3

Optional parameters

(recommended factory setting for majority of applications)

Factory Field

Code

Parameter description & choices Min Max

Setting

Setting

uu Start valve opening (%) 10 100 50

u9 Start opening duration (second) 1 30 5

uL Low superheat alarm function 0 2 1

0 = disable (for ooded evaporator)

1 = enable auto reset 2 = enable manual reset

Cut-out at 1°F (if it maintains 1 min.); Cut-in immediately at 6°F

u5 Superheat set-point (°F)

If uL enabled (auto or manual) 5.4 54 10.8

If uL disabled 0.9 54 10.8

u2 MOP function 0 1 1

0 = disable 1 = enable

u3

MOP set-point (°F) saturation temperature

* * X

Factory setting is according to selected refrigerant (u0):

+55°F for R22 +59°F for R134a +45°F for R507

+45°F for R404A +59°F for R407C +59°F for R410A

+122°F for R124 +23°F for R744

5 Units conversion (only for u3, u5,

1) 0 1 0

0 = °C, K, bar 1 = °F, R, psig

(Psig values are divided by 10. Example: Display 12.5 is 125 psig)

1 Value to show 0 4 0

0 = Measured superheat (F) 1 = Measured evaporator pressure (psi)

2 = Valve opening (%) 3 = Measured coil-out temp. (°F)

4 = calculated evaporating temperature (°F) from the pressure

b1

Battery error management, when battery

0 3 2

is defective (EC3-X33 only), see below:

Alarm Reset possibility after

Value Display Alarm Relay Valve recovery/replacement

0 – – Regulating –

1 Ab – Regulating –

2 Ab Signalling Fully close Auto

3 Ab Signalling Fully close Manual

(blinking)

Main parameters (must be checked and modied if necessary)

Factory Field

Code

Parameter description & choices Min Max

Setting

Setting

H5 Password 1 199 12

u0 System Refrigerant 0 7 1

0 = R22; 1 = R134a; 2 = R507; 3 = R404A; 4 = R407C;

5 = R410A; 6 = R124; 7 = R744 (subcritical application)

uP Installed pressure sensor type 0 1 0

0 = PT4-07M (for R22/R134a/R507/R404A/R407C/R124)

1 = PT4-18M (for R410A)

2 = PT4-30M (for R744, subcritical)

ut Installed valve type 1 5 5

1 = EX4; 2 = EX5; 3 = EX6; 4 = EX7; 5 = EX8

* Min. and Max. setting values are dependant to selected type of refrigerant.

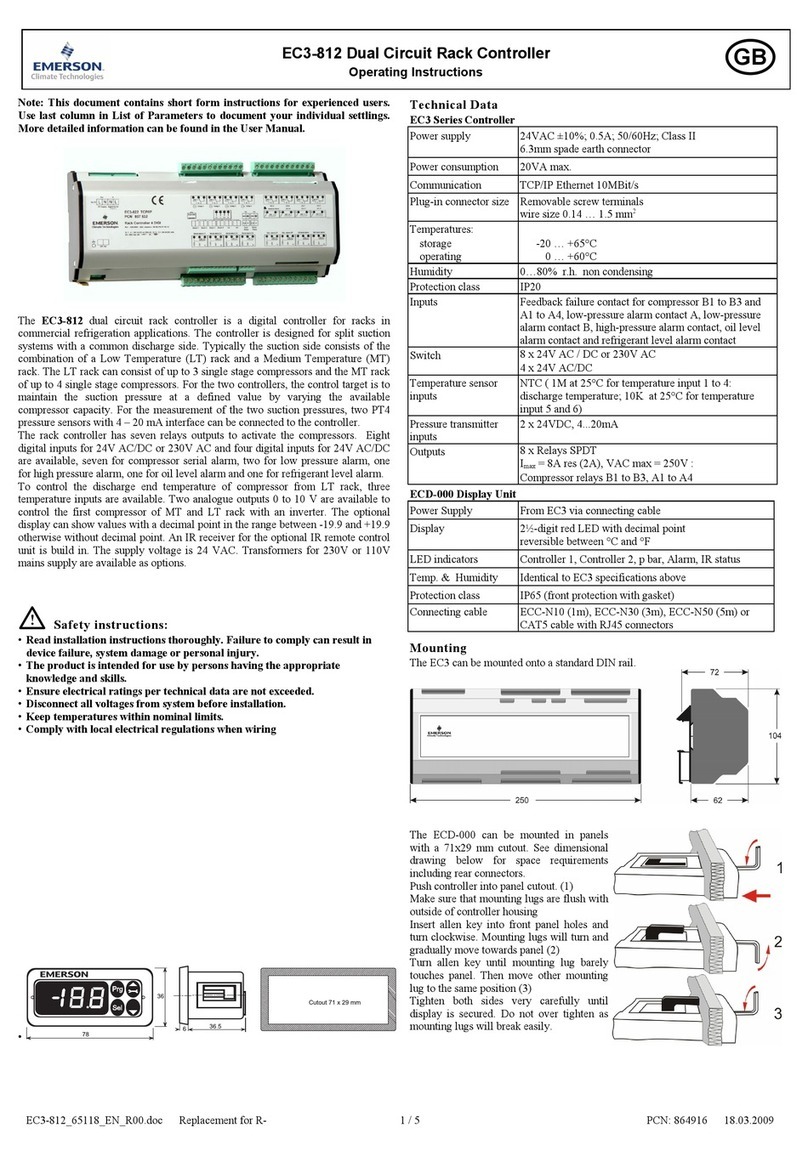

Mounting of ECD-002

ECD-002 can be installed at any time also during operation.

• ECD-002 can be mounted in

panels with 2.8x1.1 in cutout

• Push controller into panel cut-

out.(1)

• Make sure that mounting lugs are

ush with outside of controller

housing

• Insert allen key into front panel

holes and turn clockwise. Mount-

ing lugs will turn and gradually

move towards panel (2)

• Turn allen key until mounting lug

barely touches panel. Then move

other mounting lug to the same

position (3)

•Tighten both sides very carefully

until keypad is secured. Do not

over tighten as mounting lugs will

break easily.

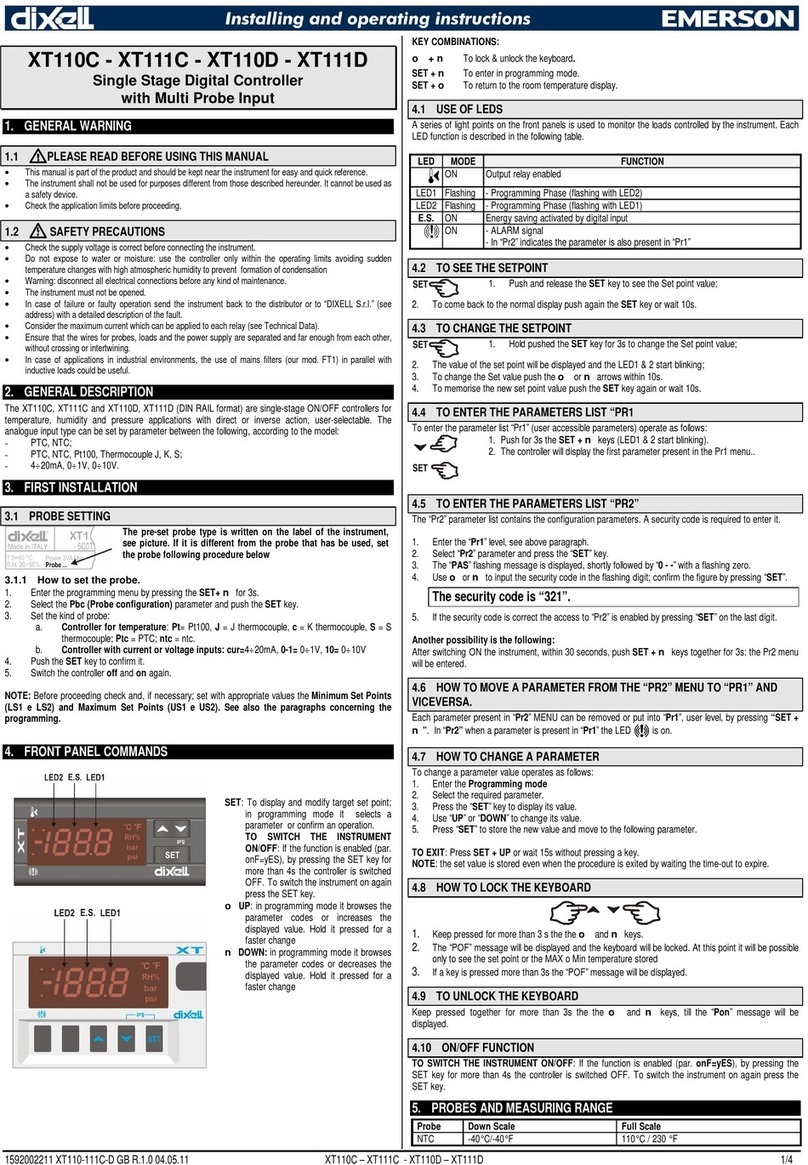

Alarm Related Alarm Requires manual reset

code Description parameter relay Valve What to do? after resolving alarm

E0 Pressure transmitter error - Signalling Fully close Check wiring connection and measure the signal 4 to 20 mA No

E1 Temperature sensor error - Signalling Fully close Check wiring connection and measure the resistance of sensor No

A

EX4…EX8 electrical - Signalling - Check wiring connection and measure the resistance of winding No

connection error

AL Low superheat (<1°F) uL: 1 Signalling Fully close Check wiring connection and operation of valve No

AL blinking uL: 2 Signalling Fully close Yes

Ab b1: 1 - Regulating Battery potentially does not have enough charge to close valve in case -

Ab Battery error b1: 2 Signalling Fully close of main power supply interruption. May occur temporarily with new -

Ab blinking b1: 3 Signalling Fully close controllers or after long storage but should disappear when battery is Yes

charged sufciently. If Ab remains active even when battery is charged,

battery may be defective and should be replaced.

Er Data error display – - - - Data send to the display is out of range. Check temperature No

out of range and pressure sensor.

Note: When multiple alarms occur, the highest priority alarm is displayed until being cleared,

then the next highest alarm is displayed until all alarms are cleared. Only then will param-

eters be shown again.

Message

— No data to display

The display will show an “—” at start up and when no data is sent to ECD-002

Error/Alarm Handling

Checking system operating conditions

The data to be permanently shown on the display can be selected by the user

(parameter

1). It is possible to temporarily display these values. However,

this function is not available in an alarm condition. The display will show for

one second the numerical identier of the data (see

1 parameter) and then

the selected data. After 5 minutes, the display will return to the value selected

by parameter

1.

Service/Troubleshooting

Symptom Cause Action

Operating superheat is several degrees higher or Incorrect signal from pressure or 1- Check the sensors

lower than set-point temperature sensors 2- Make sure ECN-N60 temperature sensor is used

3- For optimum accuracy, please use:

PT4-07M for R22/R134a/R507/R404A/R407C/R124

PT4-18M for R410A

PT4-30M for R744

4- Make sure the sensor cables are not installed along

with other high voltage cables

Operating superheat is too low i.e. compressor wet running 1- Incorrect wiring of ECVs 1- Check the wiring

2- Defective sensors 2- Check the sensor

Valve is not fully closed 1- The digital input is ON (24V) 1- Valve is shut off only when the digital input is turned off (0V)

2- Wrong setting of parameter ut. 2- Check the setting of parameter ut

Instable superheat (hunting) Evaporator is designed to operate Increase the superheat set-point

at higher superheat

Valve opens when EC3 commands to close and vice versa Wrong wiring between EC3-X33 Correct the wiring

and valve

EX8 is not able to open at high differential pressure Wrong setting of parameter ut Check the parameter ut. (Larger valve requires higher torque

and higher current)

Superheat set-point is shifting after several months of Stepper motor driven valves

Do not apply permanent 24V digital input. Interrupt digital input

uninterrupted operation or permanent jumper of 24V require synchronization once every week for 5 seconds if compressor never stops.

digital input