Standard Features for All Systems

5

STANDARD FEATURES FOR ALL SYSTEMS

All Liebert distribution and conditioning systems

incorporate standard features that ensure load pro-

tection and simplify maintenance.

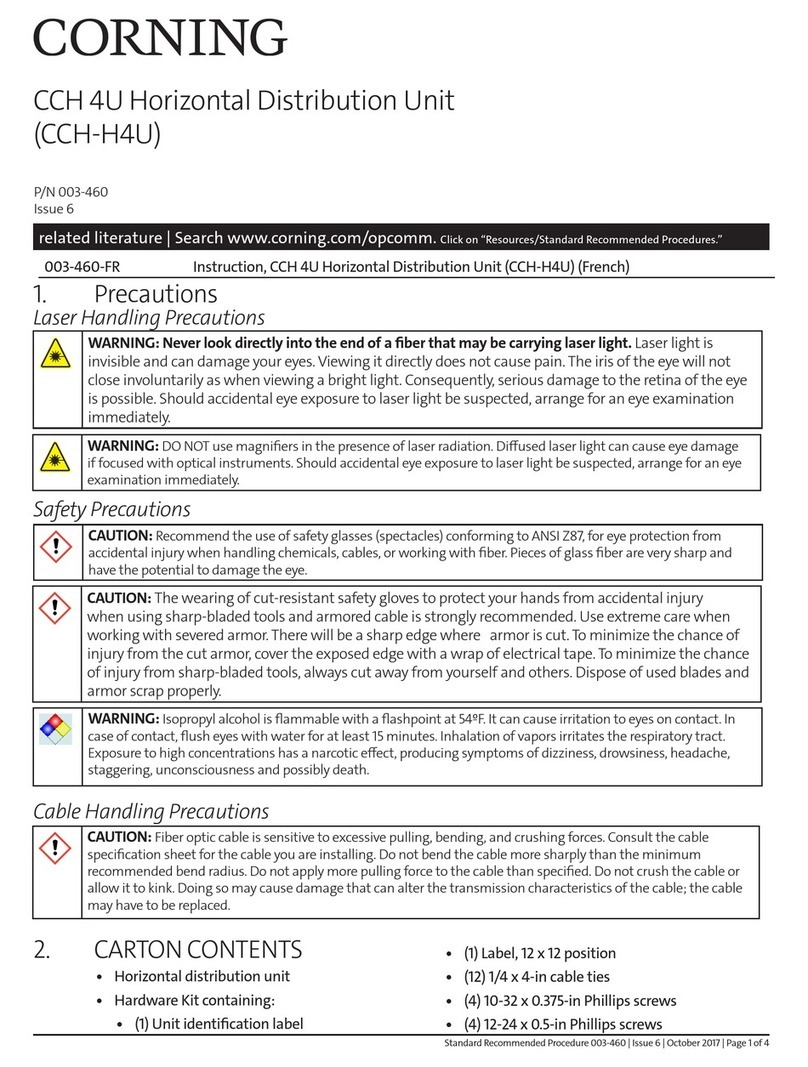

Precision Power Centers use quality, dry type,

shielded isolation transformers for noise reduction

up to 120 dB, with harmonic voltage distortion of

0.5 percent. Depending on kVA capacity, output

impedance is between 3 and 5.5 percent, while full-

load efficiency is between 96.5 and 98 percent.

The transformer has temperature sensors in the

windings to provide an alarm if internal temperature

exceeds 180°C. It will shut down the system if inter-

nal temperature exceeds 200°C. Full Class H 220°C

transformer insulation and all copper windings are

used for long life and efficient operation.

A main input circuit breaker provides either manual

control, or automatic shutdown of the system in the

event of an overcurrent condition. The breaker is

sized for 125 percent of the system input full load

amperes. In addition to manual and thermal-mag-

netic trip, the input breaker can be tripped by an

electrically actuated shunt trip mechanism. As a

standard feature, the shunt trip of the input circuit

breaker is activated by the 200°C temperature sen-

sor, local Emergency Power Off switch, and Manual

Restart circuit.

The local Emergency Power Off (EPO) switch is an

illuminated push button, easily accessible for emer-

gency shutdown, but fully guarded by a hinged cover

to prevent accidental operation.

The manual restart circuit shunt-trips the main

input breaker whenever input power fails. This iso-

lates the system from repetitive power applications

during fault-clearing operations by the utility, and

allows an orderly restart of the system when normal

power returns.

The manual restart circuit can be disabled by the

manual restart select switch. The auto position of the

switch defeats manual restart, and allows the condi-

tioner to automatically restart when power returns.

Auto restart is useful for unattended remote sites

where the load can automatically restart, and in

those applications where the manual restart function

is provided elsewhere in the system.

The low-voltage shunt trip circuit also allows system

shutdown by external relays, Remote Emergency

Power Off (REPO) switches, or other remote devices.

A double-pole, double-throw (dpdt) building interface

relay is powered by a 24 VDC supply from the output

of the unit. Energized whenever the system is on, the

relay drops out if the output voltage disappears. The

relay can be used for remote alarming of system

shutdown, or shutdown interface with additional

loads such as environmental control units.

Power conditioner system components are housed in

a welded steel frame with removable panels for max-

imum accessibility to the interior. For safety and

security, any panels that provide access to high volt-

age require a tool for removal.

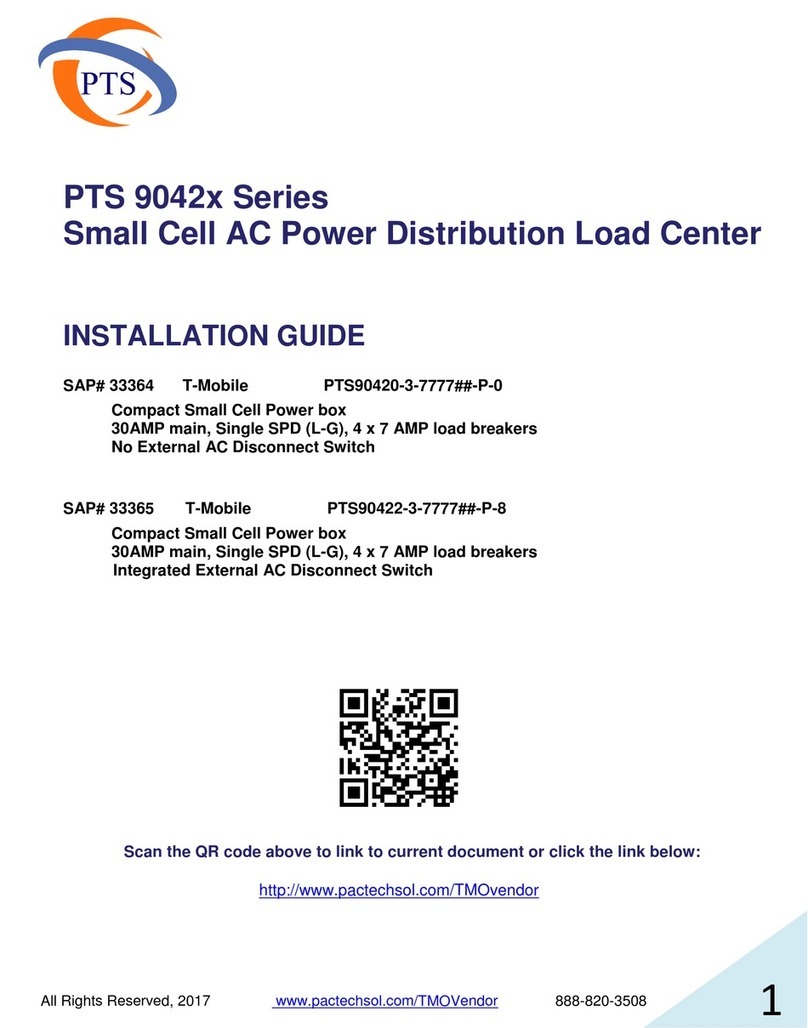

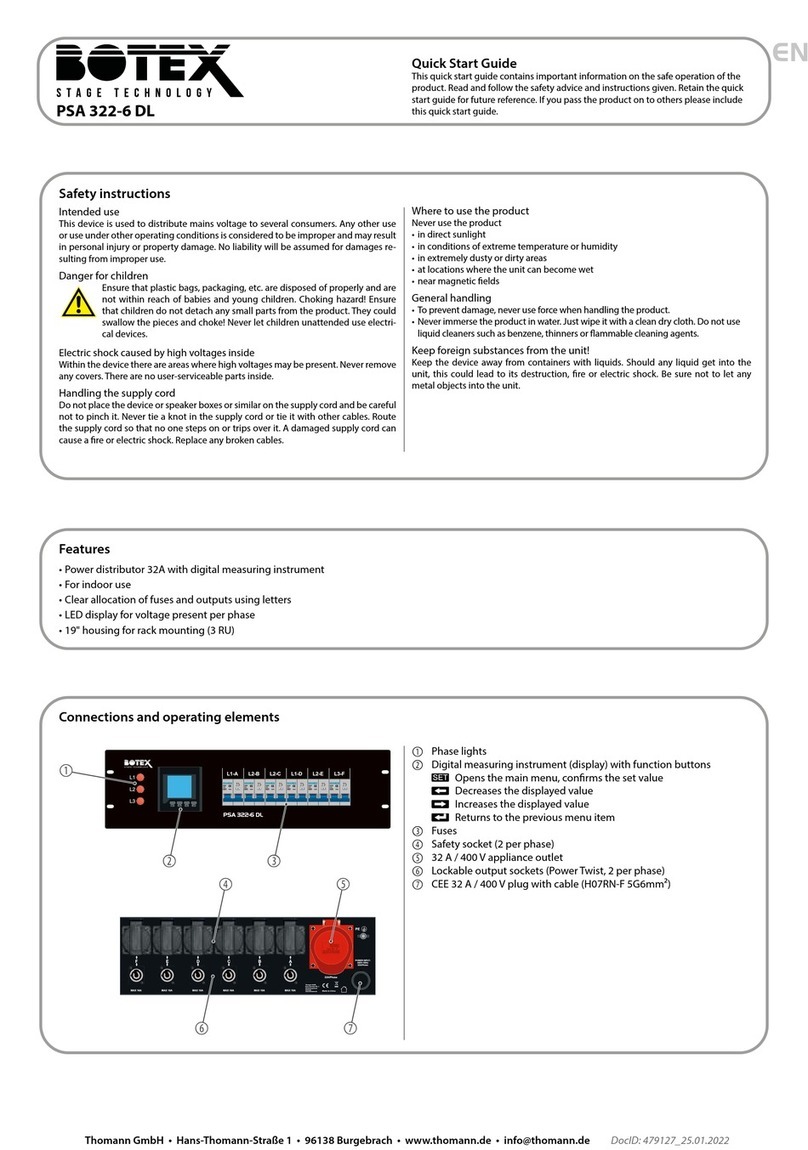

Panelboards

One 42-pole panelboard is provided on 15 and

30 kVA Precision Power Centers. Two 42-pole panel-

boards (for a total of 84 poles) are provided on 50

through 125 kVA Precision Power Centers. Three

42-pole panelboards (for a total of 126 poles) are pro-

vided on 150 through 225 kVA Precision Power Cen-

ters. (The three-panelboard configuration is not

available on Top Exit units.) Each panelboard is

enclosed for safety and has individual isolated neu-

tral and safety ground busbars.

Each panelboard is protected by a main circuit

breaker, which also allows manual shutdown of the

entire panelboard without affecting the other panel-

board(s).

Output circuits are protected by single-, two-, or

three-pole thermal-magnetic molded-case branch cir-

cuit breakers sized specifically for the load to be

served. (Standard panelboards use plug-in breakers.)

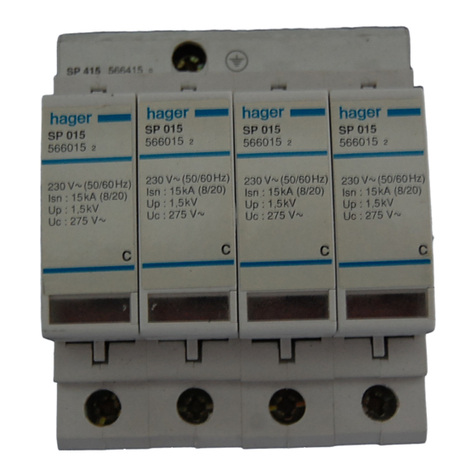

Shielded Isolation Transformer Temperature Sensors Input Circuit Breaker