p 4

Eraser Company Inc. • Syracuse, NY USA • Ph: 315-454-3237 • info@eraser.com • www.eraser.com • Fax 315-454-3090

ENSURE PROPER ALIGNMENT OF MOVING

PARTS Check for any binding of moving parts,

breakage of parts, and any other condition(s) that

may affect operation. Any damaged part(s) should

be properly repaired or replaced prior to any

continued use of the machine.

ONLY ALLOW TRAINED AND QUALIFIED

PERSONNEL TO OPERATE UNIT Always keep

these instructions within reach of the machine.

USE RECOMMENDED ACCESSORIES ONLY

Consult this operating manual for recommended

accessories. Use only parts supplied by The Eraser

Company, Inc. Use of improper accessories will void

Eraser’s warranty and may increase risk of injury.

ALL REPAIRS SHOULD BE PERFORMED BY AN

ERASER COMPANY REPRESENTATIVE ONLY

Unauthorized disassembly of machines will void

Eraser’s warranty.

WHEN USING MACHINERY, ALL SAFETY

PRECAUTIONS – INCLUDING, BUT NOT LIMITED TO,

THOSE LISTED ABOVE - SHOULD BE FOLLOWED

TO REDUCE THE RISKS OF FIRE, ELECTRIC SHOCK,

AND PERSONAL INJURY, AND DEATH.

IMPORTANT: NO LIABILITY WILL BE INCURRED

BY THE ERASER CO. FOR INJURY, DEATH, OR

PROPERTY DAMAGE CAUSED BY A PRODUCT

WHICH HAS BEEN SET UP, OPERATED, AND/OR

INSTALLED CONTRARY TO ERASER’S WRITTEN

OPERATING MANUAL, OR WHICH HAS BEEN

SUBJECTED TO MISUSE, NEGLIGENCE, OR

ACCIDENT, OR WHICH HAS BEEN REPAIRED

OR ALTERED BY ANYONE OTHER THAN THE

ERASER COMPANY, OR WHICH HAS BEEN

USED IN A MANNER OR FOR A PURPOSE FOR

WHICH THE PRODUCT WAS NOT DESIGNED.

SET-UP: Check your shipment to be sure all items

listed under the parts section are in the box. If

anything is missing, please let us know immediately.

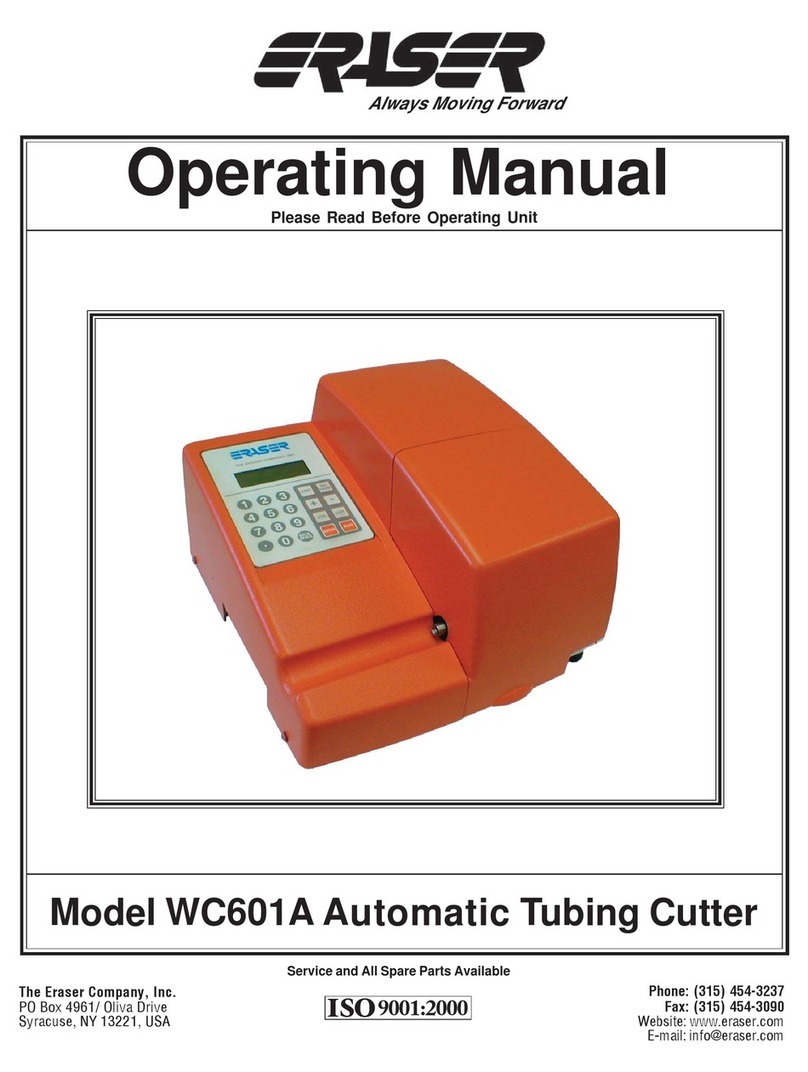

Place the model WC601D on a sturdy workbench.

A material collection bin can be placed on the right

side of the unit, beneath the clear guard.

NOTE: It is possible for the WC601D to be controlled

by an external device or process, by using the DB9

connector located on the rear panel of the unit. Contact

a sales representative for more details.

The WC601D may also be used with a tensioning

dereeler or an automatic pre-feed system. Use

of the Model DE700 Compensating Dereeler

is recommended. This device will improve the

accuracy and/or productivity of the WC601D. If

using the DE700 (or any other dereeling system),

place the dereeler to the left side of the WC601D,

approximately 24” (for elastic materials the distance

may be reduced) from the entrance bushing in a

straight line and align the exit pulley of the dereeler

with the entrance bushing of the WC601D. If using

the DE700, refer to the operating manual for further

set up details.

First, remove the unit’s front cover/guard by

loosening the (2) thumb screws located on the front

and top of the front cover. Referring to the drawing

on page 16, locate the blade stop adjusting screw

on the cutting head.

Prior to shipment, the blade stop adjusting screw

has been set to lock the blade holder in the open

position, to secure it during transport. Prior to

bushing installation (see below) loosen the locking

set screw (which secures the blade stop screw),

then back the blade stop screw away from the blade

holder mechanism.

BUSHING INSTALLATION:(Refer to the drawing on page 15)

The WC601D requires one (1) set of custom

bushings. A bushing set consists of one (1) of each

of the following: the entrance bushing (7/8” long w/

hub); the head (middle) bushing (2 5/8” long); & the

exit bushing (1 3/8” long), for a total of 3 bushings.

If different sizes of material are going to be cut,

additional bushing sets may be ordered.

First install the head bushing. Lift the clear guard on

the right side of the unit and insert the ID-chamfered

end of the head bushing into the hole under the

clear guard. Slide the head bushing completely past

the blade on the cutting head.

Manually actuate the blade holder (see Set-up,

above) and slide the head bushing back toward the

blade until the clearance between the bushing &

the blade is approximately 1/32”. Tighten the head

bushing in place, then lift the clear guard and insert

the exit bushing until the bushing is approximately

1/32” from the opposite side of the blade from the

MODEL WC601D AUTOMATIC TUBING CUTTER