2

1.0 RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage.

Shipping damage is not covered by warranty. If

shipping damage is found notify carrier at once. The

carrier is responsible for all repair and replacement

costs resulting from damage in shipment.

safety first

Read all instructions, warnings and cautions carefully.

Follow all safety precautions to avoid personal

injury or property damage during system operation.

Enerpac cannot be responsible for damage or

injury resulting from unsafe product use, lack of

maintenance or incorrect product and/or system

operation. Contact Enerpac when in doubt as to the

safety precautions and applications.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of equipment or other

property

A WARNING indicates a potential danger that

requires correct procedures or practices to avoid

personal injury.

2.0 SAFETY ISSUES

Failure to comply with the

following cautions and warnings

could cause equipment damage

and personal injury.

IMPORTANT: Minimum age of the

operator must be 18 years. The operator

must have read and understood all

instructions, safety issues, cautions and warnings

before starting to operate the Enerpac equipment.

The operator is responsible for this activity towards

other persons.

CAUTION: Make sure that all system

components are protected from external

sources of damage, such as excessive

heat, flame, moving machine parts, sharp edges and

corrosive chemicals.

WARNING: Immediately replace worn or

damaged parts with genuine Enerpac

parts. Enerpac parts are designed to fit

properly and withstand rated loads.

WARNING: Always wear safety glasses.

The operator must take precaution

against injury due to failure of the tool or

workpiece

We recommend the use of special

loosening liquids or sprays. Enerpac

hydraulic torque wrenches offer both

square and hexagon drive units to loosen or tighten

bolts and nuts. Enerpac offers nut splitters in case a

nut can not be removed.

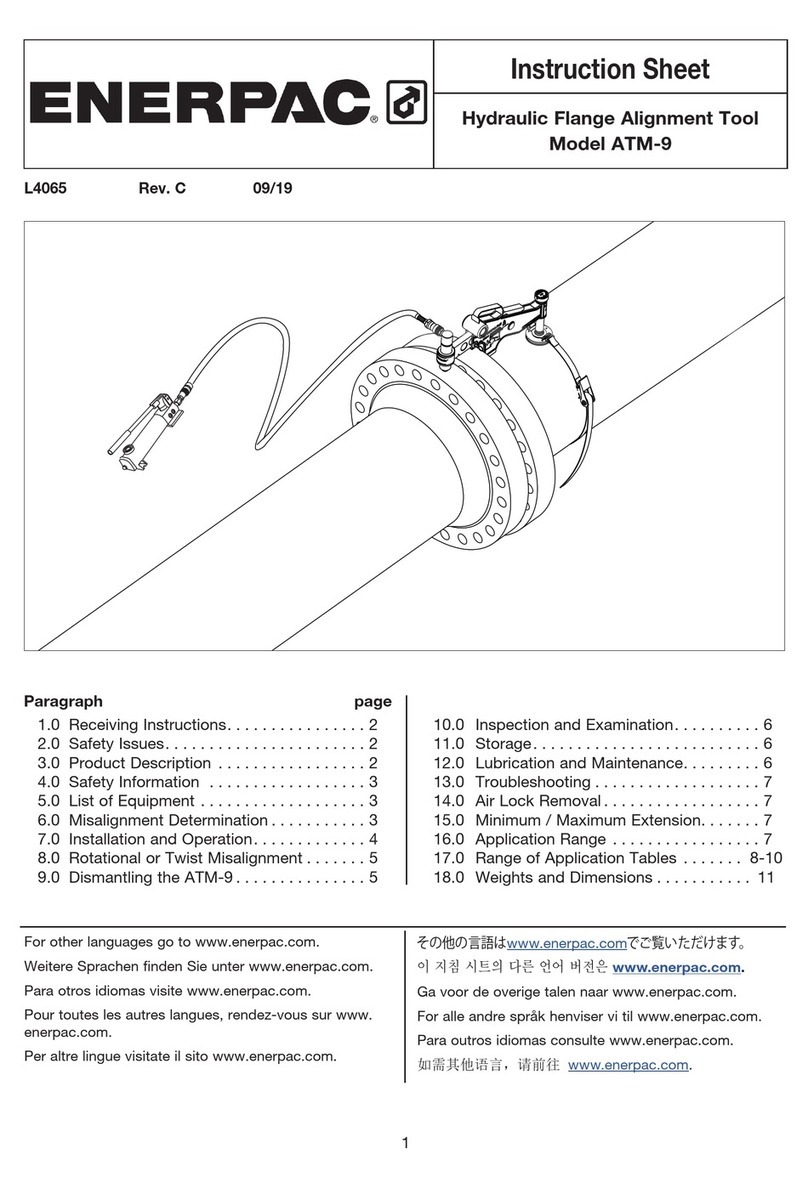

3.0 PRODUCT DESCRIPTION

The ATM-4 Alignment Tool is intended for use in

typical maintenance and installation procedures. It

allows the realignment of misaligned flanges within

a 4 ton [40 kN] physical capacity. It may be used

to assist in the replacement of ring and other type

joints.

The use of these instructions will promote the safe

use and maximum service life of the tool. All sections

of this instruction sheet should be read prior to using

the tool.

3.1 Applications

The ATM-4 Alignment Tool can be used for:

Flange change outs, repair of pipe lines, replacing

bolts, gaskets and seals and for aligning parts for

fabricating.

3.2 Major Features and Components

See Fig. 1. for an overview of ATM-4 major features

and components.

LIFT HOOK

TORQUE WRENCH

AND 22 mm SOCKET

DROP LEG

Fig. 1

SCREW BOLT

WING RETAINING KNOB

DROP

LEG

KNOB

SWIVEL

3.3 Capacity Information

Maximum Load

Wing Fully Retracted: Wing Fully Extended:

3.0 T [30 kN] from 50

ft-lbs [68 Nm] of torque.

4.0 T [40 kN] from 50

ft-lbs [68 Nm] of torque.