eschmann T20-a User manual

T20-a

OPERATION TABLE

Service manual

T-SM47j

111707

Service manual

Preliminary

Information

Technical data

Technical

description

Safety notes

Maintenance

Part removal

adjustment

replacement

Read these Instructions before use

Keepthese‘Instructions’inasafeconvenientplaceforfuturereference.Readinconjunction

with the Publications detailed in Section 1.1.

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours.To avoid delays when making enquiries, please quote the

Modeland SerialNumberofyour OperationTable whichisshownon theSerialNumberplate, the

location of which is shown below. Please ensure you include all alpha and numeric digits of the

Serial Number.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limited.

“Eschmann Equipment” is a trading name of Eschmann HoldingsLimited.

“T20-a”is atrademarkofEschmannHoldingsLimited.

Patents: WorldwidePatentsPending.

Copyright © 2005 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann HoldingsLimited.

The information in this publication was correct at the time of going to print. The Company, however,

reservesthe rightto modifyorimprove theequipment referredto.

The CE marking affixed to the product certifies that it complies with the

EuropeanMedical DevicesDirective93/42/EEC andrelatedlegislation.

T-SM47j July 2005

The Serial Number

plate is located here

T-SM47j P3/54

T20-a

OPERATION TABLE

CONTENTS

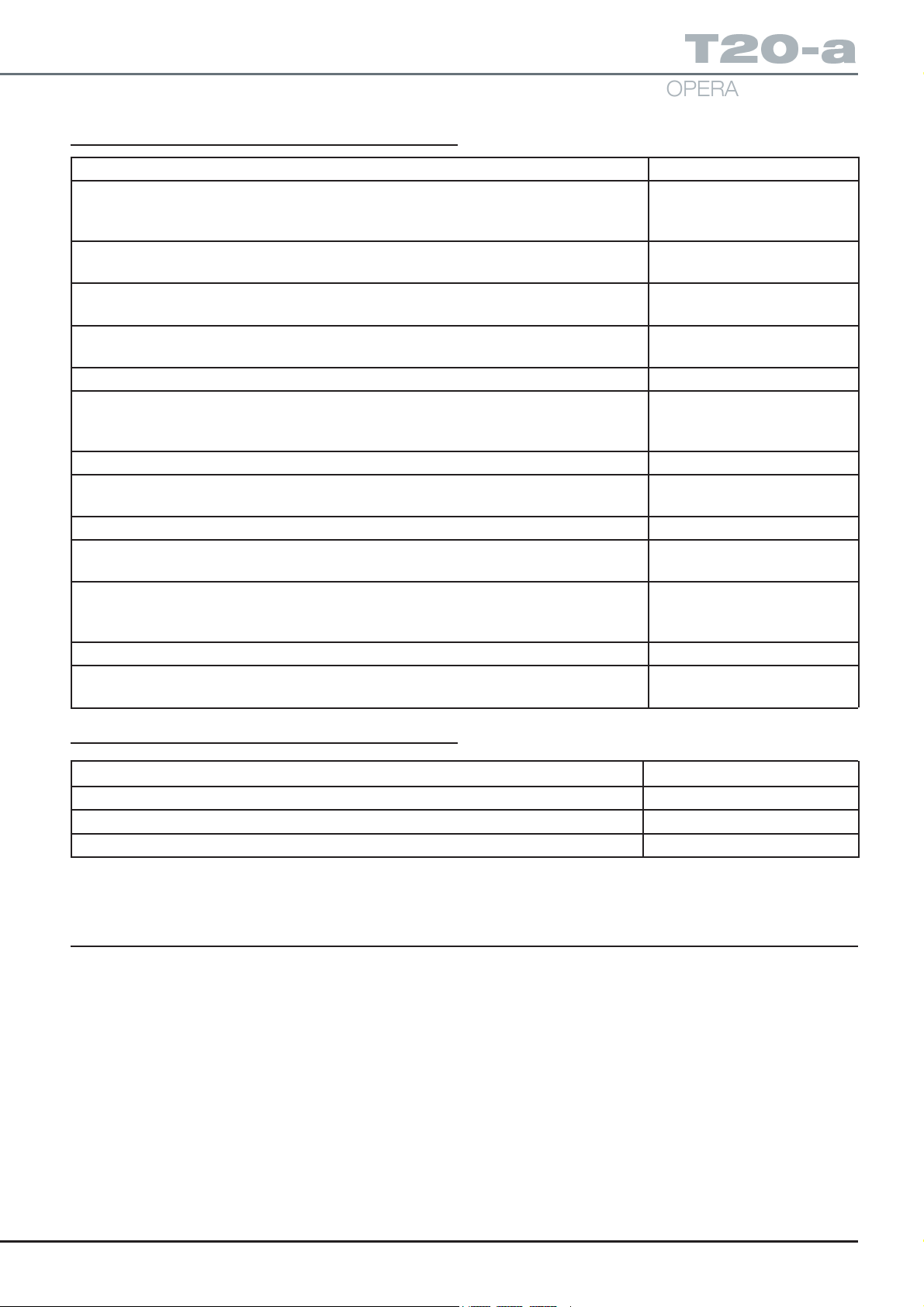

1.0 Preliminary information

1.0 Preliminary information . . . . . . . . . . . . . . . . . . . 5

2.0 Technical data

2.1 Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Table loading . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Classification and symbology . . . . . . . . . . . . . . 9

2.7 Use in conjunction with other equipment . . . . . . 9

2.8 Standards compliance . . . . . . . . . . . . . . . . . . . . 9

2.9 Environmentalconditions . . . . . . . . . . . . . . . . . . 9

3.0 Technical description

3.1 Powersupply assembly . . . . . . . . . . . . . . . . . . 13

3.2 Control electronics . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Handset overview . . . . . . . . . . . . . . . . . . . . 14

4.0 Safety warnings

4.1 ‘Service position’ . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 M10 trunk screw removal . . . . . . . . . . . . . . . . 16

4.4 Trend andtilt actuatorremoval . . . . . . . . . . . . . 16

4.5 Working with mains voltage . . . . . . . . . . . . . . . 16

4.6 Gas springs . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.7 Hot parts on PCAs . . . . . . . . . . . . . . . . . . . . . 16

4.8 Biologicalcontamination . . . . . . . . . . . . . . . . . 16

4.9 Connection of leads . . . . . . . . . . . . . . . . . . . . . 16

4.10 Leaking batteries . . . . . . . . . . . . . . . . . . . . . . . 16

5.0 Maintenance

5.1 Powersupply assembly . . . . . . . . . . . . . . . . . . 17

5.2 Table faultfinding . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.4 Break motion control . . . . . . . . . . . . . . . . . 17

5.2.5 Trunk section connector blocks . . . . . . . . . 17

5.3 Fuse location . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Service schedule and safety check . . . . . . . . . 18

6.0 Part removal/adjustment/

replacement

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Table base and column covers . . . . . . . . . . . . 20

6.2.2 Base covers . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2.1 Removal of base covers . . . . . . . . . . 20

6.2.2.2 Replacing base covers . . . . . . . . . . . 21

6.2.3 Access to column . . . . . . . . . . . . . . . . . . . . 21

6.2.3.2 Lower column access . . . . . . . . . . . . 21

6.2.3.3 Lower-mid column access . . . . . . . . 21

6.2.3.4 Upper-mid column access . . . . . . . . 21

6.2.3.5 Top of column access . . . . . . . . . . . . 23

6.2.4 Telescopic covers . . . . . . . . . . . . . . . . . . . . 23

6.2.4.1 Removal of telescopic covers . . . . . . 23

6.2.4.2 Refitting the telescopic covers . . . . . 23

6.2.5 Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.5.1 Removalof thebellows . . . . . . . . . . . 23

6.2.5.2 Replacingthebellows . . . . . . . . . . . . 24

6.3 Table base components . . . . . . . . . . . . . . . . . . 24

6.3.2 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3.3 Pedal dampers . . . . . . . . . . . . . . . . . . . . . . 24

6.3.4 Frontwheels . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.5 Castors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.5.1 Castorassembly . . . . . . . . . . . . . . . . 25

6.3.5.2 Castorwheels . . . . . . . . . . . . . . . . . . 25

6.3.6 Brakepads . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.7 Castorpillar bushes . . . . . . . . . . . . . . . . . 29

6.3.8 Pedalspindlebushes . . . . . . . . . . . . . . . . 29

6.3.9 Lifting roller assembly.. . . . . . . . . . . . . . . . 29

6.3.10 Pedal catchblock . . . . . . . . . . . . . . . . . . . 29

6.3.11 Pedal anti-skid pads . . . . . . . . . . . . . . . . . 29

6.3.12 Pedalcatch pawlandspring . . . . . . . . . . . 29

6.4 Tablecolumncomponents . . . . . . . . . . . . . . . . 30

6.4.2 Trendelenburgactuator . . . . . . . . . . . . . . . . 30

6.4.3 Tilt actuator . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.4 Telescopic columnassembly . . . . . . . . . . . . 30

6.4.5 Tilt &Trendelenburgmotor . . . . . . . . . . . . . . 32

6.4.6 Tilt bush . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.7 Trendelenburgbush . . . . . . . . . . . . . . . . . . . 32

6.4.8 Bearing pads . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Table sections . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5.1 Head and leg section . . . . . . . . . . . . . . . . . 33

6.5.1.1 Guidepins . . . . . . . . . . . . . . . . . . . . 33

6.5.1.2 Gassprings . . . . . . . . . . . . . . . . . . . 33

6.5.1.3 Topcover . . . . . . . . . . . . . . . . . . . . . 33

6.5.1.4 Gasspring release head/pin . . . . . . . 33

6.5.1.5 Gasspring release handle . . . . . . . . 35

6.5.1.6 X-raytranslucent top . . . . . . . . . . . . 35

6.5.2 Trunksections . . . . . . . . . . . . . . . . . . . . . . . 35

6.5.2.1 Traversemotor . . . . . . . . . . . . . . . . . 35

6.5.2.2 Traversedrive belt . . . . . . . . . . . . . . 36

6.5.2.3 Breakmotor . . . . . . . . . . . . . . . . . . . 36

6.5.2.4 Breakgearbox . . . . . . . . . . . . . . . . . 36

6.5.2.5 Side rails . . . . . . . . . . . . . . . . . . . . . 39

6.5.2.6 Top covers . . . . . . . . . . . . . . . . . . . . 39

6.5.2.7 Pushbutton components . . . . . . . . . 39

6.5.2.8 Traverserodbearing . . . . . . . . . . . . . 39

6.5.2.9 Drivebeltguide bearing . . . . . . . . . . 41

6.5.2.10 Attachment blocks . . . . . . . . . . . . . . 41

6.5.2.11 Black tops . . . . . . . . . . . . . . . . . . . . 41

6.6 Electricalcomponents . . . . . . . . . . . . . . . . . . . 41

6.6.2 Three actuator PCA . . . . . . . . . . . . . . . . 42

6.6.3 Fouractuator PCA . . . . . . . . . . . . . . . . . 42

6.6.4 Infraredreceiver PCA . . . . . . . . . . . . . . 42

6.6.5 Powersupply assembly . . . . . . . . . . . . . 43

6.6.6 Traversemotor . . . . . . . . . . . . . . . . . . . . 43

(continued over page)

P4/54 T-SM47j

6.6.7 Breakmotor . . . . . . . . . . . . . . . . . . . . . . 43

6.6.8 TiltandTrendelenburgmotors . . . . . . . . 43

6.6.9 Telescopic columnassembly . . . . . . . . . 43

6.6.10 Breakpotentiometer loom . . . . . . . . . . . 43

6.6.11 Tiltpotentiometer loom . . . . . . . . . . . . . 43

6.6.12 Trendelenburgpotentiometer . . . . . . . . . 43

6.6.13 Heightpotentiometerloom . . . . . . . . . . . 43

6.6.14 Traverse motorloom& m’switches . . . . . 45

6.6.15 Connector blocks & looms . . . . . . . . . . . 45

6.6.16 Switch & accessory panel looms . . . . . . 45

6.6.17 Columnenergy chainandloom . . . . . . . 45

6.6.18 Breakgearbox loom . . . . . . . . . . . . . . . . 46

6.6.19 Batteries, table & handset . . . . . . . . . . . 46

6.6.20 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.6.21 Tableinfrared codechange . . . . . . . . . . 46

6.6.22 Infraredhandset code change . . . . . . . . 46

6.6.23 Handsetservice . . . . . . . . . . . . . . . . . . . 47

6.6.24 Processor PCA . . . . . . . . . . . . . . . . . . . 47

6.6.25 Standbypanel andloom . . . . . . . . . . . . 47

6.6.26 Batterymanagementreconditioning . . . . 47

6.7 Function tests . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.1 Batteries . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.2 Batterycharger . . . . . . . . . . . . . . . . . . . 47

6.7.3 Cordedhandset . . . . . . . . . . . . . . . . . . . 47

6.7.4 Infraredhandset . . . . . . . . . . . . . . . . . . . 47

6.7.5 Footswitchcontrol . . . . . . . . . . . . . . . . . 47

6.7.6 Standbycontrol panel . . . . . . . . . . . . . . 47

6.7.7 Sections(head andleg) . . . . . . . . . . . . . 47

6.7.8 Basepedals . . . . . . . . . . . . . . . . . . . . . . 48

6.7.9 Cycle of movements . . . . . . . . . . . . . . . 48

6.8 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figures

1.0 Identification of main parts . . . . . . . . . . . . . . . . . 6

2.1 Major dimensionsandmovements . . . . . . . . . . 10

2.2 Maximum patientweights . . . . . . . . . . . . . . . . 11

2.3 Maximum patientweights . . . . . . . . . . . . . . . . 12

3.1 Schematic diagrams . . . . . . . . . . . . . . . . . . . . 15

6.1 Tablecoversgeneralarrangement . . . . . . . . . . 22

6.2a Tablebasegeneralarrangement (ext’lcatch) . . 26

6.2b Tablebasegeneralarrangement (int’lcatch) . . . 27

6.2c Tablebase generalarrangement(int’lcatch

andincreasedheight) . . . . . . . . . . . . . . . . . . . . 28

6.3 Tablecolumngeneralarrangement . . . . . . . . . . 31

6.4 General arrangement,head& legsection. . . . . 34

6.5 Tablelongtrunkgeneral arrangement . . . . . . . . 37

6.6 Tableshort trunk generalarrangement . . . . . . . 38

6.7 Tabletraversegeneralarrangement . . . . . . . . . 40

6.8 Table basemainelectrical components . . . . . . 42

6.9 Handset buttonfunctions andseriallabels . . . . 44

6.10 Oldand newinfraredHandsetbuttons . . . . . . . 44

A1 T20-a Schematic diagram - Base Section . . . . 51

A2 T20-aSchematic diagram-Pedestal Section . . 52

A3 T20-a Schematic diagram-Trunk Section . . . . 53

Appendix 1

Torqueconversions . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix 2

Applicationsoftware guide . . . . . . . . . . . . . . . . . . . . . 50

Appendix 3

T20-aTableschematics . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix 4

Electrical safety checks . . . . . . . . . . . . . . . . . . . . . . . 54

T-SM47j P5/54

T20-a

OPERATION TABLE

1.0 PRELIMINARY INFORMATION

WARNING

Before servicing this operation table the

engineer should be familiar with all the

warnings and cautions contained within the

‘Instructions for use’ detailed in section 1.1.

This service manual does not provide details

of how to operate the table nor does it provide

information on the symbols and warning signs

provided on the table. All this information is in

the‘Instructions foruse’supplied withthe table.

Additional copies of the ‘Instructions for use’

can be obtained from Eschmann Equipment.

Only qualified and trained engineers should

service or maintain this operation table to

ensure that all the built-in safety features are

not compromised.

1.1 This ServiceManualshouldbereferredto for details

oftheT20-aPoweredOperationTable,SerialNumber(SN)

T2AA3A0000 orabove:

REFT20-223-2301* & T20-108-2301*

REFT20-221-2301 & T20-106-2301

REFT20-221-2101 & T20-106-2101

*These models haveDenyer styleaccessorysiderails.

The related publications listed below provide additional

information.

T-IM102 (111701) -Instructions foruse

T-IPL35 (111706) - Illustrated parts list

T-IM94 (111012) -‘T’SeriesApplicationsoftwaremanual

T-IM56 (698907)-Generalaccessory leaflet

The number in brackets above, is the part number for that

publication.

1.2 ‘Instructions for use’ and ‘Service manuals’ should

be readily accessible for reference prior to and when

operating,cleaning,servicing,or,maintaining the operation

table.

1.3 Thetable and allaccessories arenot suppliedsterile

therefore the table and all accessories should be cleaned

and disinfected in line with hospital practice and the

informationsuppliedinthe‘Instructions for Use’beforeuse.

1.4 The manuals listed above and the Application

software,areavailabletoorderfromEschmannEquipment,

see inside front cover for address details.

1.5 Make sure that routine servicing is carried out as

detailedinthe serviceschedule,section5.4,by Eschmann

trained or accredited engineers.

1.6 Theservice scheduleprovided inthis manualdetails

a program of maintenance work to be carried out at six

monthly intervals, refer to the applicable section of this

manualfordetailsofhowtoperformthese variousfunctions.

Any special adjustments required for components are

detailed in the part replacement (section 6.0) for that item

tosaveduplication.Asroutinethe Service Scheduleshould

be followed in the event of an additional service due to a

faultdevelopingwithanyaspectofthe table, thiswill ensure

that all aspects of the table are covered.

WARNING

Ensure that the correct screw torque settings

are used as detailed within this manual to

ensure safety and that parts are not damaged.

1.7 Throughout this manual there are recommended

torque settings for many of the screws. In the main, these

are only provided on the illustrations. Ensure that these

arecheckedandthecorrecttorquesettingsare used where

specified.These areprovidedtoensure safety(i.e.screws

are tightened correctly) and that components are not

damaged by excessively high torques.

1.8 Fig. 1.0 identifies the main parts of the T20-a

operationtable.

1.9 The tablecanbeplacedinto a ‘ServicePosition’that

provides easy access to components within the ‘top of

column’area (ensuretableis switched‘off’beforeopening

top). To achieve this position first note the safety warning

insection 4.1.Removeasmuch aspossiblefromthe table

top (e.g. leg and head sections, accessories and

mattresses etc.). Remove the top of column steel covers

(items13 and 14ofFig.6.1). RemovethefourM10 screws

(each side) that secure the trunk sections to the pedestal

(not the M6 cap head screws that can be seen passing

throughthe oilitebushesoneach side)andallow thetrunk

section to pivot (short trunk down) about the oilite bush

pivots(item 16, Fig.6.3).Extreme careshouldbe takenat

all times with the table in this position, especially during

transition into and out of the ‘Service Position’. Use tool

numberT2203to maintain contactbetweenthe connector

blocksifrequired when thetableisinthe‘Service Position’.

Whenreturningthetableoutofthe‘ServicePosition’ensure

the eight M10 screws are tightened to the correct torque

and that the covers are replaced.

1.10 The ‘Instructions for use’ (provided with the table)

containall thecleaning,disinfection andcareinstructions,

consultthis fortheseaspects astheyare notduplicatedin

this manual. CAUTION

Continued use of the table batteries when

‘criticallylow’candamage thebatteries. Charge

batteries regularly to maintain peak

performance. Do not remove the table from

charge until both charging LED’s are ‘green’to

avoid false battery level indication on the

handset.

P6/54 T-SM47j

Fig. 1.0 Identification of main parts

NOTE:The table illustrated hasexternalpedallocking catches. Some

tableshaveinternallockingcatches,see section 6.2 and 6.3 fordetails.

T-SM47j P7/54

T20-a

OPERATION TABLE

Key to Fig. 1.0

1 Head section

2 Long trunk section

3 Short trunk section

4 Leg section

5 Leg section gas spring

6 Short trunk section release button

7 Long trunk section release button

8 Batteryfuses

9 Wheel foot pedal

10 Head section release bar

11 Head section gas spring

12 Standby control panel

13 Base

14 Pedestal

15 Castor foot pedal

16 Leg section release bar

17 Mains fuses

18 Connection socket for mains (ONLY use Eschmann mains cord, Part No. 391177)

19 Main battery charging state LED:

Red = Mains ‘on’, batteries in ‘bulk’ charge

Amber = Mains ‘on’, batteries in ‘top-up’ charge (duration 2 hours)

Green = Mains ‘on’, batteries in ‘trickle’ charge (i.e. fully charged)

20 Standby battery charging state LED (colour code as main battery above)

21 Main table ‘On/Off’switch ( = Off, = On)

22 Connection socket for Eschmann footswitch (ONLY)

23 Table ‘On’ LED (green)

Bright = Table in use, micro-controllers active

Dim = Table ready for instant use but in battery save (sleep) mode

24 Connection socket for Eschmann handset (ONLY)

25 Head and leg section end blocks (use to stow UK handset)

26 Accessory side rails (can also be used to stow handset*)

27 Standby battery switch

* Clip on handset must match side rail type, see ‘Instructions for Use’.

Note: For location of the Serial Number plate see inside front cover.

P8/54 T-SM47j

2.0 TECHNICAL DATA

2.1 Weights

The nominal weights of the standard table components

are listed below (for 50mm mattresses):

Leg section (without mattress) .. ..11.50kg

Leg section mattress .. .. .. .. 2.75kg

Headsection (withoutmattress) .. .. 7.75kg

Head section mattress .. .. .. 2.00kg

Table (baseandcolumnonly) .. 192.00kg

Long and short trunk assembly* .. 55.75kg

Long and short trunk mattress .. .. 7.25kg

Total weightstandardtable .. .. .. 279kg

Lightweight leg section.. .. .. .. 4.50kg

Footrest(incl. mattress) .. .. .. 7.00kg

Widthextender (incl.mattress) .. .. 6.00kg

Perinealinstrument tray .. .. .. 3.00kg

* (without mattress)

2.2 Dimensions

The following are the nominal major dimensions of the

standard table (with head and leg sections fitted) and

includethe 50mm mattressandsiderails ifapplicable(see

Fig. 2.1 for illustration, the number in brackets after the

item details which part):

Overalllength (2) .. .. .. 2102mm

Maximumheight (4) .. .. .. 1120mm*

Minimumheight (5) .. .. .. 720mm*

Maximumtop traverse(2) .. .. 250mm

Overallwidth (6) .. .. .. 600mm

Sidebars(Denyer) .. .. .. 37.8 x 5.5mm

* 5mm less for Serial Numbers prefixed T2AAor T2AB

2.3 Movements

Thefollowingtable movementsaremaximumsandcannot

be assumed to be available in all combinations of table

positioning (see Fig. 2.1 for illustration, the number in

brackets after the item details which part). For example,

with the table in its normal configuration and at minimum

height the maximum Trendelenburg and leg section

movements cannot be achieved due to the proximity of

thefloor.Similarly withalarge amountoftilt set,maximum

Trendelenburg cannotbeachieved.

Max.Trendelenburg (1) .. .. .. 35°

Max.reverseTrendelenburg (1) .. .. 35°

Max.extension (4) .. .. .. .. 230°

Max.flexion (4) .. .. .. .. .. 90°

Head section (5) .. .. .. .. ±45°

Leg section (3) .. .. .. .. -100° +55°

Max. lateral tilt (7) .. .. .. .. ±18°

2.4 Table loading

Seemaximum patientweightdistribution chartsinFig. 2.2

and 2.3 for various table positions and orientations.

Maximum section loading is stated on each item and is

detailed below for reference:

Legsection .. .. 44kg

Head section .. .. 22kg

For accessories the maximum loading is stated on each

itemanddetailedintheUserHandbooksupplied with them.

Forspecificnotesonthe obese patientsee the ‘Instructions

for Use’.

2.5 Electrical

2.5.1 Antistatic requirements

The table has an antistatic pathway from the table top,

through an internal resistor, to the castors.

CAUTION

To complete and maintain the antistatic

pathway the table must be used on an

electrically conductive or antistatic floor and

with mattresses supplied by Eschmann

Equipment.

2.5.2 Batteries

Table base:

Mainbatteries**:

Two, 12V 10.0Ah, sealed lead acid

Backupbatteries**:

Two, 12V1.2Ah,sealed leadacid

(seebatterydisposal cautioninthe‘Instructionsfor Use’)

Infraredhandset:

Two, 1.5V size AA Alkaline (Note: Must only be

changedinaccordance with thenotesinthe section

6.6.19.2toensurethe IPratingisnot compromised).

2.5.3 Internal battery charger**

Input

100-240V a.c. 2.4A (max) 50-60Hz

Output

29.2Vd.c. 2A(max.)when chargestateLED

red or orange, 27.6V d.c. when charge state

LED green

2.5.4 Fuses

2.5.4.1

External fuses

Mains input fuses (item 17, Fig. 1.0)

2 x T4A(5 x 20mm) 250V

Battery fuses (item 8, Fig. 1.0)

2 x T20A(6.35 x 32mm) 500V

T-SM47j P9/54

T20-a

OPERATION TABLE

Note:Therighthandfuseislinkedtothemainbatteries

andthelefthandfuse(i.e.nearesttothebackupbattery

switch) is linked to the backup batteries.

Mains plug fuse

.. .. 10A(typeisdependentonplug

which may have been changed from that originally

supplied)

2.5.4.2

Internalfuses**

(onlyaccessiblebyengineer)

Battery fuses** (joining each battery pair)

2 x 30A blade type* (1 per battery pair)

2.5.5 Duty cycle

Thissymbolis usedtoindicatethetable’sdutycycle

which, in the worst case, is ‘60s : 600s’, the ratio of the

operating time to the sum of the operating time and the

ensuing interval (see note below). Each motor drive has

its own duty cycle and this is dependent on loading and

table position as detailed below.

Trendelenburg 1 : 4 (60s : 240s) at a maximum torque of

417Nm (e.g. 135kg load offset 31cm from the

fulcrum, or a 300kg load offset 14cm from the

fulcrum. Where this load is the patient and

accessoriesweightandtheoffsetishowfartheloads

centre of gravity is, from the centre of the column).

Traverse 1 : 4 (60s : 240s) when the table is

horizontal and at the maximum load of 300kg, or at

17.5°with apatientweight of 225kg,orat 35°witha

patient weight of 150kg.

Break 1 : 10 (60s : 600s) at maximum patient

weight of 300kg.

Height 1 : 4 (60s : 240s) at maximum patient

weight of 300kg (not offset).

Tilt 1 : 4 (60s : 240s) at maximum patient

weight of 300kg.

Note:Theduty cyclesaboveare allforthe worstcase(i.e.

maximum loads). For reduced loading the above duty

cycles can be increased.

2.6 Classification and symbology

Allthesymbolsused onthis tableareshownandexplained

inthe‘InstructionsforUse’.Thesedetailthesafetycategory

andclass ofthistableas markedonthe table orsectionby

the use of these symbols.

2.7 Use in conjunction with other

equipment

2.7.1 Electrosurgical equipment (h.f.)

TheT20-aoperation tablehasbeen designedtominimise

the possibility of accidental electrosurgery burns and can

be used in conjunction with electrosurgical equipment.

However, contact with any metal surfaces (e.g. table side

bars, or other equipment etc.) can cause burns during

electrosurgery and must be avoided.

2.7.2 Defibrillation equipment

With the mains cord attached the equipment has

defibrillator proof applied parts with type BF protection

against electric shock.

2.7.3 Other

When the T20-a is used in conjunction with other infrared

controlled devices, their controllers should be checked to

ensurethatno interferencebetweenthemandtheT20-ais

possible, prior to surgical intervention. Also see the

‘Instructions for Use’.

2.8 Standards compliance

The table has been designed and built to comply with the

followinginternational standards:

BS EN 60601-1: 1990 (issue 2, October 1997)

BS EN 60601-1-2: 1993

BS EN 60601-2-46: 1998

BS EN 60601-1-4: 1997

2.9 Environmental conditions

2.9.1 Operating environment

The table has been designed to operate in the following

environment:

Temperaturerange .. .. 10°C to +40°C

Pressure range .. .. .. 69KPato 106KPa.

Humidity range .. .. .. 30% to 75% RH

non-condensing.

2.9.2 Transport & storage environment

The table can be transported and stored safely, in the

followingenvironment:

Temperaturerange .. .. -30°C to +50°C

Pressure range .. .. .. 69KPa to106KPa

Humidity range .. .. .. 30% to 90% RH

non-condensing.

** NOTE: Items marked ** are to be changed with caution. During change or

replacement they must only be disconnected for a maximum of 60 seconds. If

batterypowerisremovedfromthetableforlongerthanthisthenreconditioning

of the battery management system must be carried out, see section 6.6.26.

P10/54 T-SM47j

Theseare maximummovements foreachaspect, theymay notbeavailable incertain combinations(e.g.maximum

tilt and maximum Trendelenburg). Movements that could cause damage cannot be catered for (e.g. position of the

leg section). Fig. 2.1 Major dimensions and movements

1

2

3

4

5

6

7

(seesection2.2)

(seesection2.2)

T-SM47j P11/54

T20-a

OPERATION TABLE

Fig. 2.2 Maximum patient weight v table position graphs

P12/54 T-SM47j

Fig. 2.3 Maximum patient weight v table position graphs

T-SM47j P13/54

T20-a

OPERATION TABLE

3.0 TECHNICAL DESCRIPTION

See Fig. 3.1 andAppendix 3 for schematic diagrams.

3.1 Power supply assembly

This assembly (Part number 111765) which is located in

thetable base,hasno userserviceableparts andmustbe

changed as a complete unit. The assembly includes, a

Batterycharger loom,aBattery chargermodule,a Battery

management PCA, a Battery connector loom, a Chassis

plate, two Battery support brackets, a Switch, two Fuses

(32 x 6.35mm 20A‘T’type), two Fuse holders, two battery

pairs and all connections, cable ties and screws etc.

3.2 Control electronics

3.2.1 Overview

Thecontrolelectronics fortheT20-ais distributed between

two PCA’s (the ‘4 actuator PCA’ and the ‘3 actuator PCA’).

These two PCA’s contain three distinct microprocessor

daughter PCAs (two on the ‘4 actuator PCA’ and one on

the ‘3 actuator PCA’).

The ‘4 actuator PCA’ (111524) is located on the column

and includes the ‘main controller’ and the ‘4 actuator

controller’. Each of these ‘controllers’ consists of a

‘microprocessordaughter PCA’(111526)which havetheir

control electronics on the ‘4 actuator PCA’.

The ‘Three actuator PCA’ (111525) is located in the long

trunk section of the table and contains the ‘3 actuator

controller’, another ‘microprocessor daughter PCA’

(111526)with its controlelectronicson the‘Threeactuator

PCA’.

3.2.1.1 Microprocessor daughter PCAs

ThedaughterPCAsconsistofa Motorola MC68HC912B32

micro controller, a watchdog circuit, an RS232 line driver

and an SPI UART and RS485 line driver. All the micro

controllers on the T20-a require these components. The

RS232communicationscanbeused to providea telemetry

link to custom software running on a PC. Once fitted to

theirrespective controllerboardsthe microcontrollersare

programmed with the appropriate software application.

There is a ‘main controller application’ (110442) and an

‘actuator controller application’ (110443). Both the 4-

actuator and 3-actuator are programmed with the same

‘actuator controller application’ (110443). A configuration

file is then downloaded to each micro controller that

specifies which controllers are present on which board. It

ispossibleto configure anyactuatortoanyboard,however

the configuration of the electronics is specific to each

actuator.

3.2.1.2 The ‘main controller’

The ‘main controller’provides the control and supervisory

functions for the table. This consists of the interface to the

infrared handset, corded handset (via RS232), footswitch

andstandby panel.Italso controlsthetable powerLED.

The main controller communicates with the two actuator

controllers (one of which is co-located on the 4 actuator

PCA) by means of an RS485 multi-drop bus. This system

enables multiple slave controllers to be attached at any

time. The main controller issues a health check poll

message to each of the actuators (up to four of which can

be controlled by the single PCA) to ensure that they are

functioningcorrectly.

When a command is received from any of the user-input

devices the main controller issues the appropriate

movementcommandsto therequiredactuator(oractuator

groups in the case of combined movements).

3.2.1.3 The ‘4 actuator PCA’

The ‘4 actuator PCA’ is responsible for movement of four

actuators on or within the table’s column. These are the

‘top and bottom height actuators’ inside the column

assembly,the‘Trendelenburgactuator’andthe‘Tiltactuator’

mounted on the column. A number of signals control the

movement of each actuator.

APWMsignal isusedto setthespeed ofthemotor; digital

signals control direction (forward/reverse), a digital signal

enables the drive circuit and another digital signal effects

a brake on the motor by shorting the windings together.

Theelectronicsprovideadigitalfaultsignaltoindicatewhen

thereisa problem withthe controlcircuit,oranovercurrent

situationhasoccurred. Ananaloguesignal is alsoprovided

onallbut the‘bottomheightactuator’.Theanalogue signal

onthetopheightactuatoristheoutputfromapotentiometer

thatindicatesthecombinedpositionofthe height actuators.

Although the column contains two motors, there is only a

single potentiometer to indicate the height of the column.

Thisanalogue signalisfed to the‘topheight actuator’; the’

bottom height actuator’is effectively slaved to the top.

3.2.1.4 The ‘Three actuator PCA’

The ‘Three actuator PCA’ is responsible for movement of

the three actuators within the tables long and short trunk

sections. These are the ‘left break actuator’, ‘right break

actuator’ and the ‘traverse actuator’. These actuators are

controlled by the same signals as on the ‘4 actuator PCA’.

Intermsoffeedback,boththe‘leftandrightbreakactuators’

have potentiometers and the ‘traverse actuator’ has limit

switches which open when the long trunk reaches either

end of its movement. The ‘left and right break actuators’

are independently controlled to move at a set speed and

to maintain a minimum deviation between them.

P14/54 T-SM47j

3.2.2 Handset overview

Therearetwoversionsofhandset,a cordless type(infrared

handset) with an infrared emitter powered by 2 AA cells

anda cordedversion(corded handset) withanRS232 link

to the main processor on the ‘4 actuator PCA’. The latter

versionderives itspower fromtheT20-a.

3.2.2.1 Infrared handset

The 4 x 5 matrix keyboard is decoded using a proprietary

keyboard decoder. This device is powered down and

remains dormant until a key is pressed causing its clock

oscillatortobeinitialised.Thekeyisdecodedandthe38kHz

modulated signal is fed to the infrared LED via a FET. The

whole system is powered via 2 AAbatteries

3.2.2.2 Corded handset

The 4 x 5 matrix keyboard is decoded using a proprietary

keyboard decoder. This device is powered down and

remains dormant until a key is pressed causing its clock

oscillatortobeinitialised.Thekeyisdecodedandthe38kHz

modulatedsignal isfedto aPICprocessor.Theprocessor

decodestheoutputfromthekeyboard decoder intoRS232.

This output is fed to an RS232 line driver. The corded

handset’s power is supplied directly from the T20-a, 5V

powersupply.The handset containsaDC-DC converter to

supply3.3V forthe keyboard decoder.There areindicator

LED’sto show thecharge status ofthe tablebatteries (main

and standby).

T-SM47j P15/54

T20-a

OPERATION TABLE

PROCESSOR

CONTROL FET DRIVERS

MOTOR

POSITIONAL

FEEDBACK

OVER

CURRENT

MANAGER

CONTROL FROM

HOST MICRO

AXIS TILT

AXIS TREND

AXIS HEIGHT 1

AXIS HEIGHT 2

POSITION ENCODERS AND

ANCILLARIES

OVER CURRENT MANAGERS

CONNECTORS

INC:

CONNECTORS & INTERFACES

MICRO CONNECTORS

POWER

MANAGEMENT

AXIS BREAK RIGHT

AXIS BREAK RIGHT

AXIS TRAVERSE POSITION

MONITORS

OVER CURRENT

MANAGERS

CONNECTORS

POWER

MANAGEMENT

PROCESSOR COMMUNICATIONS

INTERFACE

CONNECTOR 64 WAY

4

12

44

Keyboard Encoder

Infrared Driver / Emitter

BatteryKeyboard

Power Management

Keyboard Encoder

Connector/LeadKeyboard

Power Management

Processor

RS232 Decoder/Driver

Basic control and feedback - all actuator drivers

Four Actuator PCA

Three actuator PCA

Processor PCA

Handset corded version

Handset remote version

Fig. 3.1 Schematic diagrams

P16/54 T-SM47j

4.0 SAFETY WARNINGS

4.1 ‘Service position’

When the four M10 screws (each side) that secure the

trunk sections to the pedestal are removed, to place the

table in the ‘Service position’ as detailed in section 1.9,

always take extreme care (and ensure table is switched

‘off’ before tilting top into or out off the ‘Service position’).

WhentheM10screwsareremovedthe table trunksections

maytiltdramatically unless thesectionsarefullysupported

duringscrew removal.Alwayslowerthe trunk sectionsinto

(andout of)the‘Service position’slowlyand alwaysreturn

thetabletrunk sectionstothe‘normal’position(takingcare

notto trapfingers)assoon aspossible,replacingthe eight

M10 screws securely. Also remove the following before

placing the table into the ‘Service position’:

Head section Leg section

Trunk mattress All accessories

When powering the table in the ‘Service position’ using

tool T2203 (to connect the table top connector blocks)

extreme care should be taken and powering the table in

thisposition shouldbelimited toessentialtesting only. Itis

preferable to return the table out of the ‘Service position’

before powering the table.

4.2 Lifting

Duringsome oftheprocedures detailedinthis manualitis

necessarytolift heavyassemblies.Thesearethe long and

short trunk assembly, the wrapround assembly and the

telescopic assembly. These all require two people to lift

safelyandanyprocedurethatrequiresthesetoberemoved

from the table should not be attempted if two people are

not available. Other components although not heavy

enough to require two people, should be handled using

the correct lifting techniques to minimise personnel injury.

Itis advisedthatsuitableprotective footwearisworn when

handling heavy parts.

4.3 M10 trunk screw removal

When removing the four M10 (hexagonal head) screws

thatsecurethetrunksections to thecolumn, alwaysensure

that precautions similar to those detailed in 4.1 above are

taken.Removeallaccessories,sectionsandtrunkmattress

and support the trunk sections during screw removal.

4.4 Trend and tilt actuator removal

WhentheTrendand /or tiltactuatorsareremovedthetrunk

sections will not be stable. Before removal follow similar

precautions to those detailed in section 4.1. Remove all

accessories, sections and trunk mattress and support the

trunk sections during actuator removal. Replace the

actuator as soon as possible.

4.5 Working with mains voltage

The only time that it may be required to work with mains

voltage applied to the table is whilst testing the battery

charger. During this procedure ensure that normal safe

workingproceduresareemployedforanactivitythat entails

working with mains voltage, such as:

i Reducethe amountoflivework totheminimum

possible.

ii Use common sense and stop working if

approached, distractions can kill.

iii Ensure the area is clear of all unnecessary

personnel or warn people in the area to stay

clear during live work.Also ensure that you are

notentirelyalone andthat someonecouldcome

toyourassistanceif you shouldsufferan electric

shock.

iv Only use the correct equipment, probes and

cables for the work in hand.

v Mains power should be supplied via an RCD

(residualcurrent device).

vi Turn off the mains power whenever possible to

reduce risks.

4.6 Gas springs

Whenremovingorservicingthetableheadandlegsections

gas springs refer to the warning in section 6.5.1.2. They

donot require lubricationanddonot attempttoopenthem.

Also note the disposal notes provided in 6.5.1.2 (vii).

4.7 Hot parts on PCAs

During service and when covers are removed note that

partsof the PCAscanbecomehot enoughtocauseburns.

Beware that touching these assemblies when hot could

result in unexpected body movements.

4.8 Biological contamination

During servicing of the table it is advised that protective

glovesshould be warntoavoid biologicalcontamination.It

is preferable that the table be cleaned and disinfected

before service.

4.9 Connection of leads

When connecting test leads to the table during service

ensure that these do not constitute a tripping hazard.

4.10 Leaking batteries

In the unlikely event of a battery leaking in the table base

avoid spreading the contamination (sulphuric acid) and:

i Wearsuitable personnelprotection(goggles,gloves

etc.) do not smoke and avoid sparks.

ii Use a bonding agent such as sand, or sodium

carbonate to absorb and neutralise the bulk of the

electrolyte.Wash (andrinsewell) thecontaminated

areawithwater,takingcare not tosplashelectronics

or any other table base components.

iii Do not flush electrolyte into the sewer system but

dispose of the used bonding agent and all cleaning

materialsinaccordancewithlocalwasteregulations.

In the case of skin contact wash and rinse immediately

with water. If splashed into eyes rinse well with water and

seek medical advice. If acid mist is inhaled, inhale fresh

air and seek medical advice.

T-SM47j P17/54

T20-a

OPERATION TABLE

5.0 MAINTENANCE

5.1 Power supply assembly

This assembly (Part number 111765) which is located in

thetable base,hasno userserviceableparts andmustbe

changed as a complete unit (also see section 3.1).

5.2 Table fault finding

5.2.1 The‘Instructionsforuse’containsabasicfaultfinding

table that can be used to solve any minor problems. This

covers the main user errors (i.e. there is no fault) that can

occur when the user has not read and understood the

‘Instructions for use’. It also contains the first line of fault

finding (i.e. check external fuses, try another handset, try

anothermainslead).Thefollowing section(5.2.2)provides

atestsequence tohelpdeterminethefault (forthe majority

offaultsthatmayoccur)thatcouldstopthetable responding

to an input via a control device. Mechanical faults are

normally self evident in that a part is worn, damaged or

broken. In this case refer to the appropriate section of this

manual for part replacement information. Appendix 3

providesthe schematic diagrammesthatcan also beused

in fault finding.

5.2.2 Follow the sequence below to identify most major

faultsthatresultinalackofresponsetoacontrolcommand:

1 When the table is initially switched ‘on’ is the table

‘on’ LED (item 23 of Fig. 1.0) bright, dull or ‘off’ for

the first few seconds.

Ifdull turnthetable ‘off’wait atleast10seconds

and then turn back on. If the LED is still dull or

‘off’this indicates an electronics fault see 5.2.3.

If bright move to 2 below.

If it is flashing this also indicates an electronics

fault see 5.2.3.

2 Try the ‘standby control panel’ (any motion except

Trendelenburg), if this fails try the ‘standby control

panel’with thebackupbattery switchdepressed.

Ifthetableworksfromthe‘standbycontrolpanel’

this indicates a fault with the control device or

its connection to the table.

Ifthetableworksfromthe‘standbycontrolpanel’

onlywhen thebackup battery switchis pressed

this indicates a fault with the main batteries

(replacethe whole Powersupplyunit).

Now try Trendelenburg from the ‘standby control

panel’, if this and only this motion works it indicates

a problem with the main control PCA.

3 If one of the motor groups ‘only’has failed then this

indicatesaproblemwithitsassociatedPCAasfollows:

Breakand traverse-Threeactuator PCA

Tilt, Trend and Height - 4Actuator PCA

This distinction may help in reducing the amount of

diagnosticsand coverremoval.

4 Remove covers and check battery fuses (see

section 5.3.1 and 6.6.26). Also look to see if the

PCA indicator lights are flashing ‘on’ for 1 second

and ‘off’ for 1 second. If they are ‘off’ or flashing

faster, this indicates an electronics fault see 5.2.3.

5 Ifthe faultisonly apparentforone motionthiscould

indicateafailedmotororfailedsensorforthatmotion,

or, an electronics fault. If the motion starts and then

stopsimmediately thiscouldindicate a failedsensor

or an over current situation. Test motor (as detailed

in section 6.6), if the motor works and no small

movement is observed following a demand for that

motion, it indicates an electronics fault, see 5.2.3.

5.2.3 Electronicfaults can onlybedeterminedwith the

tableconnectedtoa PCwith the‘T20ApplicationSoftware’

installed. Consult the Application Software Manual (as

detailed in section 1.1) which provides guidance on fault

diagnosis.Also notethatwhen correctingelectronicfaults

(andfollowingsomepartsreplacement)thetable willrequire

reprogramming,reconfiguringorrecalibration.Theseaspects

arealso fullycoveredin the ApplicationSoftwareManual.

5.2.4 Break motion control

5.2.4.1 Thetwobreakarmsare independentlycontrolled

andaresynchronised to operatewithinaprogrammedlimit

of each other. This control system can result in small

variances that appear as a slight misalignment, this is

acceptable and a part of the normal table control software

routine.Intheunlikelyeventthatthisdeviation goes outside

of the programmed limit the table break motion (only) will

stop working. This can sometimes be corrected as below.

5.2.4.2 Whilst observing the two break arms press (for

approximately0.5 secondsonly)a break controlbuttonon

the handset (B7 or B8 of Fig. 6.9) once or twice. If this

makes the deviation worse press the other break control

button as above once or twice. If the break motion still

does not work correctly after this there could be a fault in

one of the following:

Breakmotor

Breakpotentiometer

Wiring to any of the above

Significantuneven tableloading*

*This problem will only be evident during use and if

investigated at service it will be difficult to reproduce.

5.2.5 Trunk section connector blocks

5.2.5.1 Ifallthetoptablefunctionsstopworking(e.g.break

andtraverse)theconnectorblocks(item5,Fig.6.7anditem

14, Fig 6.3) could be failing to connect correctly due to

contaminationetc.Checkthatagoodcontactisbeingmade

betweenthe columnand trunksconnectorblocks.

5.3 Fuse location

5.3.1 All fuse locations are identified in section 2.5.4 and

Fig.1.0.DONOTREMOVEORCHANGEINLINEBATTERY

FUSES UNLESS YOU HAVE READ SECTION 6.6.26.

P18/54 T-SM47j

5.4 Service schedule and safety check

4. Priorto changinga motor checkit hasfailed andthat

thefaultisnotinthecontrolelectronics(6.6.6-6.6.9).

5. In the sections below where the word ‘check’ is used

it is inferred that if the check reveals a fault then this

should be corrected.

6. Tilttabletopintoservicepositionasrequired(1.9)but

note safety warning, section 4.1.

7. Theright-handcolumnshouldbeusedtotickoffeach

item of the schedule on completion and to note parts

replaced (or wearing that will soon need replacing).

8. Thisscheduleshouldbephotocopiedandcompleted,

copiesto beretained by theengineer conductingthe

service and the person responsible for the table.

This should be performed every 6 months to ensure the

continued safe operation of the table.

NOTES:

1. The numbers in brackets in this schedule details the

sectionofthismanualthatshouldbereferredtowhen

performing or checking the activity detailed.

2. Prior to service operate all table functions (6.7) to

ensure correct operation, note any problems for

investigation during the service.

3. Remove base covers as required (6.2.2.1). Access

canbegainedtothelower,lower-mid,upper-midand

topofthecolumn(6.2.3.2to6.2.3.5).Ifnecessarythe

telescopic covers can be removed (6.2.4.1).

1. Checkpedal dampersforwear or leaking(6.3.3).

2. Disassemble, clean and lubricate the two fixed wheel assemblies and the four

castor assemblies (6.3.4, 6.3.5). Test resistor assembly as 6.3.5.1 (viii).

3. Check brake pads for wear, damage, or hard and brittle (6.3.6).

4. Check the castor pillar and pedal spindle bushes for wear (6.3.7 and 6.3.8).

5. Check and lubricate both lifting roller assemblies (6.3.9).

6. Check for wear of both pedal catch mechanisms (6.3.12) and renew the anti-

slippad onboth pedals(6.3.11).

7. Checksecurity ofallfixingscrews, nutsandretaining clips withinthebase area

and check the pedal operation works smoothly and correctly.

8. Checkmainandstandby battery voltage(standby and load)as 6.3.2.(iia). Check

security, connectors and loom routing of PSU.

9. Check the Trendelenburg, tilt and telescopic column actuator assemblies for

excessive wear or failure (6.4.2, 6.4.3, 6.4.4 and 6.4.5) and grease worm and

wheel on Trendelenburg and tilt motor assemblies.

10. Check the security and positioning of all wiring looms and connections. Add

cable ties, reposition or replace as necessary.

11. Check switch and fuse panels for operation and signs of damage (6.6.16).

12. Check for wear or damage to the tilt and Trendelenburg bushes in the trend

and tilt frame (6.4.6 and 6.4.7). Check all fixing screws within the inner and

outer(tilt andTrend)gimbalassemblies.

13. Check thewraparoundaligningbearingpads,adjust asrequiredtoremoveplay

orreplace (6.4.8).

14. Check height potentiometer is secure to the wrapround and that the cable is in

good condition and secure to the base (6.6.13).

15. Check the security and the routing of the 4 actuator PCA, connectors, energy

chains and all looms within the column. Cable-tie if necessary

16. Remove and replace bellows if split/damaged (6.2.5).

17. Check the security and the routing of the Three actuator PCA, connectors,

energychainsand traverseandbreakmotor looms withinthetraversehousing.

Cable-tie if necessary.

18. Checkthat traverse motorand traversebelt tensionersare secureto thesupport

plateand lubricatetensionerbearings betweenscrewand bearing only. Check

traversemotor(6.5.2.1)andadjustment of thetraverse belttensioners’(6.5.2.2).

19. Check the condition and lubricate if necessary the drive belt guide needle

bearingsbetween screw andbearingonly(6.5.2.9).

Base and column:

T-SM47j P19/54

T20-a

OPERATION TABLE

Trunk sections and covers.

Service / Table details

Service Engineer

Engineers Name (Eschmann / Hospital*).................................................................... ContactTel.No. ...........................................

Person responsible for table

Name....................................................... Position ...............................................Dept. ............................................

Hospital ................................................... Health Authority ..................................Tel.No...........................................

Table details

Table SN .................................................. Location ..............................................Account No. (If appl.) .............................

Service detail

Date......................................................... Time completed ..................................2nd visit reqd. YES /NO*

(* Delete as required)

20. Check condition (excessivewear/breakage)of traverserodbearings (6.5.2.8).

21. Checkoperationandadjustmentofthetraverselimitswitchassemblies’(6.6.14).

NOTE:Check thatthetraverse movementstopswhen thetraverselimit switch

pin is depressed from both ends and from both sides of the table.

22. Checkthat theset screws thatretain thetraverse leadscrewsare tight (20Nm)

and lubricate the lead screw and traverse rod.

23. Clean the male and female pins on the 4-way communication connector block

to ensure a good contact, check for cracks or damage (6.6.15).

24. Remove long / short trunk push button assemblies, clean and check condition

of catch blade (6.5.2.7), do not lubricate.

25. Checkguide pinholes(in theattachmentblocks) forexcessivewear(6.5.2.10)

26. Checksfor equaland even movementof the twobreak motors(i.e.check both

breakarms intheshorttrunk moveupand downtogether).Ifrequired, replace,

adjust or recalibrate (6.5.2.3 and 6.5.2.4).

27. Serviceinfraredhandset(6.6.23).Checkfunctionandconditionofcordedhandset.

28. Check thatallsiderailfixing screws aretightinthelong andshorttrunksections

(21Nm) and the head and leg sections (15Nm).

29. Check the condition of the trunk section covers (6.5.2.6 and 6.5.1.3).

30. Ensuretabletop isnot in theserviceposition and thelocking screws are replaced

to lock the trunk sections out of the service position.

31. Ensure free movement of the telescopic covers. Check condition and function

of Standby control panel, replace if adhesion to column cover shows any sign

offailure (6.6.25).

32. Ensure the base covers are refitted (6.2.2.2).

33. Conduct the function tests (6.7) correct any faults and conduct the function

tests again until all functions are working correctly.

Head and leg sections.

34. Checkall guidepinsfor wearor damage (6.5.1.1).

35. Checkgas springsfor leaks orpoor performance (6.5.1.2).

36. Check gasspring pivotpinsandshoulderscrews forsecurityandwear(6.5.1.4)

36. Check the condition of the head and leg section covers (6.5.2.6 and 6.5.1.3).

Ensure the ‘Electrical safety checks’ have been carried out (seeAppendix 4 of the ‘Service Manual’).

Leave table clean and in a fully functioning condition with batteries on charge and table switched off.

P20/54 T-SM47j

6.0 PART REMOVAL/ADJUSTMENT/

REPLACEMENT

6.1 GENERAL

6.1.1 Thissectionhasbeensplitintothefollowingsections

for easy reference, note safety warnings in section 4.0:

6.2 Table base and column covers

6.3 Table base components

6.4 Table column components

6.5 Table sections

6.6 Electrical components

6.7 Function tests after maintenance

6.8 Accessories

6.1.2 Within the text detailing a part replacement any

specificsettingor adjustmentisfullydetailed.Each section

also provides specific details of any required lubrication

during assembly, the use of threadlock fluids and any

specific torque settings that should be adhered to.

Note: Conversion chart and conversion data for Torque

values inAppendix 1.

6.1.3 All replacement parts must be supplied by

Eschmann and note that this also includes all the nuts,

screws, roll pins, pivot pins etc. that are specified in the

‘Illustrated parts list’. Some of these are provided to a

specificstandard (e.g.hightensile) andtheuseof ‘similar’

items could compromise the strength and therefore the

safety of the table.

6.1.4 All electrical components are non-repairable and

must be replaced with new Eschmann parts only, to

maintain the safety of the system. Replacement is usually

a self-evident procedure but ensure :

i Good wiring practice is observed and static

discharge procedures are adopted as applicable

when handling PCAs (printed circuit assemblies).

ii All wiring is replaced as found and secured away

fromany movingpartsusing adequatequantitiesof

cable clips and restraints.

iii All fixings are replaced as found and no substitutes

are used.

iv Thefunction checks detailedinthismanual (section

6.7) are carried out on completion of any part

replacement.

6.1.5 After all procedures the table should be left clean

and in full working order (run function test detailed in 6.7)

to ensure safety and ensure the (Electrical safety checks)

inAppendix 4.

6.1.6 Before any part removal/replacement procedure

ensure the table is not connected to the mains. If mains

power is required at any time during diagnostic checks

ensure that appropriate safe working procedures for live

working are adopted (see section 4.5).

6.1.7 Toavoid duplicationofcommonprocedures across

reference to the required part of the manual detailing the

procedureisprovided whererequired. Notethesesections

also contain assembly notes that must be followed.

6.1.8 Allpartnumbers canbe foundintheIllustratedparts

list(Publication number T-IPL35availablefrom Eschmann

Equipmentat theaddresson theinsideof thefrontcover).

This Illustrated parts list should be available for reference

during part removal or replacement.

6.1.9 The locking catch for foot pedals can be external or

internal. Please check which type is fitted to the table and

followthe appropriate notesinthesections thatfollow.The

externalcatchisshowninFig.6.2a,item20 and the internal

catch is shown in Fig. 6.2b, item 6.

5.1.9 Tables with a Serial Number prefix T2AC or later

have been increased in height by 5mm. Check that the

correct parts are fitted by referring to the Illustrated parts

list. Fig. 6.2b and Fig. 6.2c shown both configurations.

6.2 TABLE BASE & COLUMN COVERS

6.2.1 The removal, replacement and method of gaining

access behind the table covers, has been split into the

following sections for easy reference:

6.2.2 Base covers.

6.2.3 Access to column.

6.2.4 Telescopic covers.

6.2.5 Bellows.

For reference Fig. 6.1 shows the general arrangement of

all the cover components.

6.2.2 Base covers

CAUTION

Ensure the cable to both of the infrared PCA’s

are released before sliding the base covers

away from the base, see ‘v’ below.

6.2.2.1 Removal of base covers.

i Raisetheheightofthetabletop sufficientlyto expose

thescrewsatthe lower edgeof thelowest telescopic

section where it joins the base covers.

ii Removebothfootpedals byreleasing theirretaining

screws, taking care not to loose the return spring

(springonlyfitted ifthepedalhasan externalcatch).

iii Remove the button head screw from the end of the

longbasecoverandthecountersunkscrewfromboth

sidesofthecoverswheretheyjoinattheirloweredge.

iv Removethetwo screwsfrom thelower edgeof each

sideof thelowesttelescopiccover (nottheendface

screws).

Note:Thesescrews differin lengthandmust beput

back as found (short 12mm to short trunk end, long

15mm to long trunk end).

Table of contents

Other eschmann Medical Equipment manuals