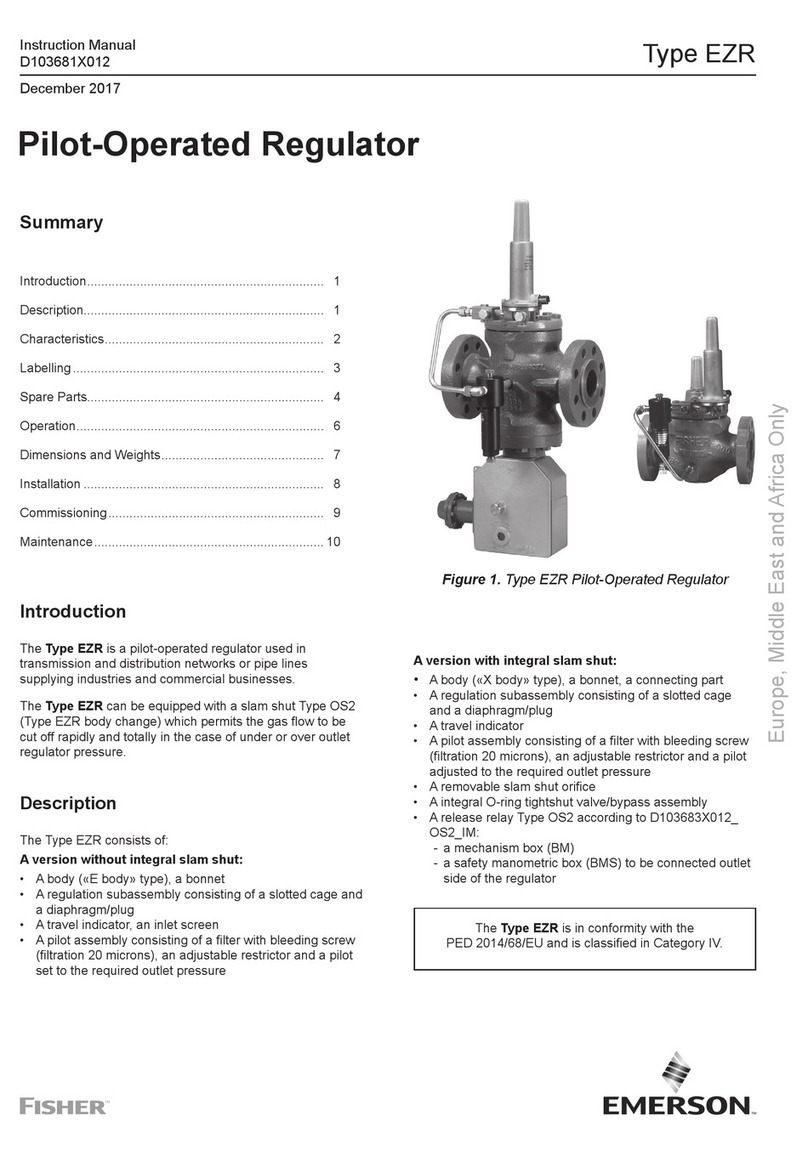

Introduction

This installation guide provides instructions for

installation, startup and adjustment. To receive a copy

of the Instruction Manual, contact your local Sales

Ofce or view a copy at www.sher.com. For further

information refer to: 67C Series Instruction Manual,

form 5469, D102601X012.

P.E.D. Category

This product may be used as a safety accessory with

pressure equipment in the following Pressure Equipment

Directive categories. It may also be used outside of the

Pressure Equipment Directive using sound engineering

practice (SEP) per table below. For information on the

current PED revision see Bulletin: D103053X012.

PRODUCT SIZE CATEGORY FLUID TYPE

1/4 NPT SEP 1

Body Size and End Connection Style

1/4 NPT

17.2 bar / 250 psig

3.4 bar / 50 psig over outlet pressure setting

All Pressure Retaining Components have been

proof tested per PED

0 to 1.4 bar / 0 to 20 psig

0 to 2.4 bar / 0 to 35 psig

0 to 4.1 bar / 0 to 60 psig

0 to 8.6 bar / 0 to 125 psig

Standard Bolting: -29 to 82°C / -20 to 180°F

Stainless Steel Bolting: -40 to 82°C / -40 to 180°F

Polyethylene Filter(3) (Standard):-18 to 82°C /

0 to 180°F

Polyvinylidene (PVDF), Stainless steel or Glass Filter

(Optional): -18 to 149°C / 0 to 300°F

Diaphragm and Low

-51 to 82°C / -60 to 180°F

-40 to 82°C / -40 to 180°F

!

WARNING

in accordance with international and

Clean out all pipelines before installation of the

regulator and check to be sure the regulator has not

been damaged or has collected foreign material during

shipping. For NPT bodies, apply pipe compound to

the external pipe threads. For anged bodies, use

suitable line gaskets and approved piping and bolting

1. The pressure/temperature limits in this Installation Guide and any applicable standard or code limitation should not be exceeded.

2. Silicone (VMQ) is not compatible with hydrocarbon gas.

3. Do not use in high aromatic hydrocarbon service.

67C and 67CF Series

Installation Guide

D102601X014

English – March 2017