1.Introduction

The unit provides automatic start and stop the engine and protect the generator system. Both

automatic and manual control is possible. A test mode is also available which allows the

generator to be run for checking the generator system.

(supported ECUs: Volvo EMS2, Volvo EDC4,

Perkins, Scania S6 and standard messages).

The unit calculates engine RPM from Magnetic Pickup sensor input (Trans-MiniAUTO.MPU

devices only) and/or generator voltage signal. At Trans-MiniAUTO.CAN devices, unit gets

engine RPM information from J1939 ECU and/or generator voltage signal.

The unit monitors J1939 ECU messages and provides remote start/stop control via J1939

protocol at only Trans-MiniAUTO.CAN devices.

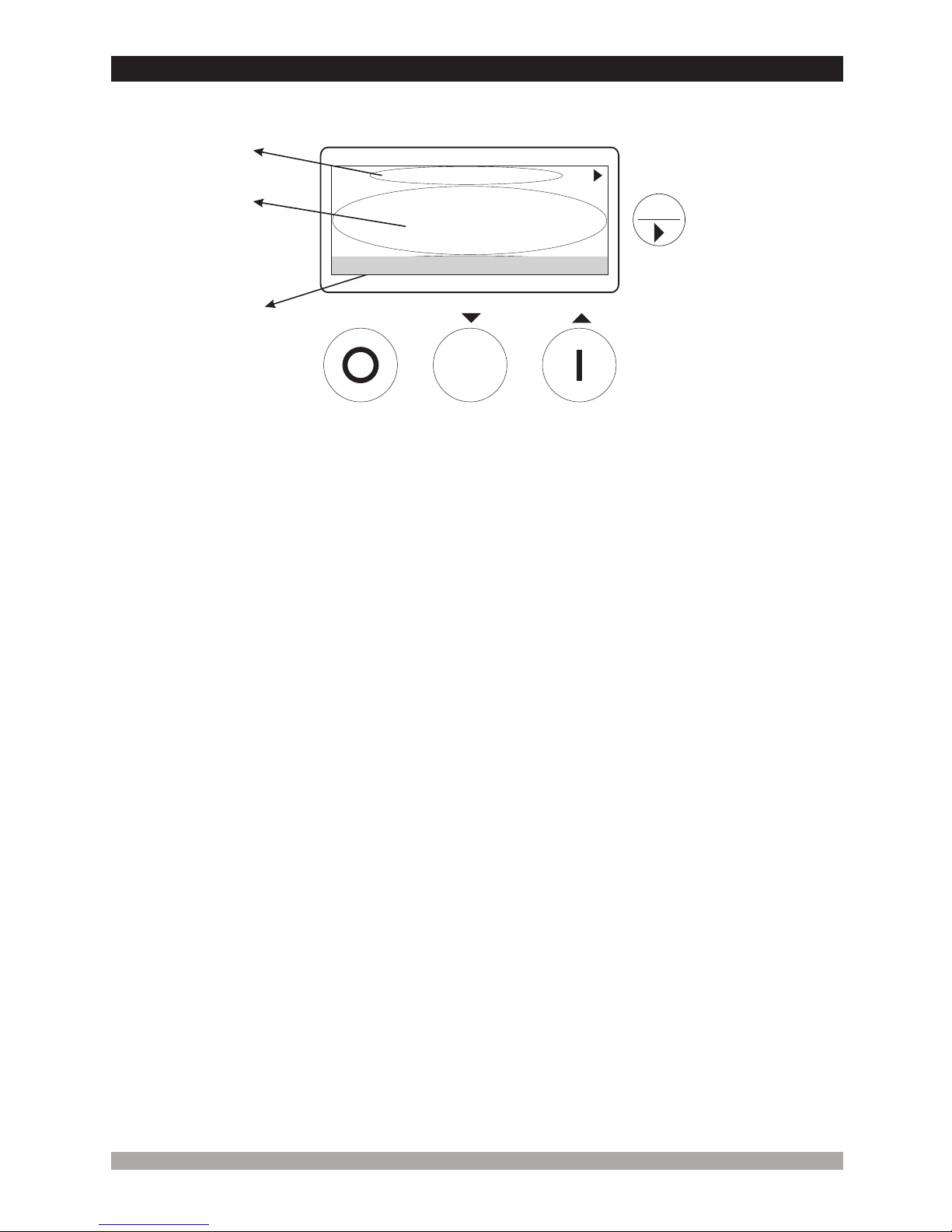

The unit is extensively programmable through the front panel, with password protection on two

levels. Operational parameters can also be monitored and controlled from a PC via a built-in RS-

232 communication port.

In the event that the engine fails to start on the first attempt, the attempt will be repeated a

programmed number of times or until successful.

The unit monitors generator operation and gives warning of any faults that are detected.

If a fault is detected, the unit shuts down the engine and shows the failure message on the LCD

display.

The unit has Remote Start input for remote control of the engine.

The configurable inputs can be programmed to perform 28 different functions.

1.1 General Specifications

1.2 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty document and instruction manual performs by the customer completely.

1.3 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the device

before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

4

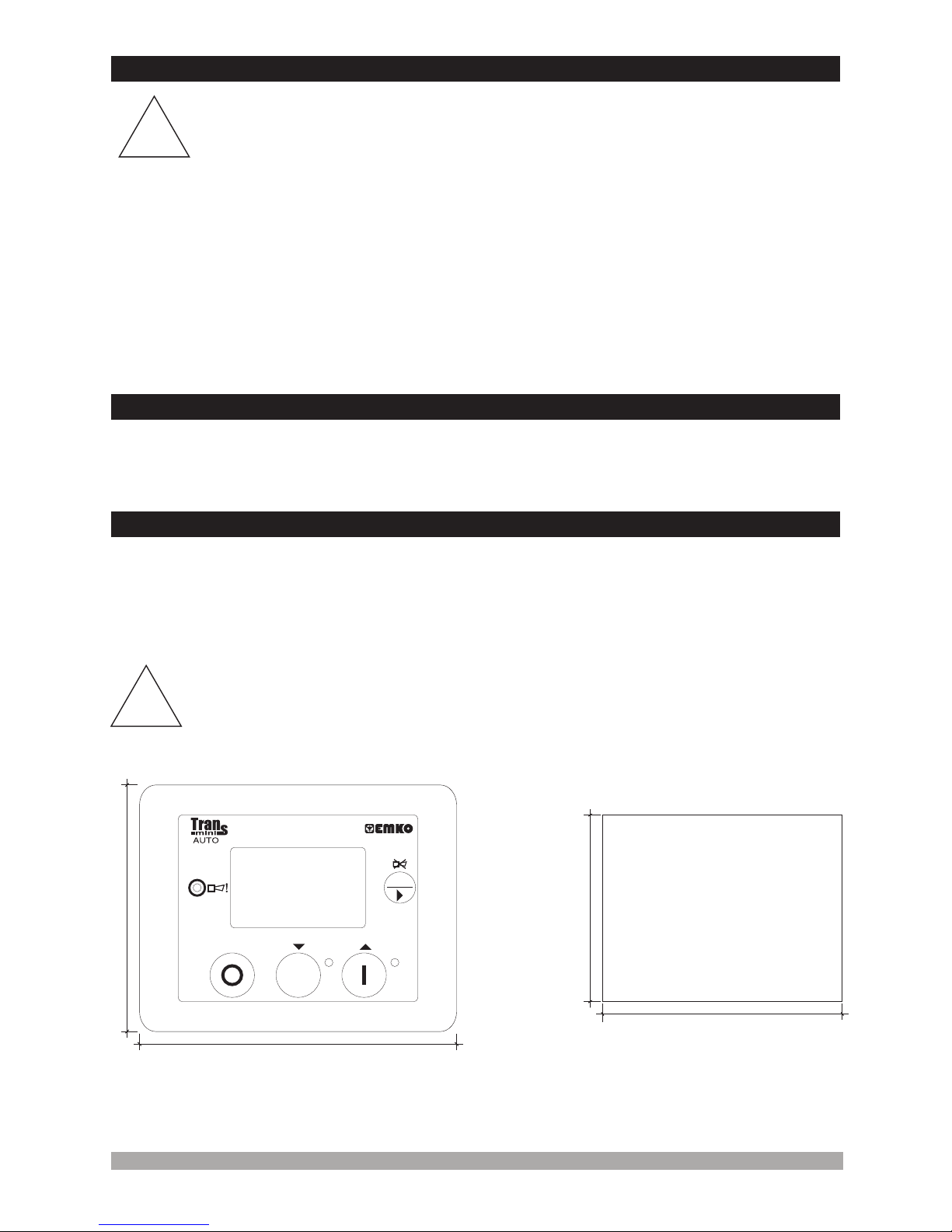

1.4 Order Information

Trans-MiniAUTO :

Trans-MiniAUTO.CAN :

Trans-MiniAUTO.MPU :

Auto Start GenSet controller, LCD display

Auto Start GenSet controller, CanBus J1939 ECU comm.

Auto Start GenSet controller,

speed sensing from Magnetic Pickup

Note: Devices have time clock. If real time clock is needed, “RTC” expression must be added to end of order code.

Example: Trans-MiniAUTO.MPU.RTC