Art.-Nr./Art. No./Réf./N° art/N° art.: 9010015B01M Version: 1.1 Date: 30.04.2020 2/11

6DIHW\LQVWUXFWLRQV

:DUQLQJDJDLQVWPLVXVH

([FOXVLRQRIOLDELOLW\

No liability shall be accepted for any damage or operational faults caused by a fail-

ure to observe these operating instructions. All further liability of the manufacturer

is excluded in the case of damage caused by the use of replacement and acces-

sory parts that have not been authorized by the manufacturer.

No unauthorized repairs, conversions or modifications are permitted for reasons

of safety and the manufacturer shall not be liable for any resulting damage.

)XQFWLRQ

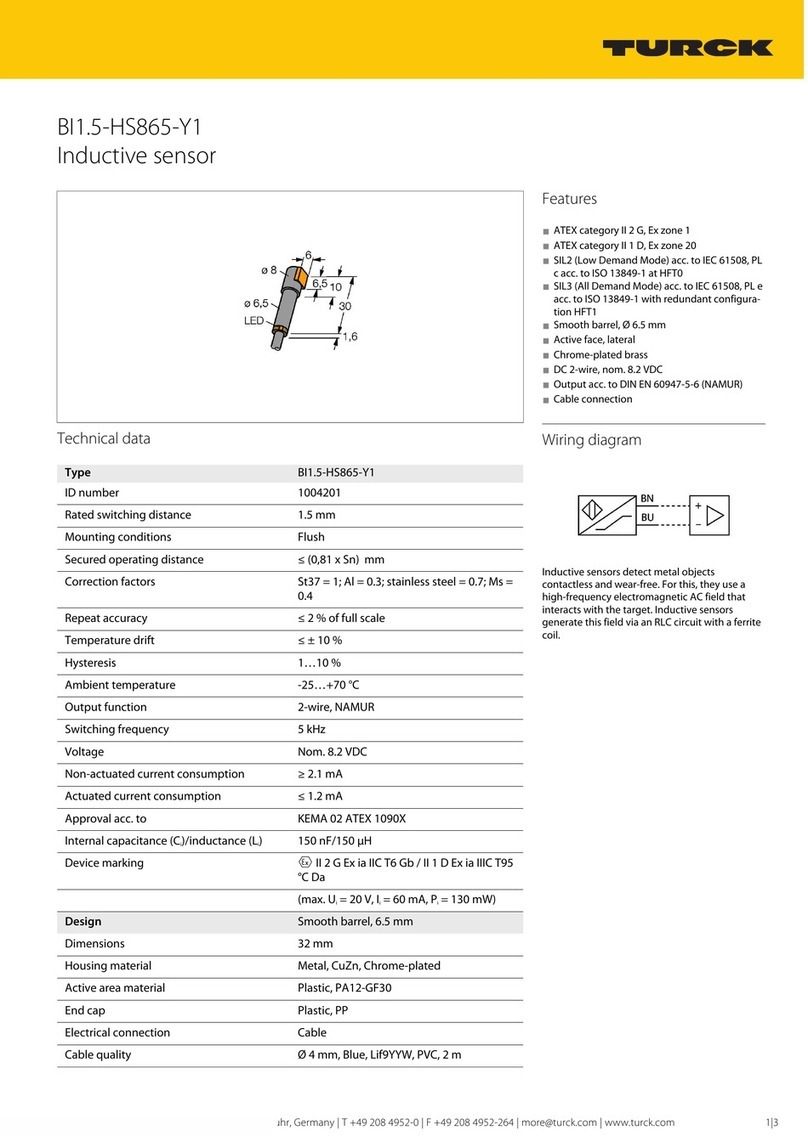

Coded magnetic safety sensor with integrated evaluation, with a non-contact

activation through a coded actuator.

(Type 4; low coding level acc. to EN ISO 14119)

The evaluation logic integrated in the safety sensor evaluates the switching sta-

tus of the safety sensor and switches the safety output through when correctly

actuated.

/('GLVSOD\V

If connected correctly, the LED indicates the following statuses:

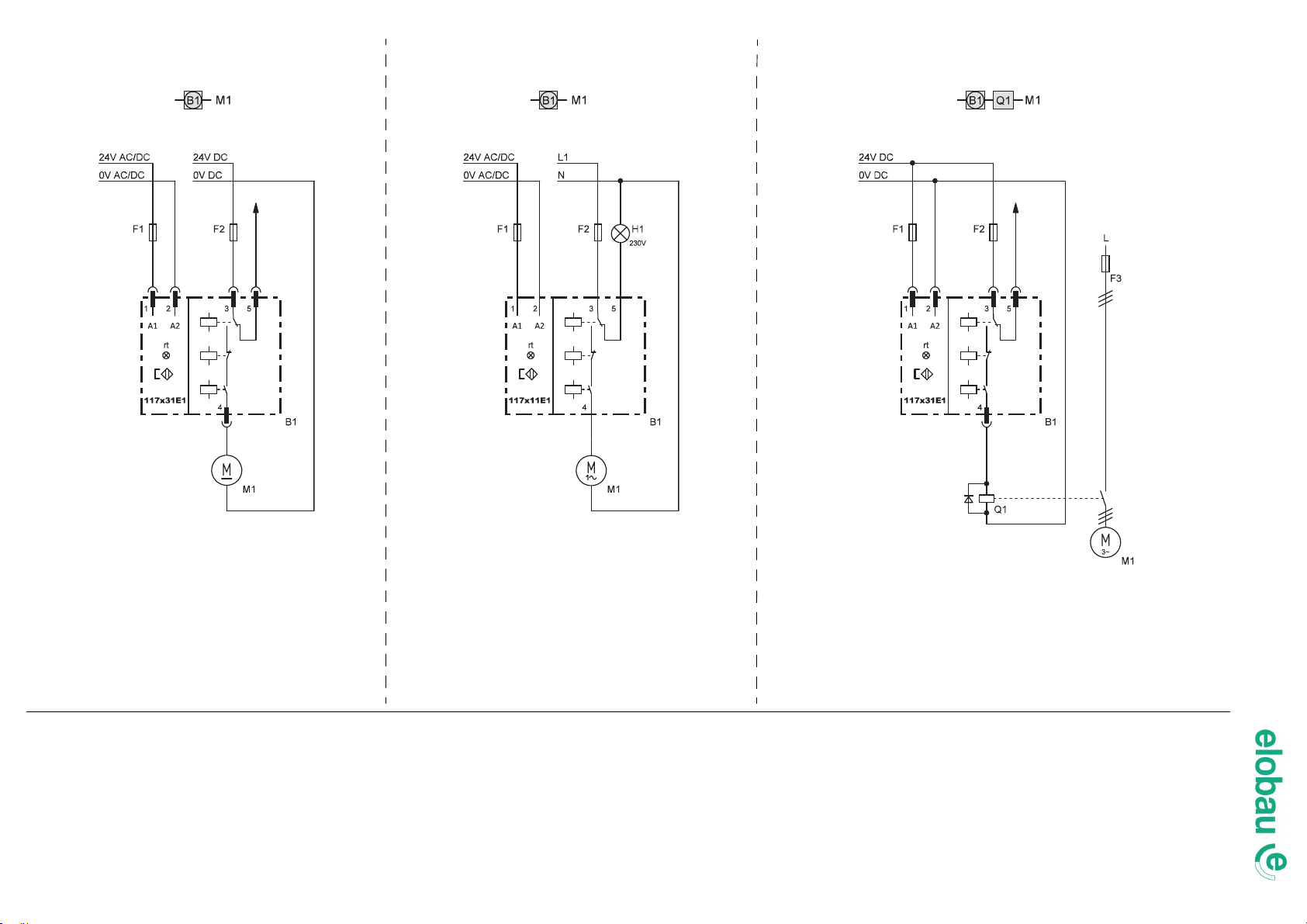

&RQWURORXWSXW

The control output (normally closed contact) indicates whethe r the safety output

has switched. This means the control output can be used as a further status dis-

play for diagnosis, e.g. via a PLC.

The control output must not be used as a safety output.

6DIHFRQGLWLRQ

The safety outputs are opened or with high resistance.

+D]DUGRXVFRQGLWLRQ

The safety outputs are closed or with low resistance.

7HFKQLFDOVSHFLILFDWLRQV

See „Technical specifications

"

from page 13 onwards.

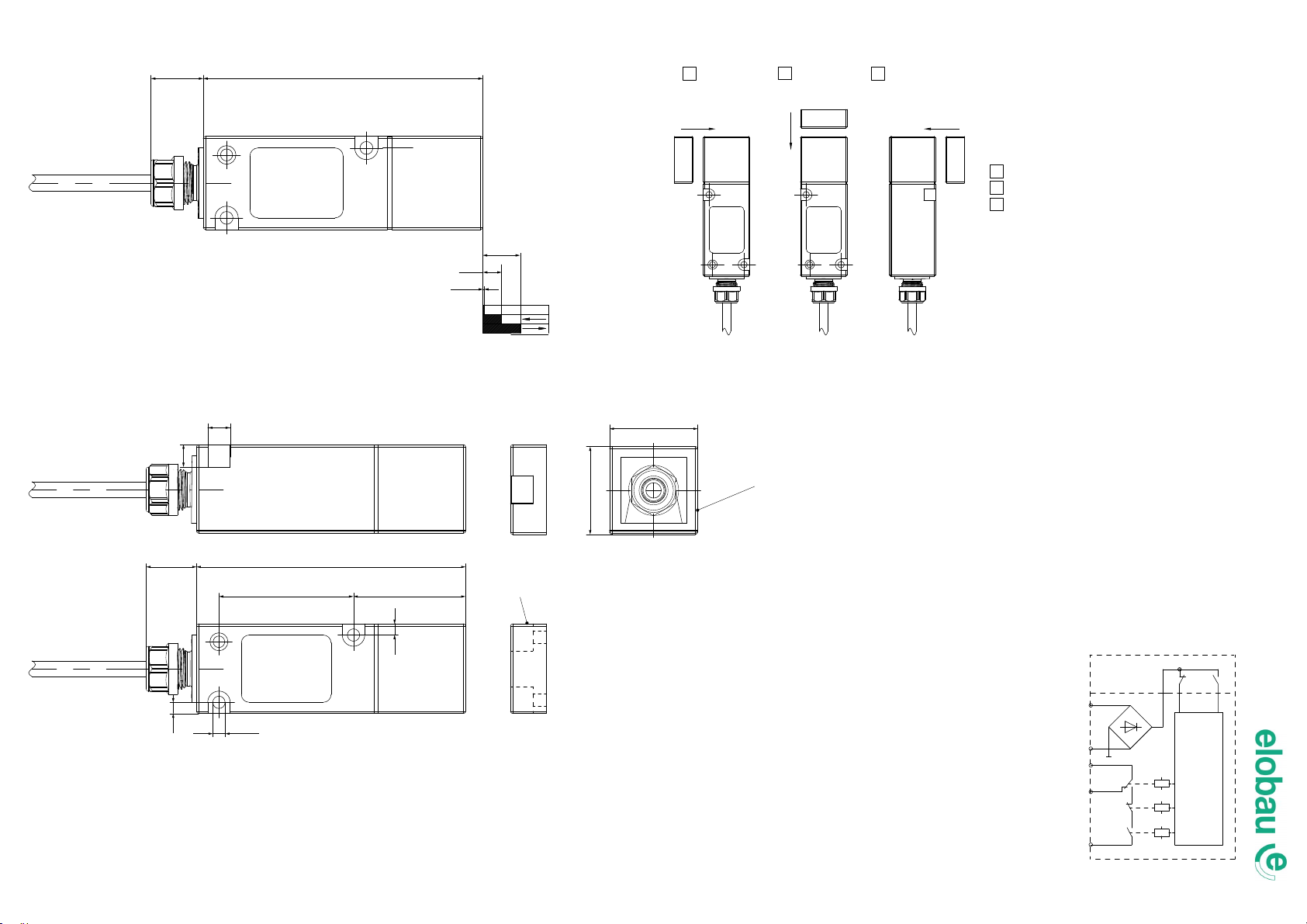

,QVWDOODWLRQ

- Safety sensor and actuator

Do not use as end stops

Do not install in strong magnetic fields

Do not expose to any strong shocks or vibrations

The safety sensor with integrated evaluation and the accompanying actuator

are only allowed to be mounted in a voltage-free state.

- Make sure that the specified fuses are used (see "Technical specifications").

- Ensure that all safety sensor and actuator markings are congruently op-

posed to one another.

- The installation position is arbitrary. The safety sensor and actuator must

however be mounted in parallel, facing each other.

- Please note the specified installation tolerances and the approved control

options.

- Safety sensor with integrated evaluation and actuator should be mounted on

non-ferromagnetic material. A free zone of 25 mm is required in the event

that this cannot be avoided.

- Mount the safety sensor with integrated evaluation and actuator on non-ferro-

magnetic material if possible. Changes to the switching distances are to be ex-

pected. A non-ferromagnetic spacer with a thickness of at least 15 mm must be

used in order to avoid influencing the switching distances. The above-mentioned

free zone still applies to the sensor and actuator.

- Ensure that the safety sensors with integrated evaluation are

only mounted and put into operation by specially-trained and au-

thorised personnel.

-Only install and put the device into operation once you have

read and understood the operating instructions and are familiar

with the applicable regulations on occupational safety and acci-

dent prevention.

-The safety sensor with integrated evaluation is only allowed to be

activated by a correctly mounted actuator on the safety device.

Actuation by a spare actuator that is not mounted to the safety de-

vice is prohibited.

- Operate the safety sensors with integrated evaluation only in un-

damaged condition.

-Make sure that the safety sensor with integrated evaluation is

used exclusively for monitoring protective devices and to protect

against hazards.

-Make sure that the appropriate fuses are used (see "Technical

specifications"). Never bypass or repair any fuses.

-Ensure that the safety output is provided with a protective circuit

for capacitive and inductive loads.

-Make sure that the control output is used exclusively for indicat-

ing the switching status of the safety output.

-Ensure that all of the valid safety regulations for the respective

machine are complied with.

-Ensure that all of the valid laws and directives are complied with.

-There are no known residual risks, if all of the information

contained in these operating instructions is complied with

- In case of incorrect or unintended use or manipulation, the use of

the safety sensors with integrated evaluation does not exclude

risks to persons or damage to machine or system components.

Please also observe the relevant information stipulated in

EN ISO 14119.

-Make sure that no current or voltage peaks that are higher than

the specified electrical specifications of the safety sensor with in-

tegrated evaluation are caused by any external components. Cur-

rent or voltage peaks are produced, for example, by capacitive or

inductive loads.

-The safety sensor with integrated evaluation is not short-circuit

proof.

-Exceeding the electrical data of the safety sensor with integrat-

ed evaluation (e.g. in the event of incorrect wiring or short-cir-

cuits) can cause irreparable damage to the sensor. Non-

compliance can result in reduced service life.

-Operation of the safety sensor with integrated evaluation is only

permitted in the released control options (see “Technical speci-

fications“).

/('GLVSOD\

/('OLJKWVUHG Device is ready for operation and not actuated

/('RII Device operated correctly

Suitable spacer plates for the sensor and actuator are available

from elobau under order number 350006.