Specac Selector GS19900 User manual

The Selector™

Diffuse Reflectance Accessory

User Manual

2I-19900 Issue 7

The Selector™

Diffuse Reflectance Accessory

User Manual

2I-19900 Issue 7

User Manual

2

The Selector™ Diffuse Reflectance Accessory

P/N GS19900

USER MANUAL- CONTENTS

1. INTRODUCTION ................................................................................. 3

2. UNPACKING AND CHECKLIST ............................................................. 5

3. SAFETY IN USE OF THE SELECTOR™ ACCESSORY ............................. 6

4. OPTICAL LAYOUT AND INSTALLATION OF THE SELECTOR™ ................. 7

L TO R SELECTOR™ ACCESSORY OPTICAL LAYOUT ........................... 7

R TO L SELECTOR™ ACCESSORY OPTICAL LAYOUT ......................... 10

INSTALLATION OF THE SELECTOR™ ACCESSORY ............................. 13

5. ALIGNMENT OF THE SELECTOR™ ACCESSORY ................................. 16

SAMPLE INTRODUCTION INTO THE SAMPLING CUP ............................ 16

FINE ALIGNMENT - FINAL OUTPUT MIRROR ADJUSTMENT ................. 18

OUTPUT ELLIPSOID MIRROR E2 ADJUSTMENT.................................. 21

MICROMETER SCREW ADJUSTMENT ................................................ 22

6. SAMPLE ANALYSIS .......................................................................... 24

SAMPLE CUP OPTIONS ................................................................... 24

11MM DIAMETER STANDARD SAMPLE CUP....................................... 24

4MM DIAMETER MICRO SAMPLE CUP ............................................... 25

DIABRAZE PAD AND DIABRAZE PAD MOUNT HOLDER ........................ 25

TILTED (TOTAL REFLECTANCE) SAMPLE CUP .................................. 27

PROCEDURE FOR SAMPLE MEASUREMENTS .................................... 28

USING A SAMPLE CUP OPTION ........................................................ 28

USING A DIABRAZE PAD OPTION ..................................................... 29

7. CARE AND MAINTENANCE ................................................................ 31

8. LEGEND FOR THE SELECTOR™ ACCESSORY .................................... 32

9. SPARE PARTS FOR THE SELECTOR™ .............................................. 33

10. SELECTOR™ BASEPLATE INSTALLATION GUIDE.............................. 34

© April 2016 Specac Ltd. All rights reserved.

Brilliant Spectroscopy is a trademark of Specac Ltd.

Other product names mentioned herein may be trademarks

of their respective owners.

Selector™ Diffuse Reflectance Accessory

3

1. Introduction

Thank you for purchasing a Specac product.

Infrared radiant light when reflected from a solid surface can be either

diffuse, specular or both (total reflectance) in nature.

Diffuse reflectance is based upon the collection of radiation that has

been diffusely scattered from the sample. From illumination by

infrared radiation of a solid sample surface that can deemed non linear

or irregular (e.g. powdered, granular or fabric/textile type samples),

although there will be components of some specularly reflected light

from the surface, the majority of light to collect for measurement will be

diffusely scattered.

The Selector™ accessory P/N GS19000 uses an optimized off-axis

optics configuration which selectively collects and maximizes the

diffusely reflected components of light, whilst minimizing the specular

component. The off-axis design also allows for the expansion of use of

the Selector optics with alternative specialized baseplates such as the

Environmental Chamber (P/N GS19930).

The Selector™ accessory is provided with a range of sampling cups

for appropriate sample study which include a standard 11mm diameter

cup, a micro 4mm diameter cup and a tilted cup. The tilted cup can be

used for the collection of total reflectance (diffuse and specular

components of light) spectra, if desired. In addition, there are also

abrasive sample mounts for use with 12mm diabraze pads. The

diabraze material is rubbed against the surface of an intractable solid

to deposit a small amount of the solid on the abrasive pad surface. The

diabraze pad, on the sample mount, is then placed into the sampling

position post of the Selector™ accessory.

The design of Selector™ accessory for the arrangement and infrared

light beam passage sequence for its optical mirror components means

that it is a beam direction dependant accessory for correct

installation into a spectrometer system. A left to right or right to left

beam direction (source to detector) as it passes through the

User Manual

4

spectrometer sample compartment means a Selector™ accessory will

only fit on to its appropriate beam direction dependant baseplate. The

Selector™ accessory can be installed into different spectrometer

systems by change of an appropriate baseplate, but the spectrometer

systems themselves must have the same common left to right or right

to left beam direction.

If you are in doubt as to whether your particular build of Selector™

accessory may be suitable for use and installation into a specific

spectrometer system, please contact Specac for advice.

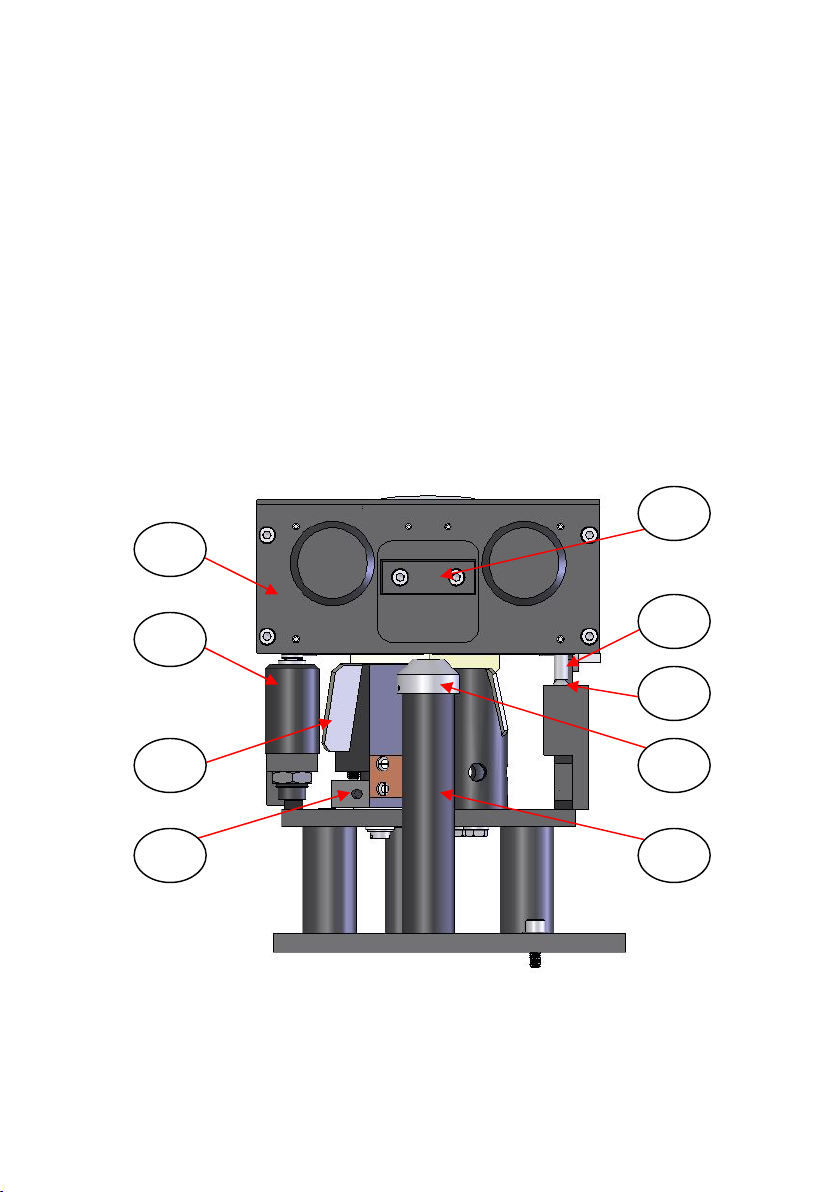

Selector™ Accessory (in Right to Left Beam Build Configuration)

Selector™ Diffuse Reflectance Accessory

5

2. Unpacking and Checklist

On receipt of your Selector™ accessory please check that the

following have been supplied: (The Selector™ accessory will be

supplied in its own carry case.)

1 Selector™ optical unit assembly in left to right or right to left

beam direction configuration.

1 Selector™ baseplate fitted with 4 support posts in left to right or

right to left beam direction configuration (for your make and model

of spectrometer)

1 Sample holder post (already fitted to the Selector™ baseplate on

some versions – simply screws into position).

1 Micro sample cup (4mm dia x 2.5mm deep).

2 Standard sample cups (11mm dia x 2.5mm deep).

1 Tilted cup. (For total reflectance measurement.)

2 Abrasive sampler (diabraze pad) mounts.

1 Packet of self-adhesive diabraze pads (20pads - 12mm dia).

1 Extended ‘T’ bar Allen key.

1 Allen Key 1.5mm A/F

1 Allen Key 2.0mm A/F

1 “Tommy Bar” (metal rod) for mirror adjustment

Baseplate fixing screws and washers (where necessary).

Carefully remove the Selector™ optical unit assembly, its baseplate

and associated components from the carry case in preparation for

installation into the spectrometer.

User Manual

6

3. Safety in Use of the Selector Accessory

There are no specific precautions to be taken when the optical unit

assembly of the Selector™ accessory is being used on its own

standard Selector™ baseplate and sampling cups or diabraze sample

pads, other than those associated safety procedures you may need to

adopt for a specific sample type. (e.g. if the sample is toxic or

hazardous, etc), as the sample for analysis is exposed to the local

environment.

Warning!

If you are to use the optical unit assembly of the Selector™

accessory on the baseplate of the complimentary

Environmental Chamber accessory (P/N GS19930), along

with any considerations that may be required for safe

handling of the sample itself, the recommended operating

safety procedures found from the Environmental Chamber

instruction manual, must be followed.

With the combination of Selector™ optical unit affixed to the

Environmental Chamber accessory, an appropriate sample can be

measured for diffusely reflected scatter of light at elevated

temperatures (up to 800°C) and pressures (up to 500psi). The

sampling post position of a standard Selector™ baseplate assembly

that accepts the individual sampling cups and diabraze sample pads of

the standard Selector™ accessory is effectively replaced by an

environmentally controllable chamber, whereby the sample for analysis

is placed into an enclosed heatable cup and covered by a pressure

certified window cap assembly. As standard the window material for

the pressure certified window cap assembly is zinc selenide (ZnSe).

Further information for the Environmental Chamber accessory is found

within its own instruction manual.

Selector™ Diffuse Reflectance Accessory

7

4. Optical Layout/Installation of the Selector™

The Selector™ accessory is a beam direction dependent accessory

whereby infrared light radiation passes from the source to the detector

of a spectrometer through the sample compartment area from a left to

right (L to R), or right to left (R to L) orientation, as viewed from the

front or above the spectrometer.

L to R Selector™ Accessory Optical Layout

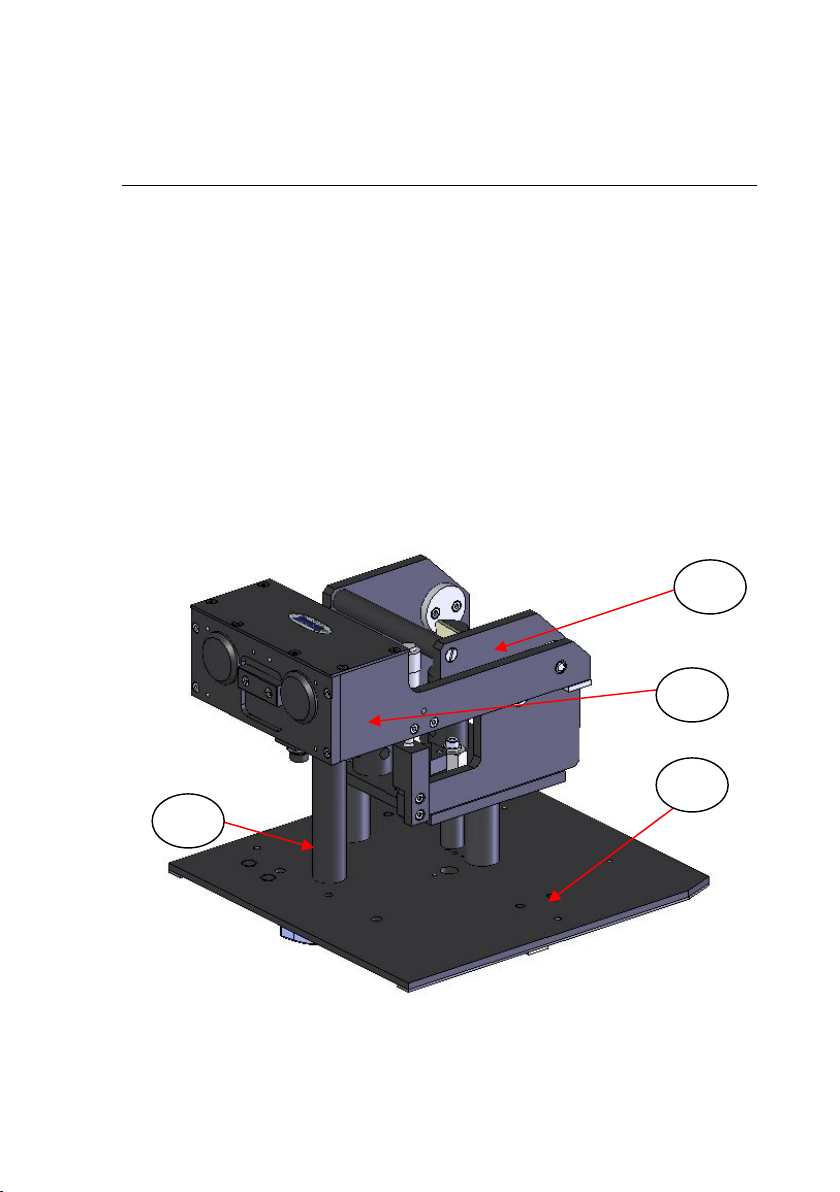

Fig 1 shows an L to R beam Selector™ optical unit (1) when fitted to

its corresponding L to R Selector™ baseplate assembly (2) and in the

Operating Position. In this case for Fig 1, the combination of the parts

as shown forms the Selector™ accessory that can be used in a Perkin

Elmer Spectrum One spectrometer.

Fig 1. L to R Beam Selector™ Accessory Fitted to an appropriate

L to R Beam Baseplate (e.g. for Perkin Elmer Spectrum One)

1

2

3

4

User Manual

8

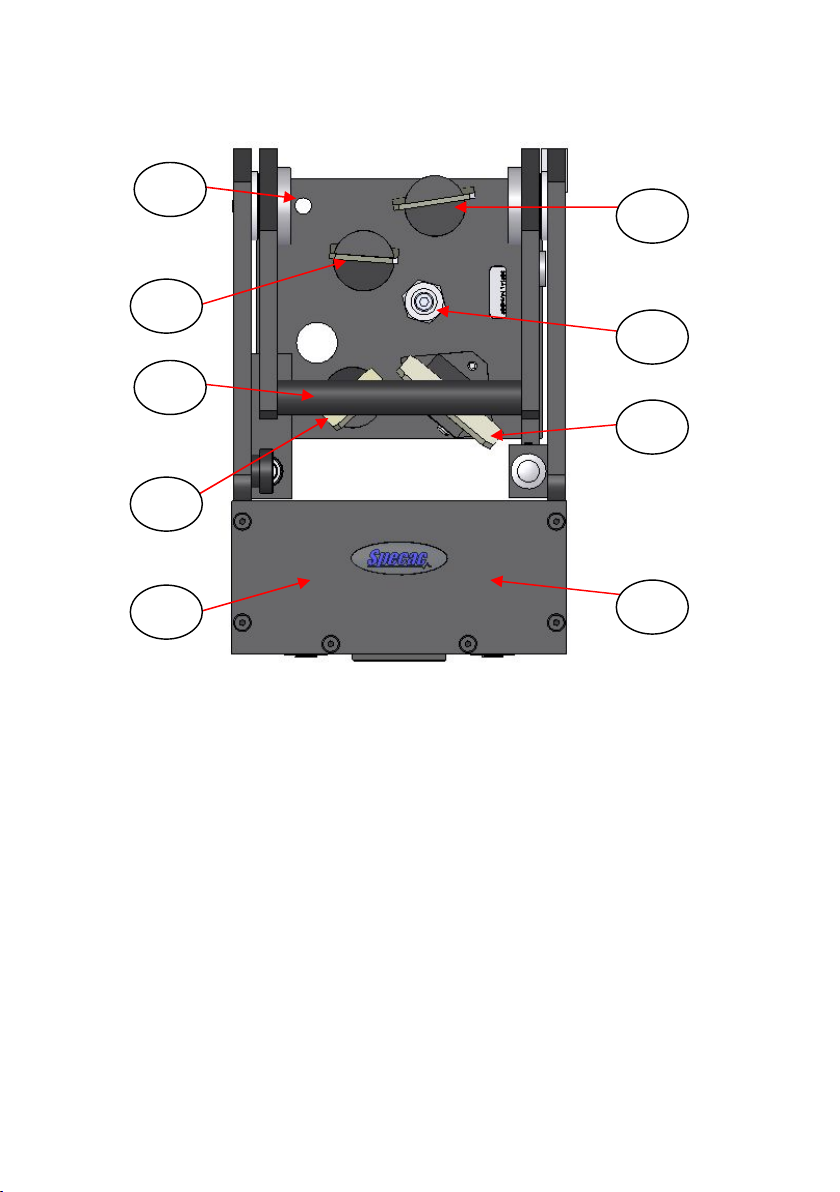

Fig 2. Top View of L to R Beam Selector™ Optical Unit

Fig 2 shows a top view of an L to R Selector™ optical unit alone and

Fig 3 shows the same L to R Selector™ optical unit but from the

underside. From the Figs 2 and 3, the light beam sequence for

passage of light through the Selector™ optical unit for an L to R

direction is as follows:-

The light beam from the source is directed to a fixed angled mirror (5)

on its mount post and onto another fixed angle mirror (6) on its mount

post. The light beam is then projected to an input ellipsoid mirror E1

(7) which then focuses the light onto the surface area of a sample held

in a cup that is positioned on top of the sample post (3) – see Fig 1. (In

Fig 2 the E1 mirror (7) has been indicated, but it is positioned

underneath the top cover of the ellipsoid mirrors arm assembly (4) –

see Fig 1.) It is easier to see E1 (7) from the underside view of Fig 3.

6

5

7

9

11

10

8

13

18

Selector™ Diffuse Reflectance Accessory

9

Fig 3. Underside View of L to R Selector™ Optical Unit

At the sample surface (e.g. a powder sample contained in a sample

cup) the incoming light from E1 (7) will be scattered and it is the

diffusely reflected component of this scattered light that is collected by

the output ellipsoid mirror E2 (8).

Note: The “off axis” design for both E1 (7) and E2 (8) mirrors being

forward and on the same side of the sampling surface area

means that when a flat, horizontal sample surface cup is used,

then only diffusely reflected light will be collected by the E2

(8) mirror. Any specularly reflected component of incident

light is lost to the system.

7

12

13

8

11

User Manual

10

After the scattered light has been collected by the E2 (8) mirror, the

light is focused towards a fixed mirror (9) on its sample mount which

then deflects the light to a movable (for rotation and tilt) mirror (10) on

its mount. The light beam can then be deflected precisely to the

detector of the system.

In summary, the beam sequence for an L to R Selector™ as indicated

for the mirrors from Figs 2 and 3 is:-

Source – (5) – (6) – (7) – Sample – (8) – (9) – (10) – Detector.

R to L Selector™ Accessory Optical Layout

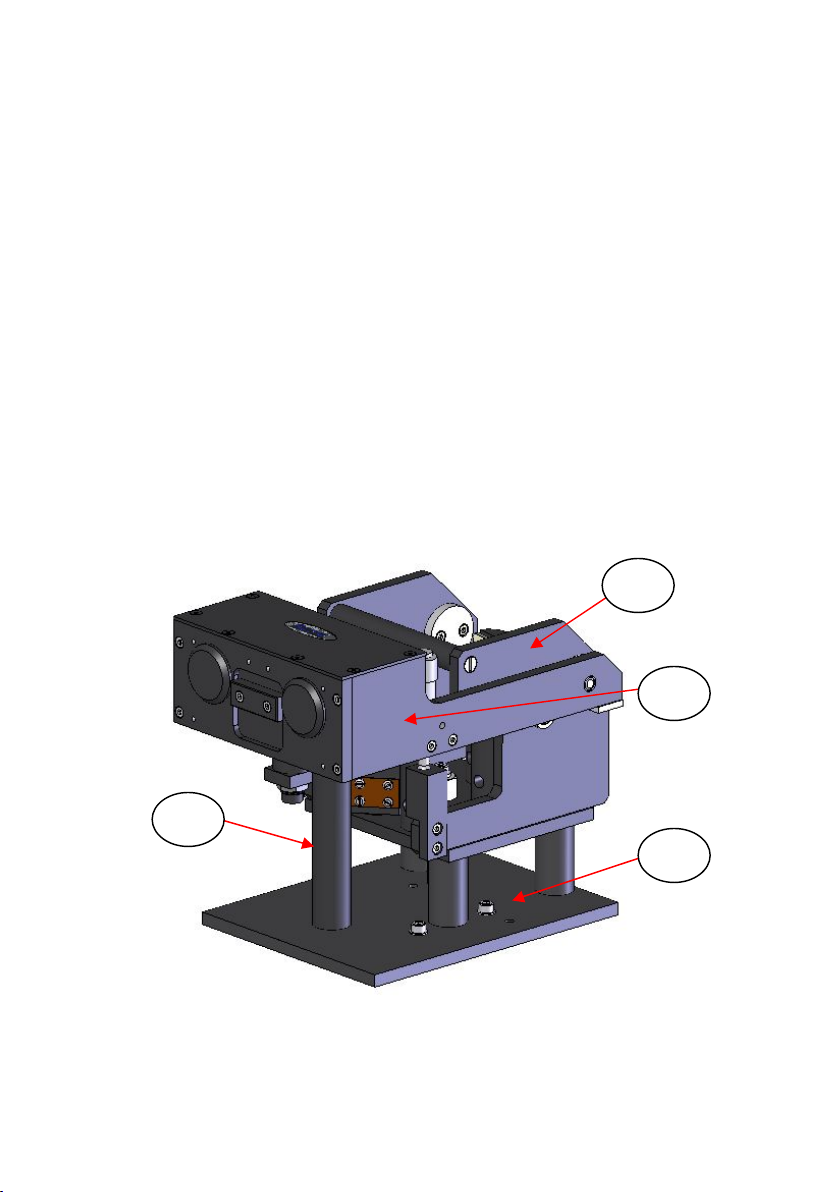

Fig 4 shows an R to L beam Selector™ optical unit (1) when fitted to

its corresponding R to L Selector™ baseplate assembly (2) and in the

Operating Position. In this case for Fig 4, the combination of the parts

as shown forms the Selector™ accessory that can be used in a variety

of Nicolet Spectrometers (Nexus, Avatar, iS10, etc).

Fig 4. R to L Beam Selector™ Accessory Fitted to an Appropriate

R to L Beam Baseplate (e.g. for Nicolet iS10)

3

1

4

2

Selector™ Diffuse Reflectance Accessory

11

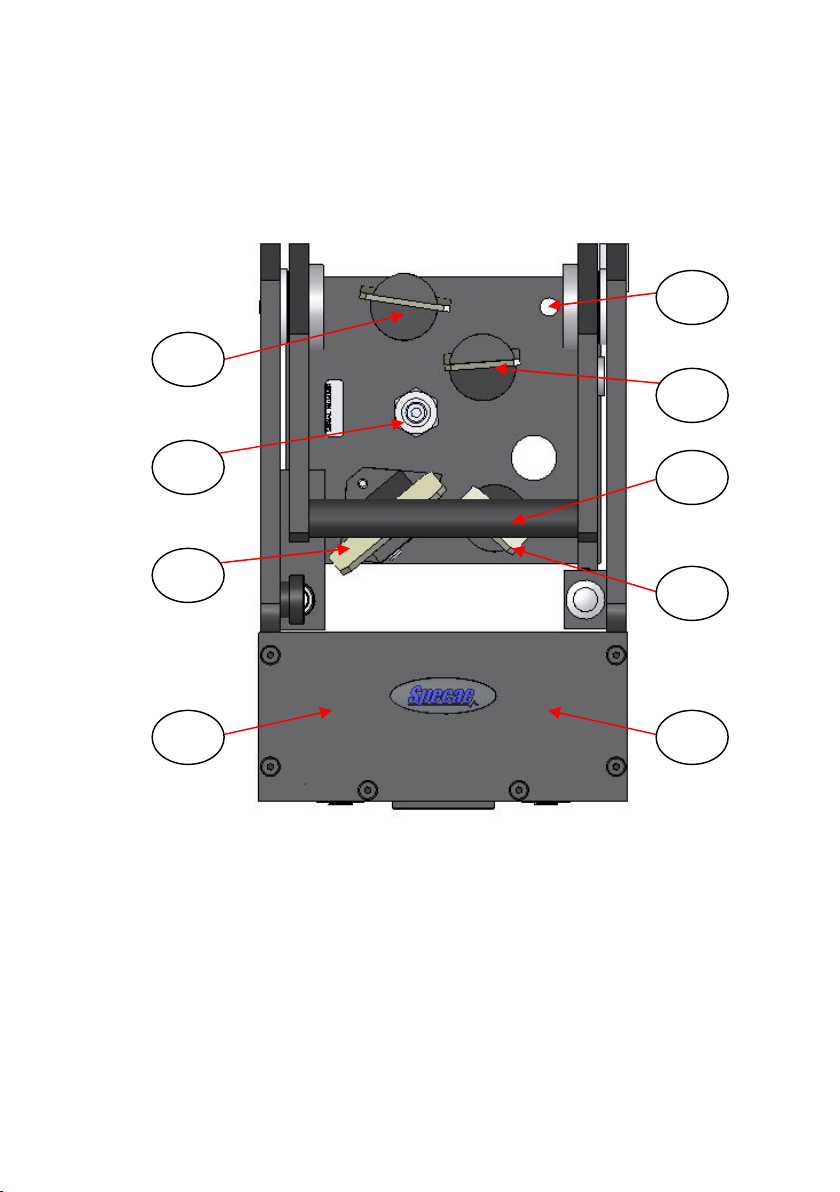

Accordingly, similar to an L to R Selector™, Fig 5 shows a top view of

an R to L Selector™ optical unit alone and Fig 6 shows the same

R to L Selector™ optical unit but from the underside.

Fig 5. Top View of R to L Beam Selector™ Optical Unit

From the Figs 5 and 6, the light beam sequence for passage of light

through the Selector™ optical unit for an R to L direction is as follows:-

The light beam from the source is directed to a fixed angled mirror (5)

on its mount post and onto another fixed angle mirror (6) on its mount

post. The light beam is then projected to an input ellipsoid mirror E1

(7) which then focuses the light onto the surface area of a sample held

9

11

10

8

6

5

7

13

18

User Manual

12

in a cup that is positioned on top of the sample post (3) – see Fig 4. (In

Fig 5 the E1 mirror (7) has been indicated, but it is positioned

underneath the top cover of the ellipsoid mirrors arm assembly (4) –

see Fig 4.) It is easier to see E1 (7) from the underside view of Fig 6.

Fig 6. Underside View of R to L Selector™ Optical Unit

At the sample surface (e.g. a powder sample contained in a sample

cup) the incoming light from E1 (7) will be scattered and it is the

diffusely reflected component of this scattered light that is collected by

the output ellipsoid mirror E2 (8).

8

11

7

12

13

Selector™ Diffuse Reflectance Accessory

13

Note: The “off axis” design for both E1 (7) and E2 (8) mirrors being

forward and on the same side of the sampling surface area

means that when a flat, horizontal sample surface cup is used,

then only diffusely reflected light will be collected by the E2

(8) mirror. Any specularly reflected component of incident

light is lost to the system.

After the scattered light has been collected by the E2 (8) mirror, the

light is focused towards a fixed mirror (9) on its sample mount which

then deflects the light to a movable (for rotation and tilt) mirror (10) on

its mount. The light beam can then be deflected precisely to the

detector of the system.

In summary, the beam sequence for an R to L Selector™ as indicated

for the mirrors from Figs 5 and 6 is:-

Source – (5) – (6) – (7) – Sample – (8) – (9) – (10) – Detector.

Installation of the Selector™ Accessory

The Selector™ optical unit (1) is mounted onto a baseplate (2) to

provide high stability when installed into the spectrometer. Initially, the

spectrometers own sample mount and/or sample compartment (if this

is part of the spectrometer’s design) will have to be removed before the

Selector™ accessory can be installed. The L to R or R to L Selector™

optical unit (1) is supplied with an appropriate baseplate (2) and the

necessary fixing screws specifically for the spectrometer into which it is

to be installed and used.

Some spectrometer systems (such as Mattson, Bruker and Nicolet

500/700 Series instruments) require the baseplate (2) to be installed

into the sample compartment before the Selector™ optical unit (1) is

attached to the baseplate (2). For other spectrometers, the Selector™

optical unit (1) can be mounted on the baseplate (2) prior to installation

in the sample compartment.

For installation of the Selector™ baseplate (2) itself into a specific

spectrometer (with or without the Selector™ optical unit (1) fitted),

please see the Installation Guide in Section 10) of this manual.

User Manual

14

Attachment of the Selector™ Optical Unit (1) to the Baseplate (2)

It can be seen by comparison of the build of Selector™ accessory that

an R to L beam direction version is a reversed “mirror” image of an

L to R beam direction version for positioning of the mirror components.

On the Selector™ optical unit base (for both L to R and R to L

versions) there is a central fixing M4 x 25mm captive screw (11). There

is also a slot hole (12) and circular hole (13) on the Selector™ optical

unit base. (See Figs 3 and 6.) From the combination of fixing screw

(11) and location holes (12) and (13), an L to R or R to L Selector™

optical unit is fitted to its appropriate baseplate. Similar to the mirrors,

the fixing hole positions on the Selector™ optical unit base and central

fixing screw for attachment to the specific L to R or R to L baseplate

are also in a reversed mirror image configuration.

For attachment of the Selector™ optical unit (1) to its baseplate (2)

carefully lift the Selector™ optical unit by the lifting handle (18) - see

Figs 2 and 5 - and position over the baseplate (2) – see Figs 7 and 8.

Note: It is best to have the Selector™ ellipsoid mirrors arm assembly

(4 in the down/closed (Operating Position) such that you can

see the locating holes (12 and 13) and fixing screw (11) of the

Selector™ optical unit, to match them up to the baseplate posts.

Align the slot hole (12) with the front support post (15) stud and the

circular hole (13) with the rear support post (16) stud of the baseplate

(2) and push the optical unit (1) onto the baseplate such that the

optical unit is also supported on the third post (17) of the baseplate.

Note: The locating holes and post studs will be on the left hand side of

the optical unit base for an L to R beam direction accessory and

on the right side of the optical unit base for an R to L beam

direction accessory. You cannot fit an L to R beam direction

Selector™ optical unit to an R to L beam direction baseplate (or

vice versa). The sample post (3) should be to the front of the

baseplate near to and underneath the ellipsoid mirrors (7, 8).

Using the extended ‘T’ bar Allen key supplied, carefully screw the

captive fixing screw (11) into the middle pillar (14) on the baseplate.

Selector™ Diffuse Reflectance Accessory

15

Gently tighten to secure the Selector™ optical unit (1) to the baseplate

(2), but do not overtighten the fixing screw (11). The optical unit base

underside should not actually touch the top of the middle pillar (14).

Fig 7. L to R Selector™ Baseplate (Perkin Elmer Spectrum One)

Fig 8. R to L Selector™ Baseplate (Nicolet Avatar, Nexus, iS10)

3

17 14

16

15

3

15

16

14

17

User Manual

16

5. Alignment of the Selector™ Accessory

The Selector™ diffuse reflectance accessory has been pre-aligned

before leaving Specac and will only require minor adjustment to some

of the parts to maximize the light beam throughput when the accessory

is installed in your spectrometer.

Note: Usually, only the output ellipsoidal mirror E2 (8) and final output

mirror (10) that are adjustable may need to be altered for their

settings to obtain an optimum light throughput on your

spectrometer. The mirrors (8) and (10) will be on the left side of

the optical unit (1) looking from above for a spectrometer with an

R to L beam direction and on the right side for a spectrometer

with an L to R beam direction.

Specifically, if you have a Selector™ accessory for use in a Perkin

Elmer Spectrum 2000 (GX) spectrometer, the initial input (5) and final

output (10) mirrors on the optical unit (1) are both adjustable for

rotation and tilt. This is because the Spectrum 2000 (GX) spectrometer

can be used with an L to R or R to L beam direction depending on the

position of the sampling compartment and detector system to the light

source” unit. Although the input (5) and output (10) mirror assemblies

look similar, there is a difference in the fixed angled face of the mirrors

on their adjustable mounts. Hence, you will have been provided with a

specific L to R or R to L beam direction Selector™ optical unit (1) that

will only affix to the appropriate L to R or R to L baseplate (2) for your

configuration of Perkin Elmer Spectrum 2000 (GX) spectrometer.

Sample Introduction into the Sampling Cup

Having installed the Selector™ optical unit (1) into the spectrometer via

its appropriate baseplate (2), before fine alignment and operation of

the Selector™ accessory can be carried out, a representative test

sample must be placed into position. One of the choice of sampling

cups, or a diabraze pad on its support holder that have been provided

with the Selector™ accessory can be used for positioning on the top of

the sample post (3). (Please refer to Section 6 of this manual to explain

about the sampling cups and diabraze pad sampling options.)

Selector™ Diffuse Reflectance Accessory

17

Ground spectroscopic grade KBr or KCl powder is recommended for

use as a reference material for alignment and background spectra. The

powder can be placed into the 11mm diameter sample cup (19) that is

mounted on the top of the sample holder post (3). (See Fig 9.)

Tip: It is best to fill the sample cup away from the optical unit (1) and

spectrometer in case of accidental sample spillage.

Note: For the purposes of explanation for the alignment procedure an

R to L Selector™ accessory is used in the following diagrams. If

you have an L to R Selector™ accessory the same steps for

alignment are followed but the mirrors (8) and (10) for any

adjustments are reversed for their positions as shown on the

L to R built Selector™ accessory.

Fig 9. Front View of R to L Selector™ Accessory in Operating

Position (Ellipsoid Arm Assembly Down/Closed)

24

19

3

4

25

26

27

28

10

User Manual

18

Taking the standard 11mm diameter sample cup, fill it with finely

ground KBr or KCl powder. When filled, carefully flatten the top surface

of the powder with a piece of glass or polished metal, so that is level

with the top edge of the sample cup (19).

Raise the ellipsoid mirrors arm assembly (4) by the recessed finger

handle (24) on the Selector™ optical unit (1) to its up/open Sample

Loading Position. When the ellipsoid mirror arm assembly (4) has

been raised upright, it will remain in position. (See Fig 10.)

Place the KBr or KCl filled sample cup (19) carefully onto the top of the

sample holder post (3). Try to avoid any spillage of the flattened

sample powder when fitting the cup (19) to the post (3).

Lower the ellipsoid mirrors arm assembly (4) back to its down/closed

Operating Position so that the height adjustment micrometer screw

(25) rests on the steel ball stop (26). (See Fig 9.) A shock absorber

(27) is fitted to ensure that the ellipsoid mirrors arm assembly (4)

comes to rest gently on the steel ball (26) without damaging the

micrometer (25).

With the ellipsoid mirrors arm assembly (4) closed the beam sequence

through the Selector™ optical unit (1) should be completed and at this

stage some energy throughput from diffusely collected light off of the

sample surface should be observed by the spectrometers own

detection system.

Fine Alignment – Final Output Mirror (10) Adjustment

When the sample cup (19) with sample is in position and there is some

energy throughput being measured by the spectrometers detection

system, then fine alignment of the optics that are adjustable can be

carried out to “peak up“ the throughput signal.

Firstly, the final output mirror (10) should be adjusted to try and

improve the throughput signal. The “Tommy bar” supplied enables

rotational adjustment of the final output mirror (10). Insert the “Tommy

bar” from the front of the Selector™ accessory into the hole in the base

(28) of the final output mirror mount (10). (See Fig 9.) Carefully move

the “Tommy bar” horizontally in a left or right direction to improve the

throughput energy signal value. If the movement in one direction

Table of contents

Other Specac Laboratory Equipment manuals

Specac

Specac APEX QUICK RELEASE DIE User manual

Specac

Specac Storm 10H User manual

Specac

Specac Gateway ATR User manual

Specac

Specac GS12000 Series User manual

Specac

Specac Quest User manual

Specac

Specac Quest ATR GS10800 Series User manual

Specac

Specac Golden Gate GS10500 Series User manual

Specac

Specac Gateway ATR User manual

Specac

Specac Quest User manual

Specac

Specac Golden Gate GS10640 User manual