2/3 ETI741-E-04-R

ýnP.

OFFS.

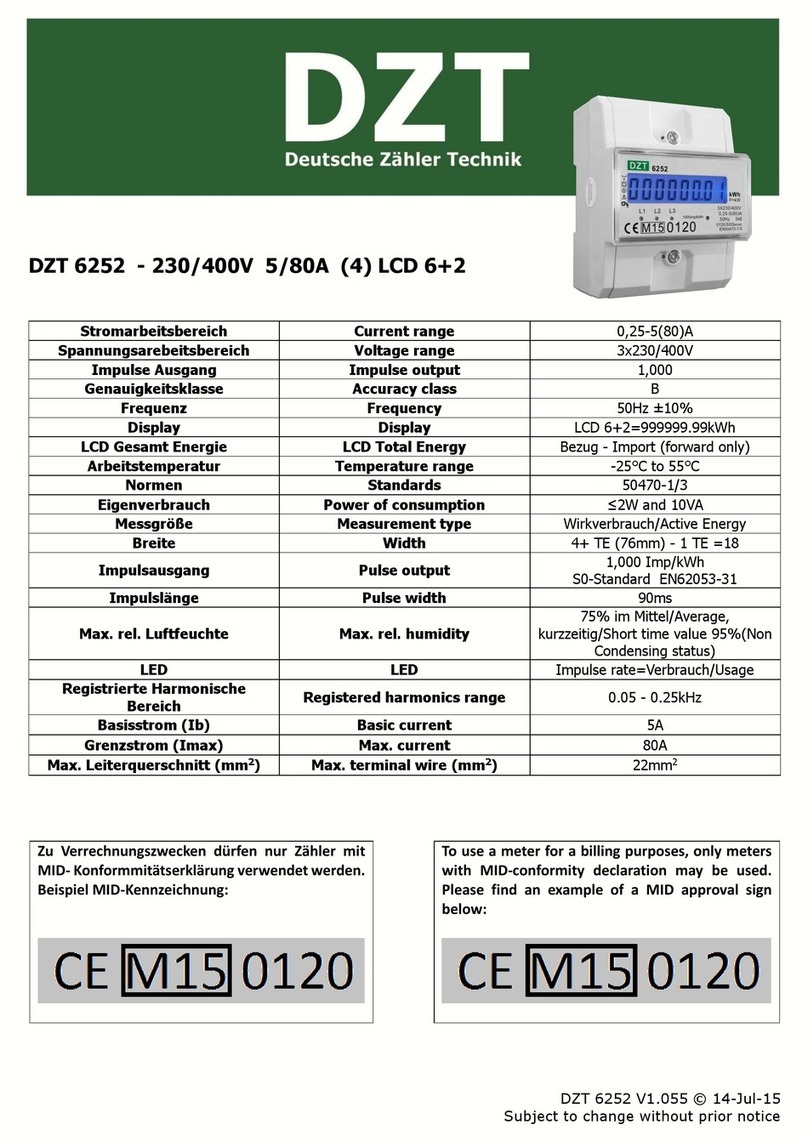

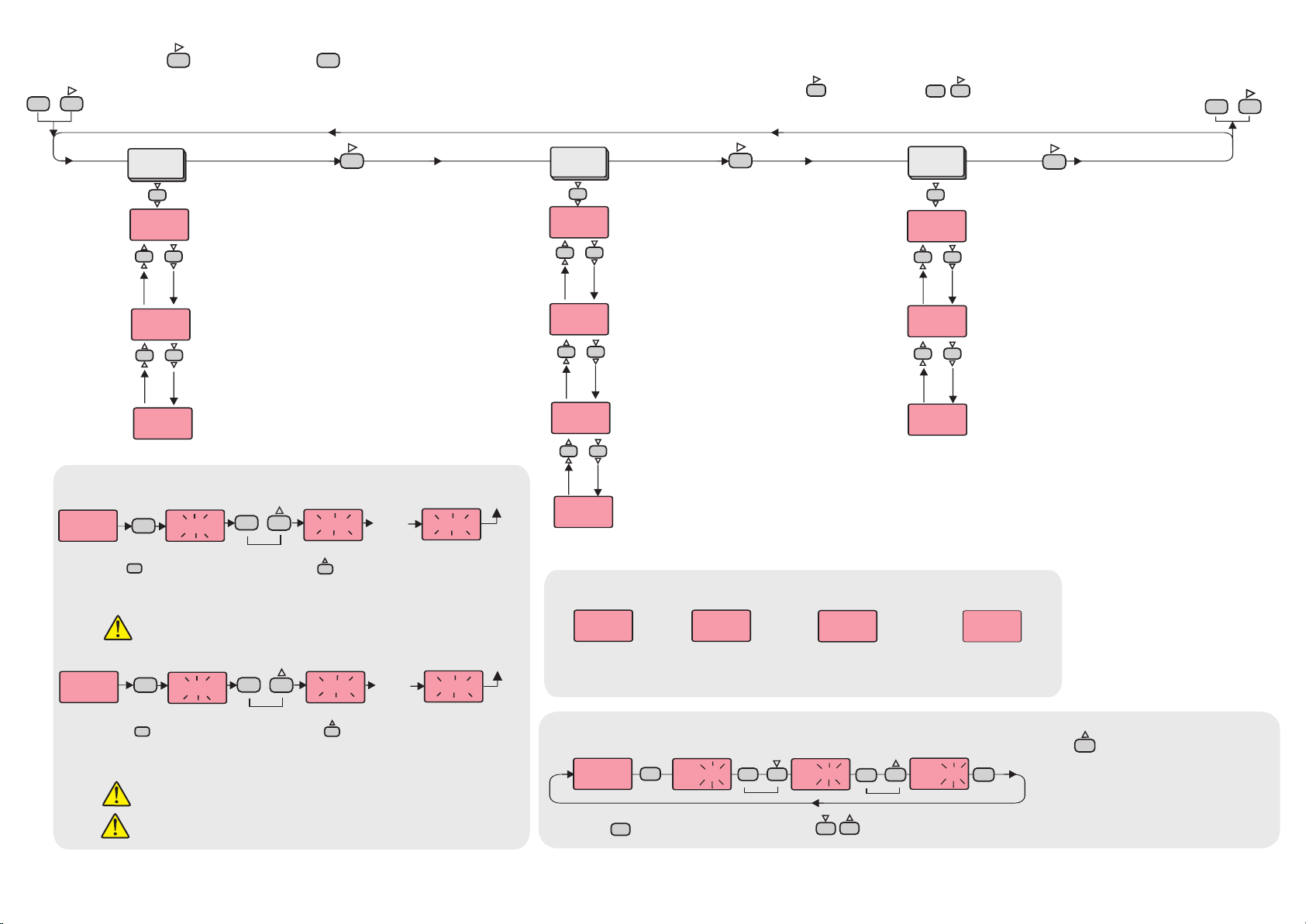

inP. = Type of sensor and scale.

Pt = Pt 100 -200 to +600°C

Pt.0 = Pt 100 -99.0 to +300.0°C

FE.cn. = J (Iron vs. Copper-Nickel) 0 to +600°C

nc.nA. = K (Nickel-Cr.vs. Nickel-Alum.) 0 to +1200°C

c.cn. = T (Copper vs. Copper-Nickel) 0 to +400°C

P10.r. = S (Platinum-10%Rhodium vs. Pt.) 0 to +1600°C

P13.r. = R (Platinum-13%Rhodium vs. Pt.) 0 to +1600°C

S.cod. =

menu access code

It should be 333.

Calibration

rt.CA. =

temperature is calibrated by

this parameter. It is not

displayed if input type is

selected Pt 100.

The environment

tC.CA. =

calibration of thermocouple

input can be made.

(See Note 1 below)

In this case, the

Pt.CA. =

calibration of Pt 100 input

can be made.

(See Note 2 below)

In this case, the

oFFS.=

Offset value is added to the measurement value.

Adjusted between -99 and +99°C.

The normal value is 0.

Offset value.

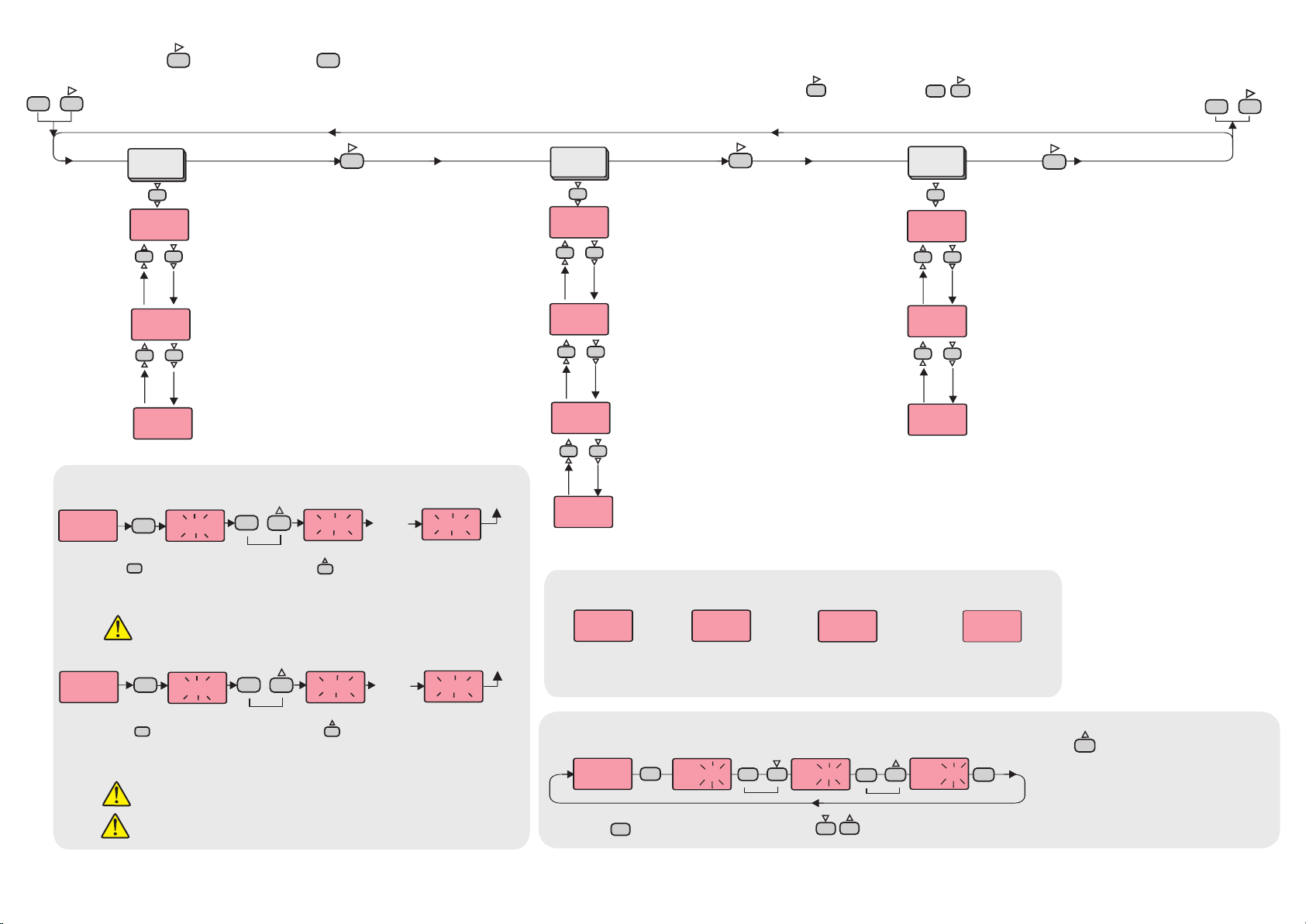

S.cod.

Rt.CA.

TC.CA.

Pt.CA.

A.Con.

A.CAL.

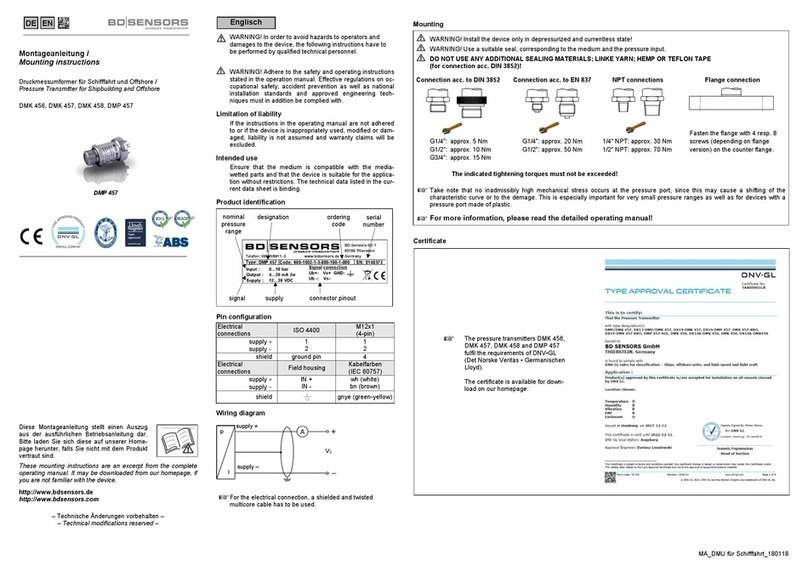

Before starting calibration procedure, 50.000mV referance voltage must be applied to the

thermocouple inputs.

CAL.

When holding key the message run flashes. In this case if key is pressed, calibration for TC input

starts. Then the messages C.Str, a four digit number and Cal are seen in sequence on the lower display. After 5

seconds End message is seen. If the four digit number is 4999 or 5000 or 5001, it means TC calibration was

successful. Otherwise calibration procedure should be repeated.

SET

SET

SET

press and

hold

NOTE 1

NOTE 2

Before starting calibration procedure, make a connection between terminal 8 and 9. Then connect a

212.052ohm referance resistor should be connected between terminal 9 and terminal 10 or apply 300 °C

from Pt-100 calibrator.

if key is pressed while holding key, the programming mode is enabled.

If key is pressed and held 0.6 seconds,

the value of the selected parameter changes

rapidly. If waited enough, the value

increases 100 at each step. After 1 second

following the release of the key, initial

condition is returned. The same procedure

is valid for the decrement key.

SET

SET

SET

Modification of Parameter

When holding key, the value of parameter flashes and using keys the requested value can be adjusted.

Values on the displays are default values.

When holding key the message run flashes. In this case if key is pressed, calibration for Pt 100

input starts. The messages C.Str, a four digit number and Cal are seen in sequence on the lower display. After

5 seconds End message is seen. If the four digit number is 3190 or 3191 or 3192, this means Pt 100

calibration was successful. Otherwise, Calibration procedure should be repeated.

SET

Entering from the programme mode to the run mode:

Alternatively, the same function occurs first pressing key and then pressing keys together.

If no key is pressed within 20 seconds during programming mode, the data is stored automatically and the normal mode is entered.

SET

UnIt =

Selectable as °C or °F.

The temperature unit.

5 seconds

later

S.cod. =

access code.

It should be 444.

Security menu

A.Con. = Parameters of

configuration menu access level

code.

nonE = Not visible.

P.yES = Visible and modification

can be done.

P. no = Visible and not modified.

A.CAL. = Parameters of

calibration menu access level

code.

no = Not visible

yES = Calibration can be done.

Returns to the normal

operation mode.

SET

SET

SET

SET

SET

Error Messages

Temperature value is

higher than the end

of the scale

Temperature value is

higher than the end

of the scale

Temperature sensor

is broken or

over temperature

Pt 100 or a sensor

line is short circuited

SeCU.

S.Cod.

CAL.

ConF.

UnIt.

Run End.

CAL.

SET SET

Press and

hold

5 seconds

later

Returns to the normal

operation mode

Run End.

TC.CA.

Pt.CA.

----

----

PFA

PSC

HyS.H.

6

5 6