Elsner 71300 Guide

EN

Installation and Adjustment

KNX eTR gl

Temperature Sensor with integra-

ted PI Control

Item numbers 71300 (white), 71302 (black)

1 Contents

Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany

Temperature Sensor KNX eTR gl • from application 1.0

Version: 07.04.2021 • Technical changes and errors excepted.

1. Safety and operating instructions ....................................................... 3

1.1. Installation notes ...................................................................................................... 3

2. Description ........................................................................................... 3

2.1. Scope of delivery ...................................................................................................... 4

2.2. Technical data ........................................................................................................... 4

2.2.1. Accuracy of the measurement ..................................................................... 5

2.2.2. Device structure ............................................................................................ 5

3. Installation ........................................................................................... 6

3.1. Installation location and preparation ...................................................................... 6

3.2. Mounting ................................................................................................................... 6

4. Notes on mounting and commissioning .............................................. 8

4.1. Addressing of the device at the bus ....................................................................... 8

5. Maintenance and care .......................................................................... 8

6. Disposal ............................................................................................... 8

7. Transmission protocol ......................................................................... 9

7.1. List of all communication objects ........................................................................... 9

8. Setting the parameters ...................................................................... 11

8.1. Behaviour on power failure/ restoration of power .............................................. 11

8.2. General settings ..................................................................................................... 11

8.3. Temperature measured value ............................................................................... 11

8.4. Temperature PI controller ...................................................................................... 12

8.4.1. Heating control stage 1/2 ........................................................................... 17

8.4.2. Cooling control stage 1/2 ........................................................................... 19

2 Clarification of signs

This manual is amended periodically and will be brought into line with new software

releases. The change status (software version and date) can be found in the contents footer.

If you have a device with a later software version, please check

www.elsner-elektronik.de in the menu area "Service" to find out whether a more up-to-

date version of the manual is available.

Clarification of signs used in this manual

Installation, inspection, commissioning and troubleshooting of the device

must only be carried out by a competent electrician.

Safety advice.

Safety advice for working on electrical connections, components,

etc.

DANGER! ... indicates an immediately hazardous situation which will lead to

death or severe injuries if it is not avoided.

WARNING! ... indicates a potentially hazardous situation which may lead to

death or severe injuries if it is not avoided.

CAUTION! ... indicates a potentially hazardous situation which may lead to

trivial or minor injuries if it is not avoided.

ATTENTION! ... indicates a situation which may lead to damage to property if it is

not avoided.

ETS In the ETS tables, the parameter default settings are marked by

underlining.

3 Safety and operating instructions

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted.

1. Safety and operating instructions

1.1. Installation notes

Installation, testing, operational start-up and troubleshooting should

only be performed by an authorised electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• Comply with the locally applicable directives, regulations and provisions

for electrical installation.

• De-energise all cables to be mounted and take safety precautions

against unintentional switch-on.

• Inspect the device for damage before installation. Only put undamaged

devices into operation.

• Immediately take the device or system out of service and secure it

against unintentional switch-on if risk-free operation is no longer guaranteed.

Use the device exclusively for building automation and observe the operating

instructions. Improper use, modifications to the device or failure to observe the

operating instructions will invalidate any warranty or guarantee claims.

Operate the device only as a fixed-site installation, i.e. only in assembled condition and

after conclusion of all installation and operational start-up tasks, and only in the

surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

2. Description

The Temperature Sensor KNX eTR gl measures the room temperature. The indoor

sensor can receive an external measured value via the bus and process it with own

data to an overall temperature value (mixed value).

The KNX eTR gl has a integrated PI controller for a heating/cooling system.

Functions:

•Measurement of temperature

•Mixed values from own measured value and external values (proportions can

be set in percentage)

•PI controller for heating (one or two step) and cooling (one or two step)

depending on temperature. Control according to separate target values or

basic target temperature

4 Description

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted.

2.1. Scope of delivery

• Temperature Sensor with mounting

• 4 screw anchors 4 × 20 mm, 4 flat head screws 3 × 25 mm

2.2. Technical data

The product conforms with the provisions of EU guidelines.

General:

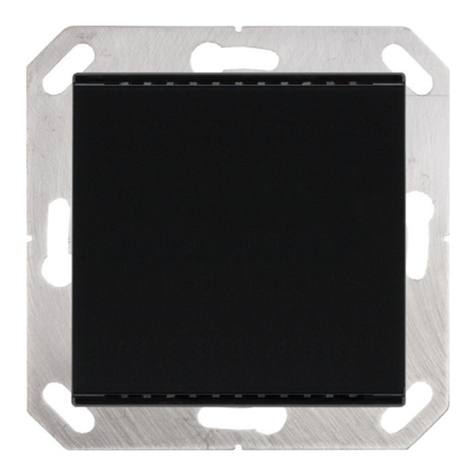

Casing Genuine glass, plastic

Colours • similar to RAL 9003 signal white

• similar to RAL 9005 deep black

Installation on the wall or on device socket according to DIN 49073

Dimensions housing approx. 81.5 mm x 81.5 mm (W x H),

mounting depth approx. 12 mm

Total weight approx. 70 g

Ambient temperature 0…+55 °C

Ambient humidity 5...95 % RH, non-condensing

Storage temperature -30…+85 °C

Overvoltage category III

Degree of contamination 2

KNX bus:

Medium TP1-256

Configuration mode S-Mode

Group addresses max. 254

Assignments max. 254

Communication objects 41

Nominal voltage 30 V SELV

Power consumption maximum 10 mA

Connection

Conductor diameter

Stripping length

KNX plug terminals

0.6…0.8 mm² s

5mm

Connection

Conductor diameter

Stripping length

Spring-loaded terminals

• rigid and flexible conductors 0.2...0.75 mm²

• flexible conductors with ferrules 0.25...0.34 mm²

7...9 mm

Duration after bus voltage

restoration until data is

received

approx. 5 seconds

Sensor:

Temperature measurement

range

0…+55 °C

Temperature resolution 0.1 °C

5 Description

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted.

2.2.1. Accuracy of the measurement

When measuring temperature, the self-heating of the device is considered by the

electronics. The heating is compensated for in the device.

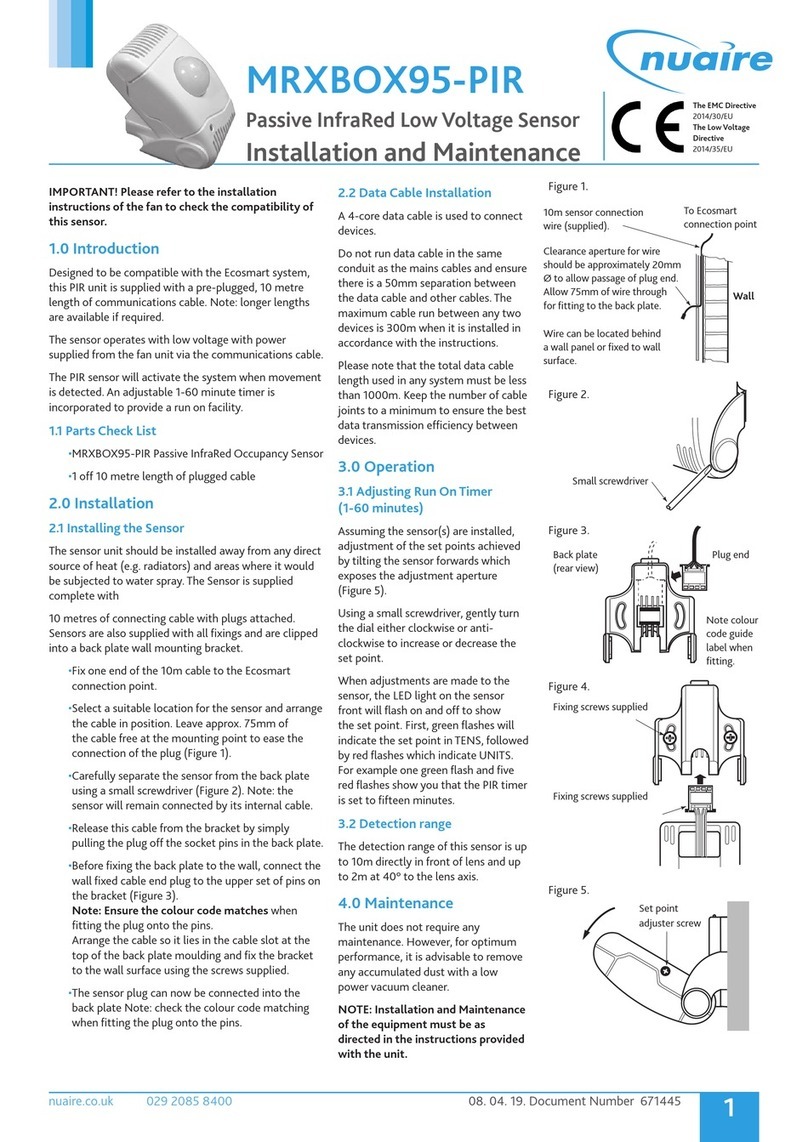

2.2.2. Device structure

2

3Fig. 1

Back view with mounting

2/3 Screw holes for different sockets. Fastening

with 2 screws is sufficient. For wall mounting,

use a fixing material suitable for the ground!

2

22

33

3

Fig. 2

Back view without mounting

4 KNX bus terminal +/- for connection when

mounted on a socket

5 Spring-loaded terminals KNX bus for moun-

ting directly on the wall

6 Programming LED

7 Programming button (recessed) for teaching

device

8 Temperature sensor

PRG key is accessible from below/outside when

the device is mounted (see chapter Addressing

the device).

4 576 8

6 Installation

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted.

3. Installation

3.1. Installation location and preparation

The Temperature Sensor KNX eTR gl is made for wall mounting. The device can be

mounted directly on plaster or on device socket according to DIN 49073 and other

sockets, e.g. Swiss device socket.

May be installed and operated in dry interior rooms only.

When selecting an installation location, ensure that the measurement results are

affected as little as possible by external influences. Possible sources of interference

include:

• Direct sunlight

• Drafts from windows and doors

• Draft from ducts which lead from other rooms or from the outside to the

junction box in which the sensor is mounted

• Warming or cooling of the building structure on which the sensor is mounted,

e.g. due to sunlight, heating or cold water pipes

• Connection lines and ducts which lead from warmer or colder areas to the

sensor

Measurement variations from permanent sources of interference can be corrected in

the ETS in order to ensure the specified accuracy of the sensor (offset).

3.2. Mounting

DANGER!

Danger due to electrical voltage

(mains voltage)!

• The socket, in which the device is installed, must not contain cabling

with 230 V.

• Observe the regulations and standards applicable to SELV circuits

during installation and wiring of the KNX connection and inputs.

Prepare the device

Remove the front panel from the mounting. Release the lock by moving the front panel

a few millimetres upwards. The two parts can then be easily separated (Fig. 3).

7 Installation

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted.

Screw the mounting onto the wall or socket. The connecting wires (bus line +/-) are led

through the opening in the mounting.

Installation directly on the wall

The wires are pushed into the connection openings.

Installation on a socket

To avoid falsifying the temperature value, use a wind-proof socket and also seal the in-

let pipes against draughts.

Fig. 3 Locking of front panel and mounting

Remove the red-black KNX bus terminal, it is not

required.

Connect the bus +/- connecting wires to the spring-

loaded terminals on the front panel.

Fig. 4 Spring-loaded terminals

To pull it out, press the spring down, e.g. with a

screwdriver.

If there is a cavity behind the device, e.g. when

using a socket, you can use the red/black KNX bus

terminal for connection.

8 Notes on mounting and commissioning

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted.

Finish mounting

Snap the front panel into place on the mounting (see Fig. 3): Place it slightly above the

centre position, hook it in and slide it downwards.

The mounting must be installed so that the large opening faces downwards (see Fig.

4). This is necessary for a correct temperature measurement.

4. Notes on mounting and commissioning

Configuration is made using the KNX software as of ETS 5. The product file can be

downloaded from the ETS online catalogue and the Elsner Elektronik website on

www.elsner-elektronik.de in the “Service” menu. There you will also find the

product manual.

After the bus voltage has been applied, the unit will enter an initialisation phase lasting

approx. 5 seconds. During this period, no information can be received or transmitted

via the bus.

4.1. Addressing of the device at the bus

The individual address is assigned via the ETS. A button and a control LED are located

on the unit for this purpose (Fig. 2, No. 6+7).

The programming button is located at the bottom outer side of the front panel of the

device and is recessed. Use a thin object to reach the button, e. g. a 1.5 mm² wire.

The equipment is delivered with the bus address 15.15.255. Another address can be

programmed using the ETS.

5. Maintenance and care

Fingerprints on the glass panel are best removed with a cloth moistened with water or

a microfiber cloth. Do not use an abrasive cleaning agent or aggressive cleansing

agents.

6. Disposal

After use, the device must be disposed of or recycled in accordance with the legal reg-

ulations. Do not dispose of it with the household waste!

PRG

Fig. 5

View from bottom

Temperature sensor

9 Transmission protocol

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

7. Transmission protocol

Units:

Temperatures in degrees Celsius

7.1. List of all communication objects

Abbreviations Flags:

C Communication

R Read

WWrite

T Transmit

UUpdate

No Text Function Flags DPT type Size

0 Software version Output R-CT [217.1] DPT_Ver-

sion

2 Bytes

5 LED brightness in % Input -WC- [5.1] DPT_Scal-

ing

1 Byte

6 Switch LED Input -WC- [1.1] DPT_Switch 1 Bit

7 Temperature sensor: malfunction Output R-CT [1.1] DPT_Switch 1 Bit

8 Temperature sensor: measured

value external

Input -WCT [9.1] DPT_Val-

ue_Temp

2 Bytes

9 Temperature sensor: measured

value

Output R-CT [9.1] DPT_Val-

ue_Temp

2 Bytes

10 Temperature sensor: measured

value total

Output R-CT [9.1] DPT_Val-

ue_Temp

2 Bytes

11 Temperature sensor: measured

value min./max. query

Input -WC- [1.17] DPT_Trig-

ger

1 Bit

12 Temperature sensor: measured

value minimum

Output R-CT [9.1] DPT_Val-

ue_Temp

2 Bytes

13 Temperature sensor: measured

value maximum

Output R-CT [9.1] DPT_Val-

ue_Temp

2 Bytes

14 Temperature sensor: measured

value min./max. reset

Input -WC- [1.17] DPT_Trig-

ger

1 Bit

15 Temp.control: HVAC mode (prior-

ity 1)

Input /

Output

-WC- [20.102] DPT_H-

VACMode

1 Byte

16 Temp.control: HVAC mode (prior-

ity 2)

Input RWCT [20.102] DPT_H-

VACMode

1 Byte

17 Temp.control: Mode frost/heat

protection activt.

Input RWCT [1.1] DPT_Switch 1 Bit

18 Temp.control: Block (1 = Blocking) Input -WC- [1.1] DPT_Switch 1 Bit

19 Temp.control: Current setpoint Output R-CT [9.1] DPT_Val-

ue_Temp

2 Bytes

10 Transmission protocol

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

20 Temp.control: Switch. (0: Heating |

1: Cooling)

Input -WC- [1.1] DPT_Switch 1 Bit

21 Temp.control: Setpoint Comfort

heating

Input /

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 Bytes

22 Temp.control: Setpoint Comfort

heat.(1:+ | 0:-)

Input -WC- [1.1] DPT_Switch 1 Bit

23 Temp.control: Setpoint Comfort

cooling

Input /

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 Bytes

24 Temp.control: Setpoint Comfort

cool.(1:+ | 0:-)

Input -WC- [1.1] DPT_Switch 1 Bit

25 Temp.control: Basic 16-bit setpoint

shift

Input /

Output

RWCT [9.2] DPT_Val-

ue_Tempd

2 Bytes

26 Temp.control: Setpoint Standby

heating

Input /

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 Bytes

27 Temp.control: Setpoint Standby

heat.(1:+ | 0:-)

Input -WC- [1.1] DPT_Switch 1 Bit

28 Temp.control: Setpoint Standby

cooling

Input /

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 Bytes

29 Temp.control: Setpoint Standby

cool. (1:+ | 0:-)

Input /

Output

-WC- [1.1] DPT_Switch 1 Bit

30 Temp.control: Setpoint Eco heat-

ing

Input /

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 Bytes

31 Temp.control: Setpoint Eco heat-

ing (1:+ | 0:-)

Input -WC- [1.1] DPT_Switch 1 Bit

32 Temp.control: Setpoint Eco cool-

ing

Input /

Output

RWCT [9.1] DPT_Val-

ue_Temp

2 Bytes

33 Temp.control: Setpoint Eco cool-

ing (1:+ | 0:-)

Input -WC- [1.1] DPT_Switch 1 Bit

34 Temp.control: Control variable

heating (level 1)

Output R-CT [5.1] DPT_Scal-

ing

1 Byte

35 Temp.control: Control variable

heating (level 2)

Output R-CT [5.1] DPT_Scal-

ing

1 Byte

36 Temp.control: Control variable

cooling (level 1)

Output R-CT [5.1] DPT_Scal-

ing

1 Byte

37 Temp.control: Control variable

cooling (level 2)

Output R-CT [5.1] DPT_Scal-

ing

1 Byte

38 Temperature control: Variable for

4/6-way valve

Output R-CT [5.1] DPT_Scal-

ing

1 Byte

39 Temp.control: Status Heat. level 1

(1=ON|0=OFF)

Output R-CT [1.1] DPT_Switch 1 Bit

40 Temp.control: Status Heat. level 2

(1=ON|0=OFF)

Output R-CT [1.1] DPT_Switch 1 Bit

41 Temp.control: Status Cool. level 1

(1=ON|0=OFF)

Output R-CT [1.1] DPT_Switch 1 Bit

No Text Function Flags DPT type Size

11 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

8. Setting the parameters

8.1. Behaviour on power failure/ restoration of

power

Behaviour following a failure of the bus power supply:

The device sends nothing.

Behaviour on bus restoration of power and following programming or reset:

The device sends all outputs according to their send behaviour set in the parameters

with the delays established in the "General settings" parameter block.

8.2. General settings

Set the basic properties of the data transmission.

8.3. Temperature measured value

Select, whether a malfunction object is to be sent if the sensor is faulty.

Use Offsets to adjust the readings to be sent.

42 Temp.control: Status Cool. level 2

(1=ON|0=OFF)

Output R-CT [1.1] DPT_Switch 1 Bit

43 Temp.control: Comfort extension

status

Input /

Output

RWCT [1.1] DPT_Switch 1 Bit

44 Temp.control: Comfort Extension

time

Input RWCT [7.5] DPT_Time-

PeriodSec

2 Bytes

Transmission delay after reset/bus restora-

tion

5s• ... • 7200 s

Maximum message rate • 1 message per second

• ...

• 10 messages per second

• ...

• 50 messages per second

Use malfunction object No • Yes

Offset in 0.1°C -50…50; 0

No Text Function Flags DPT type Size

12 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

The unit can calculate a mixed value from its own reading and an external value. Set

the mixed value calculation if desired. If an external portion is used, all of the following

settings (threshold values, etc.) are related to the overall reading.

The minimum and maximum readings can be saved and sent to the bus. Use the

"Reset temperature min/max. value" objects to reset the values to the current readings.

The values are not retained after a reset.

8.4. Temperature PI controller

Activate the controller if you want to use it.

General rules

Decide in which cases nominal values and delay times received per object are to be

kept. The parameter is only taken into consideration if the setting by object is activated

further down. Please note that the setting "After power restoration and programming"

should not be used for the initial start-up, as the factory settings are always used until

the first call (setting via objects is ignored).

For an adequate regulation of the indoor temperature, comfort, standby, eco and build-

ing protection modes may be used.

Comfort when present,

Standby when absent,

Eco as a night-time mode and

Frost / heat protection (building protection) e.g. when the window is open.

The settings for the temperature control include the setpoint temperatures for the in-

dividual modes. Objects are used to determine which mode is to be selected. A change

of mode may be triggered manually or automatically (e.g. by a timer, window contact).

The mode may be switched with two 8 bit objects of different priority. Objects

„... HVAC mode (Prio 2)“ for switching in everyday operation and

„... HVAC mode (Prio 1)“ for central switching with higher priority.

The objects are coded as follows:

0 = Auto

Use external measured value No • Yes

Ext. Reading proportion of the total reading 5% • 10% • ... • 50% • ... • 100%

Sending pattern for internal and total

measured value

• never

• periodically

• on change

• on change and periodically

At and above change of

(if sent on change)

0.1°C • 0.2°C • 0.5°C • ... • 5.0°C

Send cycle

(if sent periodically)

5 s • 10 s • ... • 2 h

Use minimum and maximum value No • Yes

Use controller No • Yes

13 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

1 = Comfort

2 = Standby

3 = Eco

4 = Building protection

Alternatively, you can use three objects, with one object switching between eco and

standby mode and the two others are used to activate comfort mode or frost/heat pro-

tection mode. The comfort object then blocks the eco/standby object, and frost/heat

protection objects have the highest priority. Objects

„... Mode (1: Eco, 0: Standby)“,

„... comfort activation mode" and

„... frost/heat protection activation mode"

Select the mode to be activated after reset (e.g. power failure, reset of the line via

the bus). (Default).

Then configure a temperature control block using the blocking object.

Specify when the current control variables are to be sent to the bus. Periodic trans-

mission is safer if a message does not reach a recipient. You may also set up periodical

monitoring by the actuator with this setting.

The status object reports the current status of the output (0 = OFF, 0 = ON) and may

for example be used for visualisation, or to switch off the heating pump as soon as the

heating is switched off.

Switch mode via • two 8-bit objects (HVAC modes)

• three 1-bit objects

Mode after reset • Comfort

• Standby

• Eco

• Building protection

Behaviour of the blocking object with value • 1 = Block | 0 = release

• 0 = block | 1 = release

Value of the blocking object after reset 0 • 1

Send control variable • on change

• on change and periodically

from change of (in % absolute) 1...10; 2

Cycle

(if sent periodically)

5 s • ... • 5 min • … • 2 h

Send status objects • on change

• on change to 1

• on change to 0

• on change and periodically

• on change to 1 and periodically

• on change to 0 and periodically

Cycle

(if sent periodically)

5 s • ... • 5 min • … • 2 h

14 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

Then define the type of setting. Heating and/or cooling may be controlled in two

stages.

General setpoint values

You may enter separate setpoint values for each mode or use the comfort setpoint as

a basic value.

If you are using the controls for both heating and cooling, you may also select the set-

ting "separately with switching object". Systems used for cooling in the summer and

for heating in the winter can thus be switched from one to the other.

If you are using the basic value, only the deviation from the comfort setpoint value is

listed for the other modes (e. g., 2°C less for standby mode).

The grades for the setpoint changes is predefined. Whether the change remains active

only temporarily (do not store) or remains stored even after restoration of power (and

programming) is determined in the first section of "General controller". This also ap-

plies to a comfort extension.

The controller can be switched from eco mode, i.e. night mode, to comfort mode via

the comfort extension. This means that the comfort setpoint can be maintained for

longer, for example when having guests. The duration of this comfort extension period

Type of control • Single stage heating

• Dual-stage heating

• Single-stage cooling

• Single-stage heating + single-stage cool-

ing

• Dual-stage heating + single-stage cooling

• Dual-stage heating + dual-stage cooling

Keep modified setpoints after mode

change

No • Yes

Setting the nominal values • separate with switching object

• separate without switching object

• with comfort setpoint as a basis with

switching object

• with comfort setpoint as a basis without

switching object

Analysis of the status object /

Behaviour of the switching object at value

• 0 = Heating | 1 = Cooling

• 1 = Heating | 0 = Cooling

Switching object value

before first Communication

(only if switching object is used)

0• 1

Grading for setpoint changes

(in 0.1 °C)

1… 50; 10

Storage of setpoint(s) • not be retained

• after power restoration

• after restoration of power and program-

ming

15 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

is set. After the comfort extension period is terminated, the system returns to eco

mode.

Setpoint Comfort

Comfort mode is usually used for daytime mode when people are present. A starting

value is defined for the comfort setpoint as well as a temperature range in which the

nominal value may be modified.

If setpoint values are entered separately:

If the comfort setpoint value is used as a basis:

If the comfort setpoint is used as the basis, the increase/decrease of this value is indi-

cated.

If the comfort setpoint is used as the basis, a dead zone is determined for the control

mode "heating and cooling" to avoid direct switching from heating to cooling.

Setpoint for standby

Standby mode is usually used for daytime mode when people are absent.

If setpoint values are entered separately:

A starting setpoint value is defined as well as a temperature range in which the setpoint

value may be changed.

Comfort extension time in seconds

(can only be activated from eco mode)

1…36000; 3600

Initial heating/cooling setpoint (in 0.1 °C)

valid until first Communication

(not upon saving the target value after pro-

gramming)

-300…800; 210

Min. object value heating/cooling (in 0.1 °C) -300…800; 160

Max. object value heating/cooling (in 0.1

°C)

-300…800; 280

Minimum base setpoint (in 0.1°C) -300…800; 160

Maximum base setpoint (in 0.1°C) -300…800; 280

Reduction by up to (in 0.1°C) 1…100; 50

Increase by up to (in 0.1°C) 1…100; 50

Dead zone between heating and cooling

(only if both heating AND cooling are used)

1…100; 50

Heating initial setpoint (in 0.1 °C)

valid until first Communication

-300…800; 180

Cooling initial setpoint (in 0.1 °C)

valid until first Communication

-300…800; 240

Min. object value heating/cooling (in 0.1

°C)

-300…800; 160

16 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

If the comfort setpoint value is used as a basis:

If the comfort setpoint is used as the basis, the increase/decrease of this value is indi-

cated.

Eco setpoint

Eco mode is usually used for night mode.

If setpoint values are entered separately:

A starting setpoint value is defined as well as a temperature range in which the setpoint

value may be changed.

If the comfort setpoint value is used as a basis:

If the comfort setpoint is used as the basis, the increase/decrease of this value is indi-

cated.

Setpoint values for frost/heat protection (building protection)

The building protection mode is used, for example, as long as windows are open for

ventilation. Setpoints for frost protection (heating) and heat protection (cooling) are

determined which may not be modified from outside (no access via operating devices

etc.). The building protection mode may be activated with delay, which allows you to

leave the building before the controls switch to frost/heat protection mode.

Max. object value heating/cooling (in 0.1

°C)

-300…800; 280

Reduce heating setpoint (in 0.1°C)

(for heating)

0…200; 30

Increase cooling setpoint (in 0.1°C)

(for cooling)

0…200; 30

Heating initial setpoint (in 0.1 °C)

valid until first Communication

-300…800; 160

Cooling initial setpoint (in 0.1 °C)

valid until first Communication

-300…800; 280

Min. object value heating/cooling (in 0.1

°C)

-300…800; 160

Max. object value heating/cooling (in 0.1

°C)

-300…800; 280

Reduce heating setpoint (in 0.1°C)

(for heating)

0…200; 50

Increase cooling setpoint (in 0.1°C)

(for cooling)

0…200; 60

Nominal value frost protection\r\n(in 0,1°C) -300…800; 70

Activation delay no • 5 s • ... • 5 min • … • 2 h

Nominal value heat protection (in 0,1°C) -300…800; 350

Activation delay no • 5 s • ... • 5 min • … • 2 h

17 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

General variables

This setting appears for the control types "Heating and Cooling" only. This is where you

can decide whether to use a common variable for heating and cooling. If the 2nd stage

has a common variable, this is also where you determine the control mode of the 2nd

stage.

When using the variable for a 4/6 way valve:

0%...100% Heating = 66%...100% variable

OFF = 50% variable

0%...100% Cooling = 33%...0% variable

8.4.1. Heating control stage 1/2

If a heating control mode is configured, one or two setting sections for the heating

stages are displayed.

In the first stage, heating is controlled by a PI controller which allows to either enter

control parameters or select predetermined applications.

In the second stage (therefore only in case of 2-stage heating), heating is controlled via

a PI or a 2-point-control.

In stage 2, the setpoint deviation between the two stages must also be specified, i.e.

beyond which setpoint undershoot the second stage is then added.

PI controller with control parameters:

This setting allows individual input of the parameters for PI control.

For heating and cooling • separate variables are used

• common variables are used for

Stage 1

• common variables are used for

Stage 2

• common variables are used for

Stage 1+2

Use variable for 4/6-way valve

(only with common variable at stage1)

No • Yes

Control type

(for stage 2 only)

• 2-point-control

• PI control

Regulating variable of the 2nd Stage is on

(only for stage 2 with 2-point control)

• 1-bit object

• 8-bit object

Setpoint difference between stages 1 and 2

stages (in 0.1°C)

(At stage 2)

0...100; 40

Control type

(at stage 2, no common variables)

• 2-point-control

• PI control

Control variable is on

(for stage 2 with 2-point control, no com-

mon variables)

• 1-bit object

• 8-bit object

18 Setting the parameters

Temperature Sensor KNX eTR gl • Version: 07.04.2021 • Technical changes and errors excepted

Specify the deviation from the setpoint value at which the maximum control variable

value is reached, i.e. the point at which maximum heating power is activated.

The reset time shows how quickly the controller responds to deviations from the set-

point. In case of a short reset time, the control responds with a fast increase of the con-

trol variable. In case of a long reset time, the control responds somewhat less urgently

and needs longer until the necessary control variable for the setpoint deviation is

reached.

You should set the time appropriate to the heating system at this point (observe man-

ufacturer's instructions).

Now specify what should be sent when the control is blocked. Set a value greater 0

(=OFF) to receive a basic heating stage, e.g. for floor heating.

On release, the control variable follows the rule again.

In case of a common control variable for heating and cooling, 0 is always transmitted

as a fixed value.

PI control with predetermined application:

This setting provides fixed parameters for frequent applications.

Control type • PI control

Setting of the controller by • Controller parameter

• specified applications

Maximum control variable is reached

at setpoint/actual difference of (in °C)

1...5

Reset time (in min.) 1...255; 30

When blocked, the control variable should • not be sent

• send a specific value

Value (in %)

(only if a value is sent)

0...100

Control type • PI control

Setting of the controller by • Controller parameter

• specified applications

Application • Warm water heating

• Floor heating

• Convection unit

• Electric heating

Maximum control variable is reached

at setpoint/actual difference of (in °C)

Warm water heating: 5

Floor heating: 5

Convection unit: 4

Electric heating: 4

Reset time (in min.) Warm water heating: 150

Floor heating: 240

Convection unit: 90

Electric heating: 100

This manual suits for next models

1

Table of contents

Other Elsner Accessories manuals

Elsner

Elsner Cala KNX AQS/TH Guide

Elsner

Elsner KNX RW Guide

Elsner

Elsner Vari KNX 3L-TH-D Guide

Elsner

Elsner Vari KNX 3L Guide

Elsner

Elsner KNX VOC-UP basic Guide

Elsner

Elsner Leak User manual

Elsner

Elsner KNX LW Series User manual

Elsner

Elsner KNX L User manual

Elsner

Elsner KNX R Guide

Elsner

Elsner KNX AQS/TH Guide