1592026601 XWi70K STD FULL EN r1.6 2022.07.29.docx XWi70K 5/15

Minimum Set Point: (-100.0°C to SET; -148°F to SET) fix the minimum value for the

set point.

Maximum Set Point: (SET to 150.0°C; SET to 302°F) fix the maximum value for the

set point.

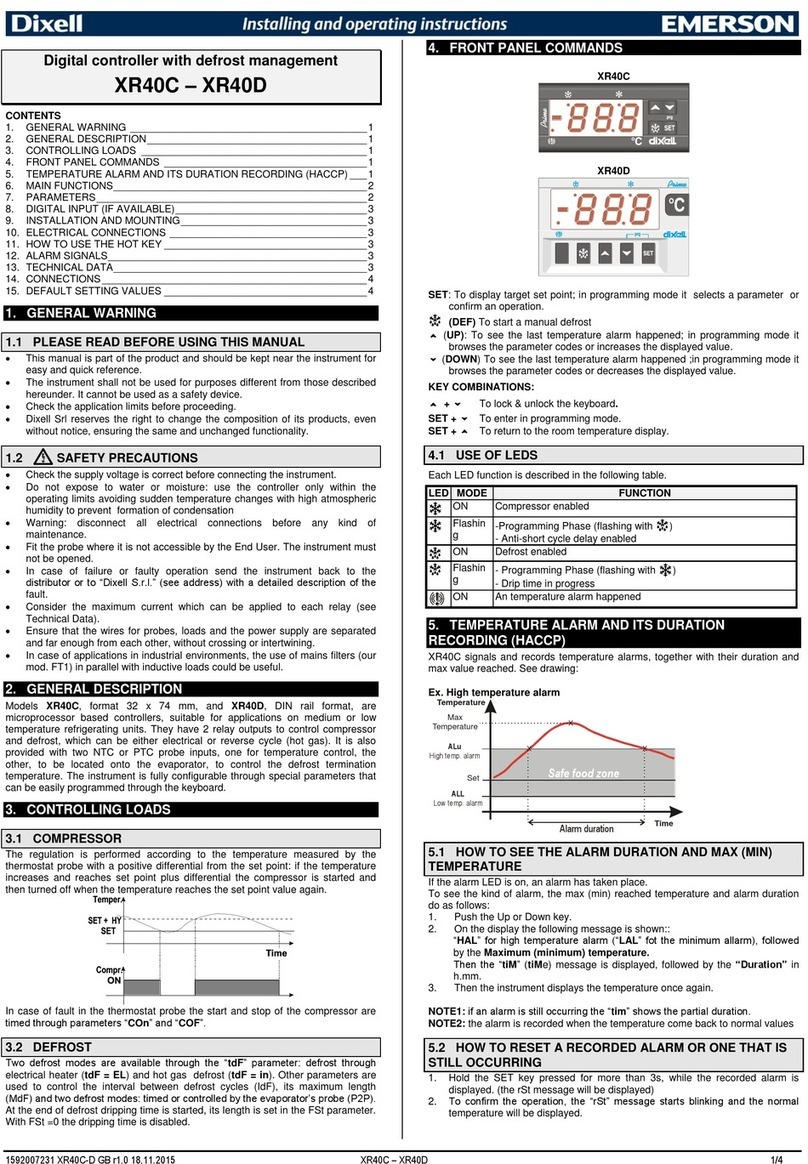

Compressor regulation differential in normal mode: (0.1 to 25.0°C; 1 to 45°F) set

point differential. Compressor Cut-IN is T > SET + HY. Compressor Cut-OUT is

T<=SET.

Proportional band in normal mode: (0.1 to 25.5°C; 1 to 45°F) define a second

regulation band which is used when double ONOFF compressor regulation or a

variable speed compressor is configured.

Output activation delay at start-up: (0 to 255 min) this function is enabled after the

instrument power-on and delays the output activations.

Anti-short cycle delay: (0 to 999 sec) minimum interval between a compressor stop

and the following restart.

Anti-short cycle delay (2nd compressor): (0 to 999 sec) delay before activating

second compressor, depending on regulation mode selected by par. 2CC

Activation mode for 2nd compressor (valid if oAx=CP1 and oAy=CP2): (FUL;

HAF) FUL=second compressor will be activated after AC1 delay. HAF=second

compressor will be activated with step logic.

Enable compressor rotation: (n;Y) n= CP1 is always the first compressor activated.

Y= CP1 and CP2 activation is alternated

Maximum time with compressor ON: (0 to 255min) maximum time with ONOFF

compressor active. With MCo=0 this function is disabled.

Regulation percentage=F(P1; P2) (100=P1; 0=P2): 100=P1 only; 0=P2 only

Maximum duration for Pull Down: (0.0 to 99h50min, res. 10min) after elapsing this

time interval, the super cooling function is immediately stopped.

Pull Down phase differential (SET+CCS or SET+HES+CCS):

(-12.0 to 12.0°C; -21 to 21°F) during any super cooling phase the regulation

SETPOINT is moved to SET+CCS (in normal mode) or to SET+HES+CCS (in

energy saving mode)

Threshold for automatic activation of Pull Down in normal mode

(SET+HY+oHt): (0.0 to 25.5°C; 0 to 45°F) this is the upper limit used to activate the

super cooling function.

Compressor ON time with faulty probe: (0 to 255 min) time during which the

compressor is active in case of faulty thermostat probe. With Con=0 compressor is

always OFF.

Compressor OFF time with faulty probe: (0 to 255 min) time during which the

compressor is OFF in case of faulty thermostat probe. With CoF=0 compressor is

always active.

Probe selection: (ntC; Pt1) ntC=NTC type; Pt1=PT1000 type

Probe P1 calibration: (-12.0 to 12.0°C; -21 to 21°F) allows to adjust any possible

offset of the first probe.

Probe P2 presence: n= not present; Y= present.

Probe P2 calibration: -12.0 to 12.0°C; -21 to 21°F) allows to adjust any possible

offset of the second probe.

Probe P3 presence: n= not present; Y= the defrost is present.

Probe P3 calibration: (-12.0 to 12.0°C; -21 to 21°F) allows to adjust any possible

offset of the third probe.

Probe P4 presence: n= not present; Y= present.

Probe P4 calibration: (-12.0 to 12.0°C; -21 to 21°F) allows to adjust any possible

offset of the fourth probe.

VARIABLE SPEED DRIVE MENU –vSC

Minimum value for Variable Speed Compressor (RPM * 10): (0 to FMA) select

according to the VSC in use

Maximum value for Variable Speed Compressor (RPM * 10): (FMi to 500) select

according to the VSC in use

Minimum value for Variable Speed Compressor (RPM * 10) in Energy Saving

Mode: (0 to EMA) select according to the VSC in use

Maximum value for Variable Speed Compressor (RPM * 10) in Energy Saving

Mode: (EMi to 500) select according to the VSC in use

Value when Variable Speed Compressor is shut down (RPM * 10): (0 to 200) select

according to the VSC in use

PI regulator, temperature sampling time: (00:00 to 42min:30sec)

PI regulator, integral sampling time: (00:00 to 42min:30sec)

Type of Variable Speed Compressor: (nu; FrE) nu = no VSC in use; FrE = VSC with

frequency control mode is used; VC1 = Embraco with serial control; VC2 = SECOP

with serial control.

Signal output variation for Variable Speed Compressor: (0 to 100 Hz or RPM*10)

VSC variation when SET-HY ≤ T ≤ SET+HY

Signal output variation for Variable Speed Compressor: (0 to 100 Hz or RPM*10;

nu)) VSC variation when SET-HY-HY1≤T<SET-HY and SET+HY<T≤SET+HY+HY1

Signal output variation for Variable Speed Compressor: (0 to 100 Hz or RPM*10;

nu)) VSC variation when SET-HY-HY1<T and T>SET+HY+HY1

Variable Speed Compressor (in %) during any Pull Down: (0 to 100%) this value

is always calculated using FMi and FMA limits. 0=function disabled.

Compressor speed (in %) in case of any probe error during Con interval: (0 to

100%) this value is always calculated using FMi and FMA limits.

Compressor speed (in %) during any defrost cycle (valid if tdf=in): (0 to 100%)

this value is always calculated using FMi and FMA limits.

Compressor speed (in%) during a pre-defrost phase (valid if tdf=in): (0 to 100%)

this value is always calculated using FMi and FMA limits.

PI regulator, max interval for output variation: (tLv to 255 sec)

PI regulator, min interval for output variation: (1 sec to tHv)

PI regulator, range for output value calculation (RPM * 10): (0=disabled; 1 to 255

RPM*10)

PI regulator, delay before range drift: (0 to 255 sec)

PI regulator, divisor for PI response time reduction (acts on both par. tSt and

iSt): (1 to 10)

Continuous control ON in normal mode: (n; Y) Y= VSC is never stopped during

regulation.

Continuous control ON in energy saving mode: (n; Y) Y= VSC is never stopped

during regulation.

Compressor speed threshold to activate lubrication (valid for variable speed

compressors only, 0=disabled): (nu; 1 to 100%; OFF) nu = not used; 1 to 100% =

select the percentage to activate function; OFF = compressor is stopped when the

condition is reached

Time range with compressor speed below MnP to activate lubrication cycle:

(00:00 to 24h00min) time before activating the lubrication function

Time range with compressor speed at 100% to activate lubrication cycle: (0 to

255 min) VSC will be forced to 100%, for tMA, after activating the lubrication function.

NOTE: if MnP=OFF, VSC will be stopped for tMA

Number of serial controlled VSC: (1 to 2) number of VSC connected

Serial address for compressor 1: (1 to 247)

Serial address for compressor 2: (1 to 247)

VARIABE SPEED FAN (MODBUS) - vSF

Number of serial condenser fans (0=disabled): (0 to 4) number of variable

speed condenser fans controlled via Modbus. Only EMB ventilators are supported.

Serial addresses for condenser fans: (1 to 247) up to 4 condenser fan can be

controlled in parallel (all of them will use the same speed value).

Serial baudrate for condenser fan (kbaud): 4.8=4800baud; 9.6=9600baud;

19.2=19200baud

Direction of rotation for condenser fan: (Lt; rt) Lt = left rotation; rt = right rotation

Time with condenser efficiency function activated: (0 to 255 sec) interval for

condenser fans cleaning function.

Default configuration sent to condenser fan (at power on): (n; Y)

Temperature measurement unit: (°C; °F) °C = Celsius; °F = Fahrenheit.

Temperature resolution: (dE; in) dE = decimal; in = integer.

Remote keyboard visualization: (P1; P2; P3; P4; Set; dtr) Px=probe “x”; Set=set

point; dtr=percentage calculated from P1 and P2 and using par. dtr.

Temperature display delay: (0.0 to 20min00sec, res. 10 sec) when the temperature

increases, the display is updated of 1°C or 1°F after this time.

Probe visualization percentage, F(P1; P2): (1 to 99)with dtr=1 the display will show

this value VALUE=0.01*P1+0.99*P2

Defrost mode: in=fixed intervals; rtC=following real time clock

Defrost type: EL=electrical heaters; in=hot gas

Probe selection for defrost control: (nP; P1; P2; P3; P4) nP=no probe; Px=probe

“x”.

Probe selection for 2nd defrost control: (nP; P1; P2; P3; P4) nP=no probe;

Px=probe “x”.

End defrost temperature: (-55 to 50°C; -67 to 122°F) sets the temperature measured

by the evaporator probe (dFP), which causes the end of defrost cycle.

End 2nd defrost temperature: (-55 to 50°C; -67 to 122°F) sets the temperature

measured by the evaporator probe (dFP), which causes the end of defrost cycle.

Interval between two successive defrost cycles: (0 to 120 hours) determines the

time interval between the beginning of two defrosting cycles.

Maximum length of defrost cycle: (0 to 255 min; 0 means no defrost) when P2P=n

(no evaporator probe presence) it sets the defrost duration, when P2P=Y (defrost end

based on evaporator temperature) it sets the maximum length for the defrost cycle.

Maximum length of 2nd defrost cycle: (0 to 255 min; 0 means no defrost) when

P2P=n (no evaporator probe presence) it sets the defrost duration, when P2P=Y

(defrost end based on evaporator temperature) it sets the maximum length for the

defrost cycle.

Start defrost delay: (0 to 255 sec) delay in defrost activation.

Compressor off-cycle before starting any defrost: (0 to 255 sec) interval with

compressor OFF before activating hot gas cycle

Displaying during defrost: (rt; it; SEt; dEF; Coo) rt = real temperature; it = start

defrost temperature; SEt = set point; dEF = label “dEF”; Coo = when a defrost ends,

it shows the label “Coo” until the regulation temperature is above SET+HY+HY1

Temperature display delay after any defrost cycle: (0 to 255 min) delay before

updating the temperature on the display after the end of any defrost.

Draining time: (0 to 120 min) regulation delay after finishing a defrost phase

Drain heater enabled after draining time (par. Fdt): (0 to 255 min) the relative output

will stay on after draining time.

Sampling time to calculate the average compressor speed before any desfrost

cycle: (0 to 255 min) the average compressor speed is used only with VSC.

Defrost cycle enebled at stat-up: (n; Y) enables defrost at power on.

Pre-defrost time: (0 to 255 min) enable a lower setpoint (SET-1°C or SET-2°F) before

activating the defrost phase.

Automatic defrost (at the beginning of any energy saving mode): (n; Y) n=function

disabled; Y=function enabled

Optimized defrost: (n;Y) n= function disabled; Y= the controller needs a temperature

probe placed on the evaporator surface to monitor the presence of ice during any

defrost phase.

Type of synchronized defrost: (n; SYn; nSY; rnd) n= function disabled; SYn =

synchronized, all devices connected will start a defrost phase at the same time. nSY

= de-synchronized, all devices connected will delay the beginning of the same defrost

phase; rnd = random defrost function.

Differential temperature for latent heating control (0.1 to 1.0 °C) to catch the latent

heating phase during any defrost

Number of connected controllers for special defrost operations (valid if

Syd=SYn, nSY or rnd): (1 to 20) number of devices connected to the same network

for syncro, desyncro or random defrost.

Probe selection for evaporator fan: (nP; P1; P2; P3; P4) nP=no probe; Px=probe “x”.