___________________________________________________________________________________________________

_________________________________________________________________________________________

Page 2/ 30 EZM7750_ENG_VER11

INSTRUCTION MANUAL..............................................................................................................1

EU DECLARATION OF CONFORMITY.............................................................................................3

1 INTRODUCTION:...............................................................................................................................5

1.1 MODEL CODE:............................................................................................................................6

2 INSTALLATION:.................................................................................................................................7

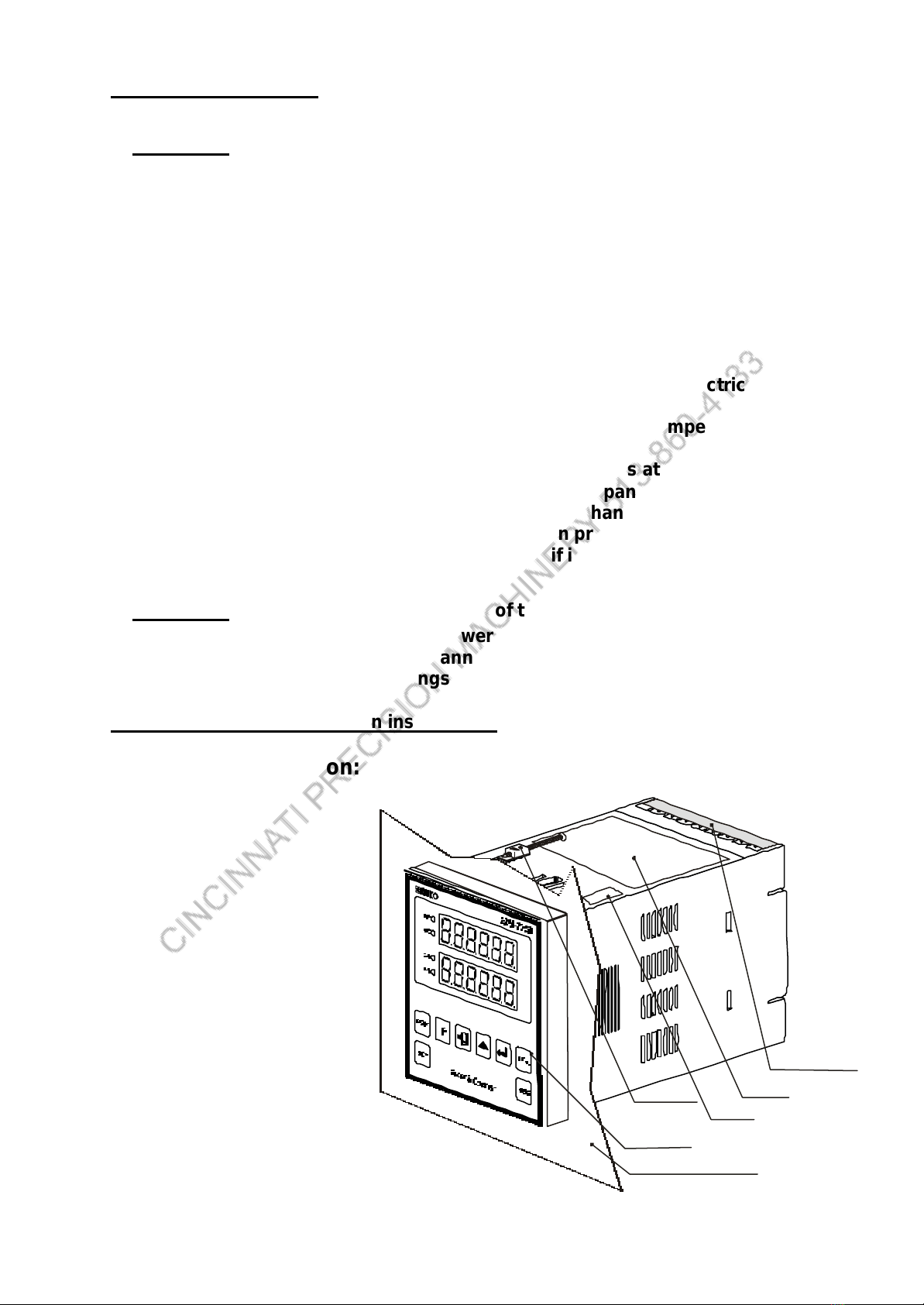

2.1 GENERAL DESCRIPTION:........................................................................................................7

2.2 DIMENSIONS:..............................................................................................................................8

2.3 PANEL CUT-OUT:.......................................................................................................................8

2.4 ENVIRONMENTAL RATINGS:..................................................................................................8

2.5 PANEL MOUNTING:...................................................................................................................9

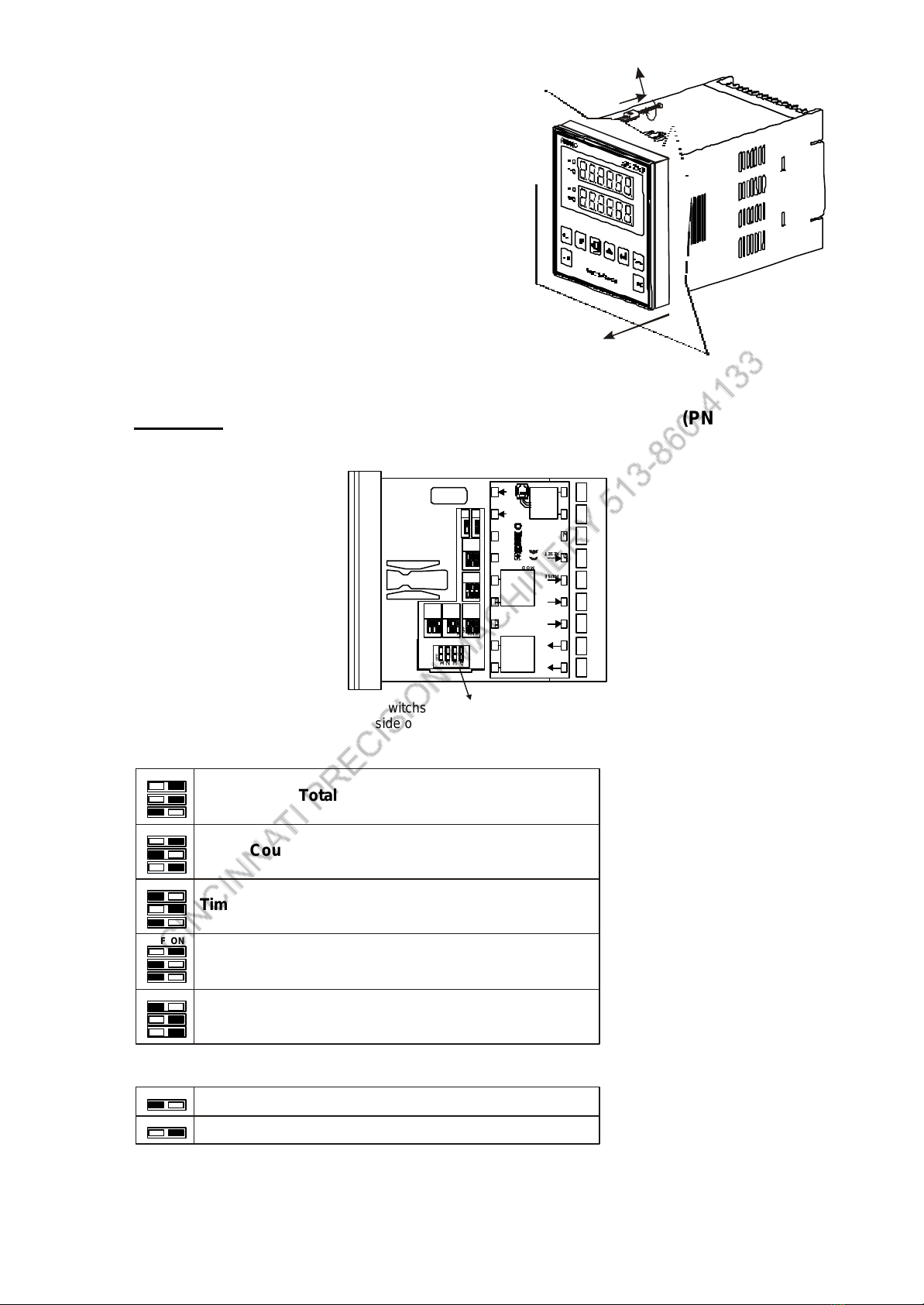

2.6 OPERATING FUNCTION SELECTION BY DIP SWITCHES:...........................................10

3 ELECTRICAL CONNECTIONS:....................................................................................................11

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTION:..............................................12

3.2 POWER SUPPLY:.....................................................................................................................12

3.3 INPUTS:......................................................................................................................................13

3.4 I/O MODULES INSTALLATION:.............................................................................................14

OPERATING MANUAL.......................................................................................................................17

4 FRONT PANEL DESCRIPTION:...................................................................................................17

4.1 SET-1 & SET-2 ADJUSTMENTS:...........................................................................................18

4.2 OBSERVING AND CHANGING PARAMETER VALUES:..................................................18

4.3 PARAMETERS LIST:................................................................................................................19

4.4 OUTPUT FUNCTIONS:............................................................................................................24

TECHNICAL SPECIFICATIONS:......................................................................................................30