Emerson Fisher POSI-SEAL A31A User manual

Other Emerson Control Unit manuals

Emerson

Emerson Fisher Slurry Vee-Ball V300S User manual

Emerson

Emerson White-Rodgers 36H Series User manual

Emerson

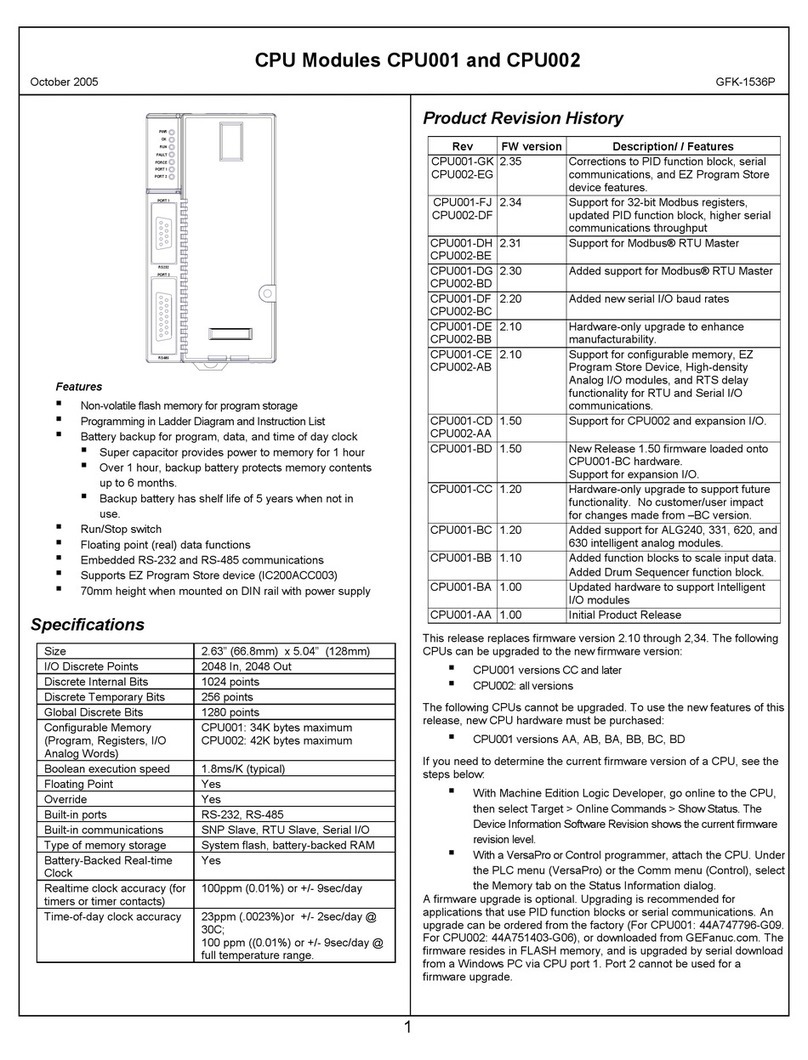

Emerson VersaMax CPU001 User manual

Emerson

Emerson Fisher V250 User manual

Emerson

Emerson SM-EZMotion Module P/N 400361-00 User manual

Emerson

Emerson Fisher N551 User manual

Emerson

Emerson Neotecha NTB User manual

Emerson

Emerson White-Rodgers 764-500 User manual

Emerson

Emerson KTM Series Quick guide

Emerson

Emerson CASH VALVE FRM User manual

Emerson

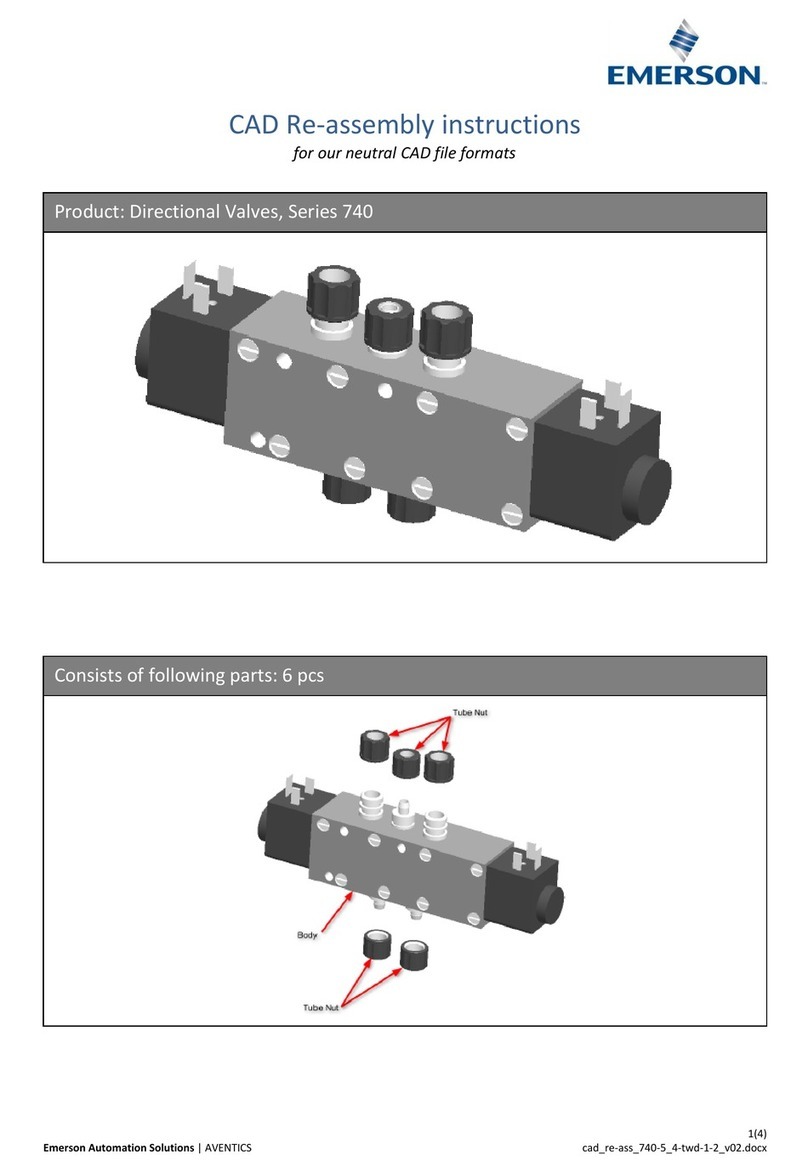

Emerson AVENTICS AV User manual

Emerson

Emerson SI-PROFIBUS User manual

Emerson

Emerson Spence Type N6 User manual

Emerson

Emerson ENARDO 860 Series User manual

Emerson

Emerson Fisher HP User manual

Emerson

Emerson Cash Valve K-10 Manual

Emerson

Emerson Vanessa 30000 Series User manual

Emerson

Emerson Fisher 63EGLP Series User manual

Emerson

Emerson Fisher 8580 User manual

Emerson

Emerson Fisher GX User manual

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual