4

SECTION 1 SYSTEM DESCRIPTION

TRANSMISSOMETER /RETRO REFLECTOR

The EMS520 is a precision, double-pass, dual beam Transmissometer that consists of a transceiver (transmitter/receiver) mounted on

one side of a stack or duct and a passive reflector mounted on the opposite side. The LED source, photo detectors, and all

measurement/reference optics used in opacity measurement are housed in the transceiver.

Normal mode of operation

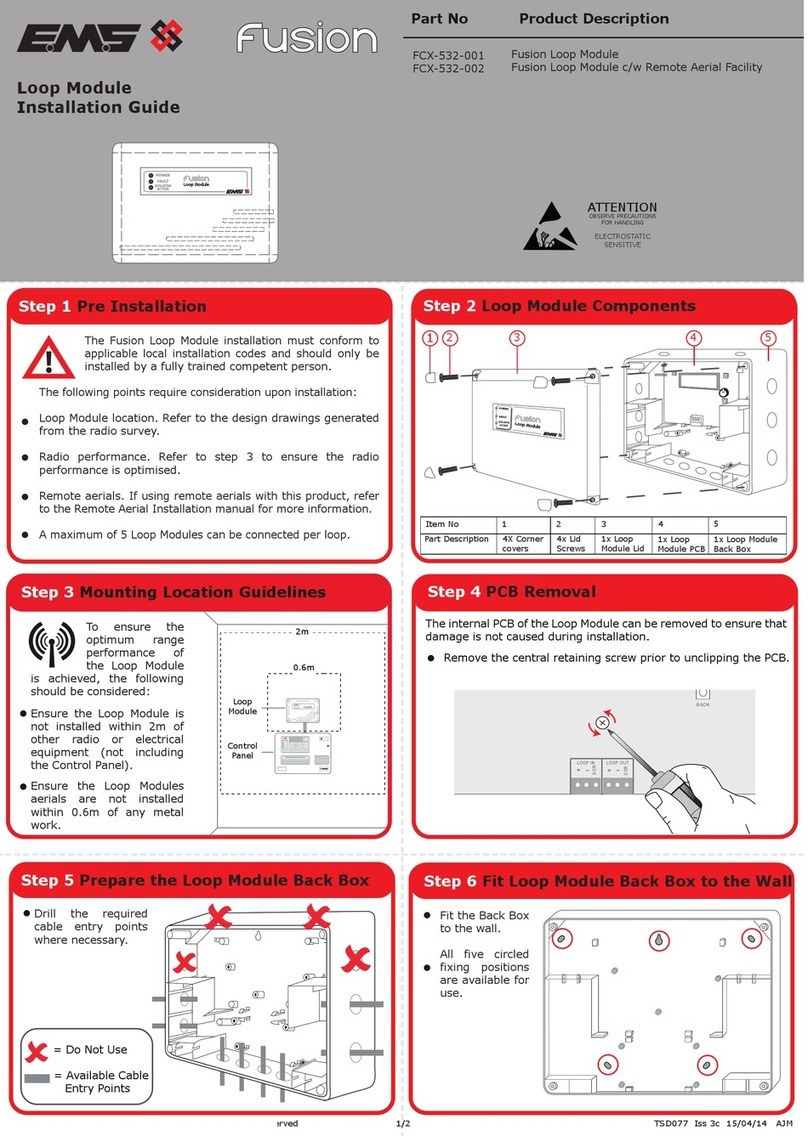

The Dual beam measurement system has a stack mounted Transmissometer sensor system consists of an optical transceiver mounted

on one side of the stack and a retro reflector mounted on the other. To avoid errors due to ambient light, the narrow beam LED (See

Drawing) is electronically modulated and projects a collimated beam of light, which is split into a reference beam, and a measurement

beam by an optical Beam splitter. The reference beam is directed to the reference detector, RD. The measurement beam is projected

across the stack to a Retro reflector that returns the beam back across the stack to a beam splitter and directs the measurement beam

to the measurement detector, MD. A portion of

the returning light is also sent to the TTL (Thru the

Lens) bulls-eye target viewed through a window

provided at the rear of the Transmissometer. The

bulls-eye is used to correct changes in alignment

and is unique in that no moving parts are used!

The ratio of the measurement and reference

detectors is used to provide Transmittance 2 (T 2)

signal. Because the same light source is used for

both detectors, and a Measurement / Reference

ratio is used throughout for the calculations, the

monitor is insensitive to variations in light

intensity. Since all measurements are made on a

ratio basis, all resulting computations are

independent of the absolute intensity of the LED

source or contamination of the optics associated with the collection and focusing of the energy from the LED. The (T 2) signal is

converted to a current format and sent to the control unit for processing. At the control unit the signal is processed to read 0-100%

Opacity, provide alarms and outputs.

Internal calibration system, zero mode

Zero and span calibration checks can be initiated manually, automatically or by a PLC or computer. During the zero calibration mode

a calibrated zero reflector is placed in front of the transceiver optical package testing all optical surfaces and electronic components

to assure zero point has not changed.

Internal calibration system, Span mode

In the span mode, a Span filter of known Neutral Density is placed in the measurement path and produces a specific upscale reading

in accordance with the latest E.P.A. requirements. The zero and span cycle provides a continuous check of all the optical components

and surfaces, the main lamp, the detector, interconnecting wiring, control unit and computation analysis.