Instruction Manual

D104304X012

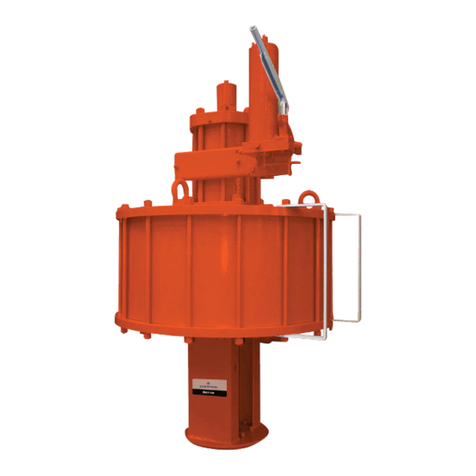

ATI Piston Actuator

June 2023

3

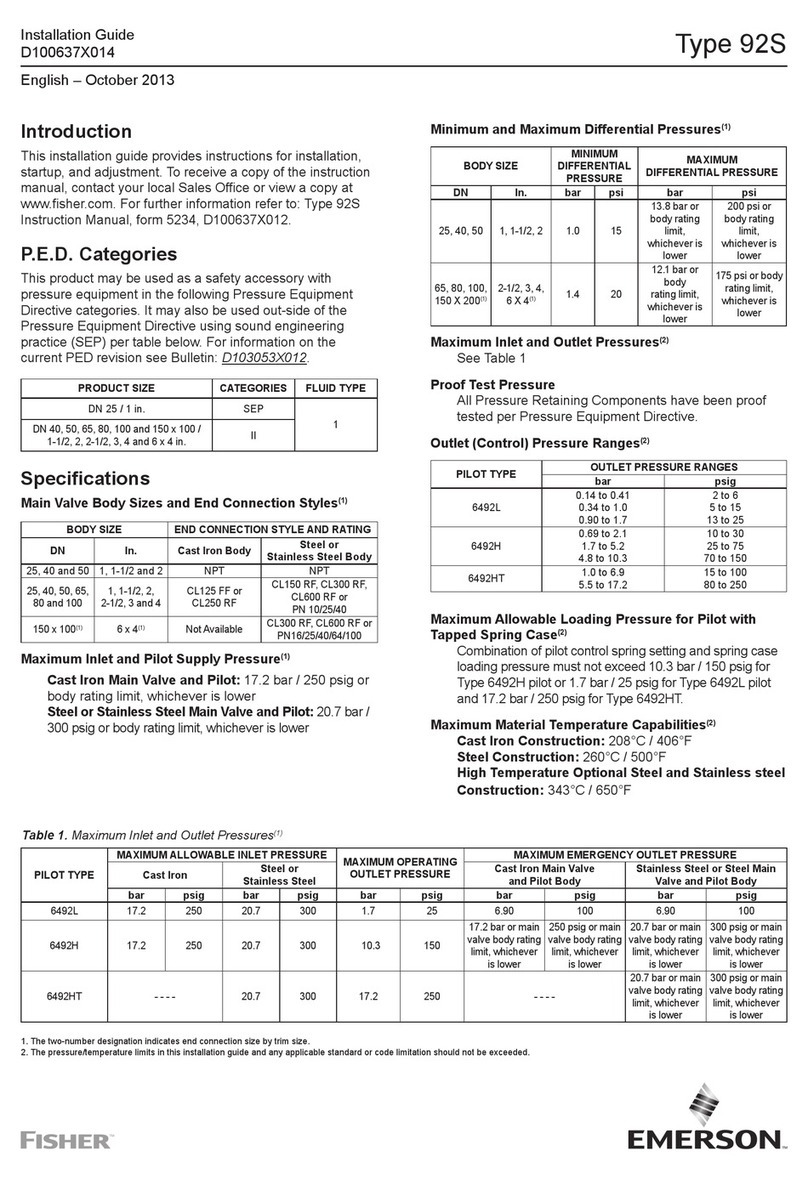

Maximum Pressure Limitations

The piston of the ATI actuator is pressure operated. This air pressure provides energy to compress the spring, to stroke

the actuator, and move the piston away from or towards the valve. The following explanations describe the maximum

pressure limits for an actuator. Refer to table 1 for maximum values.

WARNING

To avoid personal injury or parts damage, do not exceed the Maximum Pressures listed in table 1.

Exceeding any of the maximum pressures can result in uncontrolled movement of parts, damage to actuator parts and the

control valve, and loss of control of the process. Use pressure‐limiting or pressure‐relieving devices to prevent casing

pressure from exceeding these limits.

D Maximum Casing Pressure for Actuator Sizing: This is considered the standard full operating pressure. A full stroke

of 4.0 inches of the valve is expected at this pressure. If a full stroke is not achieved, consult the troubleshooting

section of this manual.

D Maximum Casing Pressure: If the Maximum Casing Pressure is exceeded, damage to the actuator might result.

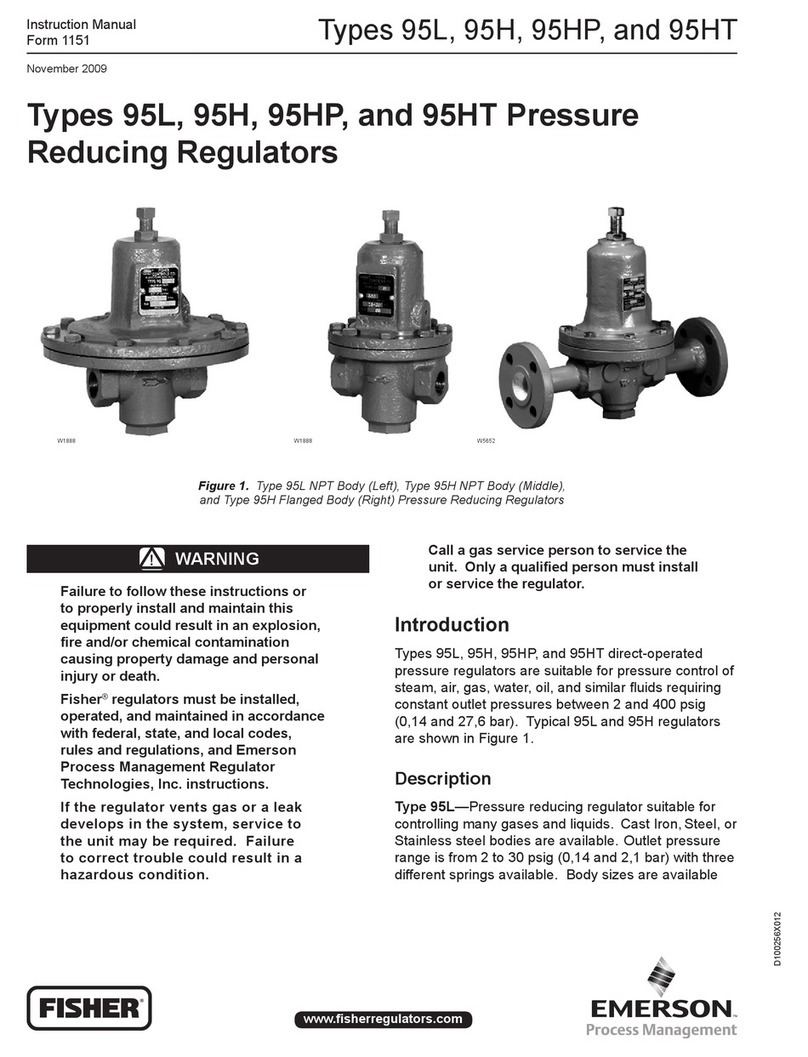

Principle of Operation

The ATI actuator positions the valve plug in response to varying pneumatic loading pressure on the actuator. For the

SRE actuator, the actuator stem moves up as the loading pressure is increased on the bottom of the piston. As the

loading pressure is decreased, the spring forces the actuator stem down. For the SRR actuator, the actuator stem

moves down as the loading pressure is increased on the top of the piston. As the loading pressure is decreased, the

spring forces the actuator stem up.

The piston actuator has been selected to meet the requirement of the application and, in service, the actuator will

produce full travel of the valve with the piston pressure as indicated on the nameplate.

Lifting Guidelines

WARNING

Failure to follow these lifting guidelines and accepted lifting and rigging practices could result in property damage and

personal injury or death.

All lifting and rigging must be completed in accordance with federal/national/provincial, state and local regulations and

applicable lifting and rigging equipment standards. Only personnel trained in proper lifting and rigging practices shall

perform valve/actuator assembly lifting, rigging and installation. Because each lift will be unique, the method of lifting the

valve assembly, the correct location for attaching and lifting the valve assembly, and what the valve assembly will do when

lifted shall be considered for each lift.

Lifting and rigging equipment used to lift, install or remove a valve assembly or component must be properly selected and

sized for the weight and configuration of the valve assembly or component being lifted. The weight of the complete valve

assembly, including attached accessories, must be taken in consideration for this purpose. The lifting and rigging

equipment must be properly maintained and inspected for damage before each use.

If the valve is supplied with an actuator or handwheel, do not use the actuator or handwheel to lift the complete valve

assembly. Lifting lugs attached to the actuator must not be used to lift the complete valve assembly unless clearly marked

as being rated to support the complete valve assembly weight.

Lifting lugs or other lifting equipment attached to the valve or actuator must never be used to lift or support the weight of

attached piping.