Enerdrive ePOWER DC2DC User manual

Owner’s Manual

Enerdrive ePOWER DC2DC Battery Charger Owner’s Manual (Rev. 2.02) February 2016

Table of Contents

1. INTRODUCTION 4

2. WARNINGS 6

3. PRODUCT DESCRIPTION 8

4. UNDERSTANDING THE UNIT 9

Multistage Charging Process 9

Smart Charging Feature 9

Battery Charger Voltage 10

Battery Bank Size Recommendation 11

5. INSTALLING THE CHARGER 12

Mounting The Charger 13

6. CONNECTING THE CHARGER 14

Chassis Grounding Connection 14

DC Output Wiring 14

DC2DC Battery Charger Connections 15

Recommended Cable Length, Size And Fuse Protection 16

Standard Temperature Sensor Connection 16

Optional Remote Display Connection 16

Battery Wiring: Connecting The Batteries The Right Way 17

7. UNIT OPERATION 18

Understanding The Charging Mechanism 18

Operating From An Alternator (CH3) 18

DC Input (CH2 - Solar / PV) 20

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 2

Understanding The Display And Function Keys During Normal Operation 21

Understanding The Function Key ‘MENU’, ‘SET’ And ‘SEL’ During Charger Setting 22

Digital Display 23

Button Functions 23

Automatic Override Function 24

Programming Your Charger 24

Understanding The Three-Stage (Mode 3) Charging 24

Understanding The Battery Temperature Functions 24

Procedure To Set Or View Charger Setting 25

Procedure To Equalise Flooded Batteries 26

Understanding The Protection Features 27

Charging A Dead Battery 27

Understanding The Display Codes 27

8. SPECIFICATIONS 30

9. WARRANTY 31

Two Year Limited Warranty 31

Return and/or Repair Policy 31

Limitations 31

10. Appendix A1 32

11. Appendix A2 34

12. Appendix A3 36

Notes (Record Your Serial Number) 38

www.enerdrive.com.au

Page 3

1. INTRODUCTION

Thank you for purchasing the Enerdrive ePOWER DC2DC Battery Charger. With our state

of the art, easy to use design, this product will oer you reliable service for providing a

multistage, multi-input battery charger to charge the dierent types of batteries you have

installed in either your home, boat, caravan, 4WD or commercial vehicle. This manual will

explain how to use this unit safely and eectively.

Please Keep This Manual For Future Reference

For safe and optimum performance, the Enerdrive ePOWER DC2DC Battery Charger must

be used properly. Carefully read and follow all instructions and guidelines in this manual

and give special attention to the CAUTION and WARNING statements.

Disclaimer

While every precaution has been taken to ensure the accuracy of the contents of this guide,

Enerdrive assumes no responsibility for errors or omissions. Note the specications and

product functionality may change without notice.

Important Note

Please be sure to read the entire manual before using your Enerdrive ePOWER DC2DC Battery

Charger. Misuse may result in damage to the unit and/or cause harm or serious injury. Read

manual in its entirety before using the unit and save manual for future reference.

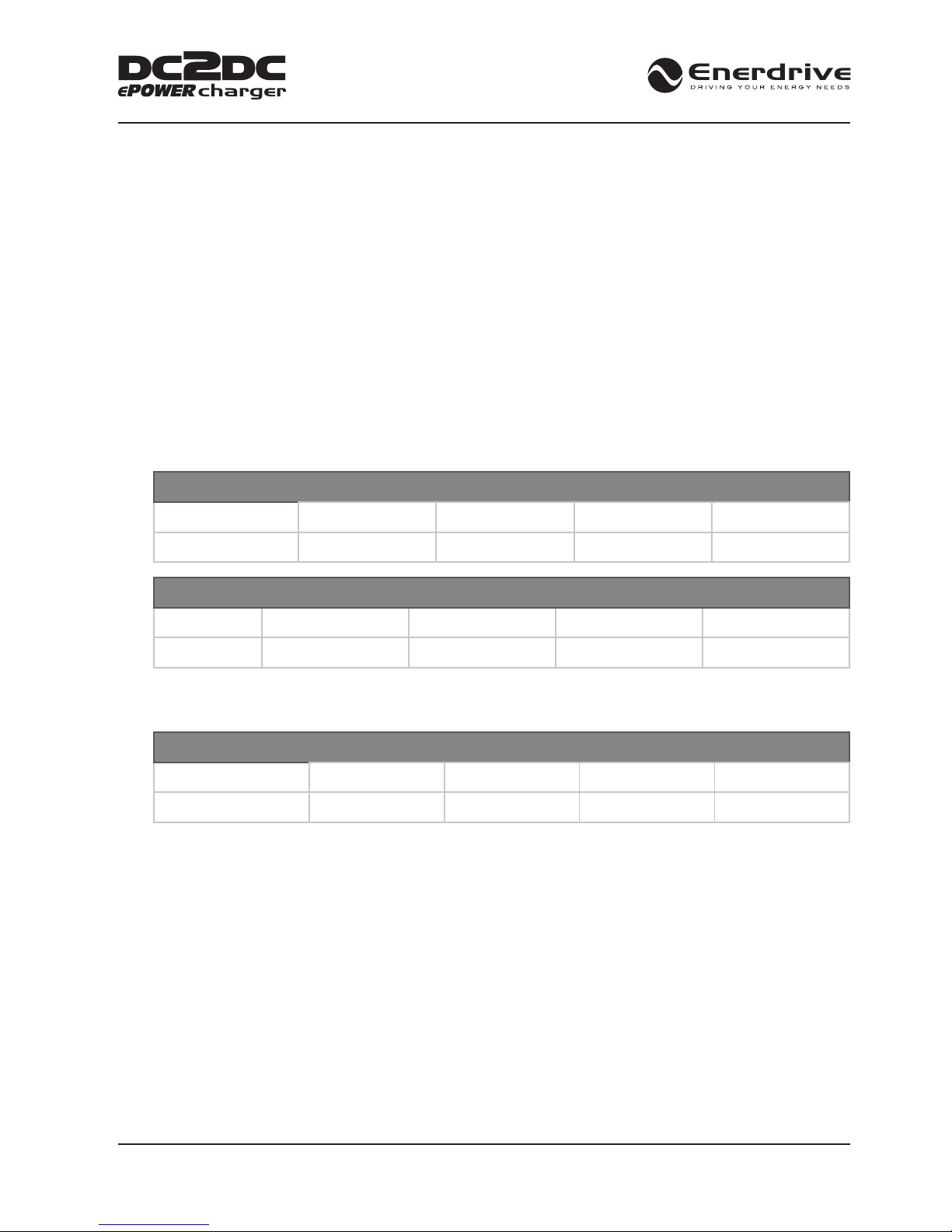

Product Numbers

ePOWER DC2DC Battery Charger Series

Product Number Product Description

EN3DC30 ePOWER DC2DC Battery Charger 12V / 30Amp

*ePOWER DC2DC Battery Charger Owners Manual Rev. 2.02. This Manual applicable to all units with serial number

prex EN.

Service Contact Information

ENERDRIVE PTY LTD

Unit 11, 1029 Manly Road Tingalpa, Queensland, Australia 4173

Ph: 1300 851 535 / Fax: 07 3390 6911

Email: support@enerdrive.com.au

Web: www.enerdrive.com.au

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 4

Notice of Copyright

Enerdrive ePOWER DC2DC Battery Charger owner’s manual © 2015 Enerdrive. All rights

reserved. No part of this document may be reproduced in any form or disclosed to third

parties without the express written permission of Enerdrive Pty Ltd, Unit 11, 1029 Manly Road

Tingalpa, Queensland, Australia 4173. Enerdrive reserves the right to revise this document

and to periodically make changes to the content hereof without obligation or organization

of such revisions or changes, unless required to do so by prior arrangement.

Exclusions For Documentation And Product Usage

Unless specically agreed to in writing, Enerdrive Pty Ltd: makes no warranty as to the

accuracy, suciency or suitability of any technical or other information provided in its

manuals or other documentation

Assumes no responsibility or liability for losses, damages, costs or expenses, whether

special, direct, indirect, consequential or incidental, which might arise out of the use of

such information. The use of any such information will be entirely at the user’s risk

Reminds you that if this manual is in any language other than English although steps have

been taken to maintain the accuracy of the translation, the accuracy cannot be guaranteed

Makes no warranty, either expressed or implied, including but not limited to any implied

warranties of merchantability or tness for a particular purpose, regarding these Enerdrive

products and makes such Enerdrive products available solely on an “as is” basis

Shall in no event be liable to anyone for special, collateral, incidental, or consequential

damages in connection with or arising out of purchase or use of these Enerdrive products.

The sole and exclusive liability to Enerdrive, regardless of the form of action, shall not exceed

the purchase price of the Enerdrive products described here in

www.enerdrive.com.au

Page 5

2. WARNINGS

Please read and follow the instructions and precautions carefully.

This section contains important safety information for the Enerdrive ePOWER DC2DC Battery

Charger. Each time, before using the Enerdrive ePOWER DC2DC Battery Charger. READ ALL

instructions and cautionary markings on or provided with the DC2DC Battery Charger, and

all appropriate sections of this guide.

CAUTION

This unit is intended for indoor use ONLY. It is not suitable for installation in an under

bonnet vehicle application and such application will void warranty.

Battery Charger contains no user serviceable parts. See Warranty section for how to

handle product issues.

Do not install the Enerdrive ePOWER DC2DC battery charger in any vehicle engine bay

or conned area where heat build up may occur.

WARNING: Shock Hazard.

Keep Away From Children!

Avoid moisture ingress. Never expose the unit to snow, water, etc..

WARNING:

Fire &/or Chemical Burn Hazard!

When charging batteries they can release explosive and corrosive gasses / chemicals.

Please wear safety glasses and protective clothing including gloves when working around

batteries

LIMITATIONS OF USE

Do not use in connection with life support systems or other medical equipment or devices.

The charger is not to be used by persons with reduced physical or mental capabilities or

lack of knowledge and experience. Not to be operated or used by children.

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 6

WARNING

Explosion Hazard!

DO NOT use the Enerdrive ePOWER DC2DC Battery Charger in the vicinity of ammable

fumes or gases (such as gas bottles).

AVOID covering the ventilation openings. Always operate unit in an open and well

ventilated area.

Prolonged contact to high heat or freezing temperatures will decrease the working life

of the unit.

WARNING

Failure To Follow These Instructions May Result In Death Or

Serious Injury!

When working with electrical equipment or lead acid batteries, have someone nearby

in case of an emergency.

Study and follow all the battery manufacturer’s specic precautions when installing,

using and servicing the battery connected to the charger.

Wear eye protection and gloves.

Avoid touching your eyes while using this unit.

Keep fresh water and soap on hand in the event battery acid comes in contact with eyes.

If this occurs, cleanse right away with soap and water for a minimum of 15 minutes and

seek medical attention.

Batteries produce explosive gases. DO NOT smoke or have an open spark or re near

the system.

Keep unit away from moist or damp areas.

Avoid dropping any metal tool or object on the battery. Doing so could create a spark or

short circuit which goes through the battery or another electrical tool that may create

an explosion.

www.enerdrive.com.au

Page 7

3. PRODUCT DESCRIPTION

The Enerdrive ePOWER DC2DC Battery Charger is a multistage, multi-input battery charger

to charge dierent types of batteries commonly installed in either boat’s, caravan’s, 4WD’s

or commercial vehicle’s.

Enerdrive’s ePOWER DC2DC Battery Charger package includes the following items;

1 x ePOWER DC2DC Battery Charge

1 x Battery Temperature Sensor

7.5 Meter Cable)

1 x Owner’s manual Rev 1

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 8

4. UNDERSTANDING THE UNIT

The Enerdrive ePOWER DC2DC Battery Charger is a fully automatic multistage, multi input

battery charger with the ability to charge from either an alternator linked to a battery; or via

solar power with the in built Maximum Power Point Tracking (MPPT) Solar Controller. With two

inputs available, the house battery will be charged from either the engine while underway,

or via the solar panels when stationary. The process to choose either engine or solar is fully

automatic and both functions are controlled from within the unit itself without the need for

external relays.

During normal operation the ePOWER DC2DC Battery Charger will do a full charge cycle to

oat stage on the house battery bank with ability to choose either GEL, AGM, Flooded, Custom

Programmable or Lithium. Once oat stage is reached the charger transitions to a power supply

mode to support any on-board DC loads.

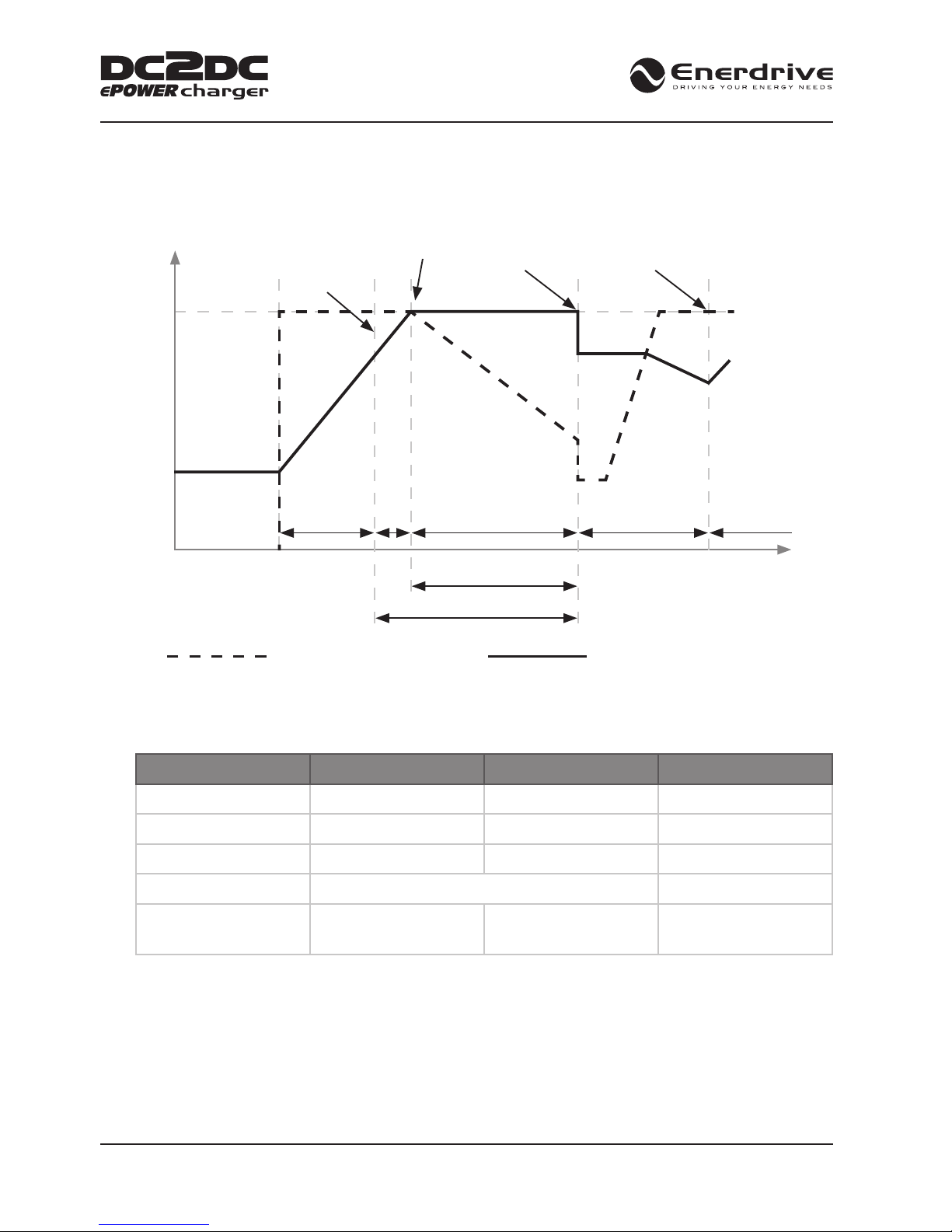

Multistage Charging Process

The ePOWER DC2DC Battery Charger is a fully automatic, set and forget charger. It is designed

to quickly and accurately recharge your deep cycle batteries utilising charger algorithms that

help to maximise the life of your specialised deep cycle batteries.

The ePOWER DC2DC Battery Charger features multistage smart charging technology that

enables the charger to be connected to your battery banks permanently. With the input of

multiple sources, you can be assured of charging your batteries whenever underway; or when

the sun is shining on your solar array.

As dictated by battery manufacturer’s recommendations, deep cycle batteries require a

multistage charge sequence for perfect, fast and accurate charging. The Enerdrive ePOWER

DC2DC smart charger delivers three primary charge stages.

Stage 1 – Bulk or Boost charge; The battery is charged at full rated output current of the

charger until the battery reaches its nal charging voltage, known as its absorption voltage.

In this step, around 80% of the battery is recovered as fast as possible.

Stage 2 – Absorption Charge; With the charger voltage held steady, the remaining 20% is

replaced with the charger allowing the current to taper o as the battery approaches full charge.

Stage 3 – Float; Finally, in the oat stage the charger voltage is lowered and held at a constant

and safe predetermined level. This prevents the battery from being overcharged, yet allows

the charger to supply enough current to make up for the self-discharge losses of the battery,

while supporting any additional loads connected to the battery (such as DC lighting and

refrigerators). This stage allows for the charger to be used as a DC power supply.

Smart Charging Feature

The ePOWER DC2DC Battery Charger will regulate its output based on the loads connected

to your battery banks. This function is important to maintain the life of your battery banks as

some battery chargers mistake loads for discharge and continue to keep the batteries in the

bulk or absorption stage for extended periods of time, which will damage the battery bank.

The ePOWER DC2DC Battery Charger has two methods of load based regulation to ensure

your battery charger transitions to oat when it should do so.

www.enerdrive.com.au

Page 9

ePOWER charger algorithm

Battery Charging Curve For GEL, AGM, Flooded & Program Batteries:

CHARGE

CURRENT

V out ≥ V abs

for 1 min

V out ≥ V abs

for 1 min I out < 10% I rating

for 1 min

If V out < 12.5 Vdc

for 15 min

BULK

CV ABS timeout 5 hr

Total ABS timeout 8 hr

FLOAT BULK

TIME

CC

ABS CV ABS

Battery Charging Curve (Current) Battery Charging Curve (Voltage)

Note: Actual voltages depend on chosen algorithm.

Battery Charger Voltage

Battery Type Absorption Float Equalisation

GEL 14.4 V 13.7 V N.A.

AGM 14.7 V 13.6 V N.A.

Flooded 14.4 V 13.3 V 15.5 V (See Note1)

Lithium Constant 14.2 V, 14.3 V, 14.4 V (See Note2) N.A

Program (Custom

Settings) 13.8V-14.8 (0.1V Step) 13.0V-13.8 (0.1V Step) N.A

* For Concorde™ branded batteries (lifeline, sun xtender) use ooded setting and consult battery

supplier for equalisation recommendations.

Note 1: Equalisation setting can only be used on ooded battery type selection only. See

more details on Procedure to Equalise the Flooded Battery.

Note 2: Charger will terminate charging when charging current drops to below the set

charger termination value.

(Battery

recharge in Bulk

mode)

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 10

Note 3: Charger is acting as a power supply with selected constant output voltage and

preset maximum output current.

NOTE: The equalisation function although included in the ePOWER DC2DC will rarely be

used. To activate the battery bank must be in oat, and manually activated. A typical drive

will not be long enough for the DC2DC function to complete the process. The MPPT Solar

function may provide enough time for Equalisation, but the best recommendation will be

an AC powered battery charger.

Battery Bank Size Recommendation

The battery charging current rating is based on the battery size. The battery bank should

meet the minimum Ah rating as shown. If a smaller size battery bank is used, set the current

rating to a lower value to match with the battery bank size. Normally, the minimum battery

bank capacity is based on a C5 rating of the battery for charging.

EN3DC30

Current Setting 5A 10A 20A 30A

Battery Capacity Min 25Ah Min 50Ah Min 100Ah Min 150Ah

EN3DC30 (Current Setting)

Bulk 30A 20A 10A 5A

ABS-Float 1.5A/ 3A/ 6A 1.0A / 2A / 4A 0.5A/ 1A/ 2A 0.3A/ 0.5A/ 1A

Note: Use the above table to set the Bulk and its related Absorption (ABS) to Float Charge Current.

Unit Setting for Lithium Type Battery (Voltage and Current):

Lithium Voltage Setting : 13.9 – 14.4 (0.1V Step) - EN3DC30 (Current Setting)

Charge Current 30A 20A 10A 5A

Terminate Current 1.5A/ 3A/ 6A 1.0A / 2A / 4A 0.5A/ 1A/ 2A 0.3A/ 0.5A/ 1A

Note: The return to charge voltage setting for Lithium Type battery is set to 13.3Vdc

www.enerdrive.com.au

Page 11

5. INSTALLING THE CHARGER

WARNING

Enerdrive recommends that all wiring be done by a skilled technician to ensure adherence

to the best practice standards for on-board DC electrical installations. Failure to follow

these instructions can damage the unit and could also result in personal injury or loss

of life.

CAUTION

Before Installing The Unit Consider The Following:

This unit is designed ONLY for internal mounting and should be used or stored in an

indoor area away from direct sunlight, heat, moisture or conductive contaminants.

DO NOT INSTALL IN VEHICLE ENGINE BAY

This is an electronic device cooled by a fan, and will prematurely fail if installed in corrosive

/ moisture rich environments.

When placing the unit, allow a minimum of 75mm of space around the unit for optimal

ventilation.

NOTE

The Enerdrive ePOWER DC2DC Battery Charger is designed to be permanently mounted.

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 12

Mounting The Charger

• Choose an appropriate mounting location.

•

For installing in an indoor location, the unit should be mounted vertically (with the

battery terminals facing downwards). This provides the best thermal performance and

drip protection. The unit should NOT be mounted upside down.

•

For installing in a boat or marine environment, the unit should only be mounted vertically

(Battery Terminals facing downwards only) to provide adequate drip protection.

•

Use the base of the charger as a mounting template to mark the positions of the xing

screws.

•

Drill the 4 xing holes and place the Charger in position and fasten the unit to the mounting

surface.

119 mm 55mm

160mm

www.enerdrive.com.au

Page 13

6. CONNECTING THE CHARGER

Chassis Grounding Connection

NOTE

This Charger SHOULD BE CORRECTLY GROUNDED.

The unit chassis has a stud point on it for grounding. Connect the unit’s chassis ground to

the common ground point through the ground stud located near one of the unit mounting

slots. (Battery DC negative is the best ground reference point in your installation) .

Failure to do so may result in poor charger performance or possible injury.

DC Output Wiring

WARNING: Correct DC Wiring Is Required

The DC wiring used must be of appropriate size.

An individual fuse or breaker is required to be installed within 20cm of the both the start

battery and house battery bank.

A DC isolator or fuse is also recommended for the solar input.

All devices must be rated for DC voltage and current.

The solar input fuse or breaker must be able to withstand the short circuit current rating

stated on the solar panel array.

All wiring must conform or exceed the recommendations stated in this manual (page 16).

This is a Dual Input device. Dierent cable sizes are required for the alternator input,

solar array input and the DC2DC charger to battery connection.

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 14

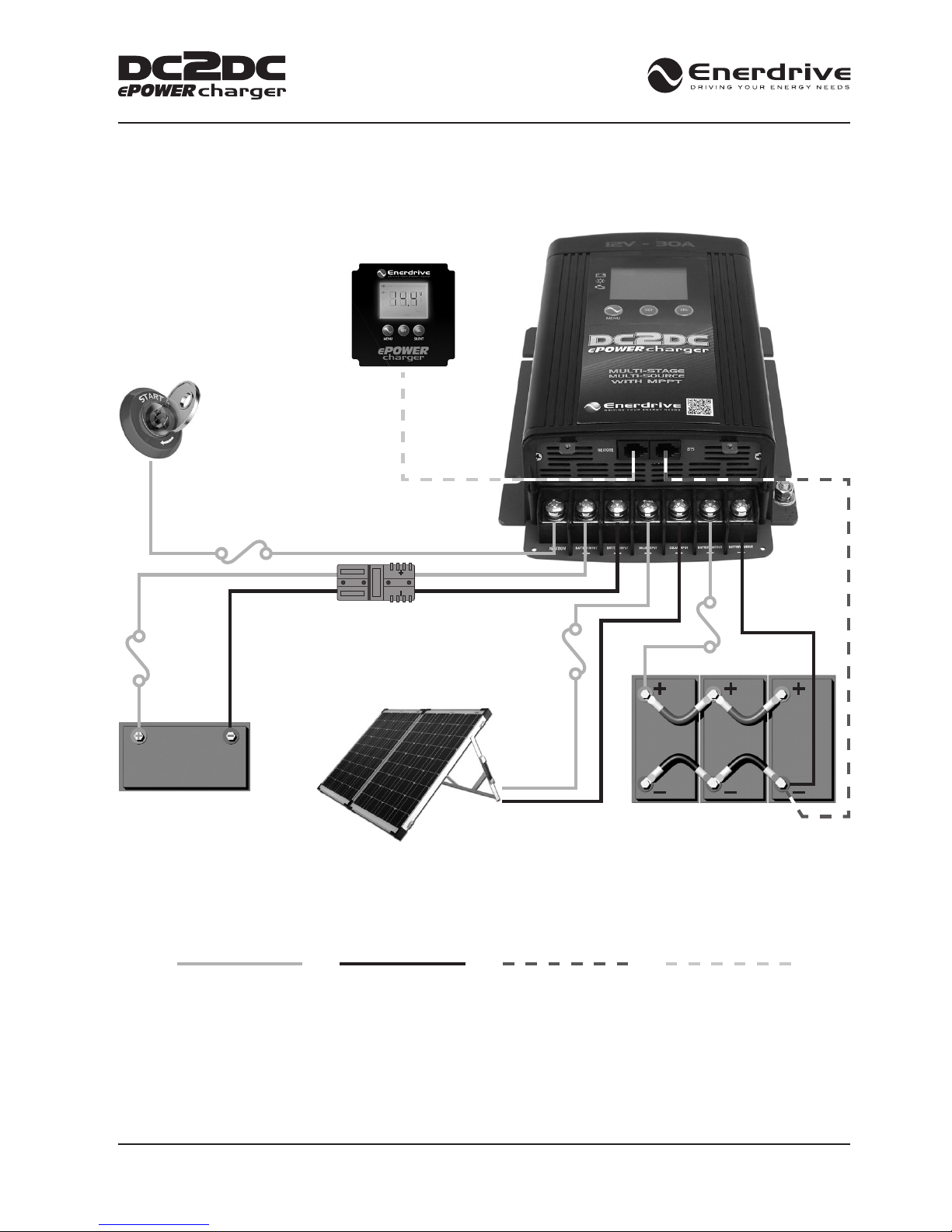

DC2DC Battery Charger Connections

SOLAR INPUT SOLAR INPUTBATTERY INPUT BATTERY INPUT BATTERY OUTPUT BATTERY OUTPUTIGNITION

Battery

Temperature

Sensor Port

Unit Ground

Remote Display

Port

(Remote Display

Sold Separately)

www.enerdrive.com.au

Page 15

Start Battery House BatterySolar Array

CH2 CH1CH3

Recommended Cable Length, Size and Fuse Protection.

DC2DC Connection

Inputs

Require Length & Battery Cable Size

< 1.5 Meters 2) 2 Meters to 5

Meters 3)

Up to 10

Meters 3)

Greater than

10 Meters 3)

From Alternator Battery 10mm2 @ 12vdc

/ 6mm2 @ 24vdc

10mm2 @ 12vdc

/ 6mm2 @ 24vdc

16mm2 @ 12vdc

/ 8mm2 @ 24vdc

25mm2 @ 12vdc

/ 16mm2 @

24vdc

From Solar Panels 1) 4mm2 per solar

panel installed

4mm2 per solar

panel installed

4mm2 per solar

panel installed

4mm2 per solar

panel installed

Primary Battery

Connection 2) 10mm2 16mm2 Not

Recommended

Not

Recommended

Note: Cable size quoted is one way from battery to device, however suggested cable size is calculated with return run.

1) Note: If solar panels are wired in Series (increased voltage), then typically 1 x 4mm2 cable run per series string

is suitable.

2) Based on 3% voltage drop.

3) Based on 10% voltage drop.

Recommended Fuse Protection

From Alternator Battery 50amp Maxi Fuse or Circuit Breaker no greater than 20cm from source

battery.

From Solar Panels

Fusing recommended no greater than 20cm from input to DC2DC

Charger. Typically 15amps per solar panel (consult your panel

specications for further details).

Primary Battery

Connection 40amp Maxi Fuse or Circuit Breaker.

Standard Temperature Sensor Connection

•

To install the temperature sensor, simply connect the RJ12 plug from the sensor to the

RJ12 Temperature Sensor Port located next to the Remote Port.

•

On the temperature sensor end, simply connect the ring terminals to the negative terminal

of the main house battery bank.

Optional Remote Display Connection

To install the optional Remote Display in a specic location, a 6 pin standard RJ12 cable

(maximum length 7.5 meters) is required.

• Install the standard RJ12 cable in your desired location.

• Connect one end of the RJ12 cable to the Remote Port and the other end of the cable to

the Display Panel. Please note polarity.

• The Remote Display is now ready for use.

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 16

Battery Wiring: Connecting The Batteries The Right Way

(Optional Ignition - On)

VSO

(Voltage Sense Override)

Optional Remote Display

(Sold Separately)

Remote Cable

(Sold Separately)

Anderson Plug (Optional)

MPPT Solar Panel Input

Max: 500w / 45VOC

(For xed or portable panels)

Start / Vehicle Battery

12V or 24V

Fuse / Breaker

12V - 50A

24V - 25A

Fuse Size 1A

Fuse / Breaker Fuse / Breaker

40A

Temp Sensor Cable

(Included)

12V House Battery Bank

This diagram is for a referance only. No cables, fuse/breakers, batteries or solar panels are supplied with this unit.

Local rules and regulations should be followed when installing this unit.

POSITIVE WIRE NEGATIVE WIRE TEMPERATURE SENSOR

CABLE (INCLUDED)

REMOTE CABLE

(SOLD SEPARATELY)

www.enerdrive.com.au

Page 17

7. UNIT OPERATION

Understanding The Charging Mechanism

Note 1: The Charger is powered by the battery connected to DC Output (CH1) and also

supplied by CH2 or CH3 if available. The display will turn o to save power when Input

Channel CH2 and CH3 are out of operating range.

Operating from a Start Battery / Alternator (CH3)

Normal Operation: Input Battery / Source

12V Input 24V Input

Input Voltage Range 10.5V – 16.0V 21.0– 32.0V

Normal Start-Up Voltage (Note A) > 13.2V > 26.4V

Normal Under Voltage Recovery Voltage (Note A) > 12.8V > 25.6V

Ignition Start Terminal

> 10.5V forces Ch3 input to the Low

Start-Up and Low-Under Voltage

recovery settings.

Low Start-Up Voltage (using Ignition Start Terminal or

using Manual Over-ride setting) (Note B) > 12.3V > 24.6V

Low Under Voltage Recovery Voltage (Note B) > 12.0V > 24.0V

De-Rated Voltage (with load) (Note C) 11. 5V 23.0V

Under Voltage Shutdown (with load) 10.5V 21.0V

Over Voltage Shutdown 16.0V 32.0V

Over Voltage Recovery 15.5V 31.0V

Input Battery System Reset Voltage (NoteC) < 7V < 7V

Maximum Input Current - EN3DC30 30A 30A

Note A:

When the battery is charging through CH3 with normal operation (not through Ignition

or override setting), the charger will charge for 3 minutes, it will then rest for 5 seconds to

verify the Input voltage.

During the 5 seconds rest period, if the measured voltage is > Normal Under Voltage Recovery

Voltage (> 12.8Vdc on a 12V system or > 25.6Vdc on a 24V system), the unit will continue the

charging cycle through CH3.

Or if the measured voltage is < Normal Under Voltage Recovery Voltage (< 12.8Vdc on a 12V

system or < 25.6Vdc on a 24V system), the unit will switch back to charge from CH2 (PV) until

CH3 returns to Normal Start-Up Voltage (13.2V on a 12V System and 26.4V on a 24V system).

Also, during the 3 minutes charging process, if the measured terminal voltage drops below

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 18

the Under Voltage de-rated voltage (11.5V for a 12V system, 23V for a 24V system), the charger

will start to derate the output current. This function is used to compensate the use of long

or thin wire between the Input Battery System and the unit terminals. If the input voltage

continues to drop below the Under Voltage Shutdown Voltage (10.5V for a 12V system and

21V for a 24V system), the charging process will terminate and the unit will switch back to

charge from CH2 (PV). It will only switch back to CH3 if the CH3 voltage returns to 13.2V on

a 12V system or 26.4V on a 24V system.

Note B:

When the unit has activated the battery charging process using the Ignition Start terminal

or using the Manual Override through the unit setting, the input voltage specication is

reduced. It has the same charging process but with the Low Start-Up Voltage set to > 12.3V

(from 13.2V) on a 12V system and > 24.6V (from 26.4V) on a 24V system. The Low Under

Voltage Recovery Voltage is set to > 12V (from 12.8V) on a 12V system and > 24V (from 26.4V)

on a 24V system. During the 5 second rest period, if the input voltage returns above 12V/24V,

it will continue the charging process and if the input voltage did not return to > 12V/24V, it

will switch back to charge from the Solar - CH2 until the Start - CH3 input has returned to

the Low Start-Up voltage of 12.3V on a 12V system and 24.6V on a 24V system..

Also, during the 3 minutes charging process, if the measured terminal voltage drops to

below the Under Voltage de-rated limit (11.5V for a 12V system, 23V for a 24V system), the

charger will start to de-rated the charger current, this function is used to compensate the

use of long or thin wire between the Input Battery System and the unit terminals. If the

voltage continues to drop, and drops to below the Under Voltage Shutdown limit of (10.5V

for a 12V system and 21V for a 24V system), the charging process will terminate and the unit

will switch back to charge from CH2 (PV). It will only switch back to CH3 if the CH3 voltage

returns to 12.3V on a 12V system and 24.6V on a 24V system.

Note C:

The CH3 DC Input (Battery Input) can accept a 12V or 24V battery with an alternator system.

When the unit is rst connected, the unit will measure the input voltage. If the voltage is >

17V, it will assume it is connected to a 24V Input Battery/Alternator system. If the voltage

detect is < 17V, it will assume it is connected to a 12V Input Battery/Alternator system. Once

detected, it will store this into the microprocessor and it will only be erased if it is Input

battery is disconnected or if the measured Input Voltage drops to < 7Vdc.

www.enerdrive.com.au

Page 19

DC Input (CH2 – Solar / PV):

PV Input Voltage Range 14.5 - 45V

PV Input Under Voltage Shutdown 14.5V

PV Input Under Voltage Recovery 15.0V

PV Input Over Voltage Shutdown 45V

PV Input Over Voltage Recovery 44V

PV Charging Mechanism MPPT type ( approx. 97% eciency)

Maximum Input 500W *See note

*Note: The recommended maximum solar wattage input for the DC2DC Charger is 500w.

You can however “overdrive” the MPPT controller. Please note that doing this is partially

an economic decision. You can install more power than the controller can use and this will

contribute to better power availability. Enerdrive suggest a total maximum overdrive of

20% (total 600w). On cloudy (or intermittent sunny) days there will be little or no power

shaving and the extra power will serve the battery well with more energy harvest earlier

and later in the day.

Enerdrive ePOWER DC2DC Battery Charger Owners Manual (Rev. 2.02)

Page 20

Other manuals for ePOWER DC2DC

2

Table of contents

Other Enerdrive Batteries Charger manuals

Enerdrive

Enerdrive ePOWER DC2DC User manual

Enerdrive

Enerdrive ePRO EPBC-1290 User manual

Enerdrive

Enerdrive ePower Industrial EPI-2430 User manual

Enerdrive

Enerdrive ePOWER Charger EN31220 User manual

Enerdrive

Enerdrive ePOWER Series User manual

Enerdrive

Enerdrive DOMETIC EN31220 User manual

Enerdrive

Enerdrive ePower Industrial EPI-2430 User manual