Important Safety Instructions

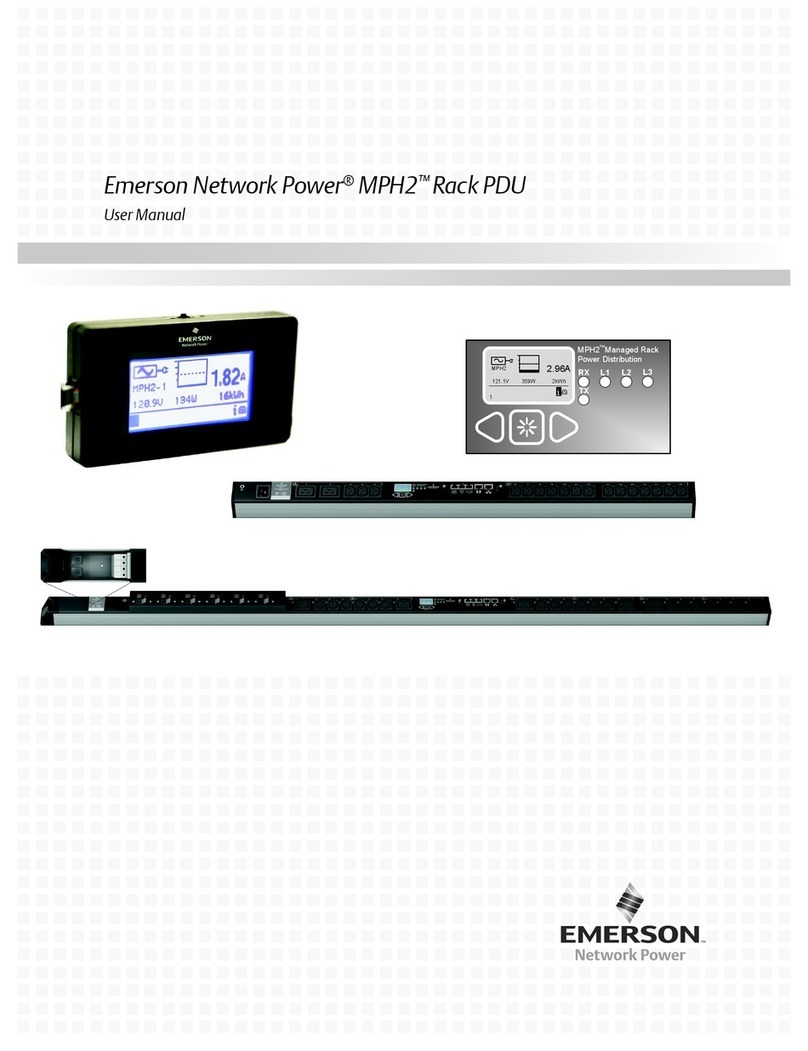

Emerson®MPH2™User Manual 1

Important Safety Instructions

SAVE THESE INSTRUCTIONS

This safety sheet contains important safety instructions. Read all safety, installation and operating

instructions before installing the Emerson Network Power MPH2 rack power-distribution unit (PDU).

Adhere to all warnings on the unit and in this safety sheet. Follow all instructions.

• The MPH2 Rack PDU is designed for information technology equipment. The MPH2 Rack PDU is not

intended for use with life support or other designated critical devices. If uncertain about its intended

application, consult your local dealer or Emerson representative.

• Maximum load must not exceed the rating shown on the MPH2 Rack PDU nameplate.

• The rated line voltage must not exceed 240VAC for connection to AC power distribution systems with

an isolated or high-impedance ground.

• Operate the MPH2 Rack PDU in an indoor environment only in the appropriate ambient temperature

range:

• 32°F to 140°F (0°C to 60°C) for 24A or less input models.

• 32°F to 122°F (0°C to 50°C) for 40A and 48A input models without case ventilation.

• 32°F to 140°F (0°C to 60°C) for 40A and 48A input models with case ventilation.

• Install the MPH2 Rack PDU in a clean environment, free of conductive contaminants, moisture,

flammable liquids, gases and corrosive substances.

• The MPH2 Rack PDU must be installed in a restricted-access location. A restricted-access location is

an area where access is possible only through the use of a tool or lock and key or other means of

security, and is controlled by the authority responsible for the location.

• The MPH2 Rack PDU has no user-serviceable parts. Under no circumstances attempt to gain internal

access due to the risk of electric shock or burn.

• Refer any unexpected behavior or unusual fault conditions to your local dealer, Emerson

representative or Emerson Network Power Applications Engineering.

• Emerson recommends powering only devices with safety agency approval from the MPH2 Rack PDU.

• For permanently connected MPH2 Rack PDUs (hard-wired versions), a readily accessible disconnect

device must be incorporated external to the equipment.

• For MPH2 Rack PDUs with integral plugs, the socket/ outlet must be installed near the equipment and

must be easily accessible.

WARNING

Opening or removing end caps from an MPH2 Rack PDU may expose personnel to lethal voltages

within the rack PDU. Observe all cautions and warnings. Failure to do so may result in serious

injury or death. MPH2 Rack PDU units contain no user-serviceable parts. For service or technical

support, contact Emerson Network Power Applications Engineering or your local Emerson

representative. Do not attempt to service this product yourself.

CAUTION

Connecting an MPH2 Rack PDU to a power supply with an incorrect rating in voltage or amperes

may damage the connected equipment and your MPH2 Rack PDU. For questions about the power

supply connections, contact Emerson Network Power Applications Engineering or your local

Emerson representative.

CAUTION

Ensure that the ratings of the electric circuit of each connected device meets the specified rating at

each branch and receptacle.