BREAKDOWNS

When the sensor detects an error condi-

tion:

• the code E1 is displayed

• the compressor is activated as indicated

by the "On" and "Off" parameters:

MINIMUM AND MAXIMUM TEMPERA-

TURE ALARMS

Regulation of the minimum and maximum

temperature alarms refers to the cold cell

sensor.

The temperature limits defined by the

“HAL” (maximum temperature alarm) and

“LAL” parameters (minimum temperature

alarm) are characterised by the “Att” para-

meter which specifies if they represent the

absolute temperature value or a differen-

tial with respect to the setpoint.

When an alarm status occurs, if no alarm

exclusion phases are underway (see alarm

exclusion parameters), the alarm set icon

is lit up and the buzzer, and/or the relay

configured as an alarm, is activated. The

occurrence of this alarm does not in any-

way effect the control activities in

progress.

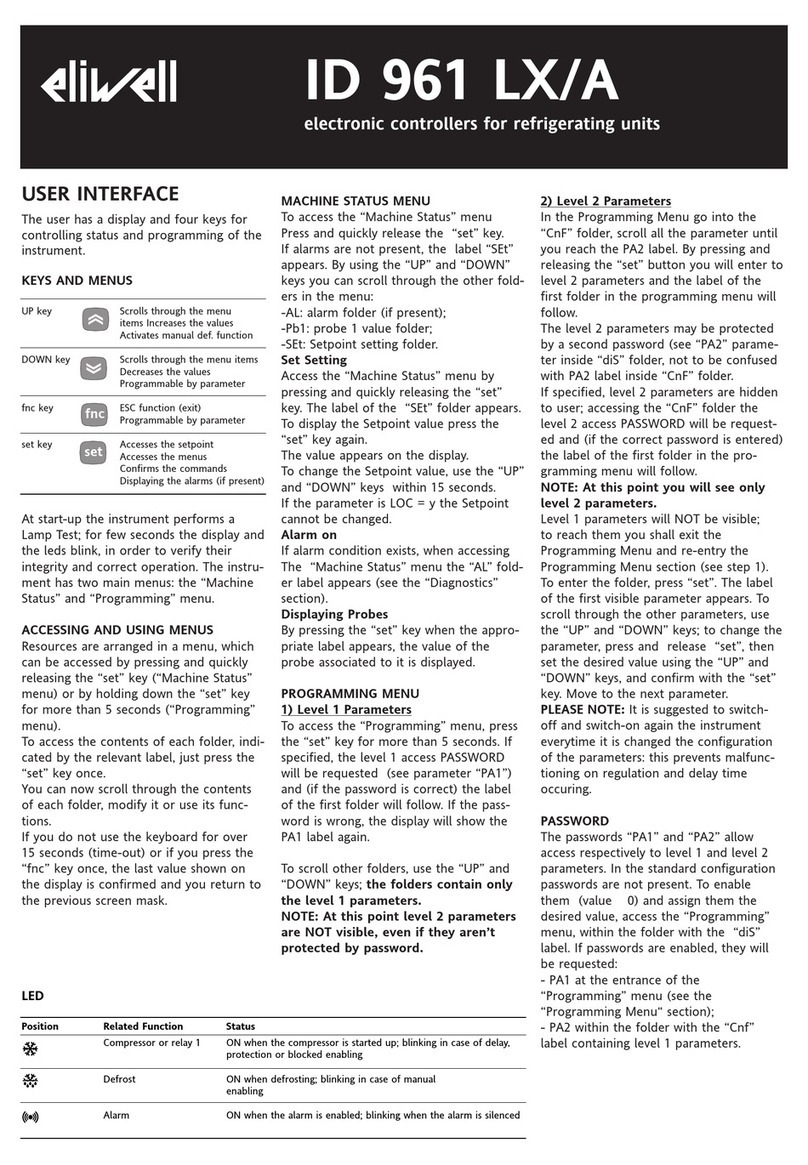

FITTER ASSEMBLY

The instruments belonging to the

DIGIFROST series range have been con-

ceived for panel mounting purposes.

Cut a hole and insert the instrument fas-

tening it with the supplied bracket. The

distance between two coupled devices is

79 mm.

With the appropriate adapter, the instru-

ments can also be assembled on holes for

the standard ELIWELL 32x74 mm. The

panel thickness must be between 0.5 mm

and 7 mm.

The room temperature range admitted for

correct operation is between -5 e 60 °C.

Furthermore, avoid mounting the instru-

ments in locations subject to high levels of

humidity and/or dirt: said instruments are

in fact suitable for use in environments

with an ordinary or normal level of pollu-

tion.

Make sure that the area near to the cool-

ing slits is left aerated.

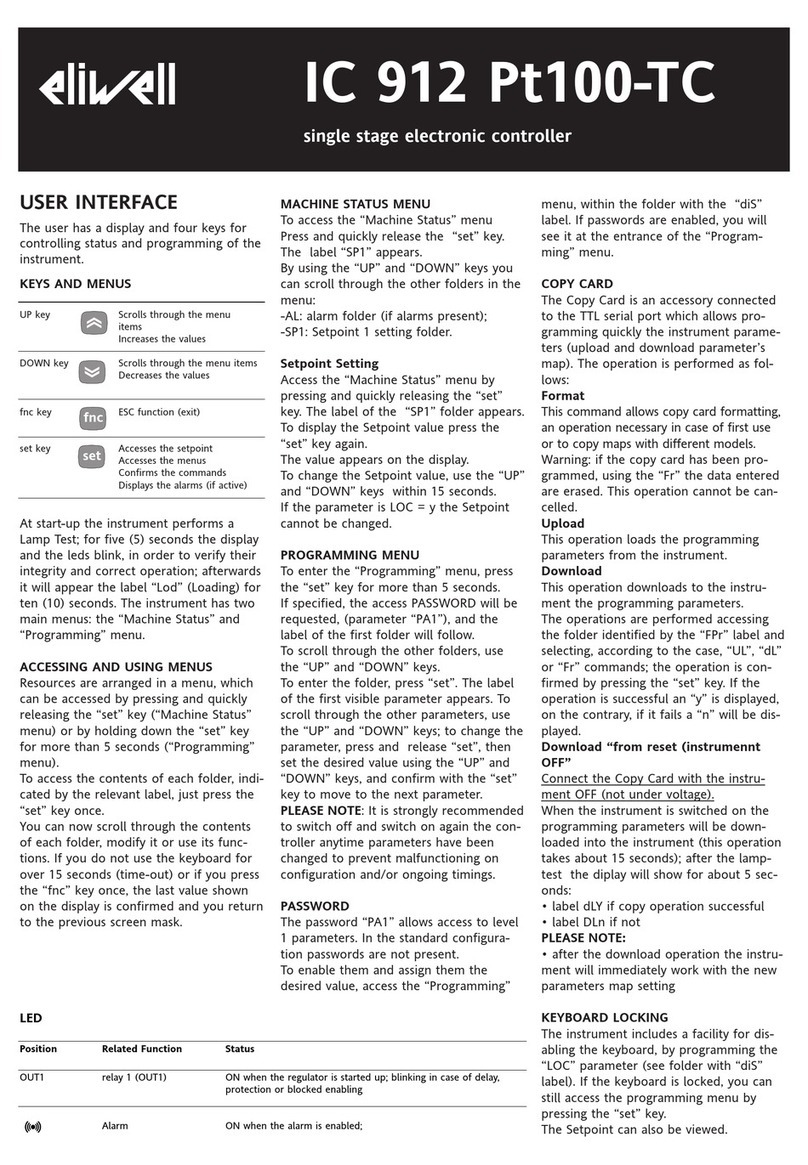

EWDB 111 2/3

PARAMETER

SEt

diF

HSE

LSE

Ont

OFt

dOn

dOF

dbi

OdO

dit

dtU

dCt

dOH

dEt

dPO

dri

Afd

Att

HAL

LAL

PAO

dAO

tAO

AOP

LOC

PA1

PA2

ndt

CAL

LdL

HdL

dLc

dro

H02

H21

H23

reL

tAb

(1) PLEASE NOTE: in the version with the buzzer.

DESCRIPTION

COMPRESSOR CONTROLLER

Setpoint: value ranging between the set minimum (LSE) and the set maximum (HSE).

Operating differential of the setpoint. For applications in the refrigeration sector the compressor

will cut off on reaching the Setpoint value set (on indication of the control sensor), only to

restart at a temperature value equal to the Setpoint plus the differential value.

Note: It will not accept a 0 value.

Maximum value attributable to the setpoint.

Minimum value attributable to the setpoint; normally set at the lowest value measurable by the

sensor.

COMPRESSOR PROTECTION CONTROLLER

ON time of the compressor due to sensor failure.

OFF time of the compressor due to sensor failure.

Start-up delay. The parameter indicates that a protection is active on the realisation of the com-

pressor/general relay.

Delay after shut-down. The parameter indicates that a protection is active on the realisation of

the compressor/general relay. At the very minimum, the time indicated must elapse between

shut-down of the compressor relay and the subsequent start-up.

Delay between start-ups. The parameter indicates that a protection is active on the realisation of

the compressor/general relay. At the very minimum, the time indicated must elapse between

two subsequent start-ups of the compressor relay.

Activation delay of the instrument start-up outputs or after a lack of voltage; expressed in min-

utes.

DEFROST CONTROLLER

Interval between one defrost cycle and the subsequent one; expressed in hours and in minutes

in relation to the “dtU”.

Time measurement unit for intervals/length of defrosting.

0 = interval between two defrost cycles in hours, duration of defrost cycle in minutes;

1 = interval between two defrost cycles in minutes; duration of defrost cycle in seconds.

Defrost interval reckoning mode.

0 = only the running time of the compressor is counted;

1 = the running time of the instrument is counted;

2 = defrosting takes place every time the compressor shuts down.

Delay in commencement of defrost cycle; expressed in minutes.

Defrost cycle Time out; expressed in minutes or seconds in relation to the “dtU”.

Request for activation of the defrost controller on start-up. y = yes; n = no.

By means of this parameter it is possible to decide if, on request of a manual defrost cycle, the

reckoning for the defrost interval must be set to zero or not. y = yes; n = no.

ALARMS

Alarm/fan set differential: temperature difference between the setting off and disconnection of

the minimum or maximum alarm or of the fans.

Mode of interpreting the value of the HAL and LAL parameters.

0 = interprets the values as absolutes (not referring to the setpoint);

1 = interprets the values as relative with respect to the setpoint.

Maximum temperature alarm. Temperature value whose excess upwards will determine the acti-

vation of the alarm signal.

NOTE: To obtain the alarm as relative with respect to the setpoint in case of Att=1 set “LAL” to a

positive value

Minimum temperature alarm. Temperature value whose excess downwards will determine the

activation of the alarm signal.

NOTE: To obtain the alarm as relative with respect to the setpoint in case of Att=1 set “HAL” to

a negative value

Exclusion of the alarms on start-up of the instrument, after a failure in the power supply. In the

event of reactivation of additional delay times the highest among these will be valid.

Exclusion of alarm after defrosting.

Delay time for signalling of temperature alarm.

Indicates the polarity type of the relay/buzzer configured as an alarm.

0 = alarm active and output disabled; 1 = alarm active and output enabled.

MISCELLANEOUS

Keypad lock (blocks the activation of the primary functions). With the keypad disabled, viewing

of the Setpoint is only permitted by means of the key associated with direct functions. However

it remains possible to enter parameter programming and modify the status of the parameter so

as to enable the unlocking of the keypad. n = do not lock; y = lock.

Password 1 (blocks PL1).

Password 2 (blocks PL2).

DISPLAY

Display mode of the temperature on the display.

n = full number; y = decimal number.

Gauging. Positive or negative temperature offset which is added to the value read by the ther-

mostating sensor before being displayed and used for control purposes.

Minimum value of the sensor which can be viewed on the display.

Maximum value of the sensor which can be viewed on the display.

Display mode during the defrost cycle.

0 = displays the temperature read by the cold cell sensor;

1 = displays the temperature read by the cold cell sensor at the time of commencement of

defrosting;

2 = displays the “dEF” label during defrosting. Once defrosting and de-tearing has finished, the

device will continue to display the information anticipated until the cold cell sensor reaches the

setpoint value. If set at zero, the display does not entail the reaching of the setpoint.

°C or °F selection. 0 = °C; 1 = °F.

MACHINE SETTINGS

Key activation time.

Configuration capacity of digital output 1.

0 = disable; 1=compressor; 2 = defrost ( do not use); 3 = fans (do not use); 4 = alarm;

Configuration output buzzer. same as H21.

Release firmware

Table of parameters

Table 6 Description parameters table

DISPLAY

E1

ERROR

Cold cell sensor fault

Table 5 Error table

Ont

0

0

>0

<0

Oft

0

>0

0

>0

Compressor output

OFF

OFF

ON

D.C.