6

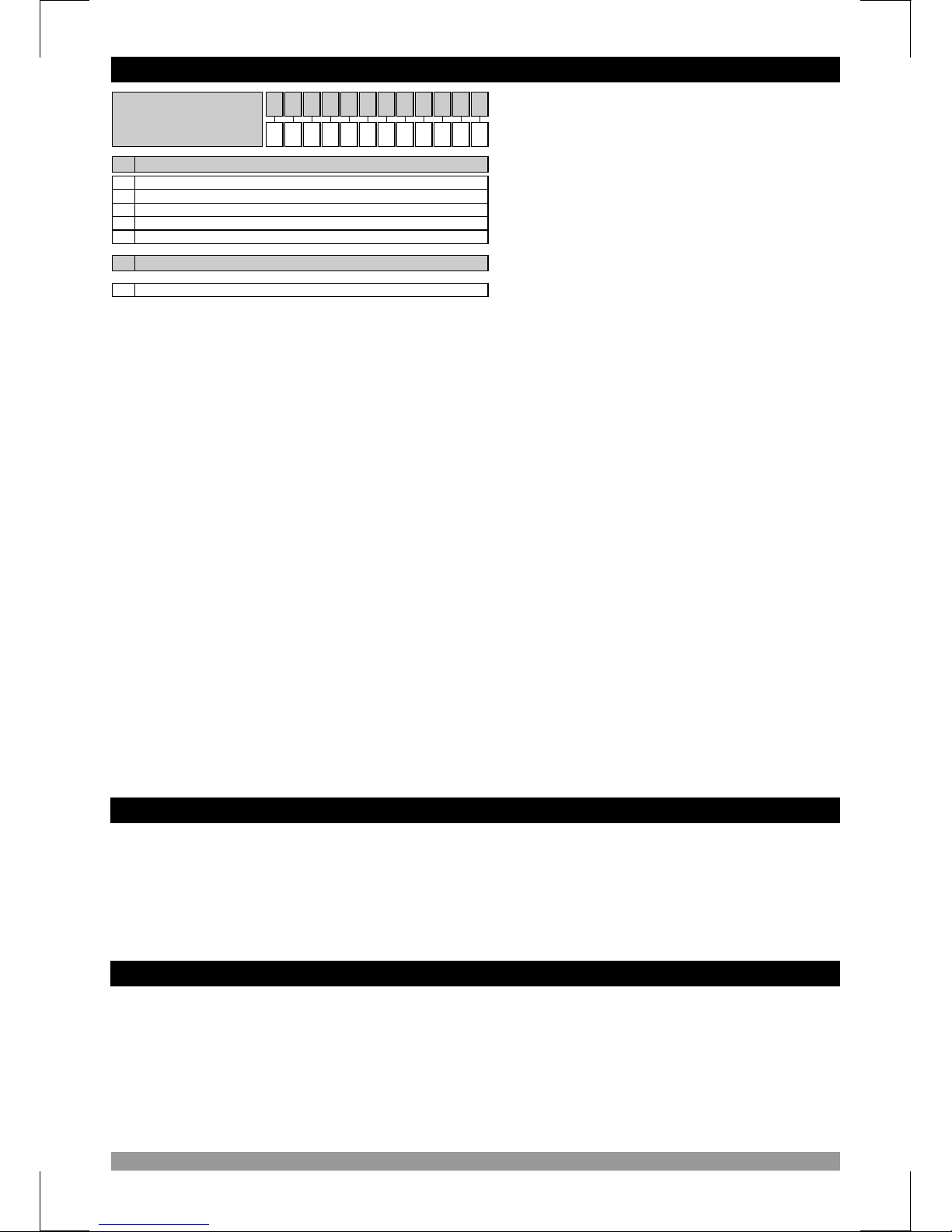

1.2 Ordering Information

EzM-9935 ( 96x96 1/4 DIN)

A BC D E FG HI /

/

U V W Z/

/

All order information of EZM-9935

Programmable Timer are given on the table

at left. User may form appropriate device

configuration from information and codes

that at the table and convert it to the ordering

codes.

Supply voltage must be determined

for your system.

Please fill the order code blanks

according to your needs.

Please contact us, if your needs are

out of the standards.

100 0 0

Supply VoltageA

V Symbol means Vac

ZSymbol means Vdc

c

0 0 0

00 00

Output-1E

Relay Output (5A @ 250 V V) Rezistive Load

1

1.3 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty document and instruction manual performs by the customer completely.

1.4 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the device

before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

24 V V(-%15;+%10) 50/60Hz

115 V V(-%15;+%10) 50/60Hz

3

4

Customer (Maximum 240V V(-%15;+%10))50/60Hz

9

230V V(-%15;+%10) 50/60Hz

5

24 V V(-%15;+%10) 50/60Hz 24 VZ(-%15;+%10)

2