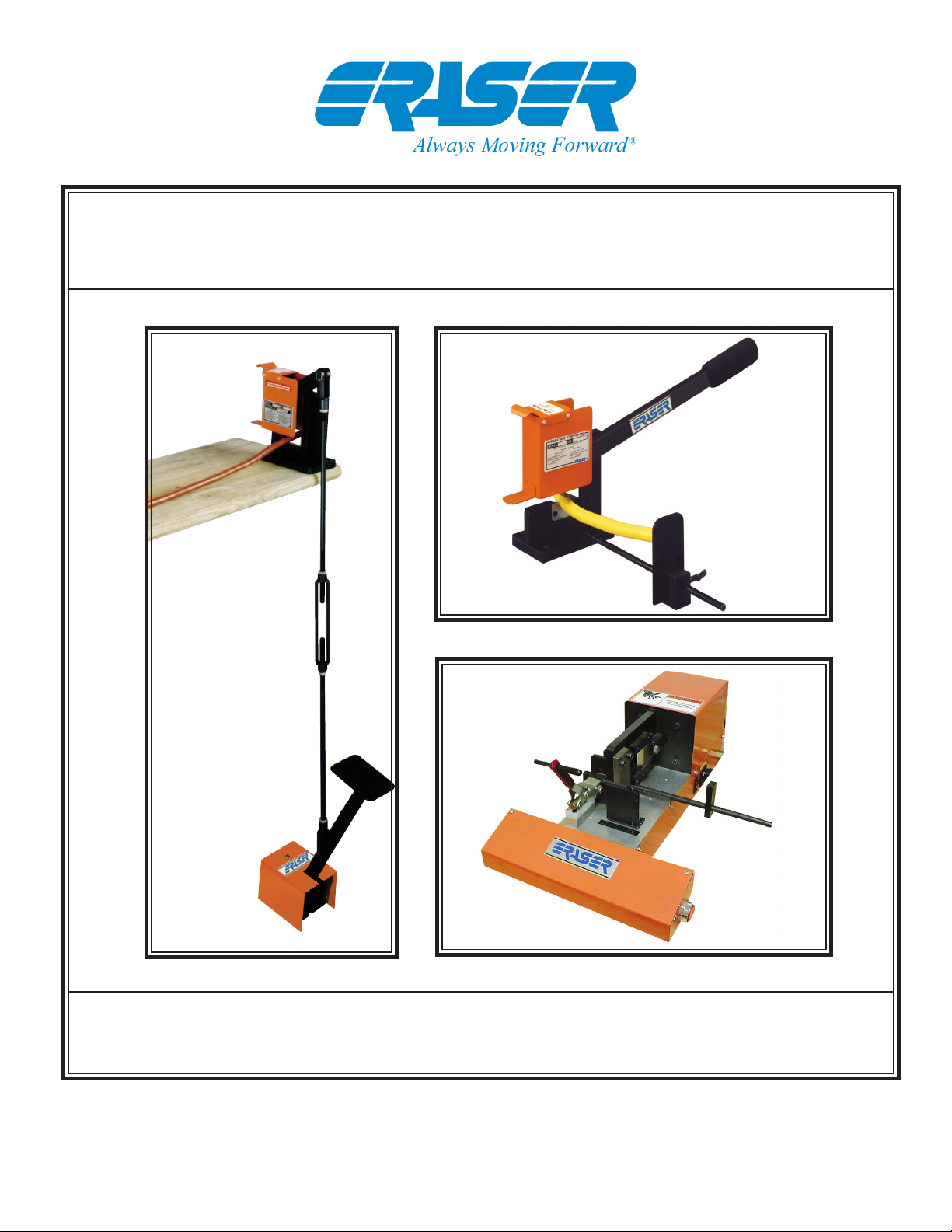

Models HC10/FC10/HCA20 Cable Cutters

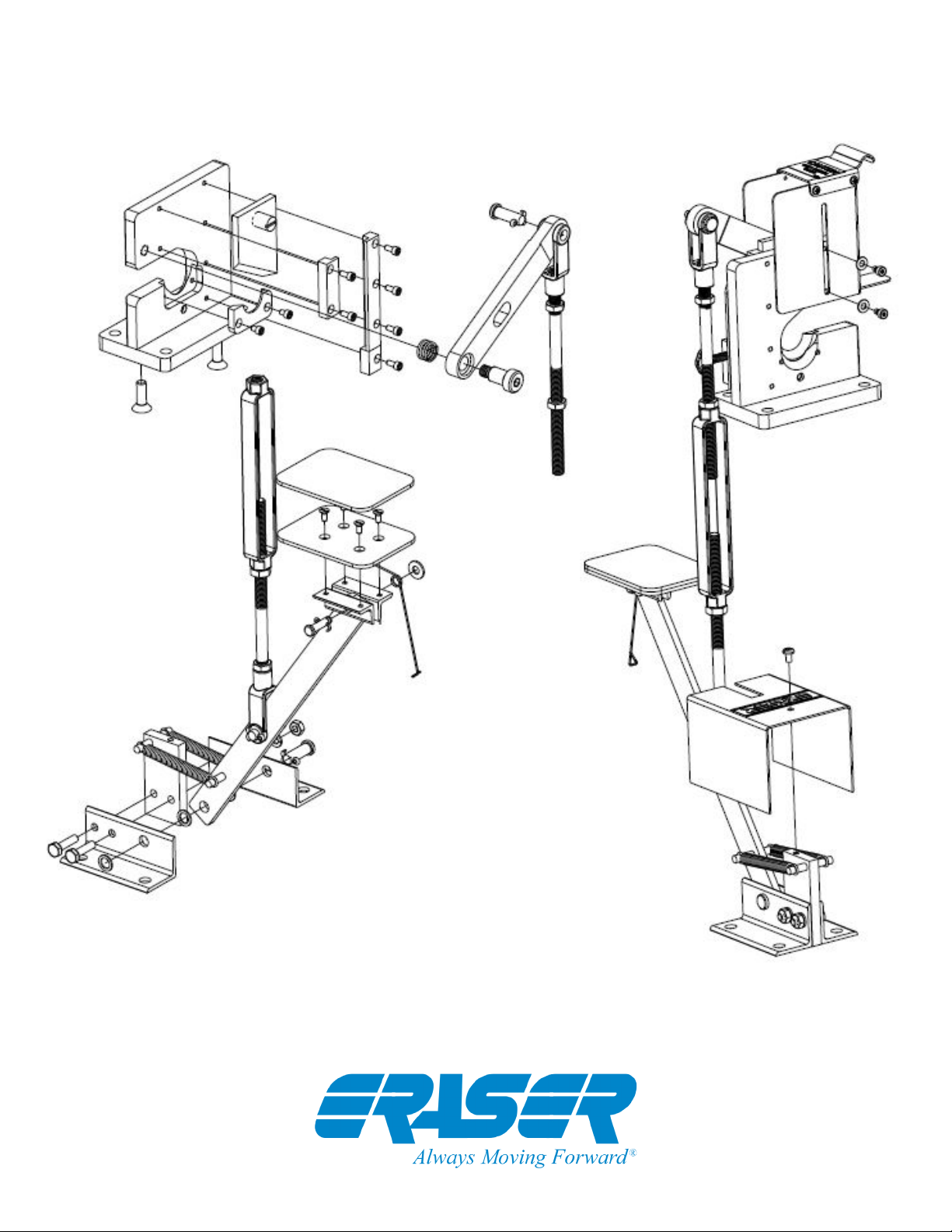

Adjust the linkage assembly by use of the turn-

buckle until the footpedal stops traveling just before

hitting the oor. Once properly adjusted, tighten all

linkage jam nuts securely to lock the adjustment

in place. To install the length stop, screw one end

of one rod into the hole at the base of the FC10.

Add other rods as desired to the rst rod. Slide the

stop plate onto the rods and secure with the screw.

The two rods are marked at 1” increments to allow

consistent measurements up to 24”.

(Additional rods may be purchased, see ordering

information)

HCA20:

The HCA20 is shipped assembled except for the

strip length stop, 5/64” and 5/32” allen wrenches

which are packaged separately. The unit requires

a clean, dry, regulated air supply, of minimum 90

PSI and not exceeding 100 PSI.

Install the length stop rod by screwing it into the

threaded hole located below the lower blade

guide and in front of the stationary blade. The rod

is marked by 1” increments to allow consistant

measurements up to 12”. (Additional rods may

be purchased, see ordering information) Connect

the air supply to the unit, using a 1/4” n.p.t. male

connector. Locate the unit on the bench so that the

two nger switches are facing the operator. Attach

the power cord to the IEC connector at the back

of the HCA20. Plug the unit into the appropriate

properly grounded power supply, 115V 60Hz.

OPERATION:

NOTE: The HC10 and FC10 are designed to be

operated with a maximum of 35 lbs of force applied

by the operator to either the footpedal or operat-

ing lever. The HCA20 is designed to operate at a

maximum 100 PSI and conveys a force of 1200

lbs. on the material to be cut. The cutters are NOT

designed to cut wires or cables containing ferrous

metals, such as steel or steel alloys. Solid copper

single conductors of up to 4 AWG (21.1mmø) may

be cut. Cables or small bundles of wire up to 1 1/4”

(31.75mmø) in diameter may be cut, DEPENDENT

ON CONSTRUCTION. Cutting cables containing

many heavy strands of copper or aluminum may

not be possible, while cables containing many

small strands may usually be cut.

A good guide to use to determine a wire or cable’s

applicability for the cutter is whether or not it is

necessary to exert excessive force on the lever

or footpedal to shear the material. If unsure, send

a sample to the factory and we will determine its

applicability for the unit.

CAUTION:

The blades are extremely sharp! Be sure to keep

hands away from blades during cutting!

HC10:

To admit the material to be cut to the blades, lift the

guard up with the material itself, utilizing the lower

tab on the guard, or by hand with the upper tab.

Raise the operating lever to lift the upper guillotine

blade and seat the material on the lower curved

blade. The guard will slide down automatically

to protect the operator during cutting. Lower the

operating lever, applying force until the material

has been sheared.

FC10:

Follow above procedure for HC10 to admit mate-

rial to blades. Note, however, that the blades are

already open on the footpedal operated cutter. After

admitting material, step on the footpedal and push

it all the way down to shear the material. Bring

the footpedal back up gently with your foot. Do

not release the footpedal at the oor and allow

it to spring back up by itself, as this may cause

damage to the unit.

A conversion kit (IR8775) is available to convert

the Model HC10 into a footpedal operated Model

FC10 if desired. Instructions will be enclosed with

the conversion kit.

HCA20:

To load the material to be cut, open the holding

clamp and adjust the length stop to the desired

cut length using the 5/32” allen wrench provided.

Place the material in the blades, and clamp, up to

the length stop, and close the clamp. Adjust the

check nut on the back of the clamp until the mate-

rial is held with the desired pressure.

To operate the unit, adjust the air supply between

40 and 100 PSI depending on the material. Turn

the power switch on using the I/O switch located

on the side of the unit. To cut the cable, depress

Eraser Company Inc. • Syracuse, NY USA • Ph: 315-454-3237 • info@eraser.com • www.eraser.com • Fax 315-454-3090