2

3

5

7

2

4

6

8

1

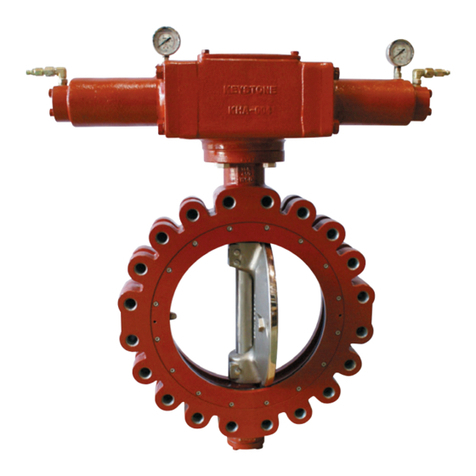

KEYSTONE FIGURE 952 KNIFE GATE VALVES

InstallatIon and operatIng manual

INSTALLATION INSTRUCTIONS

NOTE

Heavy valves will require a chain block or crane to

assist. In difficult locations, large cylinder actuators

can be removed from valve and re-fitted after

installation if necessary, but check cylinder to gate

alignment carefully and that valve seats correctly.

(Refer cylinder fittinginstructions).

1. Close valve.

2. Check valve size is correct and that there is

adequate clearance to install valve.

3. Check flange faces are clean and smooth

and that bolt hole patterns on pipe flanges

are the same as the valve, and are in line.

4. Check bolt sizes and threads are

clean and compatible with the valve.

(Separatetechnical data is available).

5. Check gaskets match flanges and are

suitable for the service.

6. Check that the pipeline, upstream and

downstream, is correctly aligned.

7. If a Deflector cone is being used, fit it to

upstream side of valve with the cone nozzle

pointing downstream, prior to installation.

Metal (Chrome Iron) cones must have

gaskets fitted between the cone and valve,

and between cone and flange. Resilient

urethane cones do not require these

gaskets.

8. Spread flanges to clear valve, check

flow arrow on side of valve is in the right

direction. (Valve seating face and gate are

downstream). Lower valve into position.

Insert gaskets, 1each side.

9. Insert flange bolts. On wafer valves, insert

bolts into the threaded bolt holes in the

chest of the valve first but do not tighten

until all bolts are fitted. Tighten bolts in

adiagonal sequence (refer Fig. 2).

10. Ensure bolts in the chest area of the valve

are not bottoming out in the blind holes.

11. Open and close valve to check it is operating

correctly.

12. After pipe line is pressurized, check for

flange leaks and for gland leaks, adjust as

necessary.

PURGE PORTS (WHERE FITTED)

Optional stainless steel purge nozzles can be

fitted in lower part of body. If sedimentation

occurs preventing gate from closing fully, purge

with compressed air or water. Alternatively,

connect permanent installation to purge ports

and purge periodically. Purge port hole is 3 mm

(⅛”)BSPP.

SAFETY

The gland on new and repaired valves may

require final adjustment after installation

and pressurisation of the valve.

Actuated valves are generally operated from a

remote location, caution should be exercised if

working in close proximity to any moving parts.

NOTE

To minimize risk to personnel, Emerson recommend

the use of purpose built guards and shrouds. Refer to

the Emerson data sheet orconsult factory for details.

GLAND ADJUSTMENT

The gland on new and repaired valves may

require final adjustment after installation and

pressurisation of the valve. If packing leaks,

tighten gland nuts equally until leaking ceases.

A 32 mm (1¼”) AF spanner fits DN 50 - 600

(NPS 2 - 24) valve size.

If gland leakage persists, check that pipeline

isnot pressurized above rating of valve.

Alternatively, packing may be damaged,

wrongly installed or have foreign matter caught

between gate and packing.

Disassemble, inspect and repair or replace

asnecessary.

CAUTION

Do NOT over tighten gland packing as it will

causeexcessive resistance to gate movement.

FIGURE 2

FIGURE 3

Gasket

Pipe flange

Bolt

Blind holes in

chest area

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Keystone is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl