912N Series

3

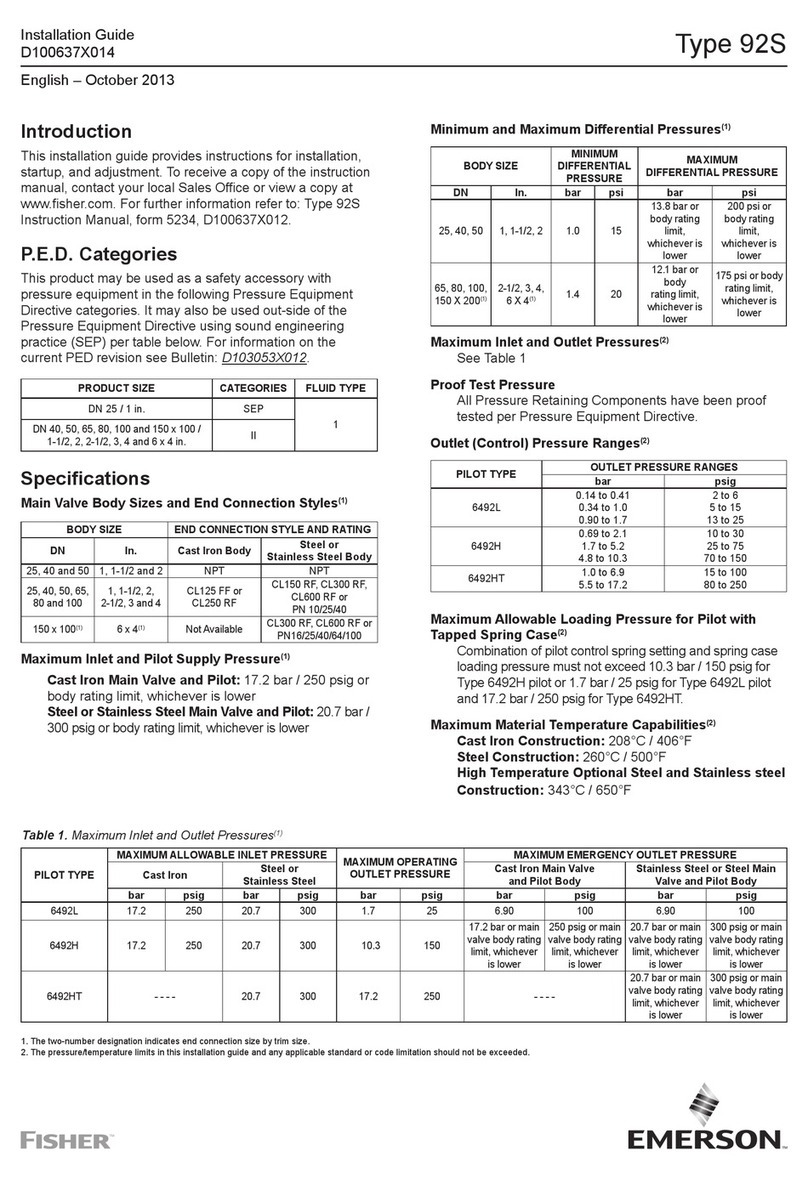

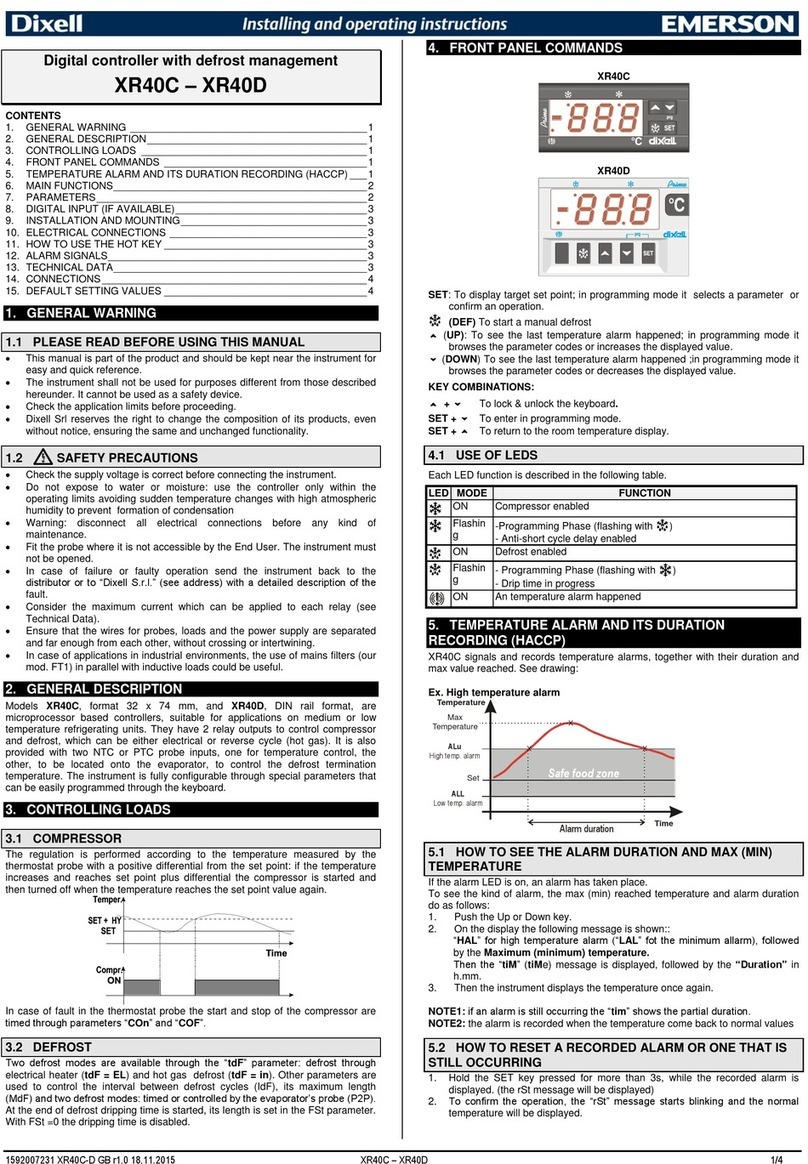

If outlet pressure adjustment is necessary, monitor

the outlet pressure with a gauge while performing the

following procedures:

1. For units without a handwheel, unscrew the closing

cap (key 3) and insert a screw driver blade into the

adjusting screw (key 4).

2. Slowly turn the adjusting screw or handwheel

clockwise to increase or counterclockwise to

decrease the output pressure setting.

3. With the output pressure adjusted to the desired

value, replace the closing cap on units without

a handwheel.

Shutdown

Close the nearest upstream shut-off valve, then close the

nearest downstream shut-off valve, and vent pressure from

the outlet of the regulator.

Maintenance

Regulator parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency of

inspection and replacement of parts depends on the severity

of service conditions or the requirements of local, state, and

federal rules and regulations.

!

WARNING

To avoid personal injury or equipment

damage, do not attempt any maintenance

or disassembly without rst isolating the

regulator from system pressure and relieving

all internal pressure from the regulator.

This procedure is to be performed if changing the control

spring for one of a different range, or for inspecting, cleaning,

or replacing any other parts. Key numbers are referenced

in Figures 2 and 3.

Note

If sufcient clearance exists, the regulator body

(key 1) can remain in the line during spring

replacement or other maintenance procedures.

Control Spring Replacement

Refer to Figure 2 on units without the handwheel, unscrew

the closing cap (key 3) and turn the adjusting screw out of

the spring case. Lift out the control spring (key 5).

Refer to Figure 3 on units with a handwheel (key 4), turn the

handwheel counterclockwise until the tension is relieved from

the control spring (key 5). Unscrew the nut at the base of the

handwheel and lift the handwheel off the spring case (key 2).

Lift out the adjusting screw (key 4) and the control spring.

Replace the control spring and complete the assembly

by replacing the adjusting screw and the closing cap or

handwheel. Adjust the spring tension as described in the

Startup section.

Diaphragm and Relief Valve Replacement

Remove cap screws (key 14) and separate the spring case

from the valve body. Remove the control spring (key 5) and the

diaphragm (key 15) along with the diaphragm head (key 10),

the relief valve seat (key 9) and the relief valve spring (key 6).

Separate these parts by removing the pin (key 8) and the spring

seat (key 7).

To reassemble the regulator, rst assemble the relief valve

spring assembly, then replace the relief valve spring assembly,

the diaphragm, the diaphragm head, and t the spring case

to the body. Install and tighten cap screws (key 14) in a

crisscross manner. Adjust the control spring tension as

described in the Startup section.

Parts Ordering

When corresponding with the local Sales Ofce about this

regulator, include the type number, date of manufacture, and

all other pertinent information from the labels. Specify the

eleven-character part number when ordering new parts from

the following parts list.

Parts List

Key Description Part Number

1 Body, Zinc

1/4 x 1/4 NPT

0.073-inch (1,9 mm) port diameter 3D377144042

1/4 x 3/8 NPT

0.073-inch (1,9 mm) port diameter 3B782444042

1/4 x 1/4 NPT

0.094-inch (2,4 mm) port diameter T4000544042

1/4 x 3/8 NPT

0.094-inch (2,4 mm) port diameter 3B892744042

2 Spring Case 3E294444042

3 Closing Cap

912N Series with handwheel, Brass 1C234414012

All others, Plastic T13269T0012

4 Adjusting Screw

912N Series with handwheel, Zinc/Steel 14B7140X022

All others, Plastic T1027706992

5 Regulator Spring, Steel See Table 1

6 Relief Valve Spring, Steel 1B784827012

7 Spring Seat, Steel 1B783425072

8 Pin, 302 Stainless steel 1B783535032

9 Relief Valve Seat, Zinc pusher (relieve valve post) 2B783044012

10 Diaphragm Plate, Zinc-plated Steel 1B783824132

11 Disc Holder GE19397X012

12 Fulcrum Rod, 302 Stainless steel 0U091435032

13 Machine Screw, Steel (2 required) T12748T0012

14 Machine Screw, Steel (6 required) 1V4131X0012

15 Diaphragm, Nitrile (NBR)

Spring Range: 3 to 24-inches w.c.

(7 to 60 mbar) 1B7837T0022

Spring Range: 0.5 to 5 psi

(0,03 to 0,34 bar) 1B783702012

16 Vent Screen, 304 Stainless steel 0W086343062