MODBUS-MAP

The measured values are saved as a 32 bit oat value from 0x19 to 0x2F.

The factory setting for the Modbus address is 241 as an integer 16 bit value. This address can be customised in the register

60001 (0x00) (value margin 1 - 247 permitted).

The serial number as ASCII-code is located at register address 30001-30008.

The firmware version is located at register address 30009.

The required units (metric or non-metric) must be selected according to the „ordering guide“, see EE800 data sheet.

FLOAT (read register):

Register

address

Communication

address

Parameter

name

30026 0x19 Temperature [°C], [°F]

30028 0x1B Relative humidity [%]

30030 0x1D Water vapour partial pressure [mbar], [psi]

30032 0x1F Dew point temperature [°C], [°F]

30036 0x23 Absolute humidity [g/m³], [g/ft³]

30038 0x25 Mixing ratio [g/kg], [gr/lb]

30040 0x27 Specic enthalpy [kJ/kg], [BTU/lb]

30042 0x29 Frost point temperature [°C], [°F]

30046 0x2D CO2Raw* [ppm]

30048 0x2F CO2[ppm]

INTEGER (write register):*

Register

address

Communication

address

Parameter

name

60001 0x00 Modbus address (Slave ID)

60002 0x01 Modbus protocol settings*

*For Modbus protocol setting please see

Application Note Modbus (www.epluse.com)

INFO (read register):

Register

address

Communication

address

Parameter

name

30001 0x00 Serial number

30009 0x08 Firmware version

* PLEASE NOTE:

Only for special applications where faster response time is

necessary. Please contact your E+E Sales representative.

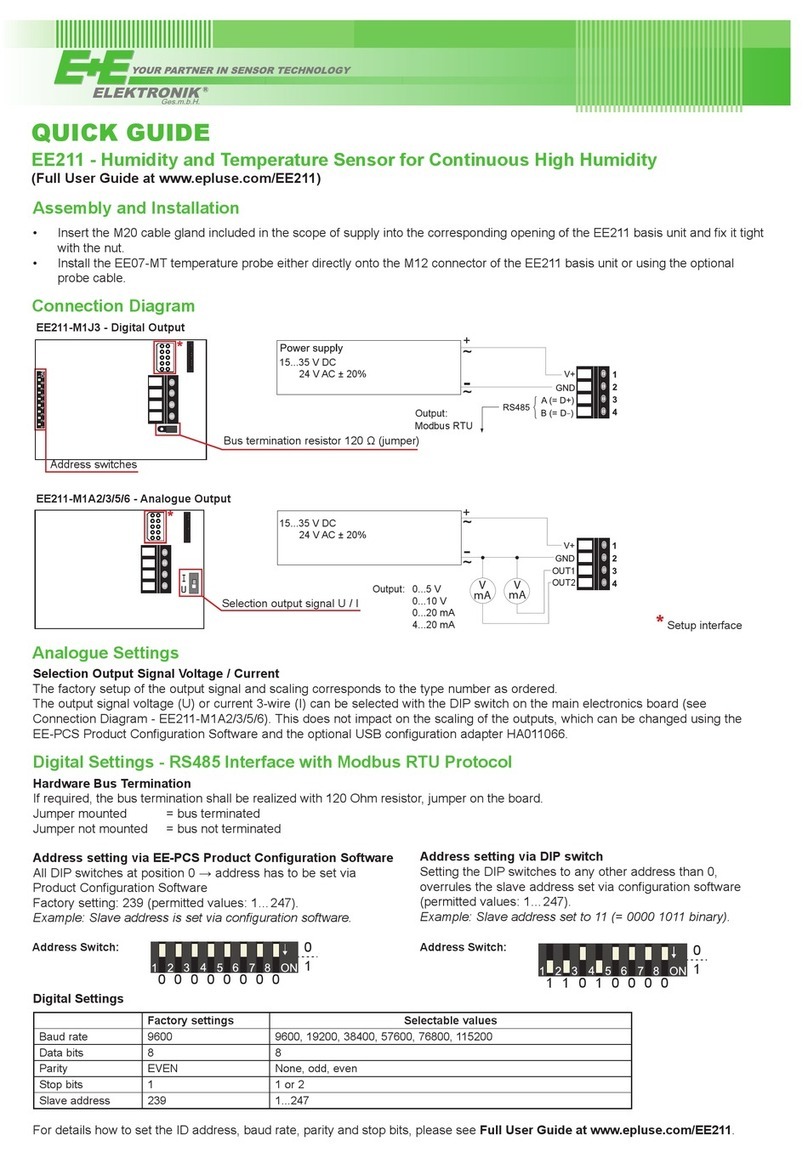

RS485 settings:

Depending on the protocol, Modbus or BACnet, the address, baudrate, parity and stop bits can be set via:

1. EE-PCS Product Conguration Software (available at www.epluse.com/Congurator)

2. Modbus protocol, refer to Modbus Application Note (available at www.epluse.com/EE800)

SETUP AND ADJUSTMENT

The EE800 room sensor is ready to use and does not require any configuration

by the user. The factory setup of EE800 corresponds to the type number

ordered. For ordering guide please see data sheet at www.epluse.com/EE800.

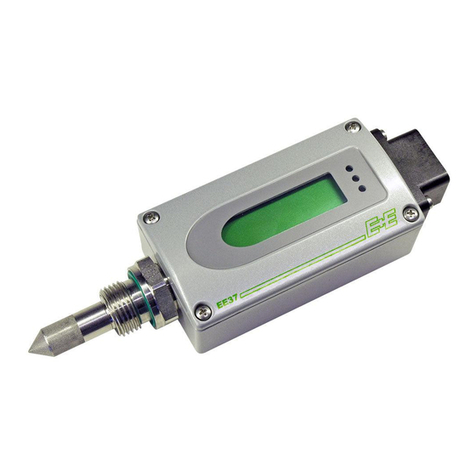

If needed, the user can change the factory setup by using the optional

Configuration Adapter Cable HA011066 and the EE-PCS Product

Configuration Software.

The user can assign physical quantities to the analogue outputs, set the

scaling of the outputs, change the display settings and perform one or two

point adjustment for CO2, RH and T.

Important:

If deemed necessary, the CO2adjustment shall be made against an appropriate, accurate and certified reference. The readjustment

based on the assumption that the minimum CO2concentration of the environment air is 400 ppm (the principle of the so-called auto-

matic background calibration ABC) may relevantly depreciate the device performance. In continuously occupied buildings like hospi-

tals, the minimum CO2concentration will stay higher than 400 ppm, while the concrete carbonation in new buildings can reduce the

CO2level way below 400 ppm.

Configuration Adapter Cable HA011066