Ensitech TIG Brush User manual

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

Stainless Steel Weld Cleaning System

TIG Brush Instruction Manual

Ensitech is committed to providing the highest quality goods, services,

and solutions for all of our customers. To achieve this goal, we adhere to

the process of a QUALITY MANAGEMENT SYSTEM which complies with

the requirements of ISO 9001:2015 for the following scope: the design,

manufacture, supply and repair of TIG Brush weld cleaning systems.

QUALITY YOU CAN TRUST

3

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

STOP!

Register your Warranty

Online and Extend your 2-Year

Warranty at no extra Cost!

Ensitech offers an extended 6-month warranty* on any new TIG Brush Control Unit that has its

warranty information registered on the TIG Brush website www.tigbrush.com/warranty.

Registering your TIG Brush online and activating your warranty is easy and links your product

with proof of ownership and warranty service. Online warranty activation also simplifies proof

of purchase in the event of a warranty claim.

Your TIG Brush extended warranty is issued on the condition that you complete the online

warranty activation within 30 days of purchase and purchase verification is attached. The

extended warranty only applies to the TIG Brush Control Unit, and does not include cables,

the PROPEL Torch, consumables or any other TIG Brush accessory.

*For full Terms and Conditions of your TIG Brush warranty see (Ensitech Warranty Against Defects)

on page 28 of this Instruction Manual.

Registration is quick and easy. Go to www.tigbrush.com/warranty

4TIG Brush™ Instruction Manual

2022

This instruction manual is an important tool and designed to help you get

the most out of your Ensitech products. We recommend you keep it with your

TIG Brush at all times.

Please take the time to read this manual as it provides users with the necessary

operating procedures and safety precautions, essential for the safe and proper

operation of the TIG Brush.

With correct usage and maintenance, you can be assured your TIG Brush will

give you reliable service for many years to come.

Due to continuous improvements, Ensitech Pty Ltd, reserves the right to make

specification changes and update this Instruction Manual accordingly.

© 2022 Ensitech Pty Ltd

FOREWORD

FOREWORD

5

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

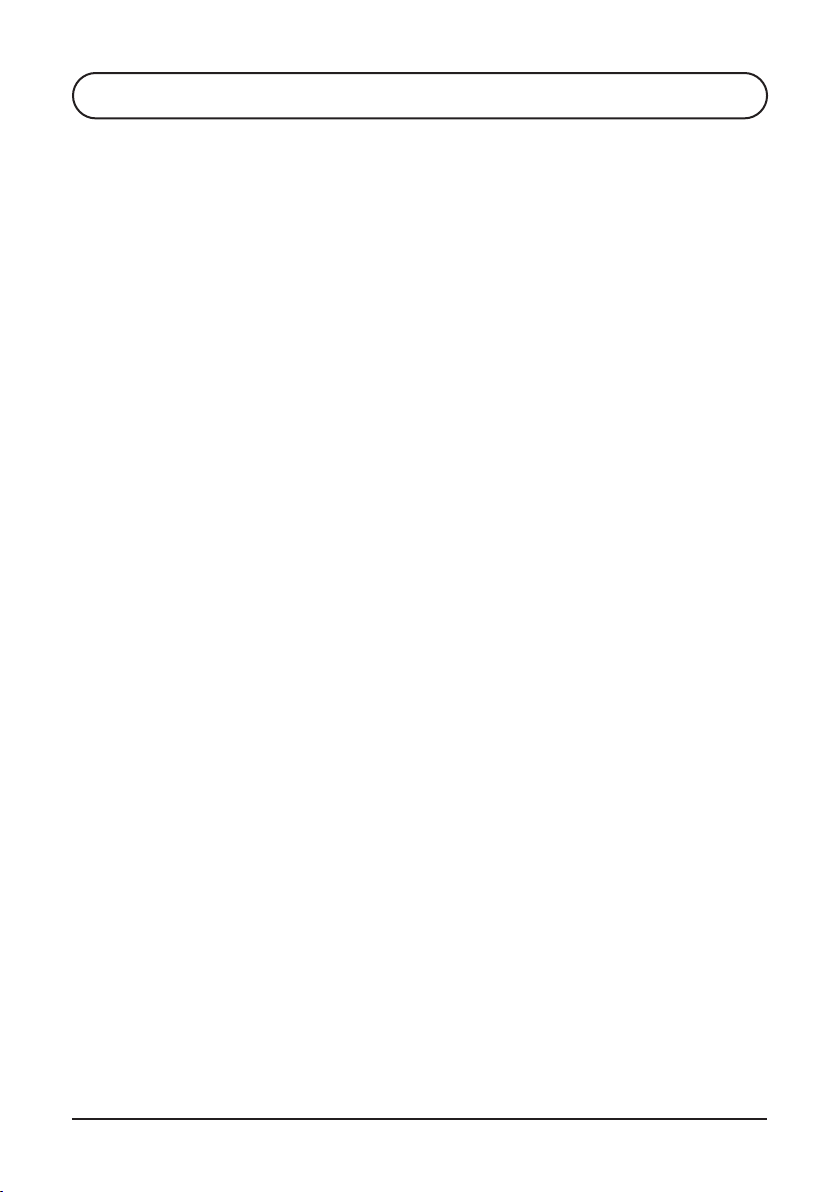

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT

YOU TO THE POTENTIAL PERSONAL INJURY HAZARDS. OBEY

ALL SAFETY MESSAGES THAT FOLLOW THIS SYMBOL TO

AVOID POSSIBLE INJURY.

WARNING

SYMBOL FOR “VOID WARRANTY” OR “DAMAGED WORK”

V

INDICATES AN IMMEDIATELY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT

MAY ALSO ALERT AGAINST UNSAFE PRACTICES.

CAUTION

THIS SYMBOL INDICATES A HAZARDOUS SUBSTANCE WHICH

MAY CAUSE MINOR OR MODERATE INJURY. SOME TIGBRUSH

KITS MAY SHIP WITH HAZARDOUS FLUIDS. CHECK SAFETY

DATA SHEETS CAREFULLY.

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

FOREWORD

6TIG Brush™ Instruction Manual

2022

FOR:

• Product safety publications

• Current owner updates

• Questions regarding product safety

• Standards and regulations compliance information

•

• Questions regarding product modifications

• Accident reporting

www.tigbrush.com/contact

Questions regarding special product applications

CONTACT

Ensitech Pty Ltd

Unit 1/144 Old Bathurst Road

Emu Plains NSW 2750

Australia

Phone: +61 2 4735 7700

Email: [email protected]

Ensitech Inc

340 Marshall Ave, Bldg#104

Aurora IL 60506

United States

Phone: +1 630 405 6440

Email: [email protected]

Your local TIG Brush distributor/dealer or Ensitech direct:

FOREWORD

7

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

REVISIONS LOG

Original issue of Manual: August 2016

Revision 1: April 2018

Revision 2: February 2020

Revision 3: July 2022

REVISIONS LOG

8TIG Brush™ Instruction Manual

2022

9

10

12

12

13

14

16

16

16

17

18

19

21

16

22

22

22

23

24

24

24

24

24

24

24

24

24

26

26

26

INTRODUCTION

SAFETY PRECAUTIONS AND INFORMATION

DESCRIPTION OF BASIC EQUIPMENT

S1

S2

S3

3.1 Classic Kit

3.2 Flexi Handle Kit

3.3 PROPEL Kit

4.1 Preparation

4.2 Assembly

4.2.1 Classic Kit

4.2.2 Flexi Handle Kit

4.2.3 PROPEL Torch

4.3 Cleaning Fluid

4.4 Operation

OPERATIONS4

POWER AND MODE SETTING

5.1

5.2

S5

Power Settings

Mode Settings

MAINTENANCES6

28

WARRANTYS9

CONSUMABLES

7.1

7.2

7.3

S7

Brushes

Insulating Shrouds

257.4 PROPEL Torch Collets

Fluids

• Pre-Weld Cleaning Fluids

• Weld Cleaning Fluids

• Neutralising Fluids

• Finishing Fluid

• Printing Fluids

• Engraving Fluids

TROUBLESHOOTING

8.1 The mains power button on the back of the Control Unit doesn’t

operate properly or illuminate.

The front panel LEDs are not illuminating.

8.2

26

The Control Unit is making a humming/buzzing noise.

8.3

27

The front Control Unit lights are illuminated but it will not clean or

it’s not performing as well as normal.

8.4

S8

CONTENTS

9

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

INTRODUCTION

Congratulations on the purchase of your TIG Brush!

Designed, developed, and manufactured in Australia by Ensitech, the TIG Brush

is an electrochemical surface finishing system. It uses the combined action of

electric current, heat, and chemistry to provide fast metal finishing. The system

is famous for its ability to remove heat tint from stainless steel TIG and MIG

welds. In addition, the TIG Brush can perform other functions such as polishing

metal surfaces, indelibly printing logos, text, and even engraving/etching.

To meet your specific needs several options are available. The 440, 550 and 700

models offer different power levels for light work on thin metal through to

removing deep heat tint from the largest metalwork. See section S5 for

more information.

Several proprietary fluids are available for different operations. There are

solvents for adhesive removal and weld preparation, acids for fast heat tint

removal with matching neutralisers, and neutral solutions for food safe work.

See section 7.3.

There are several tools available to enable the different operations. The Classic

Wand for general work, the PROPEL for the more sophisticated user and the

Flexi-Wand to get to more inaccessible work. See section 4.2

When used with the Branding Kit and custom-made or single use stencils,

the TIG Brush will also permanently brand your stainless steel with an indelible

printed mark or engraving. For more details on the Branding Kit visit

www.tigbrush.com/products/branding-kit.

As well as Stainless Steel, the TIG Brush can also be used with other metals

such as brass, copper and aluminium (aluminum). Contact your local TIG

Brush distributor/dealer team for more information, or visit our website

www.tigbrush.com

S1 INTRODUCTION

10 TIG Brush™ Instruction Manual

2022

S2

Protect yourself and others by observing all safety

information, warnings and cautions. Failure to comply with

instructions could result in personal injury and/or damage

to the product or property.

Read this documentation carefully before operating the

equipment. Please retain these instructions for future

reference.

Before using the TIG Brush, make sure the work environment

is well ventilated and away from any combustible substances.

Ensure that all required equipment is available.

Do not use the TIG Brush for any purpose other than that

described in this manual. Failure to observe this warning

may result in permanent damage to the TIG Brush, cause

damage to the workpiece, cause injury to the operator

and void the warranty.

The TIG Brush is one of the safest appliances in its class. However

some precautions must be taken with the use of the TIG Brush,

as with any electrolytic/electrochemical weld cleaner.

• The TIG Brush uses mild acids; gloves should be used to

avoid prolonged contact with any of the fluids.

•Goggles or safety glasses should be worn to prevent fluid

being splashed in the eyes.

Where an inhalation risk exists, wear a type B (Inorganic

gases & vapours) respirator.

SAFETY PRECAUTIONS

SAFETY INFORMATION

WARNING

•

SAFETY PRECAUTIONS AND INFORMATION

11

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

CAUTION

• Fluid spilled on the skin should be washed off as soon as practical.

• Safety Data Sheets are available for all fluids and should be

read before use (to access Safety Data Sheets online go to

www.tigbrush.com/resource-information/safety-data-sheets)

• The brush gets extremely hot in use, in excess of 200°C (400°F) so make

sure you wear protective gloves when touching the brush when in use or

directly after use. Do not place the brush near any flammable materials.

•DO NOT connect the TIG Brush to any metal work, which has a welding

machine, or other (cleaning) equipment attached to it. Welders can output

an open-circuit voltage, which can exceed 120 volts. While the TIG Brush

has been designed to withstand up to 150 volts, under certain circumstances

a welder can generate a high enough voltage to damage the TIG Brush.

• The TIG Brush produces an electric current which may generate small

sparks between the brush and the metal being cleaned.

• Hydrogen gas may also be generated (which is an invisible but

explosive gas). Always use the apparatus in a well ventilated area.

Do not use near flammable substances, or in areas where dense

flammable gases (such as petrol vapour) may accumulate.

• If the power cord is damaged or if the TIG Brush has been dropped

from a height and damaged, do not use the unit. Contact your

TIG Brush supplier to have the TIG Brush inspected and repaired.

• Do not short out the terminals, or use the TIG Brush with a damaged

wand or cables. Doing so may permanently damage the TIG Brush

and cause damage to the workpiece being cleaned. The high

currents involved may also cause intense heating of the shorted

or damaged part, which could result in burns to the operator.

• Ensure that the TIG Brush is located where it cannot easily

fall and cause injury. Ensure that the cables do not present

a trip hazard.

S2 SAFETY PRECAUTIONS AND INFORMATION

2022

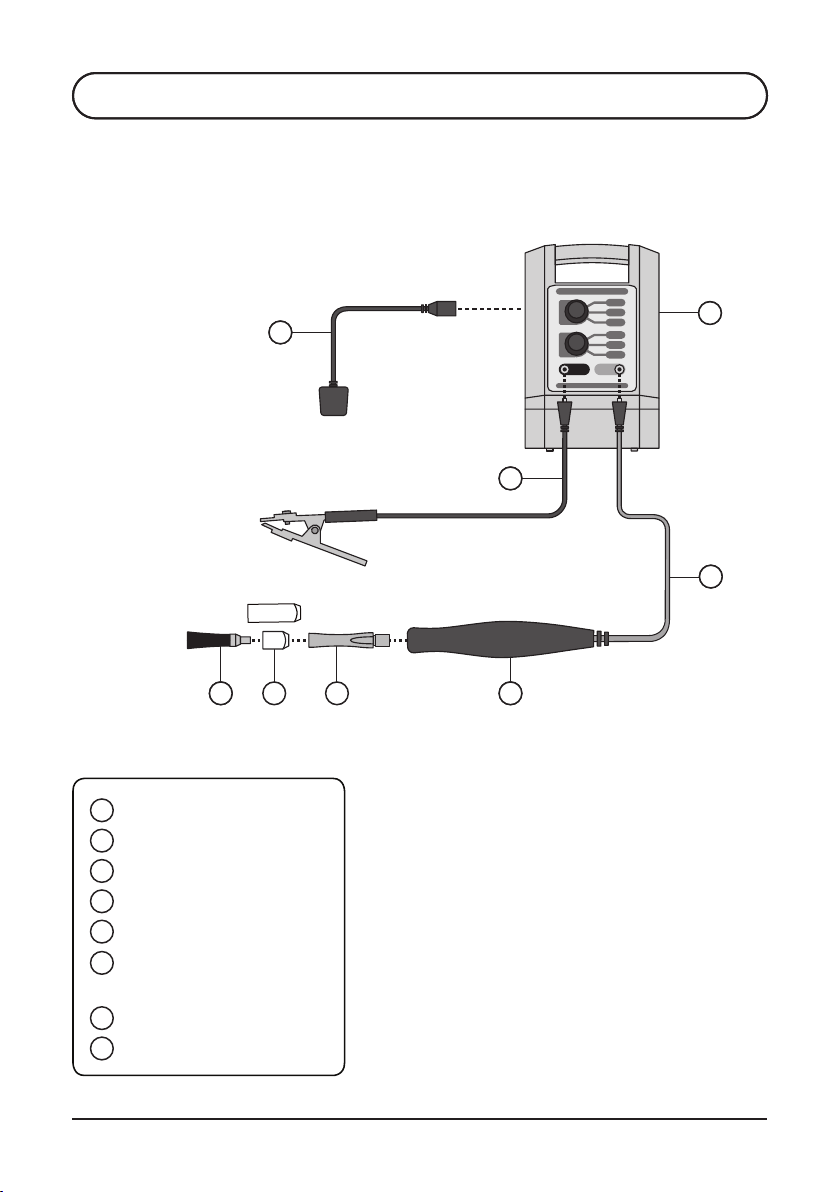

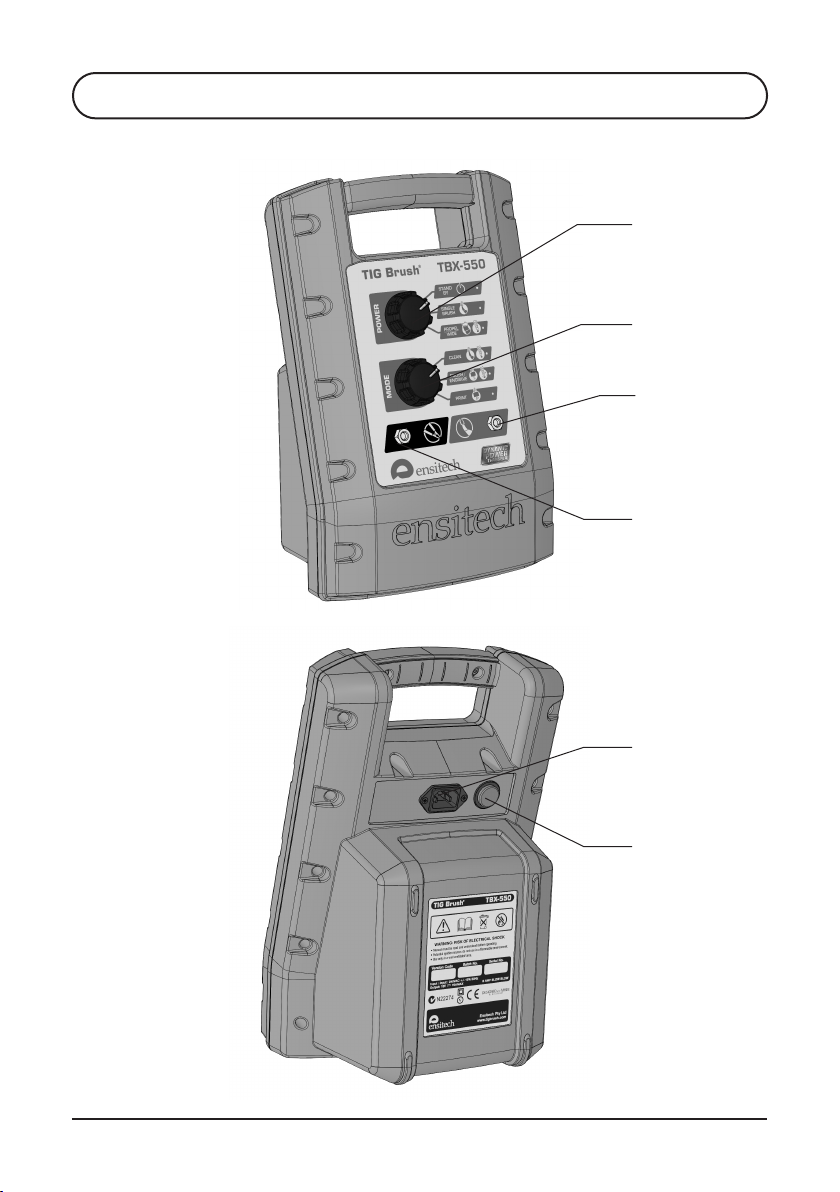

1

2

47

8

3

1

2

4

5

67

8

3

1

2

3

4

5

6

7

8

TIG Brush Control Unit

Black Ground Cable

Red Handle Cable

Handle

Classic Wand

Insulating Shrouds*

(short and long)

Standard single Brush**

Power Cord

* When the brush is new, use the long

shroud and change to the short shroud

as brush wears down.

CLASSIC KIT3.1

** Standard single brush may be replaced

by Dual or Quad brush Adaptors and Shrouds.

12 TIG Brush™ Instruction Manual

DESCRIPTION OF BASIC EQUIPMENTS3

DESCRIPTION OF BASIC EQUIPMENT

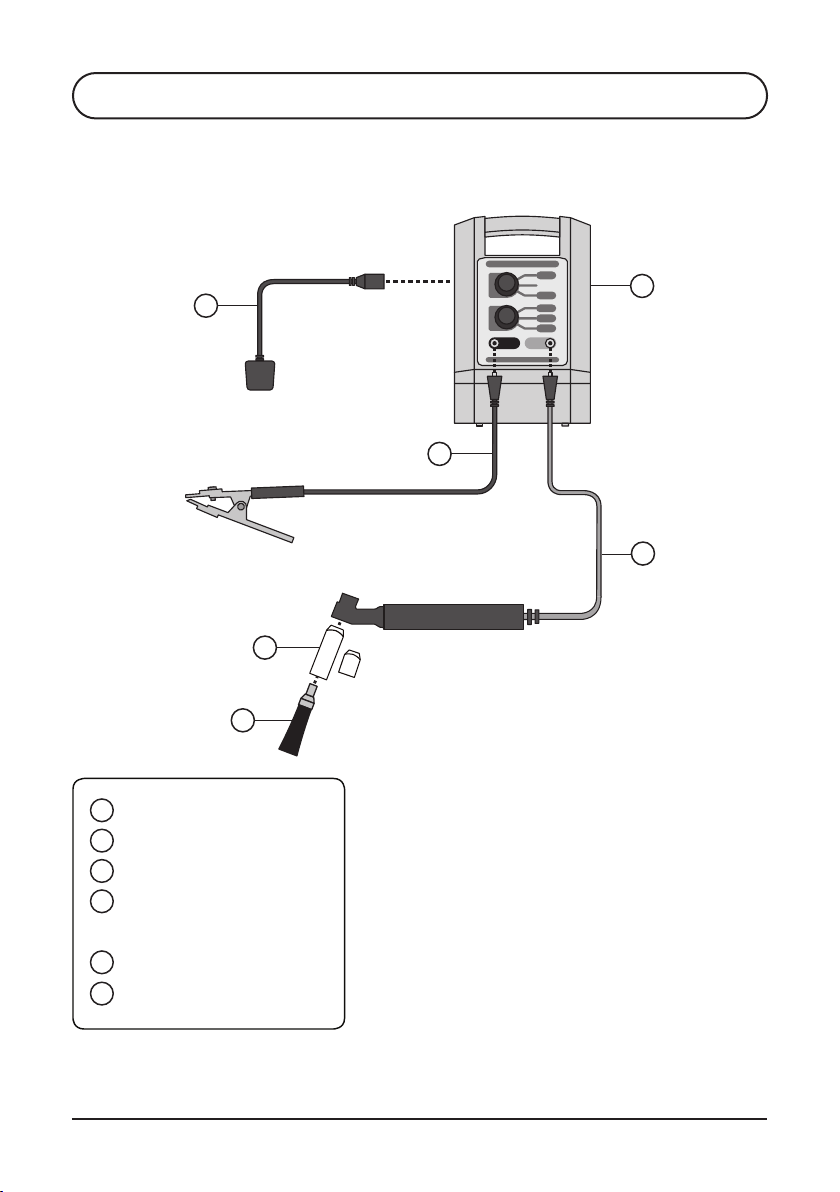

1

2

3

4

5

6

TIG Brush Control Unit

Black Ground Cable

Flexi Handle

Insulating Shrouds*

(short and long)

Standard Brush

Power Cord

*When the brush is new use the long

shroud and change to the short shroud

as brush wears down.

FLEXI HANDLE KIT3.2

13

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

1

2

8

3

1

2

2

4

2

5

6

3

S3

14

2022

DESCRIPTION OF BASIC EQUIPMENT

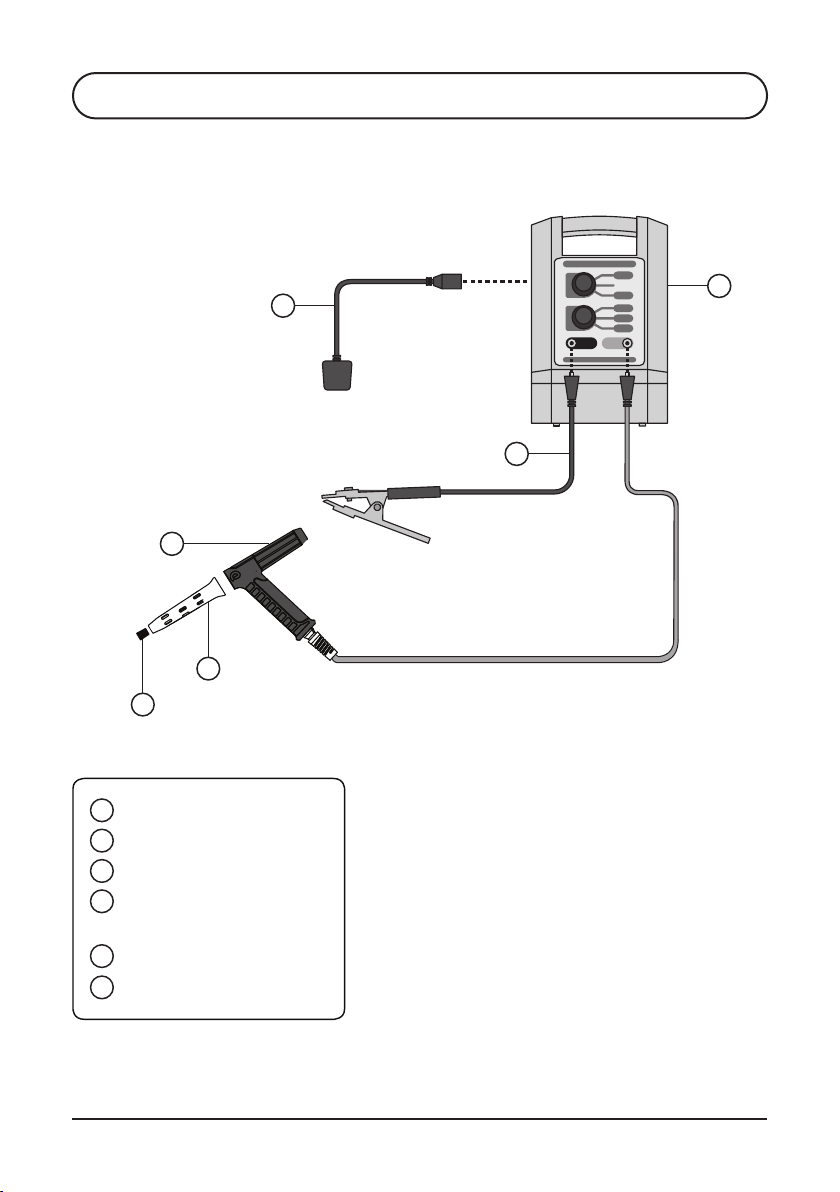

PROPEL KIT3.3

1

2

3

4

5

6

TIG Brush Control Unit

Black Ground Cable

PROPEL Torch

PROPEL Torch

Insulating Shroud

PROPEL Torch Brush

Power Cord

1

2

8

1

2

6

8

3

4

4

4

5

TIG Brush™ Instruction Manual

S3

15

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

Power Control

Mode Control

Handle Cable,

Flexi Handle or

PROPEL Torch

Socket

Ground Cable

Socket

On/Off Switch

Power Socket

DESCRIPTION OF BASIC EQUIPMENT

S3

16 TIG Brush™ Instruction Manual

2022

S4 OPERATION

PREPARATION

ASSEMBLY

4.1

4.2

CLASSIC KIT4.2.1

1. Inspect the TIG Brush Control Unit for any damage, and cables for exposed wire.

2. Ensure the Control Unit is dry.

3. Ensure the work environment is well ventilated and away from any

combustible substances.

4. Ensure the cables do not present a trip hazard.

5. Ensure there is ready access to clean water and a suitable area for washing.

6. After cleaning and/or polishing, to remove all acidic residue, wash down with

clean water, spray the cleaned area with the recommended Ensitech neutraliser,

and wash down again.

7. Wear suitable personal protective equipment as recommended in the SDS.

The minimum requirement is for gloves to protect hands from the fluid,

and goggles or safety glasses to prevent fluid splashing into the eyes.

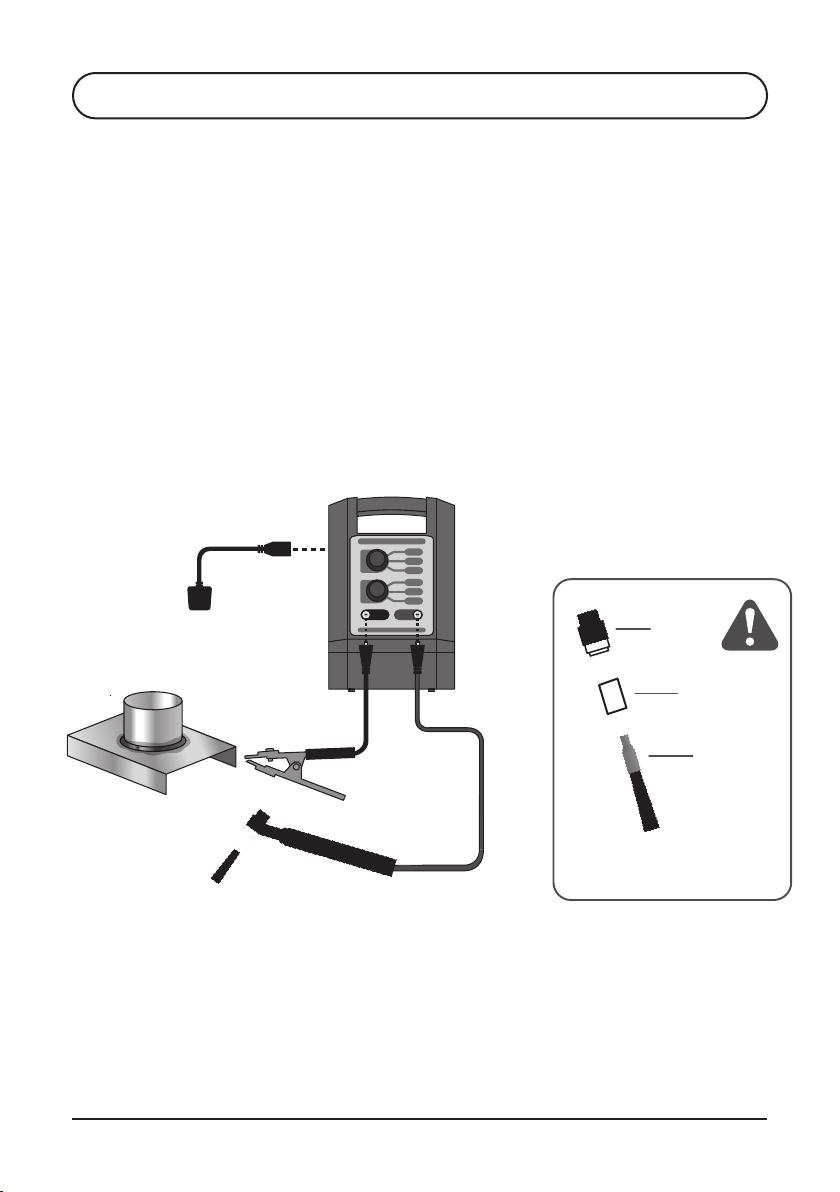

Work piece

120V AC/230V AC*

Single phase

INSULATING SHROUD

MUST BE USED!

Wand

Shroud

Brush

*240V TBX models

17 TIG Brush™ Instruction Manual

2022

Refer to illustration on page 16.

1. Attach Handle Cable plug to the red socket of the TIG Brush Control Unit

2. Screw Classic Wand into handle of the Handle Cable

3. Place long Shroud on Standard brush and screw into the Classic Wand

FLEXI HANDLE KIT4.2.2

Refer to illustration above.

1. Attach Flexi Handle plug to the red socket of the TIG Brush Control Unit

2. Place long Shroud on Standard brush and screw into the Flexi Handle

3. Attach Ground Cable plug to black Ground Cable Socket of the

TIG Brush Control Unit

4. Attach Ground Cable plug to black Ground Cable Socket of the

TIG Brush Control Unit

5. Set POWER switch on the back of the machine to OFF

6. Attach Power Cord to the Power Socket on the back of the TIG Brush

Control Unit and plug into mains power

7. Attach the Ground Clamp to workpiece

120V AC/230V AC*

Single phase

INSULATING SHROUD

MUST BE USED!

Flexi

Handle

Shroud

Brush

*240V TBX models

S4 OPERATION

4. Set POWER switch on the back of the machine to OFF

6. Attach the Ground Clamp to workpiece

5. Attach Power Cord to the Power Socket on the back of the TIG Brush

Control Unit and plug into mains power

PROPEL KIT4.2.3

Refer to illustration above.

1. Attach PROPEL Torch plug to the red socket of the TIG Brush Control Unit

2. Rotate Drive Sleeve clockwise until it stops. Do NOT overwind the

Drive Sleeve!

3. Insert the brass end of the PROPEL Torch brush into the nose of the

Shroud until it is seated in the Collet. The brush should slide into the

Collet with minimal resistance

4. Once the brush is seated in the Collet, turn the Drive Sleeve anti-clockwise

half a turn, and lightly pull the brush to ensure it is securely seated

5. Retract the brush back into the Shroud by turning the Drive Sleeve

anti-clockwise, until it leaves approximately 12-15mm (3/8”- 5/8”)

of the brush exposed

18

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

PROPEL Torch insulating

shroud must be used when

operating the PROPEL Torch

Work piece

120V AC/230V AC*

Single phase

*240V TBX models

S4 OPERATION

4.3 CLEANING FLUID

Pour a small quantity of Weld Cleaning Fluid into the fluid jar. Place the fluid

jar close to the work because the tip of the brush will be dipped into the fluid

regularly during operation.

6. Attach Ground Cable plug to black Ground Cable Socket of the

TIG Brush Control Unit

7. Set POWER switch on the back of the machine to OFF

8. Attach Power Cord to the Power Socket on the back of the TIG Brush

Control Unit and plug into mains power

9. Attach the Ground Clamp to workpiece

19

TIG Brush™ Instruction Manual

2022

Ensitech Pty Ltd

www.tigbrush.com

S4 OPERATION

Workpiece

For best performance

use tip of brush only

Wand

Brush

Shroud

Insulating shroud

must be used

20 TIG Brush™ Instruction Manual

2022

S4 OPERATION

Table of contents

Popular Cleaning Equipment manuals by other brands

Reer

Reer 36120 instruction manual

Milwaukee

Milwaukee MXFLSDP Original instructions

3M

3M Scotch-Brite quick start guide

UVISAN

UVISAN UV Cleantech VR12 user manual

Lincoln Electric

Lincoln Electric WELDLINE OPTICLEAN II Use and maintenance instructions

ICE COBOTICS

ICE COBOTICS SoftBank Robotics Whiz quick start guide