9

Type EZL

3. If the restriction or restriction plug (key 20) was

removed, coat the threads with lubricant and install it.

4. If replacing the stem O-ring (key 37), sparingly apply

lubricant and install the O-ring over the valve plug

(key 4).

5. If removed, install the valve plug (key 4) and valve

spring (key 14) into the diaphragm assembly (key 5).

Install a replacement connector cap O-ring or gasket

(key 36) on the diaphragm assembly and secure with

the connector cap (key 6).

6. Install the diaphragm assembly (key 5) and push down

on it to see if the valve plug (key 4) moves smoothly.

The diaphragm assembly should stroke approximately

1/16 in. / 1.6 mm after the valve plug contacts the port.

Note

In step 7, if installing a control spring of

a different set pressure range, be sure to

remove the set pressure range on the spring

case and indicate the new range.

7. Stack the control spring (key 7), the control spring seat

(key 8) and, if used, the diaphragm limiter (key 40) onto

the diaphragm assembly (key 5). Make sure to install

the diaphragm limiter bevelled side up.

8. Install the spring case (key 2) on the body (key 1) with

the vent assembly (key 16) oriented to prevent clogging

or entrance of moisture. Install the machine screws

(key 17) and tighten in a crisscross pattern, using 5 to

7 ft-lbs / 7 to 9 N•m of torque.

9. Replace the closing cap gasket (key 19) if necessary

install the closing cap (key 12). When all maintenance

is complete, refer to the Startup and Shutdown section

to put the relief valve or backpressure regulator into

operation and adjust the pressure setting.

Parts Ordering

Each Type EZL relief valve or backpressure regulator

is assigned a serial number, which can be found on the

nameplate. Refer to the number when contacting your local

Sales Office for technical information or ordering parts. Also

be sure to include the complete 11-character part number

from the following Parts List.

Parts List

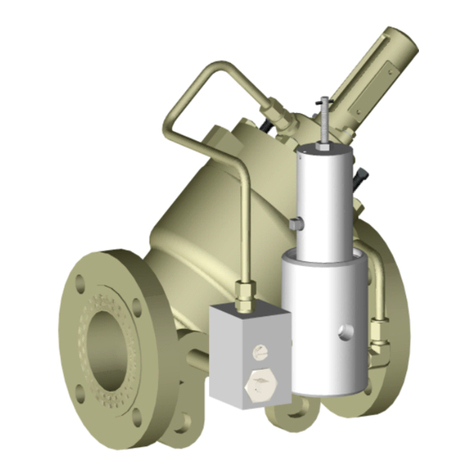

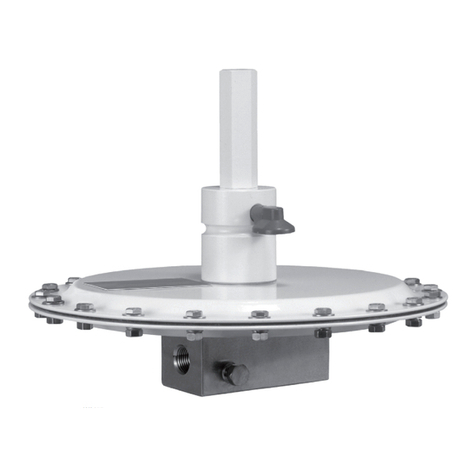

Type EZL Main Valve (Figure 4)

Key Description Part Number

Disk Parts Kits

2 and 3 in. / DN 50 and 80 (includes key numbers: 29, 30 and 34)

4 in. / DN 100 (includes key numbers: 29, 30, 34 and 75)

2 in. / DN 50, Nitrile (NBR) and

Fluorocarbon (FKM) REZL2X00N12

Key Description Part Number

Disk Parts Kits (continued)

2 in. / DN 50, Fluorocarbon (FKM) REZL2X00F12

3 in. / DN 80, Nitrile (NBR) and

Fluorocarbon (FKM) REZL3X00N12

3 in. / DN 80, Fluorocarbon (FKM) REZL3X00F12

4 in. / DN 100, Nitrile (NBR) and

Fluorocarbon (FKM) REZL4X00N12

4 in. / DN 100, Fluorocarbon (FKM) REZL4X00F12

Full Repair Kits

2 and 3 in. / DN 50 and 80 (includes key numbers:

4, 7, 8, 9, 12B, 15, 17, 20, 28, 29, 30, 34, 70 and 76)

4 in. / DN 100 (includes key numbers:

4, 7, 8, 9, 12B, 15, 17, 20, 28, 29, 30, 34, 70, 75 and 76)

2 in. / DN 50, Nitrile (NBR) and

Fluorocarbon (FKM) REZL2X00N22

2 in. / DN 50, Fluorocarbon (FKM) REZL2X00F22

3 in. / DN 80, Nitrile (NBR) and

Fluorocarbon (FKM) REZL3X00N22

3 in. / DN 80, Fluorocarbon (FKM) REZL3X00F22

4 in. / DN 100, Nitrile (NBR) and

Fluorocarbon (FKM) REZL4X00N22

4 in. / DN 100, Fluorocarbon (FKM) REZL4X00F22

Travel Indicator Parts Kits

2 in. / DN 50 (includes key numbers:

12B, 53, 54, 55, 56, 57, 58, 70 and 76) ERSA01550A0

3 and 4 in. / DN 80 and 100 (includes

key numbers: 12B, 53, 54, 55, 56,

57, 58, 70 and 76) ERSA01555A0

1 Body

2 in. / DN 50

Cast iron

NPT GE10583X012

CL125 FF GE10585X012

Steel

NPT GE10588X012

CL150 RF

Standard GE10676X032

Tapped inlet and outlet 14B5834X032

CL300 RF

Standard GE10676X012

Tapped inlet and outlet 14B5834X042

CL600 RF

Standard GE10679X012

Tapped inlet and outlet 14B5834X052

BWE, Schedule 40 GE10680X012

SWE GE10682X012

3 in. / DN 80

Cast iron

CL125 FF GE10689X012

Steel

CL150 RF

Standard GE10699X012

Tapped inlet and outlet 14B5835X032

CL300 RF

Standard GE10700X012

Tapped inlet and outlet 14B5835X042

CL600 RF

Standard GE10701X012

Tapped inlet and outlet 14B5835X052

BWE, Schedule 40 GE10702X012

- continued -