4

5 COMMISSIONING

A. Connecting to electrical supply

For single acting pneumatic actuator with

solenoid valve wired for normally closed

positions.

1. Ensure that the adjusting nut on the filter

regulator is fully out (anti-clockwise) then

turn on the air supply to the inlet supply of

the filter regulator.

2. Connect the electrical supply to the

solenoidvalve.

3. Energize the solenoid valve.

4. Screw in the adjusting nut on the filter

regulator (clockwise) until the working

pressure is obtained (Refer to certified

General Arrangement drawing for details of

air pressure requirements). The valve stem

(4) will go to the fully instroked position.

5. To ensure correct and safe operation, check

the outstroke by de-energizing the solenoid

valve. As the air pressure is relieved, the

stem (4) will move to the fully outstroked

position.

WARNING!

Care must be taken when exhausting the solenoid

valve that the area close to the valve is kept clear.

Do not attempt to obstruct exhausting orifices

byhand.

6 STORAGE

Indoor storage of valves is recommended.

Ifprolonged storage is anticipated, the valves

should be stored in humidity controlled

storageareas.

If valves are ordered to a more stringent

cleaning and storage procedure, the

recommendations in that procedure should

befollowed.

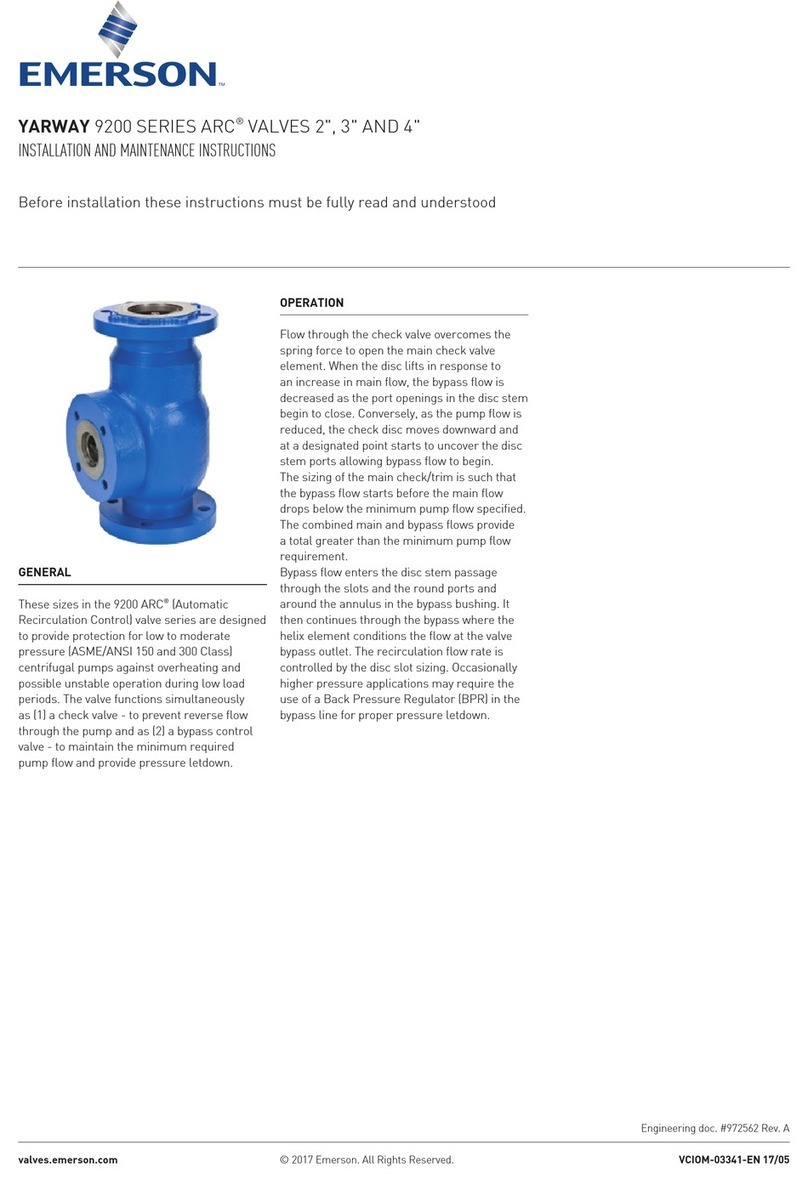

7 INSTALLATION AND WELDING

When valves are received, an enclosed ‘Packing

Note’ will provide an itemised statement of all

valves and parts included in the shipment. The

recipient should check and account for each

item on the list, and then keep this packing note

as a permanent record for these valves/parts.

Unloading the valves should be done with care.

Remember that, although the valve is a rugged

piece of equipment, it may still be damaged by

abusive handling. Skidded or chocked valves

should not be unskidded until immediately

before installation.

Improper installation of a valve can have very

serious consequences, resulting in a possible

malfunction, which may result in extensive

and costly repairs. Compliance with the

following recommendations will do much to

assure optimum performance of the valve

afterinstallation.

It is essential that precautions be taken to

prohibit the entry of foreign debris inside

the valve, which could damage the seating

surfacesbefore and/or after installation.

B. Solenoid valve check

Next, it is necessary to check the functional

operation of the solenoid to ensure that it

responds correctly via the control system.

1. With solenoid valve energized, the stem (4)

and the indicator plate (39) will move to a

fully instroked position. This will indicate the

correct operation of the solenoid. Open limit

switch operation can also be checked at this

stage.

2. Select the ‘close valve’ position via the

control system (for on-load testing) i.e.

solenoid de-energized and check the

actuator has moved to the fully outstroked

position. Closed limit switch operation can

also be checked at this stage.

3. Select the ‘open valve’ position via the

control system (for on-load testing) and

check that the actuator has moved to the

fully instroked position.

4. With the working air pressure still set, a

simulated turbine trip should now be carried

out via the control system to ensure the

correct solenoid response.

5. Local on-load testing can be achieved by

operating the push button on the solenoid

valve. When the actuator is fully outstroked,

release the push button and the pneumatic

actuator will return to the fully instroked

position.

6. After satisfactory completion of the above

steps, fully screw out (anti-clockwise) the

adjusting nut on the filter regulator and de-

energize the solenoid valve. The stem (4) will

move to the fully outstroked position.

When the valve is required to be put into

service, screw in (clockwise) the adjusting

nut on the filter regulator until the working

air pressure is obtained. The stem (4) will

move to the fully instroked position when

the valve is ready for service.

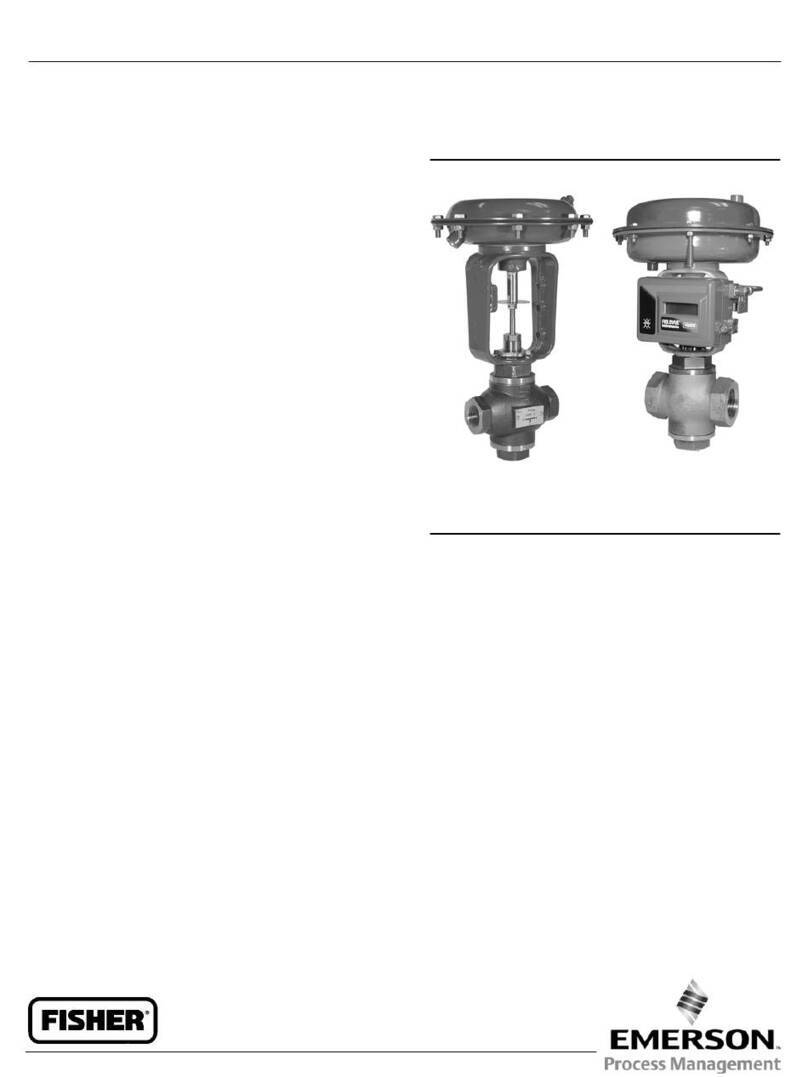

SEMPELL DEWRANCE BLEED STEAM CHECK VALVES

InstallatIon and maIntenance InstructIons