Command

View the next measurement page

Fig. 20

Enter parameter setting

Fig. 21

Open the information menu

Fig. 21

Change between increase mode

(C icon displayed) and decrease

mode (-C icon displayed)

Fig. 21

View the next information page

Fig. 21

Exit the information menu

Fig. 20

Increase value/view next option (C)

Fig. 20

Open the parameter menu

Fig. 22

Decrease value/view previous

option (-C)

Fig. 20

Exit the parameter menu (info

menu shown)

Fig. 22

(page End)

Confirm a value

Fig. 22

NOTE: after 120s of inactivity, the measurement

page will be displayed.

Note: hold the key for up to 2,5s

Setting a parameter (Fig. 24)

Procedure example:

How to set Ut rat.=11 (passing the value 13).

NOTE: the first displayed value is the current one.

Settings are applied when the value is confirmed.

The value is being edited if C or -C appears.

After 120s of inactivity on a value being set, the

title page is displayed (P int in the figure) and C/-

C disappears.

After further 120s, the measurement page is

displayed.

AEM35 User Manual

Measurement menu (Fig. 25)

The picture shows some available measure pages as example.

General measurement

Measure

Application (see also

parameter menu “APPLiC”)

Total kWh; kW sys

A

B

C

D

E

F

Total kvarh; kvar sys

Note*: in application F kvarh is calculated by both positive and negative

kvar integration

B

C

D

E

F*

PF sys; Hz

B

C

D

E

F

PF per phase, A, V LL, V LN, THD VLL, THD VLN, THD A, An, Working

hours.

Note: to see the THD measure the THD function must be enabled

C

D

E

F

Exported kWh (kWh-), working hours of exported kWh (h-)

E

Available variables only via RS485

V LN sys, V LL sys, VA sys, VA L1, VA L2, VA L3, var L1, var L2, var L3, W L1, W L2, W L3.

Wrong wiring detection function (supporting the voltages/currents connections to the metering

device).

Information menu (Fig. 26)

Available information pages for ALL MODELS

Page

Code

Description

Disp. values in the example (fig.26)

01

y. xxx r.XX

Year of production and firmware release

Y 2017 (Year); r.A0 (revision)

02

Led

kWh per pulse

kWh 0.001 (kWh per pulse); LED

03

SyS

Type of system and type of connection

SYS 3P.n (system, see also fig 6, 7);

4W (4 Wires connection)

05

Ut rAt.

Voltage transformer ratio

10

06

PuLSE

Pulse output: kWh per pulse

0.10

07

Add

Serial communication address

2

08

PArity

Parity

No

09

bAud

Baud rate

115 kbps

10

bStop

Bit stop

1

11

SN

Secondary Address

1234567

Available information pages AEM35 ONLY

Page

Code

Description

Disp. values in the example (fig.26)

04

Ct rAT.

Current transformer ratio

1.0

Available information pages for AEM35V ONLY

Page

Code

Description

Disp. values in the example (fig.26)

SEnSOR

Type of current sensor (Ct or RoG)

Ct

04

Ct Prin

Current sensor nominal primary current

90

Measurement faults

If the measured signal exceeds the admitted analyser limits, a specific message appears:

• EEE blinking: the measured value is out of limits

• EEE on: the measurement depends on a value that is out of limits

NOTE: active and reactive energy measurements are displayed but do not change.

AEM35 User Manual

Parameter menus (Fig. 27)

Available menus for ALL MODELS

Page

Description

Values

PASS

Enter current password

Current password.

CnGPASS

Change password

Three digits (000–999)

APPLiC.

Selects the pertinent application

A/ B/ C/ D/ E/ F

SYS

System type

3Pn: 3-phase unbalanced with neutral;

3P: 3-phase unbalanced without neutral;

3P1: 3-phase balanced with or without

neutral;

2P: 2-phase;

1P: single phase

Ut rAt.

Voltage transformer ratio (VT)

1.0–999

PuLSE

Selects the pulse weight

kWh per pulse, 0.01–9.99

ton

Pulse duration (ON time in msec)

30-100

P.tESt

Sets the simulated power value (kW), for

the pulse output test.

Note: with APPLiC C, E, E, F only.

1-999 kW. (The pulses frequency is

according to the “PuLSE” weight selection)

tESt

Activates the pulse output test when ON

(the function is active until you remain

within the menu).

Note: with APPLiC C, D, E, F only.

Add

Serial address

1–247

bAud

Baud rate (kbps)

9,6/ 19,2/ 38,4/ 57,6/ 115,2

PAritY

Parity

No or Even

bStoP

Stop bit

1-2

tHd

THD enabling

On: enabled / Off: disabled

EnE rES

Reset of all the meters

No: cancels reset / Yes: enable reset

End

It allows exiting the programming mode

-

Available menu for AV5, AV6 ONLY

Page

Description

Values

Ct rAt.

Current transformer ratio (CT)

NOTE*: The maximum VT by CT ratio: 1187

1.0–999*

Available menu for MV5, MV6 ONLY

Page

Description

Values

“roG” values

SEnSOr

Selects the used current sensor

Ct: current

transformer/roG:

Rogowski sensor

Ct Prin

Current sensor nominal primary current

NOTE*: the max value of the multiplication

of primary current x VT ratio is 220000

10–9990*

1,00k, 2,00k, 4,00k

Blocking access to the parameter menu

It is possible to block the access to programming by means of a specific trimmer

positioned on the rear of the removable display unit. Turn the trimmer clockwise up to

its run end with the help of a suitable screwdriver.

AEM35 User Manual

AEM35 User Manual

• EN 61010-1

• 2014/30/EU • EN 62053-21

• EN62052-11

Table of contents

Other Elcomponent Measuring Instrument manuals

Elcomponent

Elcomponent AEM33 485 DIN User manual

Elcomponent

Elcomponent AEM33 V 485 DIN User manual

Elcomponent

Elcomponent SPCPro User manual

Elcomponent

Elcomponent EnergyPro EP600i User manual

Elcomponent

Elcomponent SPCPro User manual

Elcomponent

Elcomponent EnergyPro EP600 User manual

Elcomponent

Elcomponent SPCMini User manual

Elcomponent

Elcomponent AEM33 User manual

Elcomponent

Elcomponent AEM33 P 485 User manual

Elcomponent

Elcomponent SPCMini User manual