www.valves.emerson.com VCIOM-01412-EN-15/05

© 2012 Emerson. All Rights Reserved

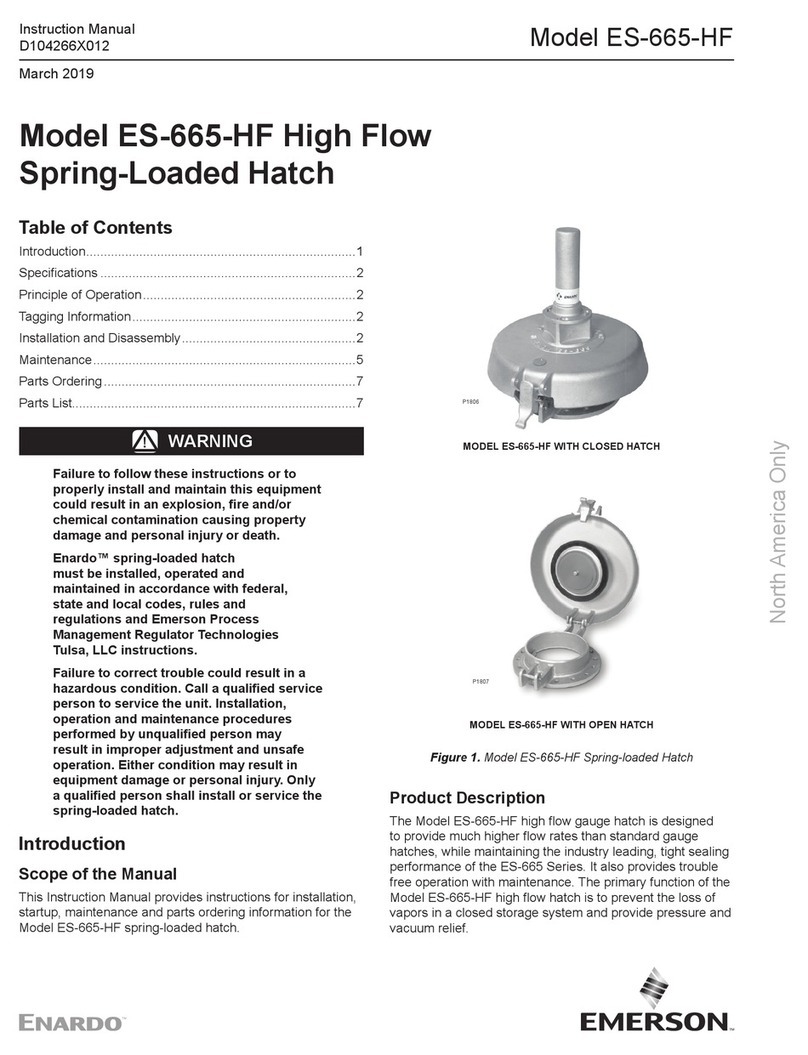

Cast pressure seal - Style A Swing check and tilting disc configuration

SEMPELL DEWRANCE PRESSURE SEAL CHECK VALVES

InstallatIon and MaIntenance InstructIons

SECTION 1 - VALVE STORAGE

1.1 Preparation and Preservation for

Shipment

All valves are properly packed in order

to protect the parts that are subject to

deterioration during transportation and storage

on site. In particular, the following precautions

should be taken:

1. The weld ends surface shall be protected

with suitable protective like Deoxaluminite.

The end shall be closed with plywood or

plastic disc fixed at the edge by strips.

2. The type of packing must be defined in the

Customer’s Order and shall be appropriate

to ensure safe transportation to final

destination and eventual conservation

before installation.

1.2 Handling Requirements

A - Packed Valves

Crates:

Lifting and handling of the packed valves in

crates will be carried out by a fork lift truck, by

means of the appropriate fork hitches.

Cases:

The lifting of packed valves in cases should be

carried out in the lifting points and at the center

of gravity position which have been marked. The

transportation of all packed material must be

carried out safely and following the local safety

regulations.

B - Unpacked Valves

1. The lifting and the handling of these valves

has to be carried out by using appropriate

means and at respecting the carrying limits.

The handling must be carried out on pallets,

protecting the machined surfaces to avoid

any damage.

2. With valves of large dimensions, the sling

and the hooking of the load must be carried

out using the appropriate tools (brackets,

hook, fasteners, ropes) and load balancing

tools in order to prevent them from falling

or moving during the lifting and handling.

CAUTION

For valve handling and/or lifting, the lifting

equipment (fasteners, hooks, etc.) must be sized

and selected while taking into account the valve

weight indicated in the packing list and/or delivery

note. Lifting and handling must be made only by

qualified personnel.

Caution must be taken during the handling to

avoid that this equipment passes over the workers

or over any other place where a possible fall

could cause damage. In any case, the local safety

regulations must be respected.

NOTE:

Storage in an open area for a limited period

can be considered only in case the valves have

appropriate packing (packed in cases lined with

tarred paper, and contents well protected with

barrier sacks).

Do not place consignment packages directly on

the ground.

Do not expose consignment packages to the

weather or directly to the sun.

Check the packaging every two months.

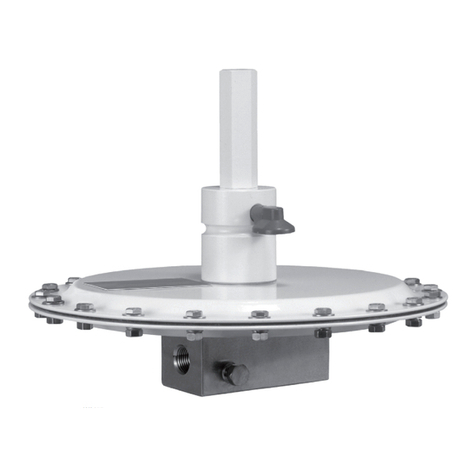

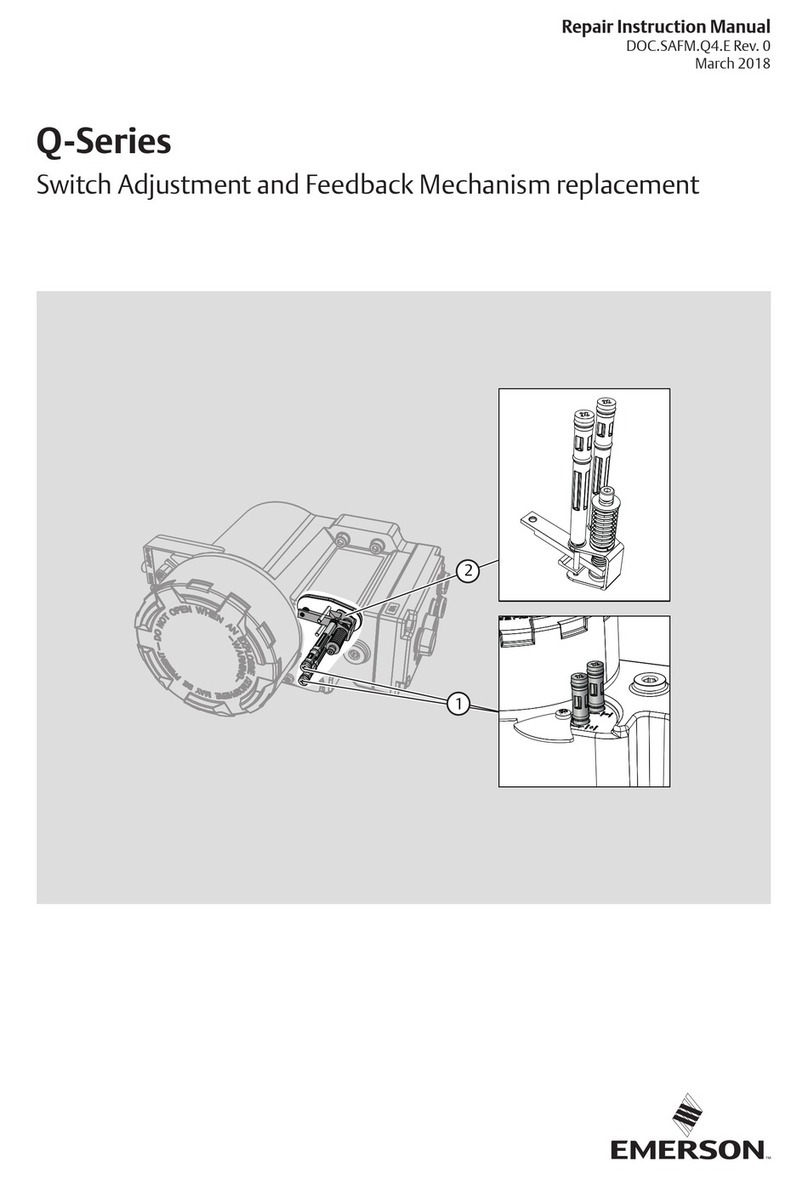

Valve slinging

FIGURE NO. 1

Swing Check and Tilting Disc Valves

1.3 Storage and Preservation before

Installation

In case the valves have to be stored before

installation, the storage has to be carried out

in a controlled way, and has to be performed in

accordance with the following criteria:

1. The valves have to be stocked in a closed,

clean and dry storage room.

2. The disc must be in the closed position,

and the end faces must be protected with

plastic or wooden discs fixed with straps. If

possible, keep the original protection.

3. Periodical checks have to be carried out

in the storage area to verify that the above

mentioned conditions are maintained.

Warning

For valve handling and/or lifting, the lifting

equipment (fasteners, hooks, etc.) must be sized

and selected while taking into account the valve

weight indicated in the packing list and/or delivery

note. Lifting and handling must be made only by

qualified personnel.

Caution must be taken during the handling to

avoid that this equipment passes over the workers

or over any other place where a possible fall

could cause damage. In any case, the local safety

regulations must be respected.