2

YY

Q

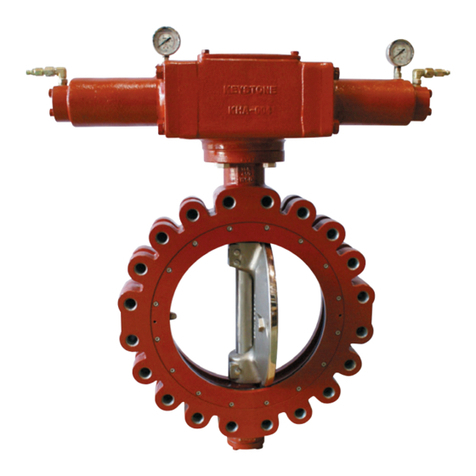

KEYSTONE COMPOSEAL BUTTERFLY VALVES, WAFER STYLE

InstallatIon and MaIntenance InstructIons

Notes

- The valve can be installed in the pipeline

either with or without the actuator mounted

on top of the valve. Make sure you are able

to turn the disc carefully to a more closed/

open position to prevent the disc edge

from touching the adjacent flanges while

positioning the valve.

- It is the responsibility of the valve user - and

not the valve manufacturer - to ensure

that the pipeline system has been built

professionally and the valve has been

properly installed.

- Adjacent piping must be positioned so that

minimal piping stresses are transmitted to

the valve flanges during or after installation.

- Handling and lifting of the valves during

installation must be performed following the

same instructions described in the previous

paragraph ‘1.3 Handling’.

- If an actuator or handle (especially the

composite handle) is to be mounted on the

valve, apply a little bit of grease to the shaft

to ensure easy assembly. Avoid hammering

or hitting on the handle or actuator during

assembling at all times.

- Remove the 4 snap-off nibs for installing the

valve between AS2129 E flanges NPS 3 only

(Fig. 2).

Fig. 1

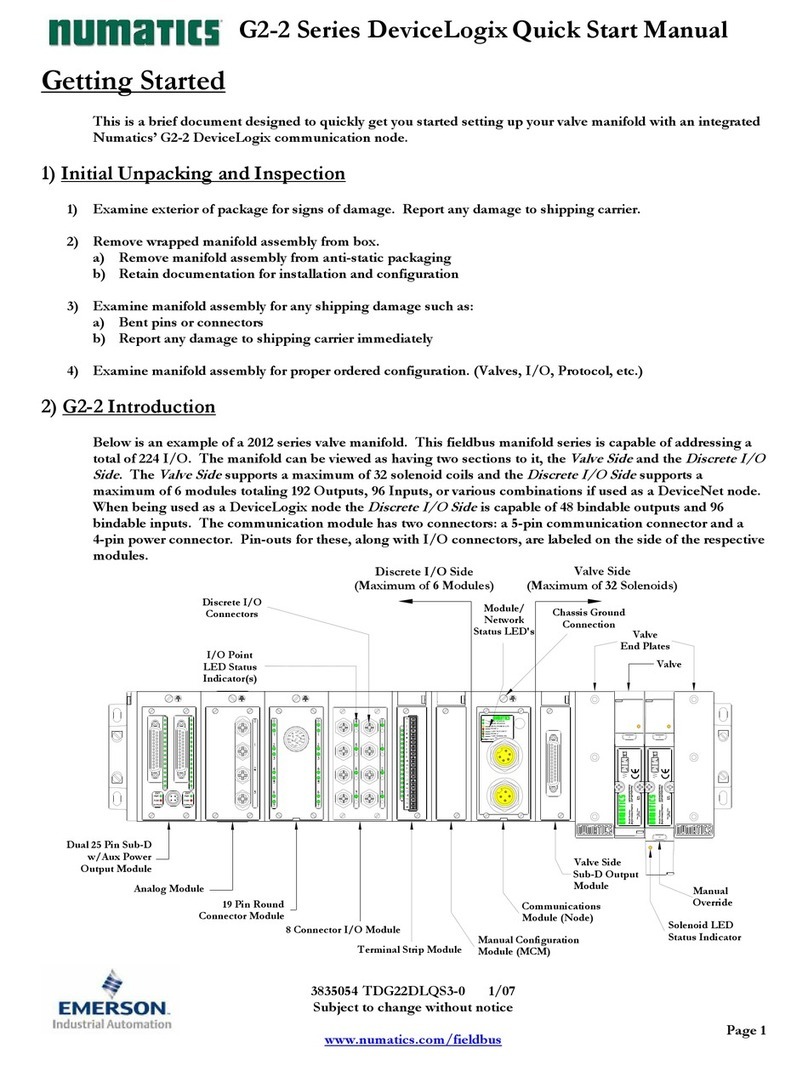

2.2 FLANGE AND PIPE COMPATIBILITY

Check matching of flange drilling pattern of

valve and pipe flange before assembly.

Flanges have to meet the following

requirements (Fig. 1):

- The face inside diameter should be:

D min: The valve Q dimension + adequate

disc clearance.

D max: The optimum inside diameter (ID)

is equal to the inside diameter of flange

standard EN 1092-1, table 8, type 11. For

larger than D max inside diameters or

other flange types please contact your local

Emerson Sales organization, as larger inside

diameters might result in reduced valve

functionality.

- If the flange or pipe is provided with a raised

face, the diameter of this shall be at least

⅜” larger than the YY-dimension of the

valve.

The O-ring design of the Keystone CompoSeal

eliminates the need for gaskets. If for some

reason required, flange gaskets can also

be used. When flange gaskets are used

(min. 0.04" / max 0.08” thick rubber gaskets are

recommended) the O-rings must be removed

from the body.Use flange bolting in accordance

with the appropriate standard.

Dmax/min

Do not use the valve as a crow-bar to spread

the flanges, this might lead to damage to

the flange area and/or damage to the O-ring

sealing.

2.3 VALVE INSTALLATION

The valves are bi-directional and can be fitted

in either direction relative to the flow. The valve

will control flow equally in either direction. The

recommended installation position is shaft

horizontal and the lower discedge opening

downstream (especially for slurry service and

media with a tendency for sedimentation).

For optimum valve control and smooth

performance, it is recommended to have 10 to

20 pipe diameters of straight run inlet piping

and 3 to 5 pipe diameters straight outlet piping.

IMPORTANT

Mating flange faces should be in good condition

and free of dirt and/or inclusions.

Both pipe insides must be well cleaned before

installing the valve.

2.3.1 Existing system

1. Check whether the flange distance meets

the valve face-to-face dimensions. Spread

the flanges with adequate tooling for easy

insertion of the valve.

2. Close the valve so far, that the disc edge is

at least ½” within the body flanges.

3. Insert the valve between the flanges, pay

extra attention to the flange sealing O-rings.

Adequate flange spreading is required to

prevent the O-rings from rolling out of its

groove. Place 2 two flange bolts trough the

pipe flanges and the locating lugs of the

valve to support the valve.

4. Check if the flange sealing O-rings are still

in place.

5. Center the valve body and insert all flange

bolts. Tighten the flange bolts hand tight.

6. Slowly open the valve completely. The disc is

in line with parallel flats.

7. Maintain the valve flange alignment while

gradually removing the flange-spreaders

and tighten the flange bolts hand tight.

8. Slowly close and open the valve to check for

adequate disc clearance.

9.

Cross tighten all the bolts with the

recommended bolt torque shown in Table

1. Do not exceed the maximum bolting

torques, as this can lead to overloading of the

composite body!

Fig. 2