© 2019 Enerpac, All Rights Reserved. 7

6.

Be sure that all nuts and threaded pullers

are free running on the studs over the entire

stud length protruding through the joint.

7. Check that each stud is correctly installed

and that there is sucient stud extension

to engage the tensioner. The exposed

portion of the stud (above the nut) should

be at least the same dimension as the stud

diameter. The total protruding length of

the stud (from joint surface to end of stud)

must be at least twice the length of the

exposed portion of the stud. See Figure 5.

FIGURE 5, STUD EXTENSION REQUIREMENTS

6.2 Tensioner Installation and Hook-up

1. Refer to Section 6.1, Before You Begin.

All personnel to be involved in tensioning

procedures must read, understand and

follow the instructions contained in Section

6.1.

2. Determine the tensioner arrangement

around the joint surface. Refer to

Section 6.3 for examples and additional

information.

3. Before installing the first tensioner, be

sure

that the threaded portions of the stud

and threaded puller are clean and free of

damage.

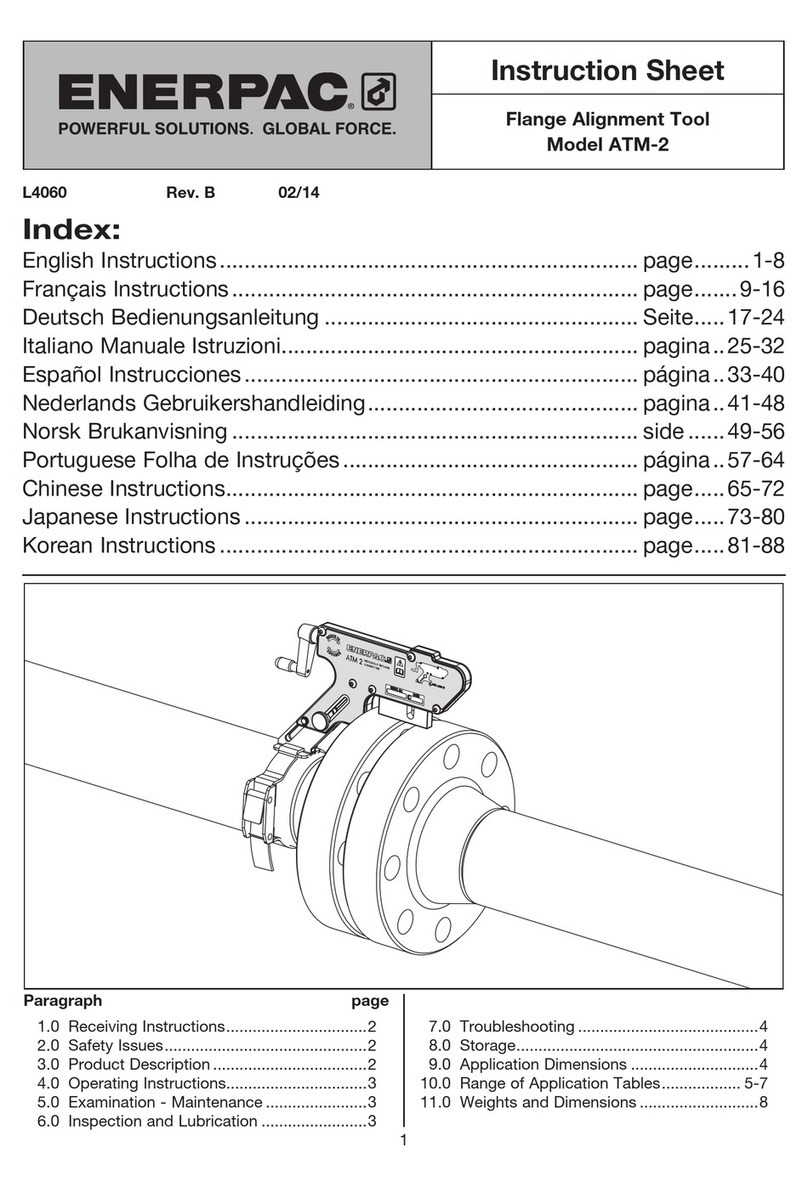

4. Place the tensioner over the stud, ensuring

that the socket fits over the nut without

force. See Figure 6, View A.

a. Ensure that the tommy bar slot in the

bridge faces outward.

b. Ensure that the hydraulic couplers are

positioned outward, to allow easier

connection of hydraulic hoses.

Note: GT bridges and sockets manufactured

prior to 2019 and which have a Date Code

of A, will not have the socket captivation

feature. For GT Tensioners with a Date Code

of A, position the socket over the nut; ensure

that the socket fits over the nut without

force. Place the tensioner over the stud.

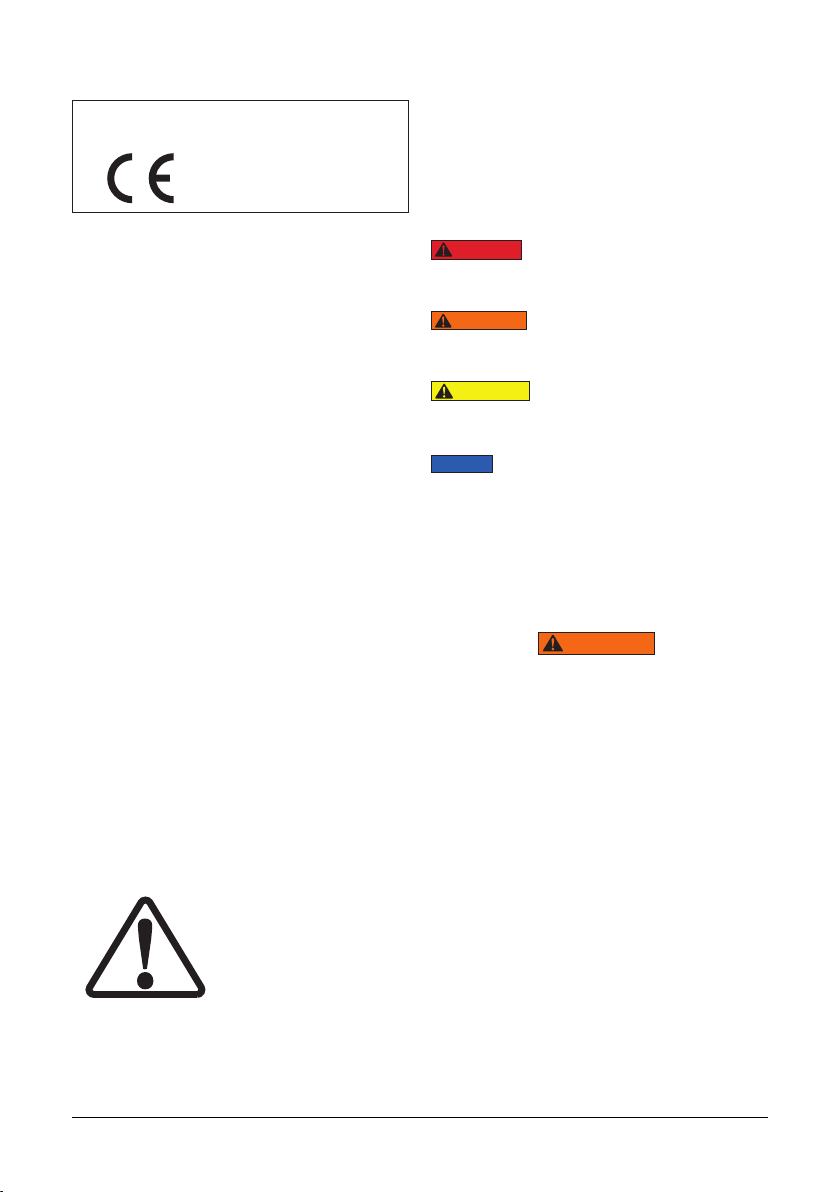

5. Locate the end of the stud with the

threaded

puller. Using a tommy bar, screw

down the threaded puller on the stud until

the puller shoulder seats firmly against the

piston. See Figure 6, View B.

6. Assemble any additional tensioners in the

system in the same manner, following

steps 3 through 6 of this section.

7. Check that the pump pressure release

valve

is OPEN. See Figure 6, View C.

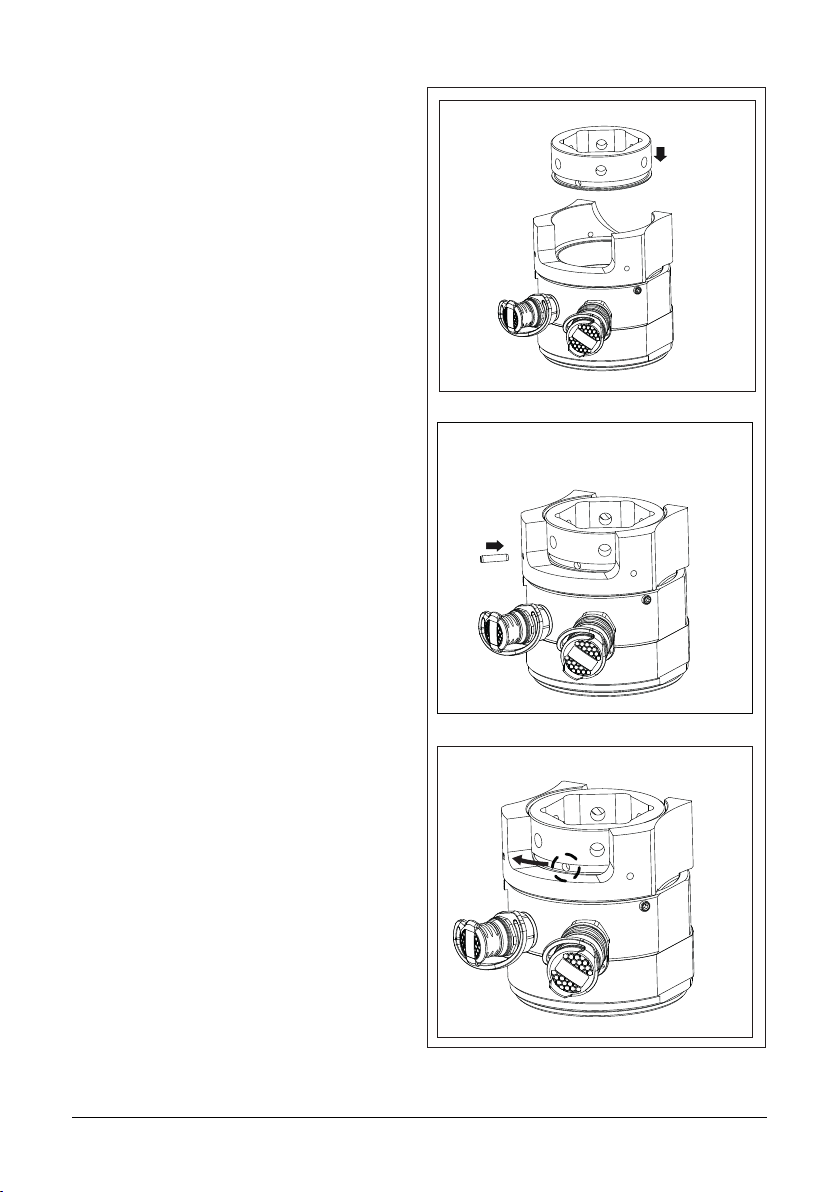

8. Connect hydraulic hoses to the tensioners.

See Figure 6, views D and E. Also refer to

Section 6.3 for typical hose connection

arrangements.

9. At each stud, verify that the piston is

fully retracted into the tensioner body. If

necessary, turn down the threaded puller

(as required) to fully retract the piston.

10. Before pressurizing the system, be sure

that all hydraulic hoses are connected.

Each male coupler must be connected to

a corresponding female coupler. Verify that

each coupler is fully engaged and securely

locked into position by physically pulling

on the connection.

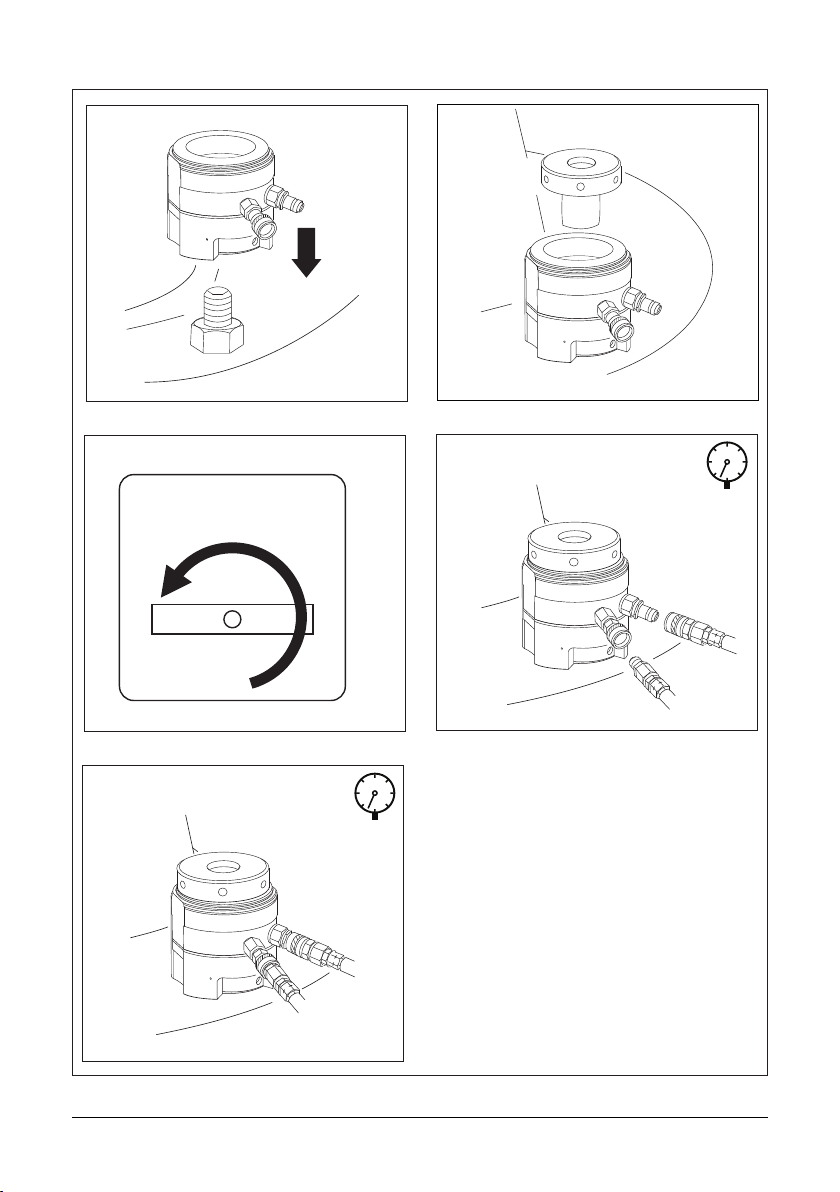

IMPORTANT: ONLY the unused female coupler

on the LAST tensioner at the end of the circuit

can remain disconnected. A blanking plug must

be installed in this coupler before beginning

pressurization.

Never pressurize the back side

of a disconnected (open ended) male coupler.

Disconnected male couplers may leak when

pressurized from the back side. Serious

personal injury could result if leakage occurs,

and a high pressure oil stream penetrates the

skin.

If only a single tensioner is being

used, always pressurize the tensioner using

ONLY the MALE tensioner coupler. To prevent

possible high pressure oil leakage, NEVER use

the female tensioner coupler to pressurize a

single tensioner.

WARNING

WARNING