SET-UP:

The WC600D is supplied with one 3/32" Allen wrench,

one 5/32" Allen wrench and one 5/64" Allen wrench.

Bushing must be purchased separately.

CAUTION:

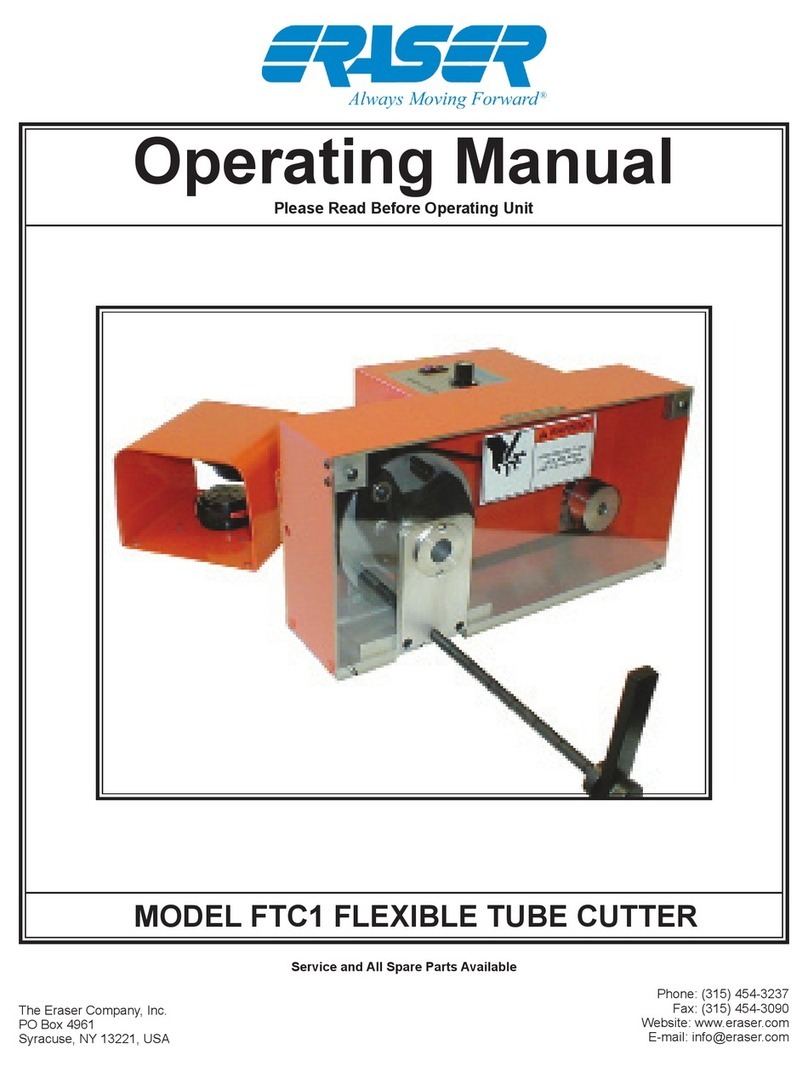

The WC600D blade is intended for use on soft flexible

tubing. However, some rigid tubing and some wire may be

cut. The blade is a very thin sharp blade and caution

should be used when handling it.

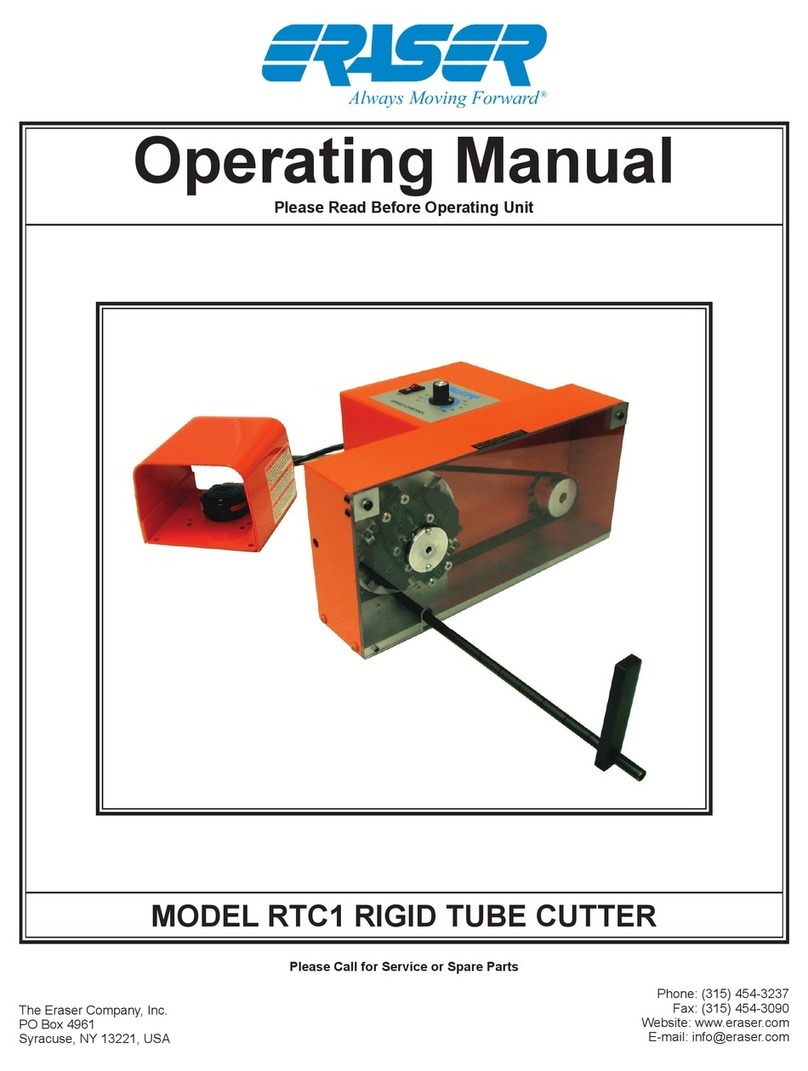

Place the Model WC600D on a sturdy workbench with the

right corner of the exit opening even with the right corner

of the bench. Short and long cut lengths will drop out the

side of the exit bushing. Material collection bins can be

placed to collect the cut material as it exits the unit. If

using the DE700 (or any other tensioning dereeler), place

the dereeler to the left side of the unit, at least 24" from the

entrance bushing in a straight line and align the lower

pulley with the entrance bushing. If using the DE700, refer

to their operating manual for further set up details.

BUSHING INSTALLATION:

To aid in bushing installation refer to the drawing. If

different sizes of material are going to be cut, additional

bushing sets may be ordered. There are three guide

bushings, the entrance, head, (or middle) bushing, and

exit bushing. First install the longer head bushing. Locate

the chamfered side of the bushing, this is the side that

goes in first. Slide the bushing in as close as possible to

the belt feed and back toward the blade, without hitting the

blade. Manually close the blade and check that the head

bushing is not touching the blade. Tighten the head

bushing in place. Insert the exit bushing in place. Manu-

ally close the blade, position the exit bushing as close to

the blade as possible. Tighten exit bushing in place. Make

certain that the blade moves freely by manually closing

the blade. Reposition the bushings if necessary. Install

the entrance bushing (chamfer side out) making certain

that it does not interfere with the belts when they are in the

fully closed position. Keep the bushings as close as

possible to the blade. This will provide the squarest cut

and allow the shortest pieces of tubing to be run. Bush-

ings that are not close to the blade will allow jamming of

short cut pieces.

Connect the power cord to the IEC connector, and plug

the unit into the appropriate power supply (either 115V

60Hz OR 230V 50Hz).

Place the material to be cut on the dereeler. Turn the

WC600D on using the I/O switch on the back side of the

unit. To open the front cover, unscrew the top and front.

The display will read “cover open system disabled” if the

cover is open or if the unit is in a run program. Back out

the belt feed adjusting knob by turning the adjusting knob

counter clockwise on belt roller tension adjuster. Feed the

tubing through the entrance bushing, between the belts

into the head bushing and through the exit bushing. To

tighten the upper and lower belts, simply turn belt adjust-

ing knob clockwise. The belt roller adjustment will prevent

tubing from being compressed, but it can also affect

length. If the material is slippery, more tension may be

applied to the belt feed by turning the tension adjusting

knob clockwise. Apply only enough tension to transport

the material. Do not over- tighten the belts. Over tightening

the belts may cause the material to crush thus creating

excessive drag in the transport bushing. The belts should

be adjusted by tightening them until the material (tubing)

can no longer be pulled between the belts. More belt

pressure may be added if the cut lengths are inconsistent.

Once material has been fed through the bushings and belt

tension is set, close the cover and use the jog button to

feed the material manually, and the cut button to cut it off.

The unit now is ready for programming. Note: The material

can be fed manually as described above or by jogging the

material through the bushings. To feed with the cover

closed, press the Jog button to enter the manual mode

and press the Jog button again to jog the material through

the entrance/cut bushings. If the material does not feed,

it can be inserted with the guard open. If in the manual

mode the unit can jog, rotate and cut the material. Press

the jog or cut keys to move or cut material. The speed of

the jog and cutter head will be determined by the last

inputted variables placed in the microprocessor.

PROGRAMMING:

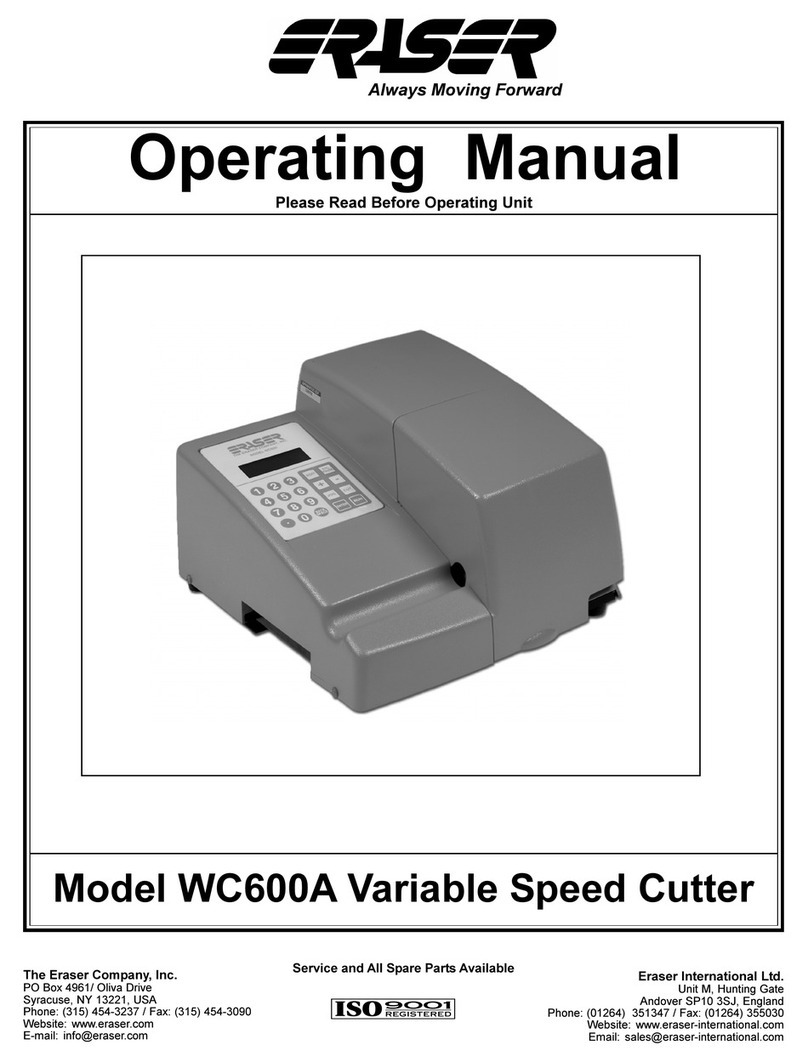

START UP: When the unit is turned on, the controller will

report that it is initializing and display The Eraser Co/

WC601B. The line being edited will display a blinking

cursor. The system will then automatically display the

batch screen:

Do one of these: 0 (Enter 1)

Enter 0 for no batch

Enter known batch #__

Enter new batch #__

The number on the first line will be the last batch run, or

in this case, 0, since this is the first run since the system

was powered up. The number on the last line is the next

available batch that has not yet had parameters stored.

The system requires that batches be created in se-

quence, so numbers higher than the number on the last

line will not be accepted. As batches are created, the

number on the last line will increase, until the current

maximum of 99 batches is reached.

Press enter to select the default, or type in a new number.

If 0 is selected, all parameters will be set to zero, and will

be entered manually. Parameters entered while using

batch 0 are never stored. Parameters for all other batches

MODEL WC600D AUTOMATIC TUBING CUTTER

OPERATING INSTRUCTIONS