Elsner KNX T-UP gl Guide

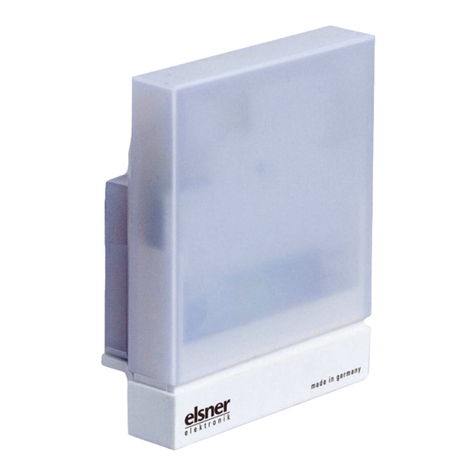

KNX T-UP gl

Temperature Sensor

Item numbers 70631 (black), 70632 (pure white)

EN

Installation and Adjustment

1 Content

Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany

Sensor KNX T-UP gl from ETS programme version 1.0

Status: 05.09.2022 • Technical changes and errors excepted.

1. Safety and operating instructions ....................................................... 3

2. Description ........................................................................................... 3

3. Commissioning .................................................................................... 4

3.1. Addressing the equipment ...................................................................................... 4

4. Transfer protocol ................................................................................. 5

4.1. List of all communications objects ......................................................................... 5

5. Parameter setting .............................................................................. 11

5.1. Behaviour on power failure/ restoration of power .............................................. 11

5.2. General settings ..................................................................................................... 11

5.3. Temperature value ................................................................................................. 12

5.4. Temperature threshold values .............................................................................. 12

5.4.1. Threshold value 1, 2, 3 ............................................................................... 12

5.4.1.1. Threshold value ............................................................................ 12

5.4.1.2. Switching output .......................................................................... 13

5.4.1.3. Block .............................................................................................. 14

5.5. Temperature PI control .......................................................................................... 15

5.5.0.1. General control ............................................................................. 15

5.5.1. General set point values ............................................................................. 17

5.5.1.1. Set point Comfort ......................................................................... 17

5.5.1.2. Standby setpoint ........................................................................... 18

5.5.1.3. Eco setpoint ................................................................................... 18

5.5.1.4. Setpoint values for frost/heat protection (building protection) 19

5.5.1.5. General control variables ............................................................. 19

5.5.2. Heating control level 1/2 ............................................................................. 20

5.5.3. Cooling control level 1/2 ............................................................................. 22

5.6. Variable comparator .............................................................................................. 24

5.6.1. Control variable comparator 1/2 ................................................................ 24

5.7. Logic ........................................................................................................................ 25

5.7.0.1. AND logic ....................................................................................... 25

5.7.0.2. OR logic ......................................................................................... 25

5.7.1. AND logic 1-4 and OR logic outputs 1-4 ................................................... 25

5.7.1.1. Block .............................................................................................. 27

5.7.2. Connection inputs of the AND logic .......................................................... 27

5.7.3. Connection inputs of the OR logic ............................................................. 28

2 Clarification of signs

This manual is amended periodically and will be brought into line with new software

releases. The change status (software version and date) can be found in the contents footer.

If you have a device with a later software version, please check

www.elsner-elektronik.de in the menu area "Service" to find out whether a more up-to-

date version of the manual is available.

Clarification of signs used in this manual

Safety advice.

Safety advice for working on electrical connections, components,

etc.

DANGER! ... indicates an immediately hazardous situation which will lead to

death or severe injuries if it is not avoided.

WARNING! ... indicates a potentially hazardous situation which may lead to

death or severe injuries if it is not avoided.

CAUTION! ... indicates a potentially hazardous situation which may lead to

trivial or minor injuries if it is not avoided.

ATTENTION! ... indicates a situation which may lead to damage to property if it is

not avoided.

ETS In the ETS tables, the parameter default settings are marked by

underlining.

3 Safety and operating instructions

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

1. Safety and operating instructions

Installation, testing, operational start-up and troubleshooting should

only be performed by an authorised electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• Inspect the device for damage before installation. Only put undamaged devic-

es into operation.

• Comply with the locally applicable directives, regulations and provisions for

electrical installation.

• Immediately take the device or system out of service and secure it against un-

intentional switch-on if risk-free operation is no longer guaranteed.

Use the device exclusively for building automation and observe the operating instruc-

tions. Improper use, modifications to the device or failure to observe the operating in-

structions will invalidate any warranty or guarantee claims.

Operate the device only as a fixed-site installation, i.e. only in assembled condition and

after conclusion of all installation and operational start-up tasks, and only in the sur-

roundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may occur

after publication of these operating instructions.

For information on installation, maintenance, disposal, scope of deliv-

ery and technical data, please refer to the installation instructions.

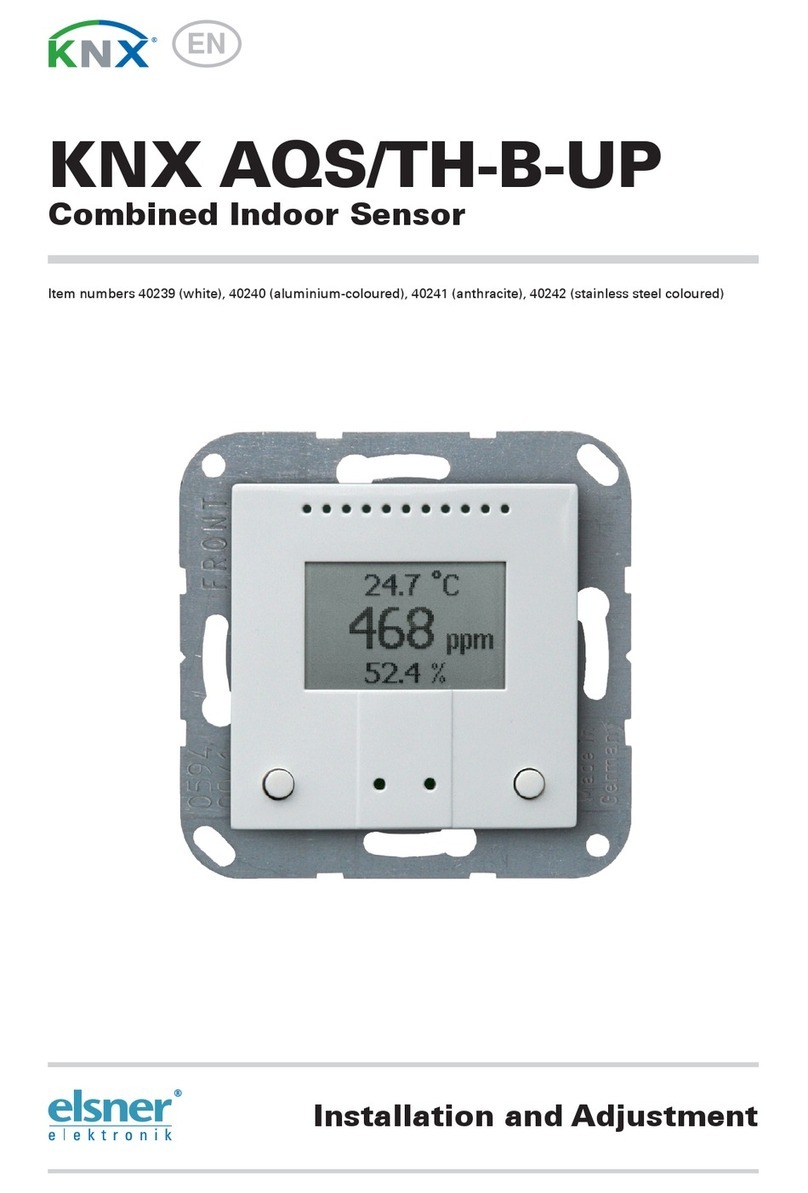

2. Description

The Sensor KNX T-UP gl measures the room temperature. The indoor sensor can

receive an external measured value via the bus and process it with own data to an

overall temperature value (mixed value).

The KNX T-UP gl provides adjustable threshold values. The threshold value outputs

and further communication objects can be linked by AND and OR logic gates.

Additionally, an integrated actuating variable comparator can compare and output

values that are received via communication objects. The sensor has integrated PI

controller for a heating/cooling system.

The device is completed with a frame of the switching series installed in the building

and thus merges with the interior.

Functions:

•Measurement of temperature

•Mixed values from own measured value and external values (proportions can

be set in percentage)

4 Commissioning

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

•PI controller for heating (one or two step) and cooling (one or two step)

depending on temperature. Control according to separate target values or

basic target temperature

•Threshold values can be adjusted per parameter or via communication

objects: 3 × temperature

•4 AND and 4 OR logic gates with each 4 inputs. Every switching incident as

well as 16 logic inputs in the form of communication objects, may be used as

inputs for the logic gates. The output of each gate may optionally be configured

as 1 bit or 2 x 8 bits

•2 actuating variable comparators for output of minimum, maximum or

average values. Each with 5 inputs (for values received via communication

objects)

3. Commissioning

Configuration is made using the KNX software as of ETS 5. The product file can be

downloaded from the ETS online catalogue and the Elsner Elektronik website on

www.elsner-elektronik.de in the “Service” menu.

After the bus voltage has been applied, the device will enter an initialisation phase

lasting approx. 6 seconds. During this phase no information can be received or sent via

the bus.

3.1. Addressing the equipment

The equipment is delivered with the bus address 15.15.255. Another address can be

programmed using the ETS.

For this purpose there is a button with a control LED on the unit.

5 Transfer protocol

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

4. Transfer protocol

Units:

Temperatures in degrees Celsius

Air humidity in %

Absolute air humidity in g/kg and/or g/m3

Variables in %

4.1. List of all communications objects

Abbreviation flags:

C Communication

R Read

WWrite

T Transfer

UUpdate

No Text Function Flags DPT Typ Size

0 Software version readable R-CT [217.1]

DPT_Version

2 Bytes

1 Temperature sensor malfunction Output R-CT [1.1]

DPT_Switch

1 Bit

3 External measured value for tem-

perature

Input -RC- [9.1]

DPT_-

Value_Temp

2 Bytes

4 Internal measured value for tem-

perature

Output R-CT [9.1]

DPT_-

Value_Temp

2 Bytes

5 Total measured value for tempera-

ture

Output R-CT [9.1]

DPT_-

Value_Temp

2 Bytes

6 Request min./max. temperature

measured value

Input -RC- [1.17]

DPT_Trigger

1 Bit

7 Minimum measured value for tem-

perature

Output R-CT [9.1]

DPT_-

Value_Temp

2 Bytes

8 Maximum measured value for

temperature

Output R-CT [9.1]

DPT_-

Value_Temp

2 Bytes

9 Reset min./max. measured value

for temperature

Input -RC- [1.17]

DPT_Trigger

1 Bit

10 Temp. thresholdV 1: Absolute

value

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

11 Temp. thresholdV 1: (1:+ | 0:-) Input -RC- [1.2]

DPT_Bool

1 Bit

6 Transfer protocol

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

12 Temp. thresholdV 1: Switching

delay from 0 to 1

Input -RC- [9.010]

DPT_Value_Time

2 Bytes

13 Temp. thresholdV 1: Switching

delay from 1 to 0

Input -RC- [9.010]

DPT_Value_Time

2 Bytes

14 Temp. thresholdV 1: Switching

output

Output R-CT [1.1]

DPT_Switch

1 Bit

15 Temp. thresholdV 1: Switching

output block

Input -RC- [1.2]

DPT_Bool

1 Bit

16 Temp. thresholdV 2: Absolute

value

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

17 Temp. thresholdV 2: (1:+ | 0:-) Input -RC- [1.2]

DPT_Bool

1 Bit

18 Temp. thresholdV 2: Switching

delay from 0 to 1

Input -RC- [9.010]

DPT_Value_Time

2 Bytes

19 Temp. thresholdV 2: Switching

delay from 1 to 0

Input -RC- [9.010]

DPT_Value_Time

2 Bytes

20 Temp. thresholdV 2: Switching

output

Output R-CT [1.1]

DPT_Switch

1 Bit

21 Temp. thresholdV 2: Switching

output block

Input -RC- [1.2]

DPT_Bool

1 Bit

22 Temp. thresholdV 3: Absolute

value

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

23 Temp. thresholdV 3: (1:+ | 0:-) Input -RC- [1.2]

DPT_Bool

1 Bit

24 Temp. thresholdV 3: Switching

delay from 0 to 1

Input -RC- [9.010]

DPT_Value_Time

2 Bytes

25 Temp. thresholdV 3: Switching

delay from 1 to 0

Input -RC- [9.010]

DPT_Value_Time

2 Bytes

26 Temp. thresholdV 3: Switching

output

Output R-CT [1.1]

DPT_Switch

1 Bit

27 Temp. thresholdV 3: Switching

output block

Input -RC- [1.2]

DPT_Bool

1 Bit

29 Temp.control: HVAC mode (prio-

rity 1)

Input -RC- [20.102]

DPT_HVACMode

1 Byte

30 Temp.control: HVAC mode (prio-

rity 2)

Input /

Output

RWCT [20.102]

DPT_HVACMode

1 Byte

31 Temp.control: Mode frost/heat

protection activt.

Input /

Output

RWCT [1.1]

DPT_Switch

1 Bit

32 Temp.control: Block (On when

value = 1)

Input -RC- [1.1]

DPT_Switch

1 Bit

33 Temp.control: Current setpoint Output R-CT [9.1]

DPT_-

Value_Temp

2 Bytes

No Text Function Flags DPT Typ Size

7 Transfer protocol

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

34 Temp.control: Switch. (Heating = 0

| Cooling = 1)

Input -RC- [1.1]

DPT_Switch

1 Bit

35 Temp.control: Setpoint Comfort

heating

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

36 Temp.control: Setpoint Comfort

heat.(1:+ | 0:-)

Input -RC- [1.1]

DPT_Switch

1 Bit

37 Temp.control: Setpoint Comfort

cooling

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

38 Temp.control: Setpoint Comfort

cool.(1:+ | 0:-)

Input -RC- [1.1]

DPT_Switch

1 Bit

39 Temp.control: Basic 16-bit setpoint

shift

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

40 Temp.control: Setpoint Standby

heating

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

41 Temp.control: Setpoint Standby

heat.(1:+ | 0:-)

Input -RC- [1.1]

DPT_Switch

1 Bit

42 Temp.control: Setpoint Standby

cooling

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

43 Temp.control: Setpoint Standby

cool. (1:+ | 0:-)

Input -RC- [1.1]

DPT_Switch

1 Bit

44 Temp.control: Setpoint Eco hea-

ting

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

45 Temp.control: Setpoint Eco hea-

ting (1:+ | 0:-)

Input -RC- [1.1]

DPT_Switch

1 Bit

46 Temp.control: Setpoint Eco coo-

ling

Input /

Output

RWCT [9.1]

DPT_-

Value_Temp

2 Bytes

47 Temp.control: Setpoint Eco coo-

ling (1:+ | 0:-)

Input -RC- [1.1]

DPT_Switch

1 Bit

48 Temp.control: Control variable

heating (level 1)

Output R-CT [5.1]

DPT_Scaling

1 Byte

49 Temp.control: Control variable

heating (level 2)

Output R-CT [5.1]

DPT_Scaling

1 Byte

50 Temp.control: Control variable

cooling (level 1)

Output R-CT [5.1]

DPT_Scaling

1 Byte

51 Temp.control: Control variable

cooling (level 2)

Output R-CT [5.1]

DPT_Scaling

1 Byte

52 Temp.control: Status Heat. level 1

(1=ON|0=OFF)

Output R-CT [1.1]

DPT_Switch

1 Bit

No Text Function Flags DPT Typ Size

8 Transfer protocol

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

53 Temp.control: Status Heat. level 2

(1=ON|0=OFF)

Output R-CT [1.1]

DPT_Switch

1 Bit

54 Temp.control: Status Cool. level 1

(1=ON|0=OFF)

Output R-CT [1.1]

DPT_Switch

1 Bit

55 Temp.control: Status Cool. level 2

(1=ON|0=OFF)

Output R-CT [1.1]

DPT_Switch

1 Bit

56 Temp.control: Comfort extension

status

Input /

Output

RWCT [1.1]

DPT_Switch

1 Bit

57 Temp.control: Comfort Extension

time

Input RWCT [7.5]

DPT_TimePeri-

odSec

2 Bytes

58 Temperature control: Variable for

4/6-way valve

Output R-CT [5.1]

DPT_Scaling

1 Byte

131 CO2 control: Act. variable ventila-

tion (1.stage)

Output R-CT [5.1]

DPT_Scaling

1 Byte

133 CO2 control: Status ventilation

(1=ON | 0=OFF)

Output R-CT [1.1]

DPT_Switch

1 Bit

134 CO2 control: Status ventilation 2

(1=ON | 0=OFF)

Output R-CT [1.1]

DPT_Switch

1 Bit

135 Actuating variable comparator 1:

Input 1

Input -RC- [5.1]

DPT_Scaling

1 Byte

136 Actuating variable comparator 1:

Input 2

Input -RC- [5.1]

DPT_Scaling

1 Byte

137 Actuating variable comparator 1:

Input 3

Input -RC- [5.1]

DPT_Scaling

1 Byte

138 Actuating variable comparator 1:

Input 4

Input -RC- [5.1]

DPT_Scaling

1 Byte

139 Actuating variable comparator 1:

Input 5

Input -RC- [5.1]

DPT_Scaling

1 Byte

140 Actuating variable comparator 1:

Output

Output R-CT [5.1]

DPT_Scaling

1 Byte

141 Actuating variable comparator 1:

Block

Output -RC- [1.2]

DPT_Bool

1 Bit

142 Actuating variable comparator 2:

Input 1

Input -RC- [5.1]

DPT_Scaling

1 Byte

143 Actuating variable comparator 2:

Input 2

Input -RC- [5.1]

DPT_Scaling

1 Byte

144 Actuating variable comparator 2:

Input 3

Input -RC- [5.1]

DPT_Scaling

1 Byte

145 Actuating variable comparator 2:

Input 4

Input -RC- [5.1]

DPT_Scaling

1 Byte

146 Actuating variable comparator 2:

Input 5

Input -RC- [5.1]

DPT_Scaling

1 Byte

No Text Function Flags DPT Typ Size

9 Transfer protocol

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

147 Actuating variable comparator 2:

Output

Output R-CT [5.1]

DPT_Scaling

1 Byte

148 Actuating variable comparator 2:

Block

Output -RC- [1.2]

DPT_Bool

1 Bit

149 AND logic 1: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

150 AND logic 1: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

151 AND logic 1: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

152 AND logic 1: Switching output

block

Input -RC- [1.2]

DPT_Bool

1 Bit

153 AND logic 2: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

154 AND logic 2: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

155 AND logic 2: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

156 AND logic 2: Switching output

block

Input -RC- [1.2]

DPT_Bool

1 Bit

157 AND logic 3: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

158 AND logic 3: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

159 AND logic 3: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

160 AND logic 3: Switching output

block

Input -RC- [1.2]

DPT_Bool

1 Bit

161 AND logic 4: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

162 AND logic 4: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

163 AND logic 4: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

164 AND logic 4: Switching output

block

Input -RC- [1.2]

DPT_Bool

1 Bit

181 OR logic 1: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

182 OR logic 1: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

183 OR logic 1: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

184 OR logic 1: Switching output block Input -RC- [1.2]

DPT_Bool

1 Bit

No Text Function Flags DPT Typ Size

10 Transfer protocol

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

185 OR logic 2: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

186 OR logic 2: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

187 OR logic 2: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

188 OR logic 2: Switching output block Input -RC- [1.2]

DPT_Bool

1 Bit

189 OR logic 3: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

190 OR logic 3: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

191 OR logic 3: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

192 OR logic 3: Switching output block Input -RC- [1.2]

DPT_Bool

1 Bit

193 OR logic 4: 1 bit switching output Output R-CT [1.1]

DPT_Switch

1 Bit

194 OR logic 4: 8 bit output A Output R-CT [5]

5.xxx

1 Byte

195 OR logic 4: 8 bit output B Output R-CT [5]

5.xxx

1 Byte

196 OR logic 4: Switching output block Input -RC- [1.2]

DPT_Bool

1 Bit

200 Logic input 1 Input -RC- [1.2]

DPT_Bool

1 Bit

201 Logic input 2 Input -RC- [1.2]

DPT_Bool

1 Bit

202 Logic input 3 Input -RC- [1.2]

DPT_Bool

1 Bit

203 Logic input 4 Input -RC- [1.2]

DPT_Bool

1 Bit

204 Logic input 5 Input -RC- [1.2]

DPT_Bool

1 Bit

205 Logic input 6 Input -RC- [1.2]

DPT_Bool

1 Bit

206 Logic input 7 Input -RC- [1.2]

DPT_Bool

1 Bit

207 Logic input 8 Input -RC- [1.2]

DPT_Bool

1 Bit

208 Logic input 9 Input -RC- [1.2]

DPT_Bool

1 Bit

209 Logic input 10 Input -RC- [1.2]

DPT_Bool

1 Bit

No Text Function Flags DPT Typ Size

11 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

5. Parameter setting

5.1. Behaviour on power failure/ restoration of

power

Behaviour following a failure of the bus power supply:

The device sends nothing.

Behaviour on bus restoration of power and following programming or reset:

The device sends all outputs according to their send behaviour set in the parameters

with the delays established in the "General settings" parameter block.

5.2. General settings

Set the basic data transfer characteristics and select whether or not malfunction ob-

jects should be sent.

210 Logic input 11 Input -RC- [1.2]

DPT_Bool

1 Bit

211 Logic input 12 Input -RC- [1.2]

DPT_Bool

1 Bit

212 Logic input 13 Input -RC- [1.2]

DPT_Bool

1 Bit

213 Logic input 14 Input -RC- [1.2]

DPT_Bool

1 Bit

214 Logic input 15 Input -RC- [1.2]

DPT_Bool

1 Bit

215 Logic input 16 Input -RC- [1.2]

DPT_Bool

1 Bit

Send delay after power-up and programming for:

Measured values 5 s • ... • 2 h

Threshold values and switching outputs 5 s • ... • 2 h

Controller objects 5 s • 10 s • ... • 2 h

Logic outputs 5 s • 10 s • ... • 2 h

Maximum telegram quota • 1 message per second

• ...

• 5 messages per second

• ...

• 20 messages per second

Use temperature malfunction object Yes • No

No Text Function Flags DPT Typ Size

12 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

5.3. Temperature value

When measuring temperature, the self-heating of the device is considered by the

electronics. The heating is compensated for in the device.

Use Offsets to adjust the readings to be sent.

Permanent measurement variations can be corrected in this way.

The unit can calculate a mixed value from its own reading and an external value. Set

the mixed value calculation if desired. If an external value is used, all of the following

settings are referred to the total value.

The minimum and maximum readings can be saved and sent to the bus. Use the

„Reset temperature min/max. value“ objects to reset the values to the current read-

ings. The values are not retained after a reset.

5.4. Temperature threshold values

Activate the required temperature threshold values. The menus for setting the thresh-

old values are displayed.

5.4.1. Threshold value 1, 2, 3

Threshold value

Set, in which cases threshold values received via object are to be retained. The pa-

rameter is only taken into consideration if the setting via object is activated below.

Please note that the setting "After power supply restoration and programming" should

not be used for the initial start-up, as the factory settings are always used until the first

communication (setting via objects is ignored).

Set the threshold value directly in the application program using parameters, or define

them via the bus using a communication object.

Offset in 0,1°C -50…50; 0

Use external reading Yes • No

Ext. Reading proportion of the total reading 5% • 10% • ... • 50% • ... • 100%

All of the following settings are referred to the total value.

Send internal and total reading • never

• periodically

• on change

• on change and periodically

From change of

(if sent on change)

0,1°C • 0,2°C • 0,5°C • ... • 5,0°C

Send cycle

(if sent periodically)

5s• 10 s • ... • 2 h

Use minimum/maximum value Yes • No

Use threshold value 1/2/3 Yes • No

13 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

Threshold value setting via parameter:

Set the threshold values and hysteresis directly.

Threshold value setting via a communication object:

Define, how the threshold value is to be received from the bus. Basically, a new value

can be received, or simply a command to increase or decrease.

During initial commissioning, a threshold value must be defined, which will be valid

until the first communication with a new threshold value. For units which have already

been taken into service, the last communicated threshold value can be used. Basically,

a temperature range is given, in which the threshold value can be changed (object val-

ue limit).

A set threshold value will be retained until a new value or a change is transferred. The

current value is saved, so that it is retained in the event of a power supply failure and

will be available once the power supply is restored.

Set the hysteresis independent of the type of threshold value specification.

Switching output

Set the behaviour of the switching output when a threshold value is exceeded/under-

cut. The output switching delay can be set using objects or directly as a parameter.

Threshold value setting via Parameter • Communication objects

Threshold value in 0.1°C -300 … 800; 200

Threshold value setting via Parameter • Communication objects

The value communicated last shall be

maintained

• never

• after power supply restoration

• after power supply restoration and

programming

Start threshold value in 0.1°C

valid until first communication

-300 … 800; 200

Object value limit (min) in 0.1°C -300…800

Object value limit (max) in 0.1°C -300…800

Type of threshold value change Absolute value • Increase/decrease

Increment

(upon increase/decrease change)

0,1 °C • ... • 5°C, 1°C

Hysteresis in % of the threshold value 0 … 50; 20

When the following conditions apply,

the output is

(TV = Threshold value)

• TV above = 1 | TV - hyst. below = 0

• TV above = 0 | TV - hyst. below = 1

• TV below = 1 |TV + hyst. above = 0

• TV below = 0 |TV + hyst. above = 1

Delays can be set via objects

(in seconds)

No • Yes

14 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

Block

The switching output can be blocked using an object.

If the block is activated, define specifications here for the behaviour of the output when

blocked.

The behaviour of the switching output on release is dependent on the value of the pa-

rameter "Switching output sends" (see "Switching output")

Switching delay from 0 to 1

(If delay can be set via objects:

valid until 1st communication)

None • 1 s • 2 s • 5 s • 10 s • … • 2 h

Switching delay from 1 to 0

(If delay can be set via objects:

valid until 1st communication)

None • 1 s • 2 s • 5 s • 10 s • … • 2 h

Switching output sends • on change

• on change to 1

• on change to 0

• on change and periodically

• on change to 1 and periodically

• on change to 0 and periodically

Cycle

(only if sending periodically is selected)

5s• 10 s • 30 s… • 2 h

Use switching output block No • Yes

Analysis of the blocking object • At value 1: block | At value 0: release

• At value 0: block | At value 1: release

Blocking object value before

1st communication

0• 1

Behaviour of the switching output

On block • Do not send message

• send 0

• send 1

On release

(with 2 seconds release delay)

[Dependent on the "Switching output

sends" setting]

Switching output sends on change • Do not send message

• Send switching output status

Switching output sends on change to 1 • Do not send message

• if switching output = 1 send 1

Switching output sends on change to 0 • Do not send message

• if switching output = 0 send 0

Switching output sends on change and

periodically

Send switching output status

Switching output sends on change to 1

and periodically

if switching output = 1 send 1

Switching output sends on change to 0

and periodically

if switching output = 0 send 0

15 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

5.5. Temperature PI control

Activate the control if you want to use it.

General control

Set, in which cases setpoint values and extension time received via object are to

be retained. The parameter is only taken into consideration if the setting via object is

activated below. Please note that the setting "After power supply restoration and pro-

gramming" should not be used for the initial start-up, as the factory settings are always

used until the 1st communication (setting via objects is ignored).

.

For an adequate regulation of the indoor temperature, comfort, standby, eco and

building protection modes may be used.

Comfort when present,

Standby during short absences,

Eco as a night-time mode and

Frost/heat protection (building protection) during longer absences.

The settings for the temperature control include the set point temperatures for the

individual modes. Objects are used to determine which mode is to be selected. A

change of mode may be triggered manually or automatically (e.g. by a timer, window

contact).

The mode may be switched with two 8 bit objects of different priority. Objects

„... HVAC mode (Prio 2)“ for switching in everyday operation and

„... HVAC mode (Prio 1)“ for central switching with higher priority.

The objects are coded as follows:

0 = Auto

1 = Comfort

2 = Standby

3 = Eco

4 = Building Protection

Alternatively, you can use three objects, with one object switching between eco and

standby mode and the two others activating comfort mode and frost/heat protection

mode respectively. The comfort object blocks the eco/standby object, and the frost/

heat protection object has the highest priority. Objects

„... Mode (1: Eco, 0: Standby)“,

„... comfort activation mode" and

„... frost/heat protection activation mode"

Select the mode to be activated after reset (e.g. power failure, reset of the line via

the bus) (Default).

Then configure a temperature control block via the blocking object.

Use control No • Yes

Switch mode via • two 8 Bit objects (HVAC Modes)

• three 1 bit objects

16 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

Specify when the current control variables of the controller are to be sent to the bus.

Periodic sending is safer, in case a message does not reach a recipient. You may also

set up periodical monitoring by the actuator with this setting.

The status object reports the current status of the control variables (0% = OFF,

>0% = ON) and may for example be used for visualisation, or to switch off the

heating pump as soon as the heating is switched off.

Then define the type of control. Heating and/or cooling may be controlled in two lev-

els.

Mode after reset • Comfort

• Standby

• Eco

• Building protection

Behaviour of the blocking object with value • 1 = Block | 0 = release

• 0 = block | 1 = release

Blocking object value

before 1st communication

0• 1

Send control variable • on change

• on change and periodically

from change (in % absolute) 1...10; 2

Cycle

(if sent periodically)

5 s • ... • 5 min • … • 2 h

Send status objects • on change

• on change to 1

• on change to 0

• on change and periodically

• on change to 1 and periodically

• on change to 0 and periodically

Cycle

(if sent periodically)

5 s • ... • 5 min • … • 2 h

Type of control • Single level heating

• Dual-level heating

• Single-level cooling

• Single-level heating + single-level cooling

• Dual-level heating + single-level cooling

• Dual-level heating + dual-level cooling

17 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

General set point values

You may enter separate set point values for each mode or use the comfort set point as

a basic value.

If you are using the controls for both heating and cooling, you may also select the

setting "separately with switching object". Systems used for cooling in the summer

and for heating in the winter can thus be switched from one to the other.

If you are using the basic value, only the deviation from the comfort set point value is

listed for the other modes (e. g., 2°C less for standby mode).

The grades for the set point changes is predefined. Modifications may only remain ac-

tive temporarily (do not save) or remain saved even after voltage recovery (and pro-

gramming). This also applies to a comfort extension.

The control may be manually reset to comfort mode from eco, or night mode. This

allows the user to maintain the daily nominal value for a longer time, e.g. when having

guests. The duration of this comfort extension period is set. After the comfort

extension period is terminated, the system returns to eco mode.

Set point Comfort

Comfort mode is usually used for daytime mode when people are present. A starting

value is defined for the comfort set point as well as a temperature range in which the

nominal value may be modified.

If set point values are entered separately:

Preserve modified set points after mode

change

No • Yes

Setting the nominal values • separate with switching object

• separate without switching object

• with comfort set point as a basis

Grading for set point changes

(in 0.1 °C)

1… 50; 10

Saving set point value(s) not

• after voltage recovery

• after voltage recovery and programming

Comfort extension time in seconds

(can only be activated from eco mode)

1…36000; 3600

Initial heating/cooling set point (in 0.1 °C)

valid till 1st communication

not upon saving the set point value after

programming

-300…800; 210

Min. object value heating/cooling (in 0.1

°C)

-300…800; 160

Max. object value heating/cooling (in 0.1

°C)

-300…800; 280

18 Parameter setting

Sensor KNX T-UP gl • Version: 05.09.2022 • Technical changes and errors excepted.

If the comfort setpoint value is used as a basis:

If the comfort setpoint value is used as a basis, the reduction/increment of the value is

set.

If the comfort setpoint is used as the basis without a switching object, a dead zone is

specified for the control mode "heating and cooling" to avoid direct switching from

heating to cooling.

Standby setpoint

Standby mode is usually used for daytime mode when people are absent.

If setpoint values are entered separately:

A starting setpoint value is defined as well as a temperature range in which the setpoint

value may be changed.

If the comfort setpoint value is used as a basis:

If the comfort setpoint value is used as a basis, the reduction/increment of the value is

set.

Eco setpoint

Eco mode is usually used for night mode.

Starting heating/cooling setpoint (in 0.1 °C)

valid until 1st communication

-300…800; 210

Minimum base setpoint (in 0.1°C) -300…800; 160

Maximum base setpoint (in 0.1°C) -300…800; 280

Reduction by up to (in 0.1°C) 1…100; 50

Increase by up to (in 0.1°C) 1…100; 50

Dead zone between heating and cooling in

0,1°C

(only if both heating AND cooling are used)

1…100; 50

Starting heating setpoint (in 0.1 °C)

valid until 1st communication

-300…800; 180

Starting heating setpoint (in 0.1 °C)

valid until 1st communication

-300…800; 240

Min. object value heating/cooling

(in 0.1 °C)

-300…800; 160

-300…800; 280

Max. object value heating/cooling

(in 0.1 °C)

Reduce heating setpoint (in 0.1°C)

(for heating)

0…200; 30

Increase cooling setpoint (in 0.1°C)

(for cooling)

0…200; 30

This manual suits for next models

2

Table of contents

Other Elsner Accessories manuals

Elsner

Elsner 71300 Guide

Elsner

Elsner KNX L User manual

Elsner

Elsner KNX R Guide

Elsner

Elsner Cala KNX AQS/TH Guide

Elsner

Elsner KNX VOC-UP basic Guide

Elsner

Elsner Vari KNX 3L Guide

Elsner

Elsner KNX LW Series User manual

Elsner

Elsner Leak User manual

Elsner

Elsner KNX AQS/TH Guide

Elsner

Elsner Vari KNX 3L-TH-D Guide

Popular Accessories manuals by other brands

Reinston

Reinston EPB011 user manual

Safety Technology International

Safety Technology International STI-3610 quick start guide

Gram Precision

Gram Precision K2P Series user manual

A&D

A&D AD-4328 specification

Aeotec

Aeotec DSB05106-ZWUS user manual

Diffraction

Diffraction Boltwood Cloud Sensor III user manual