eschmann RX600 User manual

RX600

OPERATION TABLE

606049

Service Manual

T-SM14g

Service Manual

Preliminary Information

Technical Data

Safety Notes

Introduction

Description

Maintenance

Eschmann After Sales Service Department

TheEschmannAfter SalesServiceDepartmentisstaffedandequippedtoprovideadviceand assistance

during normal office hours.To avoid delays when making enquires, please quote the Model and Serial

Number of your Operation Table which is shown on the Serial Number plate, the location of which is

shown below.Please ensure you include all alpha and numeric digits of the Serial Number.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment,Peter Road, Lancing,West Sussex , BN15 8TJ, England.

Tel: +44 (0) 1903 765040. Fax:+44 (0) 1903 762006.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents andTrade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limited.

“Eschmann Equipment”is a trading name of Eschmann Holdings Limited.

“RX600” is a trade mark of Eschmann Holdings Limited.

Patents: GB 2260075 & GB 2242624;France 536922 & 450836;US5116032;

Germany P69206378.1 & P69104883.5;Italy 536922 & 450836.

Patents pending in Japan, application numbers 263630/92 & 97990/91.

Copyright © 2002

Allrightsreserved.Thisbooklet isprotectedbycopyright.No part ofit maybe reproduced, storedina retrieval

systemortransmittedinanyformorbyany means,electronic,mechanical,photocopying,recordingorotherwise

withoutwritten permission from EschmannHoldingsLimited.

Theinformationinthispublicationwascorrectatthetimeofgoingtoprint.TheCompany,however,reservesthe

right to modify or improve the equipment referred to.

If the CE mark is affixed to the product, it indicates compliance with Council Directive

93/42/EEC of 14 June 1993 concerning medical devices.

T-SM14g October 2002

The Serial Number plate can

be found on the inside of the

long trunk section casting

indicated here.

T-SM14g 3/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

READ THESE INSTRUCTIONS BEFORE USE

Keep these Instructions in a safe convenient place for future reference. Read in conjunction

with the relevant Publications detailed in the preliminary information section.

CONTENTS

Section Contents Page

1. PRELIMINARYINFORMATION.............................. 4

2. TECHNICALDATA ................................................. 4

3. SAFETY NOTES ................................................... 5

4. INTRODUCTION .................................................... 6

General .............................................................. 7

Electrical system ............................................... 7

Maincontrol board ......................................... 7

Heightopto board........................................... 7

Basedistribution board .................................. 8

Top-of-columndistributionboard..................... 8

Top-of-columnsolenoids board....................... 8

Tiltoptoboard................................................ 8

Power circuits ................................................ 8

Handcontrol .................................................. 8

Footswitch ..................................................... 8

Table-baseon/off control ................................ 9

Built-inbattery charger ................................... 9

Externalbattery charger................................. 9

Standby system connections......................... 9

Tractionbeam stowagedetection ................... 9

5. DESCRIPTION .................................................... 10

6. MAINTENANCE................................................... 14

General ............................................................ 14

Cleaningand storage ....................................... 14

Generalcare andlubrication............................. 14

Gassprings ................................................. 14

Head, hip & leg sections & sacral extension 14

Headandhip locking mechanisms............... 14

Long and short trunk sections...................... 14

Radiographictops ........................................ 15

Undersideofthe table base ......................... 15

Tractionbeam attachment............................ 15

Access to fuses........................................... 18

Handcontrol ................................................ 18

Aftermaintenance........................................ 18

Functional checks............................................ 18

General ........................................................ 18

Hydraulic system ............................................. 19

General ........................................................ 19

Topping-up hydraulic reservoir ...................... 19

Adjustments .................................................... 19

Trendelenburgmicroswitch ........................... 19

Lateral tilt opto ............................................. 19

Breakmicroswitch ....................................... 19

Level tilt switch............................................ 20

Traction beam swivel joints .......................... 22

Removaland installation .................................. 22

General ........................................................ 22

Removetablebase covers .......................... 22

Install table base covers .............................. 22

Removetop-of-column covers ..................... 23

Installtop-of-columncovers......................... 23

Releasingtelescopiccover andupstand ...... 23

Replacingtelescopiccover andupstand ...... 23

Removing telescopic cover .......................... 23

Replacingtelescopiccover .......................... 23

Remove long and short trunk assembly....... 23

Install long and short trunk assembly .......... 24

Section Contents Page

Removebreak cylinder ................................ 26

Install break cylinder.................................... 26

Remove lateral tilt cylinder........................... 29

Install lateral tilt cylinder.. ............................ 29

RemoveTrendelenburgcylinder.................... 28

InstallTrendelenburgcylinder ....................... 30

Removeheight cylinder................................ 30

Install height cylinder ................................... 30

Gasspring replacement ............................... 31

Removebatteries......................................... 31

Install batteries ............................................ 31

Remove the base feet.................................. 31

Install the base feet ..................................... 32

Infillinterlockingmechanism replacement.... 32

Pushbuttonreplacement andadjustment .... 32

Tractionbeam removal ................................. 33

Tractionbeam replacement .......................... 33

Remove swivel joint from short trunk ........... 33

Refit swivel joint to short trunk..................... 33

Traction beam swivel joint ............................ 33

Hydrauliccomponent replacement ............... 34

Electricalcomponent replacement ............... 34

Fault diagnosis................................................. 34

Circuitdiagram index ....................................... 37

Table 1 - Fault diagnosis............................................ 35

Table 2 - Codes for 2-digit display.............................. 38

Fig.1 RX600PoweredOperationTable ........................ 6

Fig.2 RX600Operationtable -basedetail ................. 10

Fig.3 RX600Operationtable -column/trunkdetail .... 12

Fig.4 RX600basedetail (longtrunkend) .................. 13

Fig.5 RX600basedetail (short trunk end) ................. 13

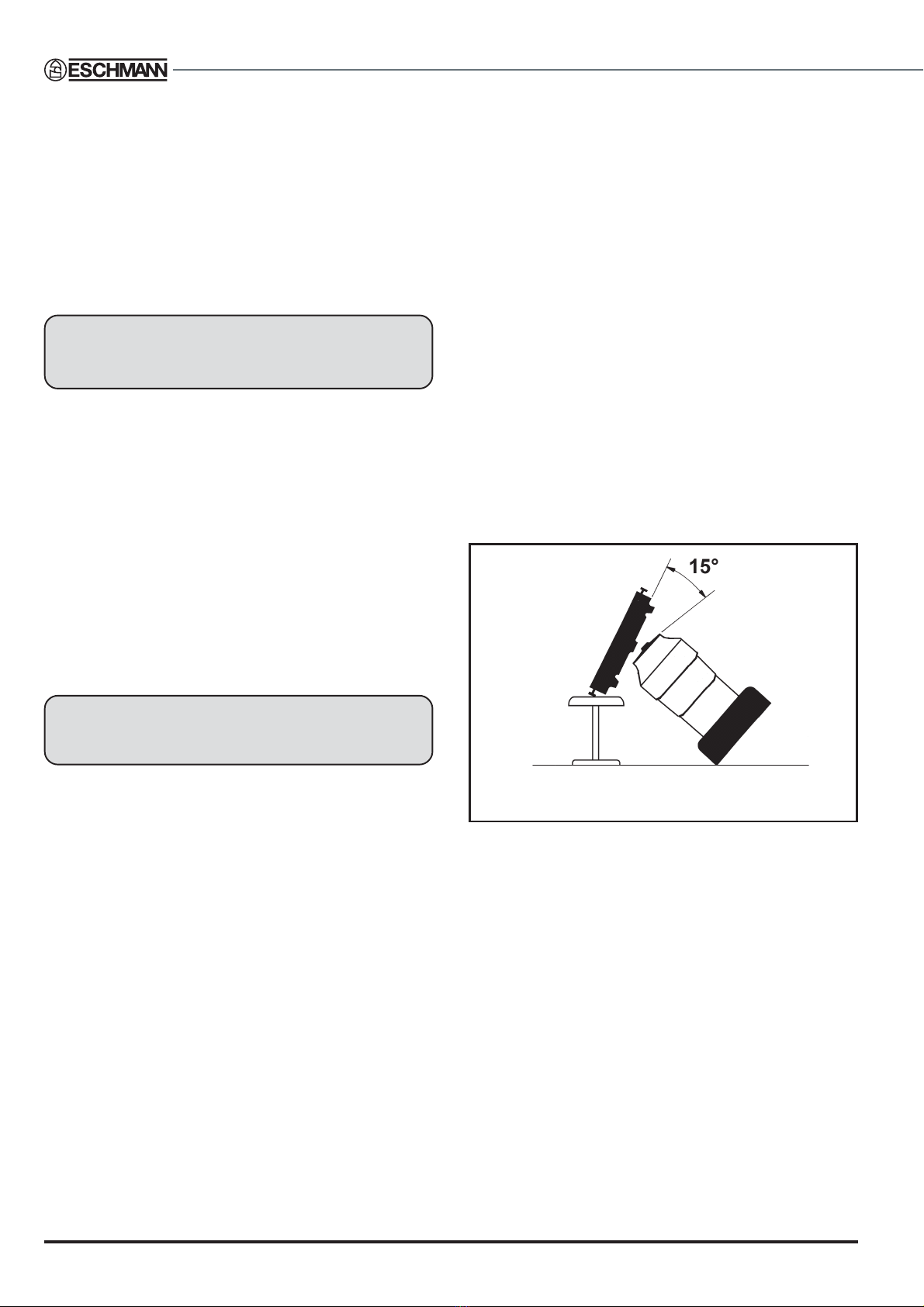

Fig.6 Table tilted for access to underside .................. 14

Fig.7 Undersideof table base ................................... 15

Fig.8 Adjustment of beam attachment ...................... 15

Fig.9 Hydraulic system - Schematic diagram............ 16

Fig.10Hydraulic system - main components .............. 17

Fig.11Maincontrolboard ........................................... 18

Fig.12Trendelenburgmicroswitch ............................... 18

Fig.13Lateral tilt opto detail........................................ 18

Fig.14Break microswitch ........................................... 20

Fig.15Level tilt switch ................................................ 20

Fig.16Swivel joint detail ............................................. 21

Fig.17Cover retainingpush rivets .............................. 23

Fig.18TopofTrendelenburgcylinder ........................... 24

Fig.19Top-of-column hingeassemblydetail ............... 25

Fig.20Break cylinders ................................................ 27

Fig.21Lateral tilt cylinder............................................ 28

Fig.22Trendelenburgcylinder ..................................... 29

Fig.23Top-of-columndetail ......................................... 30

Fig.24Bottom of height cylinder detail........................ 30

Fig.25Gas springdetail.............................................. 31

Fig.26Base feet detail................................................ 31

Fig.27Infill interlocking mechanism ............................ 32

Fig.28Catch mechanism ............................................ 32

Fig.29Beamattachment ............................................ 33

Fig.30Swivel joint attachment detail .......................... 33

Fig.31Handcontrolfunctions ..................................... 38

Fig.32-40Circuit diagrams (seeIndex page 37)......39-42

4/44 T-SM14g

1. PRELIMINARY INFORMATION

1.1 This Service Manual should be referred to for details of the RX600 Powered Operation Tables,

REF 80-606-59 and REF 80-606-13, Serial Number R6AC9K1001 or above.

RelatedTechnical Publications available on request :-

Instructions for Use -T-IM33 (issue ‘d’or later) - RX600 Powered Operation Table

Illustrated Parts List - T-IPL13 (issue‘b’or later) - RX600 Powered OperationTable

1.2 Instruction and Service Manuals should be readily accessible for reference prior to and when operating, cleaning

andservicingtheOperationTable.Allmanuals areavailablefromEschmann Equipment,seeinside front coverfor address

details. 2.TECHNICAL DATA

DIMENSIONS

Table with standard table-top (Fig. 1):

Width including sidebars .............................560mm

Sidebars ......................................(31.75 x 6.35)mm

Overall length (with infill section)...............1975mm

Minimum table height (without mattresses) .... 700mm

Maximum table height (without mattresses). 1040mm

MOVEMENTS

Maximum Trendelenburg....................................35°

Maximum Reverse Trendelenburg......................15°

Maximum Lateral Tilt (left and right)...................15°

Maximum Extension.........................................210°

Maximum Flexion .............................................130°

Head section adjustment ................................ ±45°

Note: With the table at minimum height, maximum

Trendelenburg, and maximum head and leg section

movements are reduced.

WEIGHT (nominal)

Table with standard table-top (Fig. 1) ............ 300kg

SAFETY

The table is built to comply with BS5724 Part 1,BS5724

Part 2 Section 2.22, IEC601-1 and BS6859 Part 1. The

mattresses comply with BS2891.

TABLE LOADING

The standard table (Fig. 1) satisfies a static load test in

accordance with the requirements of BS5724.

WARNING

The RX600 has been designed for patients up

to 135kg with their centre of gravity (normally

the perineum) over the infill or trunk sections.

Patient positioning and additional loads can

compromise table stability. The perineal

extension may be used to further offset the

patient, however,always ensure loading does

not compromise stability.

To comply with IEC601-1:1988 some access-

ories have been designed for a maximum

evenly distributed load. For the divided-leg

section this is 15kg per leg section (also see

PublicationT-IM49 issue ‘b’or later) and 10kg

for the detachable ophthalmic head-flap.

SYMBOLS & SAFETY CLASSIFICATIONS

Caution Refer to the accompanying documents,

the “Instructions for Use”.

or IPX 4 indicates that the equipment will withstand

a moderate quantity of fluid spilled from above.

Safety category

Indicates that the equipment is in safety category

BF,i.e.itismanufacturedtoasafetystandardwhich

agrees with international regulations for medical

electrical equipment,andprovidesahigh degreeofprotection

against electric shock. The symbol also indicates that the

equipment will not be damaged by defibrillator discharge.

Indicatesthat theequipmentisinsafetycategoryB, i.e.it

is manufactured to a safety standard which agrees with

international regulationsfor medical electrical equipment,and

providesaminimumdegreeofprotectionagainstelectricshock.

Class 2 Indicates that the built-in battery charger is

designed to electrical protection Class 2.

Anaesthetic proof

Indicates that the parts of the equipment marked

AParedesigned forusewithin adistanceof 5-25cm

of a part of an enclosed medical gas system. BS5724

Part 1, 1989 refers.

IndicatesthatthepartsoftheequipmentmarkedAPG

are designed for use within a distance of 5cm of a

partofanenclosedmedicalgassystem.BS5724Part1,1989

refers.

WARNING

The head section of this operation table is

classified as‘EQUIPMENT not suitable for use in

the presence of a flammable anaesthetic mixture

with air or with Oxygen or Nitrous Oxide’ and is

NOT classified as ‘Category AP Equipment’ or

‘Category APG Equipment’ when it (the head

section) is in its lowest position and the table top

is in fullTrendelenburg position.

Inspection

The table must be inspected at regular intervals, and if

necessary, serviced, to ensure that it complies with all AP

and APG requirements relevant to physical deterioration

or breakage of electrical components, connections and

cableinsulation.

T-SM14g 5/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

Antistatic requirements

The table has an antistatic pathway from the table-top,

through an internal resistor, to the castors, which are held

in contact with the floor at all times.

CAUTION

1. To complete the antistatic pathway, the

table must be used on an electrically

conductive, or on an antistatic floor.

2. Alwaysusepurpose-designedEschmann

mattresses to maintain the antistatic pathway.

Electrical data

System power

Batteries:

Type........................................Two sealed lead-acid

Output (each) ......................................... 12V 24Ah

Built-in battery charger:

Input ...................... 100-120 / 200-240Vac 50/60Hz

Output ..............................27.6Vdc (nom) 3A (max)

System fuses:

Motor.......................................30A 1.5in. (AGU 30)

Base Control Board: (1)........F6.3A 250V 20mm

(1)........T2.5A 250V 20mm

(1)...........T2A 250V 20mm

CAUTION

This equipment contains environmentally

hazardous lead-acid batteries. If the batteries

fail, or if the equipment is to be disposed of,it

is recommended that the batteries are taken

to a disposal site designated for the disposal

of lead-acid batteries, or that the batteries are

collected by an agent who specialises in the

collection of lead-acid batteries.

Hydraulic oil

Type.....................Eschmann RX (Part No.699408)

3. SAFETY NOTES

Attention to the following points will prolong the life and efficiency of the RX600 Powered

OperationTable and will help to avoid the risk of accidents, or damage.

DO:

?Keep the Instruction for Use close-to-hand.

?Read the instructions carefully before using table.

?Checkthattheheadandleg sectionsaresecure, and

put the table base in the braked position before use.

?Disconnect the built-in battery charger from the

power supply before washing the table.

?Read and follow the instructions for cleaning, and

for the care of the mattresses.

?Use the correct mattresses and accessories.

?Remove table accessories and their clamps (in

particular rotary clamps) from sidebars, when they

are not being used.

?Ensure that the table and accessories are serviced

at regular intervals (every 6 months is the

recommended frequency) by Eschmann personnel

only, or accredited agents.

?Store the table as detailed in this manual.

DO NOT:

?Lift the table by its table-top.

?Push the table over rough surfaces, use a trolley.

?Drop the table (or individual sections).

?Put heavy weights on the table sections.

?Put sharp objects on, or against, mattresses, pads,

or the radiographic table-tops.

?Dropheavyobjects ontotheradiographictable-tops.

?Spill oil, ether, or other fluids onto the mattresses

or the pads.

?Pull the table by any of the table-top sections,

always push it.

?Hold or support the leg section by its black

radiographic top, as this is a removable item and

might come off.

Note: The table cannot be used (under normal

circumstances) with table base stand-by door open.

WARNING

The RX600 Powered Operation Table has been designed to minimise the possibility of accidental

electrosurgery burns. Contact with any metal surfaces (e.g. table side bars, or other equipment

etc.) can cause burns during electrosurgery and must be avoided.

With the table in (or during transition into) the castor position, the centre of gravity of the patient

(normally the perineum) should lie no more than 200mm away from the centre of the column (i.e.no

more than the length of the short trunk section). Whenever this is not practical the overhanging

weight of the patient and table should be adequately supported (e.g. by at least two able people).

Also see Warnings in the Instruction for Use and within the text of this publication.

2. TECHNICAL DATA

6/44 T-SM14g

4. INTRODUCTION

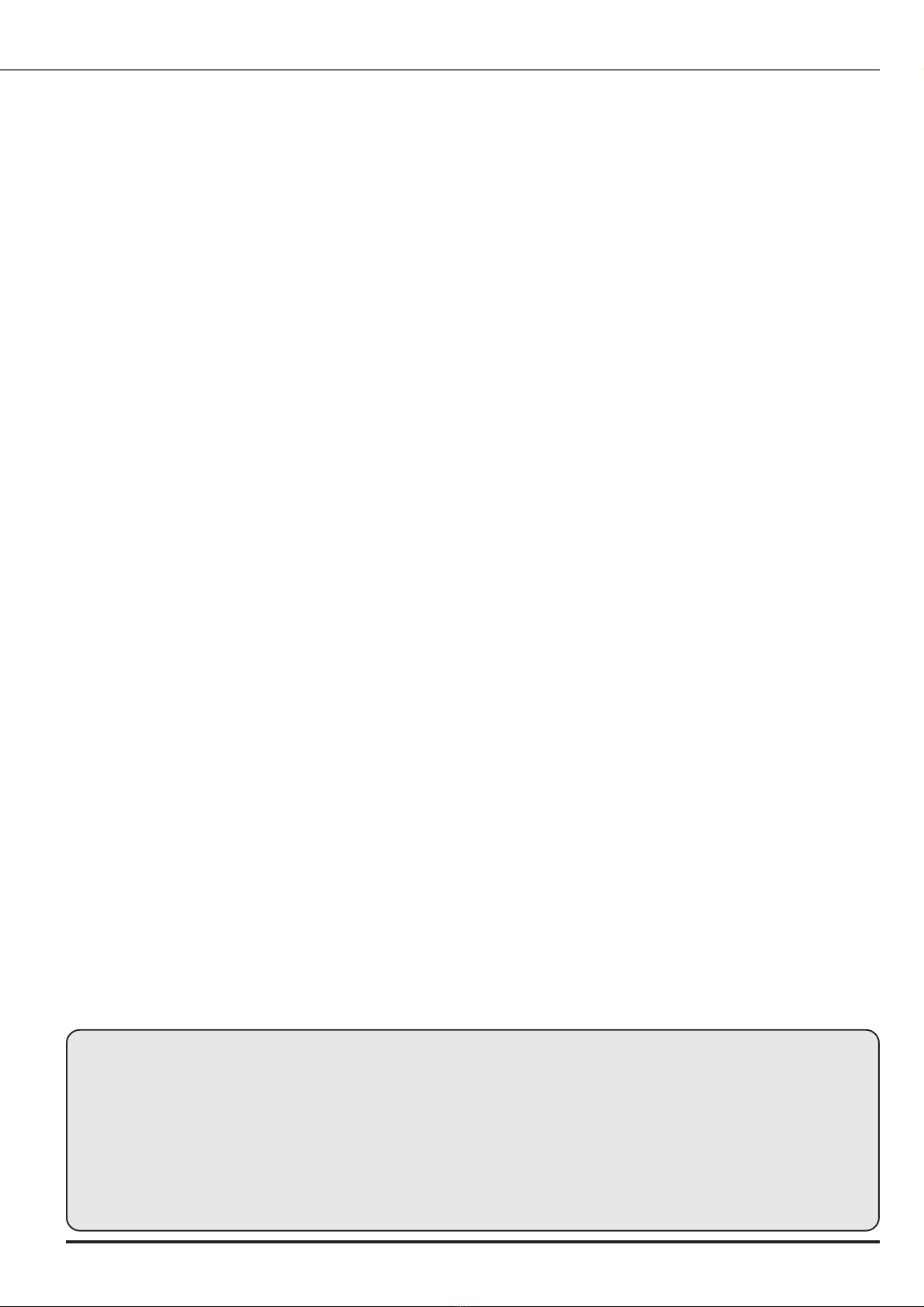

Fig. 1 RX600 Powered OperationTable

1. Headsection

2. Long trunk section

3. Short trunk section

4. Perineal post

5. Hip section

6. Sacral extension

7. Pre-traction leg section

8. Traction beam swivel joints

9. Column cover

10. Table base covers

11. Traction beams

12. Hand control

15 Hand control/Footcontroller socket

16 Hand control/Footcontroller socket

17 Hand control plug

18 Table ‘on/off’ switch ( =on, =off)

19 Standby hydraulic power-pack pushbuttons

20 Standby hydraulic power-pack connectors

21 External battery charger socket

22 High current 30A Fuse

23 Door microswitch

24 External power-pack connector

25 Standby door

26 Internal battery charger socket

27 Internal battery charger 'on' indicator

28 Internal battery charger door

29 Removable mains lead

30 Cover retaining screws

31 Top of column covers

View on base long trunk end View on base short trunk end

View on ‘A’

T-SM14g 7/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

GENERAL

4.1 This Service Manual contains a technical

description and maintenance procedures for the RX600

Powered Operation Table as shown in Fig.1.

4.2 The table is a battery powered, mobile,

orthopaedic,andtrauma tablewith twointegralarticulated

telescopic traction beams, which stow under the table-top

whennotin use. Thebeams are extended foruse,and are

used in conjunction with traction accessories. The table-

topcomprisespre-tractionlegsupports,and head,hip,long

and short trunk sections.

4.3 The table can be used as a general purpose five-

section Operation Table, by fitting optional infill sections,

and an optional leg section, in place of the pre-traction leg

supports.The tabledesignallowsafull rangeoforthopaedic

andtraumasurgicalprocedurestobe carried out,including

pin and plate femur and tibia nailing, and arm traction.

4.4 The table is operated by electrical/electronic

circuits, which control the position of hydraulic cylinders

(viaelectro-hydraulicvalves) inresponseto signals froma

touch-button hand control, or from an optional footswitch.

The hand control and the footswitch both plug into

connectors at the top of the table column.

4.5 Power is provided by two 12V sealed lead-acid

batteries inthe tablebase.The 12Vbatteriesare connected

in series to give an output voltage of 24V.Trickle charging

for the batteries is provided by an inbuilt battery charger,

provisionis alsomade for connectionofanexternal battery

chargerforquick battery charging.Connectionof theinbuilt

battery charger to the mains electrical supply is via a

removable cable which plugs into the table base.

4.6 All table top trunk movements are electrically

controlled using either the hand control or, as an optional

accessory, the footswitch which is used by the surgeon

during certain procedures for height and Trendelenburg

control.

4.7 The main operation table sections are:

?Base.

?Central column.

?Head section.

?Long and Short trunk sections.

?Hip section.

?Sacral extension.

?Pre traction leg section.

?Traction accessories.

NOTE: Instruction and Service manuals should he readily

accessible for reference prior to, and when operating,

cleaning and servicing the table.

ELECTRICAL SYSTEM

NOTE: Electrical/electronic circuit diagrams are provided

at the end of this Manual in section 6.

Main control board

4.8 The main control board receives signals from the

hand control via an RS485 serial communication link.The

boardalso receivessignals fromthe footswitch,table-base

coverswitches,levellingmicroswitches,level tiltswitch,opto

board,standbyunitsocket,doorswitch,tractionbeam opto

sensors and table base on/off controls.

4.9 Outputs from the main control board pass to the

hand control via an RS485 serial communication link, to

thehydraulic solenoidsviathetop-of-columndistributorand

solenoidboards,and tothe basedistributorboardand FET-

Relay board for motor on/off control and motor direction

control. The main control board is supplied with 24V d.c.

from the batteries and generates its own 12V d.c.and 5V

d.c.supplies.

4.10 The principal functional areas of the main control

board are:

?Input buffering (pull-up and pull-down resistors and

capacitors).

?The microcontroller, which uses software to

implement table control functions.

?Output buffering (current drivers and level shifters).

?Motor direction drive and on/off control.

Height opto board

4.11 The height opto board is fitted at the base of the

column in a fixed position relative to the baseplate. It

responds to a metal reflector plate which moves up and

down with the column chassis and hence with the table

top.When thereflector movesinfront of thethree reflective

opto sensors (only two are used) electrical signals are

generatedto signal tothe main controlboardthat the table

is at or above‘minimum height’, or in the‘castor’position.

4.12 Whenthe reflectorplate isinfrontofreflectiveopto

coupler 01 and at the correct distance from it, a signal is

produced which passes via J1 on the opto board and the

10-way ribbon cable to J22 on the main control board.

4.13 Whenthe reflectorplate isinfrontofboth reflective

optocouplers 01and03 signalsfrom bothpass tothemain

controlboardwhichstopsthe tablemovement atthecorrect

position.

4. INTRODUCTION

8/44 T-SM14g

Base distribution board

4.14 This board receives signals from the main control

boardfortheheight(extend)solenoid,theheight (contract)

solenoid, the pump-isolate (forward) solenoid and the

pump-isolate (reverse) solenoid.

4.15 The board also passes signals to the main control

board from the cover microswitches.

4.16 Any inductive overswings from the solenoids are

blocked by diodes Dl to D4. PL7 on the base distribution

board is connected via a 14-way ribbon cable to J4 on the

main control board.

Top-of-column distribution board

4.17 This board connects to J2 on the main control

board via a 34-way retractable ribbon cable which

terminates on PL1

of this board. It distributes signals to

10-way hand control/footswitch sockets PL2 and PL3, and

to:

?the level tilt switch via PL7

?theTrend level position microswitch via PL5

?the lateral tilt opto board via PL4

?the break level position microswitch via PL6

?top-of-column solenoids board via PL8

?the on/off switch via PL9

?proximity sensors on long trunk via J10/11/12.

Top-of-column solenoids board

4.18 This board receives signals on J7 via a 10-way

ribboncablefromJ8 onthe top-of-columndistributorboard

to drive the top-of-column solenoids via cage clamp

connectors J1 to J6. It also blocks inductive overswings

from solenoids using diodes D1 to D6.

Tilt opto board

4.19 Thetiltopto board is fittedat the top ofthecolumn

ina fixed positionrelativeto theyoke.It respondsto ametal

plate which moves with the yoke and hence with the table

top.When the reflector moves in front of the opto sensors

electrical signals are generated to signal the main control

board that the table is level.

4.20 When the reflector plate moves in front of the

optosensor,alogicsignal0isproducedwhichpasses

via J1 on the opto board to the top of column

distributionboard and thenvia a10-way ribboncable

to J2-4 on the main control board.

4.21 When the reflector plate is not in front of the

opto sensor, a logic signal 1 is produced which is

passed to the main control board as above.

4. INTRODUCTION

Power circuits

4.22 The power source for the table is two 12V, 24Ah

sealed lead acid batteries connected in series. A 30A in-

line, high current fuse protects the batteries, motor, FET

relay board and interconnections.

4.23 Currentfrom thebatteries passesvia thereversing

relay, where itisswitched bythe FET’s,and thenpasses to

the pump motor and returns to the batteries.The 24V d.c.

supply is also routed to the hydraulic solenoids and the

main control board.

Hand control

4.24 The RX600 hand control communicates with the

maincontrol boardviaanRS485serialcommunicationlink.

Thehand controlcontainsamicrocontrollerwhich receives

inputsfrom thehand controlbuttonsandgeneratesoutputs

which go to the hand control LED’s and the hand control

audiblewarning device.The microcontrolleruses software

to implement hand control, control functions.

4.25 Thehand-control incorporatesa 2-digitdisplaythat

indicatesacode if aproblemshould occur.Such problems

couldbe theresult ofthe userpushingabuttonin thewrong

sequence or at the wrong time or of a system failure (see

Table1- FaultDiagnosis,Table2 -Codesfor2-Digitdisplay

and Fig. 31)

Footswitch (optional accessory)

4.26 The footswitch plugs into either of the two 10-way

sockets used by the hand control. It uses the same +5V

d.c.and0V pins,butthesignallinesaredifferent fromthose

of the hand control. The footswitch does not use a serial

communication link.

4.27 There are four functions on the footswitch:

?Height up.

?Height down.

?Trendelenburg.

?ReverseTrendelenburg.

4.28 Eachof thesefourfunctionsis associatedwithtwo

microswitches mounted inside the body of the footswitch,

one normally open and the other normally closed. The

normally open microswitch for each function is connected

on one side to the +5V d.c. line and on the other side to a

common ‘alarm’ line.The normally closed microswitch for

each function is connected on one side to the 0V line and

on the other side to an individual input line on the main

controlboard.If,foranyfunctionof thefootswitch,e.g.height

up, the normally open microswitch operates and the

normally closed microswitch does not, or vice versa, the

main control board will recognise a fault and freeze the

table.Thelikelihoodoftwo microswitches failingatthesame

time is very remote.

T-SM14g 9/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

4. INTRODUCTION

Table base ON/OFF control

4.29 The table is switched‘on’and ‘off’ by selecting

and respectively.Whenswitched‘on’,24Vd.c.isswitched

directly to the main control board.When it is switched ‘off’

themaincontrol board isisolated from the24Vd.c.supply.

To isolate the system the 30Amp fuse should be removed.

Built-in battery charger

4.30 Thisis ainternallowcurrentoutput‘trickle’charger,

which replenishes an average day’s table use of the

batteries with an overnight charge.

4.31 The mains input comes via the mains lead, which

shouldbe fittedwitha fusedplug.The outputof thecharger

is regulated to provide 27.6V d.c.to the batteries for float

charging. This voltage will fall when the batteries are not

completely charged and hence are drawing a significant

current. The charger has short-circuit and thermal

protection.Thereisanoutputfromthe boardwhichsupplies

current to the batteries, an output to the ‘trickle’ charger

indicator LED and an input from the external charger.

Current from either the internal or the external charger is

routed to the batteries via the ‘trickle’charger board.

External battery charger (optional accessory)

4.32 Theexternal batterychargerplugsintothe external

battery charger socket in the table base and supplies

current via the ‘trickle’ charger board to fast-charge the

batteries.

Standby system connections

4.33 An RX Standby Unit (optional accessory) which

provides standby hydraulic and electrical services, can be

connectedto theRX600 tablevia hydraulicconnectorsand

an electrical socket behind a door on the table base.

4.34 Next to the hydraulic connectors are two push-

buttons which release stored hydraulic pressure when the

standby hydraulic connections are first made.This is done

byenergizingthe pumpforwardandreversesolenoidswith

power from the standby unit.

4.35 To connect the standby unit to the table it is

necessary to open the base door. This operates a

microswitch which disconnects the main control board

solenoid control circuits from the solenoids so that they

canbecontrolled bythe standbyunit, alsothepump motor

is hydraulically isolated from the hydraulic solenoids.The

electrical signals from the standby socket pass to J1 on

the main control board (15-way D-connector).

Traction beam stowage detection

4.36 Proximitysensorsfittedintheunderside ofthe long

trunk section detect the traction beams when they are in

their stowed position. The sensors signal the table control

system to stop the table top being driven down onto the

stowed traction beams.

10/44 T-SM14g

5. DESCRIPTION

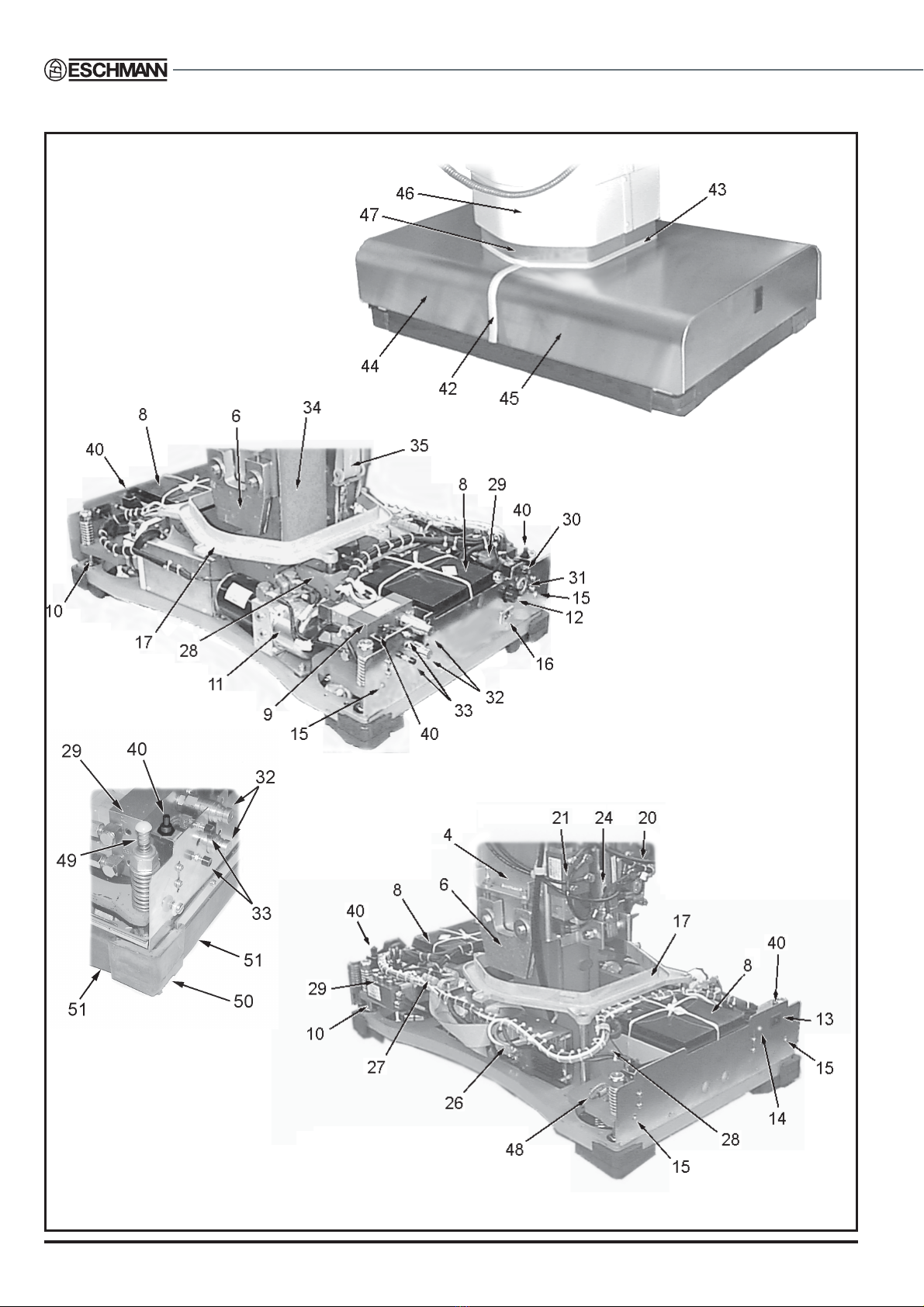

Fig. 2 RX600 Operation Table : Base details, covers on and off

For greater detail of

the table base ends also

refer to Fig. 4 and 5

T-SM14g 11/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

5. DESCRIPTION

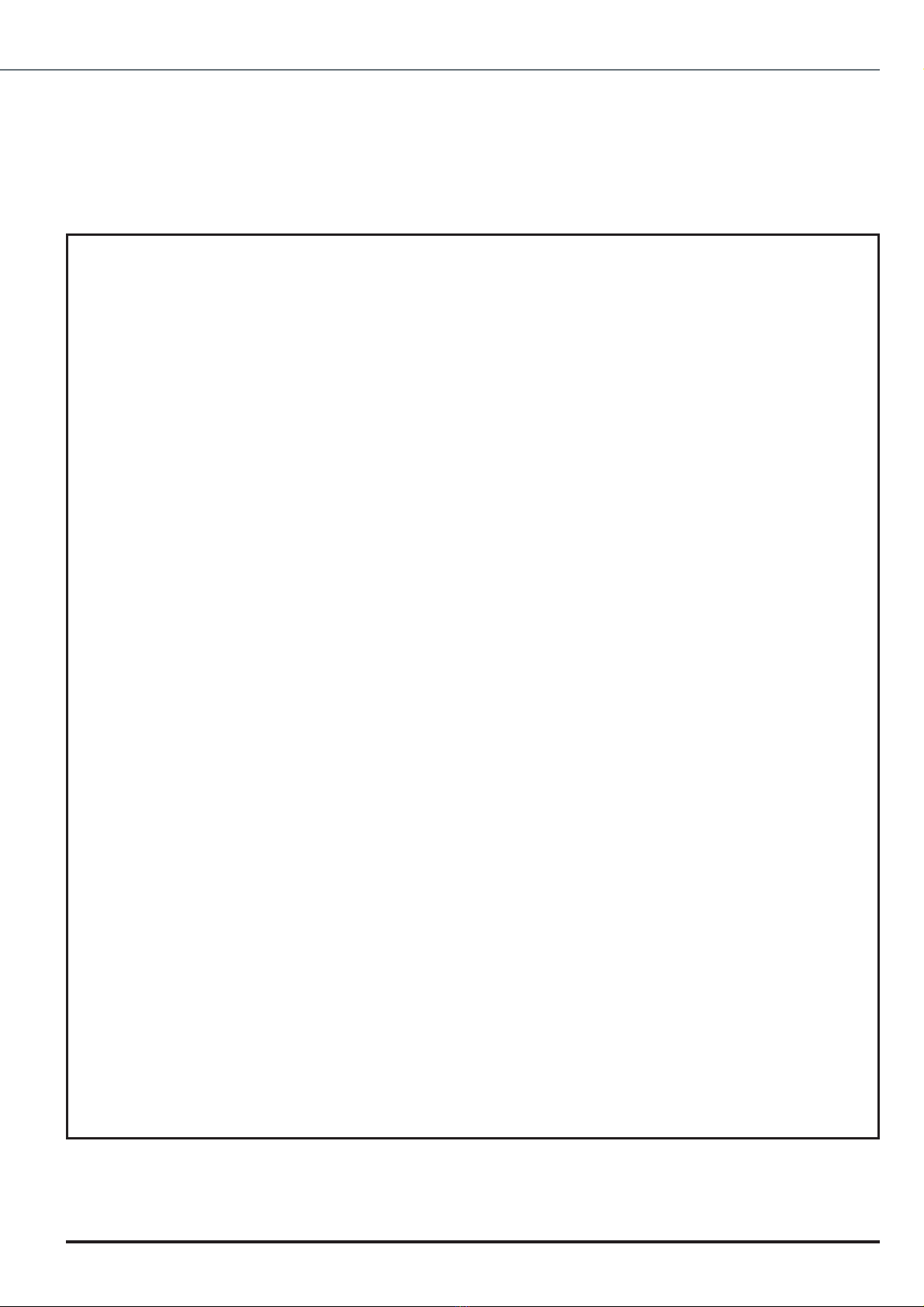

1. Longtrunk assembly

2. Short trunk assembly

3. Lateral tilt cylinder

4. Wraparound

5. Trunk assembly plastic covers

6. Wedge

7. Outercolumn

8. Battery

9. Manifold block No 1

10. Castor plateguidepillar

11. Hydraulic powerunit

12. High current fuse,30A

13. Mains socket

14. Battery chargingLED(green)

15. Cover retainingscrewlocation

16. External battery charger socket

17. Dripgutter

18. Opto reflectorplate

19. Inner column

20. Manifold block No 4

21. Manifold block No 3

22. Upperbezel

23. Hand controlandcable

24. Trendelenburgcylinder

25. Break cylinders

26. Main control PCB

27. Base distribution PCB

28. Castor frameassembly

29. Manifold block No 2

30. Door microswitch

31. Standby powerpackconnector

32. Standby hydraulicconnectors

33. Push buttons to engage standby

hydraulicconnectors

34. Hydraulicreservoir

35. Ribbon cablereelassembly

36. Top-of-columndistributionPCB

37. Hinge

38. Lateral tiltoptoboard

39. Yoke

40. Cover microswitch

41. Table‘on/off’switch

42 Base seal

43. Column seal

44. Short trunk base cover

45. Long trunkbasecover

46. Telescopic column cover

47. Columnupstand

48. Antistatic discharge path resistor

49. Base cover spring support

50. Base foot

51. Base skirt

52. Traction arm selector knob

53. Tractionhandle

54. Swivel joint, knuckle

55. Tractionarm

56. Hip section

57. Swivel joint locking knob

Key to Figs 2 and 3

12/44 T-SM14g

5. DESCRIPTION

Fig. 3 RX600 OperationTable : Column and trunk section detail

T-SM14g 13/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

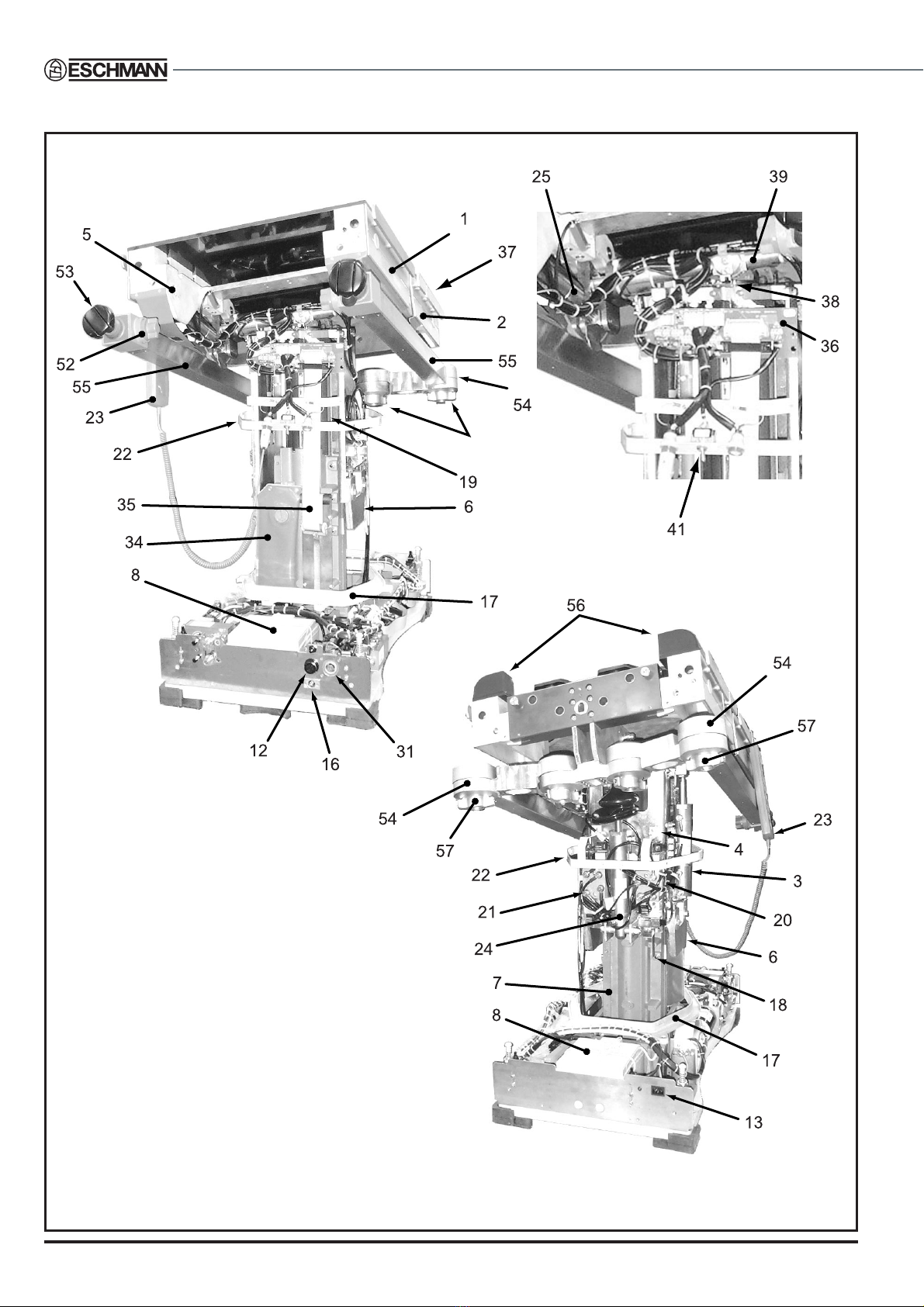

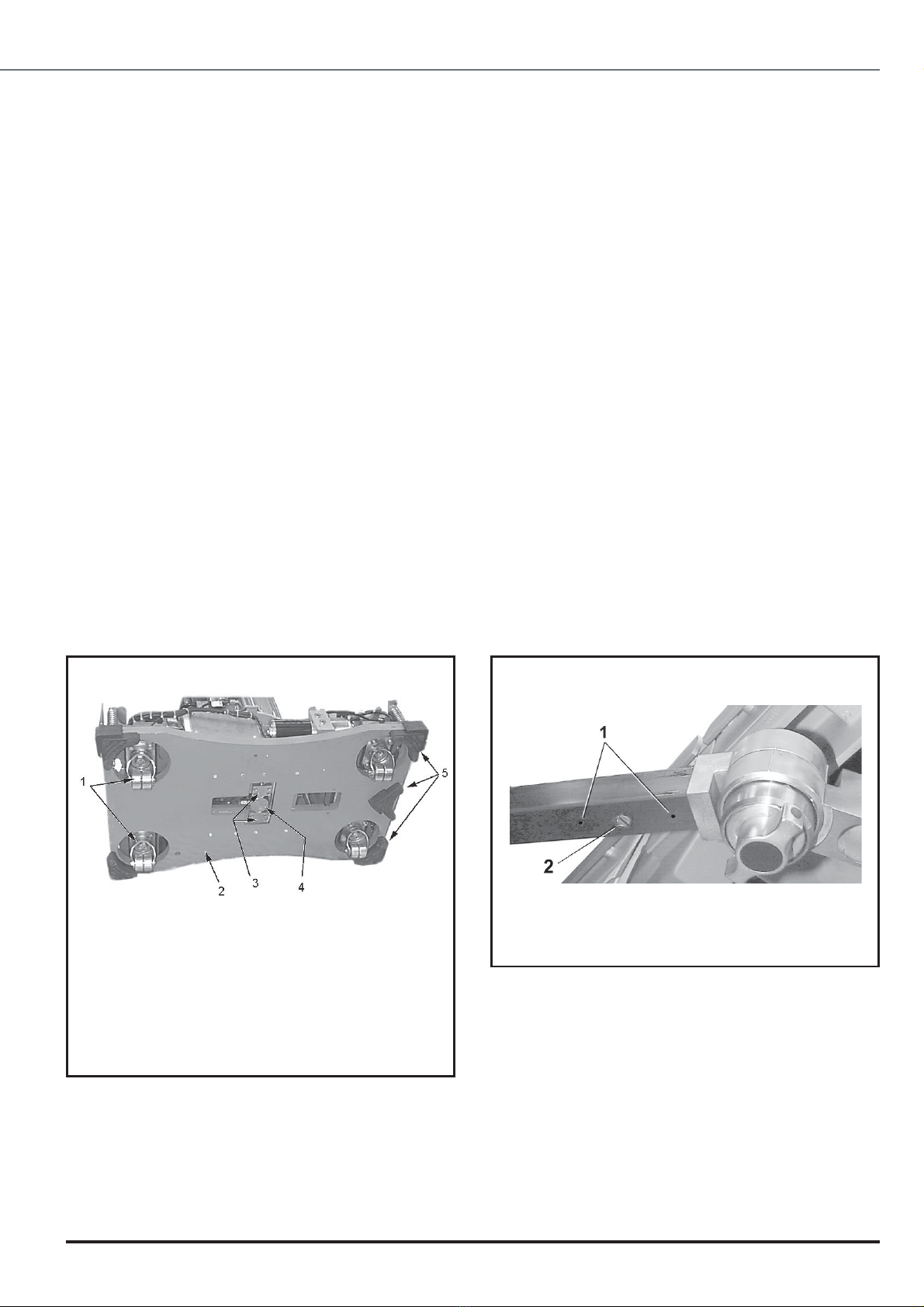

Fig. 5 RX600 OperationTable base detail (short trunk end)

1 Standby hydraulic push buttons

2 Base cover microswitch

3 Standby hydraulic connectors

4 High current (30A) fuse

5 Door Microswitch

6 Standby power pack connector

7 Base cover microswitch

8 External battery charger socket

9 Fixing for cover retaining screw

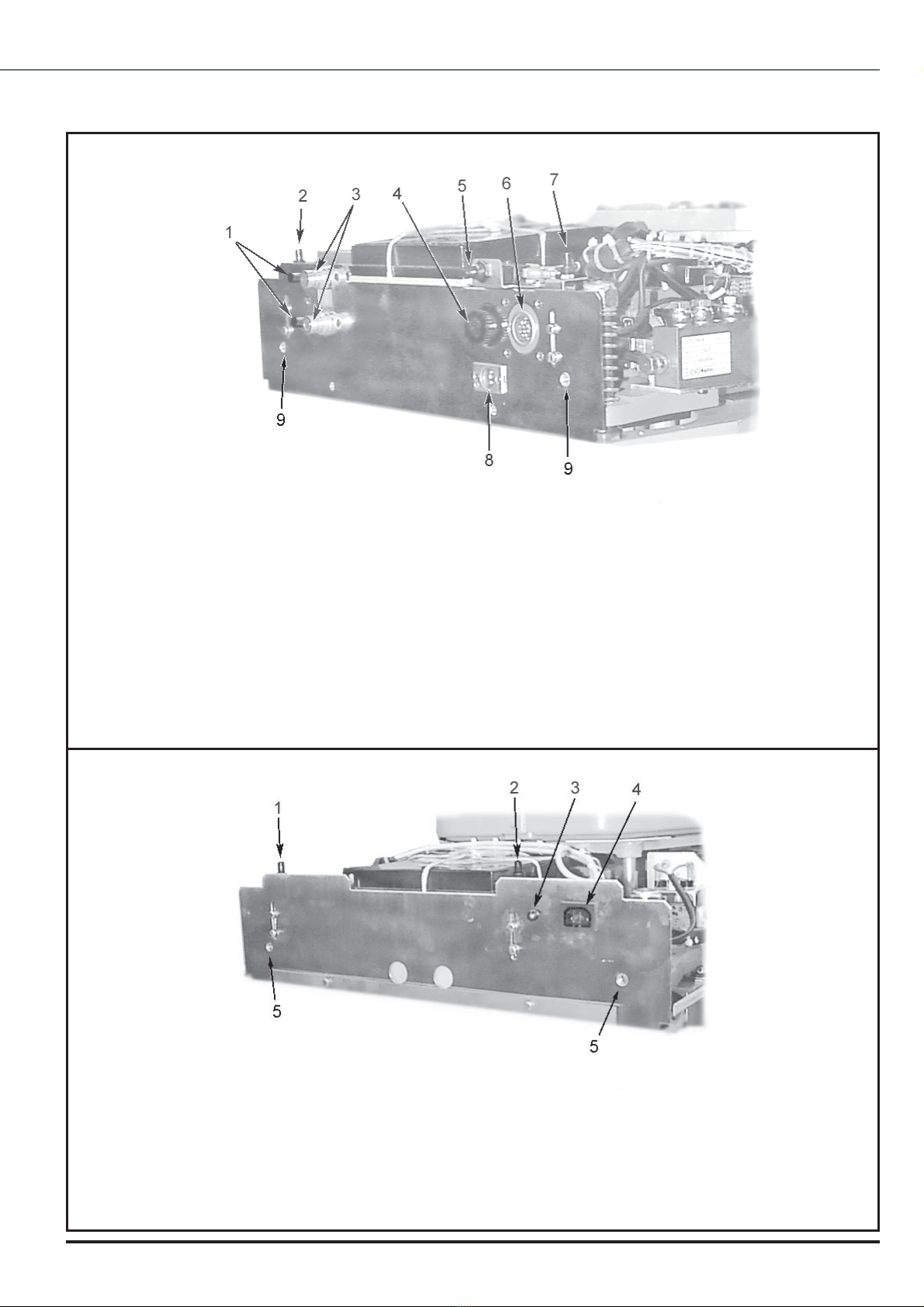

Fig. 4 RX600 OperationTable base detail (long trunk end)

1 Base cover microswitch

2 Base cover microswitch

3 Mains charging LED

4 Mains connection socket

5 Fixing for cover retaining screw

5. DESCRIPTION

14/44 T-SM14g

GENERAL

6.1 Maintenance of the RX600 Powered Operation

Table falls into the following categories:

Cleaning and storage. Adjustments.

General care and lubrication. Removaland Installation.

Functional checks. Fault diagnosis.

Hydraulic system.

CLEANING AND STORAGE

WARNING

Always switch off table at table ‘ON/OFF’

switch (item 18, Fig. 1) prior to cleaning.

6.2 For cleaning and storage instructions refer to

RX600 Powered Operation Table Instruction for Use

(Publication No.T-IM33 issue‘d’or later).

6.3 For cleaning and storage instructions of the table

accessories refer to the Accessory Instructions for Use

(PublicationNo.T-IM56).

Note: If the table is to be stored for any length of time the

head and leg sections should be fully lowered. This is

necessary to ensure that the gas spring seals and pistons

are kept fully lubricated.

GENERAL CARE AND LUBRICATION

6.4 Once a week proceed as follows:

Gas Springs

WARNING

The gas springs are filled with high pressure

gas. Do not attempt to open them.

CAUTION

Gas springs MUST NOT be

additionally lubricated.

6.5 The gas spring supports for the head section are

sealed units which require no routine maintenance.

Malfunction of a gas spring makes it impossible to lock the

headsection inposition.Seepage offluidindicates afailing

unit.

6.6 If a gas spring is faulty, the complete unit must be

renewed,gassprings arenon-repairableitems(seesection

6.44).

Head, hip, pre-traction leg support and

alternative leg sections, and sacral extension

6.7 Service thehead,hip,andpre-tractionlegsupport

sections, and sacral extension as follows:

i Apply a smear of light machine oil to the guide pins

and pivot pins on the head, hip, and pre-traction leg

sections, and the Sacral extension.

ii Examine all sections, and the sacral extension for

signs of damage, particularly for scoring or bending

of the attachment guide pins. On the head and

alternative leg section, examine the release handle

for signs of damage.

iii Check the guide pin retaining screw for tightness.

iv On the head and alternative leg section, check the

hingeand gasspringpivotsforsecurity (grubscrews

or starlock washers, whichever fitted), particularly

the main hinge pivot pin. (Note that the grub screw

for the main hinge pivot pin is underneath the

radiographictop.)

v Check the side bars for security.

vi Examinethe guidepinlockingbuttonon thehip,and

pre-traction leg support sections, and the release

latch on the Sacral extension for damage. Apply a

smear of light machine oil to all moving parts.

vii On the infill section, examine the guide pin locking

button devices for damage and ensure that the

mechanism, which prevents removal of the infill

section before any attached section has been

removed, functions correctly (refer to section 6.49).

Applyasmearoflight machineoil toallmoving parts.

Fig. 6 Table tilted for access to underside

Head and hip sections, locking mechanisms

6.8 Remove the head, hip and sacral extension

sections from the table and clean out any collected fluff or

otherdebris fromguidepin sockets in theends of thetrunk

sections, in the sacral extension attachment and location

holesinthe crossbeam.Spraya little aerosollubricant into

each socket and attachment hole. Check the operation of

the locking mechanisms when re-attaching the sections

(for adjustment refer to section 6.50).

Long and short trunk sections

6.9 Service the long, and short trunk sections as

follows:

i Apply a smear of light machine oil to the pivot pins

on the long and short trunk sections.

ii Examine the guide pin button locking devices for

damage(foradjustmentrefer to section6.50).Apply

a smear of light machine oil to all moving parts.

6. MAINTENANCE

T-SM14g 15/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

Radiographic tops

6.10 Examine the radiographic tops for cracks, chips

and scoring. Significant damage will necessitate

replacement of the damaged section. Make sure that the

radiographic tops are securely attached (not applicable to

the optional leg section).

Underside of the table base

6.11 To maintain the underside of the table base, it is

necessary to tilt the table onto its side as follows:

i Ifnecessary, removehead, andpre-traction legand

support sections or the leg and infill section

accessories.

ii Usingthehandcontrol,raisethetabletoitsmaximum

height and make sure that the long and short trunk

sections are level.

iii Using the hand control, set the table top to the

maximum lateral tilt position corresponding to the

directioninwhich the tableistobe tilted (seeFig.6).

iv Place an anaesthetist’s stool, or a similar strong

support,along onesideof thetable(seeFig.6).With

two people standing on the same side of the table

as the support (one at each end), tilt the table over

and gently lower it onto the support, making sure

that it rests on the side bars of the long and short

trunk sections.

1 Castor assembly

2 Table base plate

3 Height cylinder pivot clamp blocks

4 Height cylinder

5 Base feet

Fig. 7 Underside of table base

6.12 With the table in the tilted position, proceed as

follows (see Fig.7):

i Examinethefive basefeet for damage orexcessive

wear.Ifnecessary, replacethe appropriatebase feet

as described in sections 6.47 and 6.48.

ii Clean each castor assembly making sure that they

are free of dust and debris. Lubricate the bearings

of each castor and the directional wheel with a light

machine oil.

iii On completion, return the table to the upright

position.

Traction beam attachment

6.13 Routine maintenance of the beam attachment

consistsofchecking for secure attachmentof the beam as

follows:

i Remove the two locking socket set screws (items 1,

Fig.8) from the underside of the beam.

ii Two socket dog point set screws under the two

locking socket set screws removed in (i) above can

now be checked and tightened.

iii Replace and tighten the two locking socket set

screws removed in (i) above.

iv Check and tighten the slotted countersunk screw

(item 2, Fig. 8).

Fig. 8 Adjustment of beam attachment

6. MAINTENANCE

16/44 T-SM14g

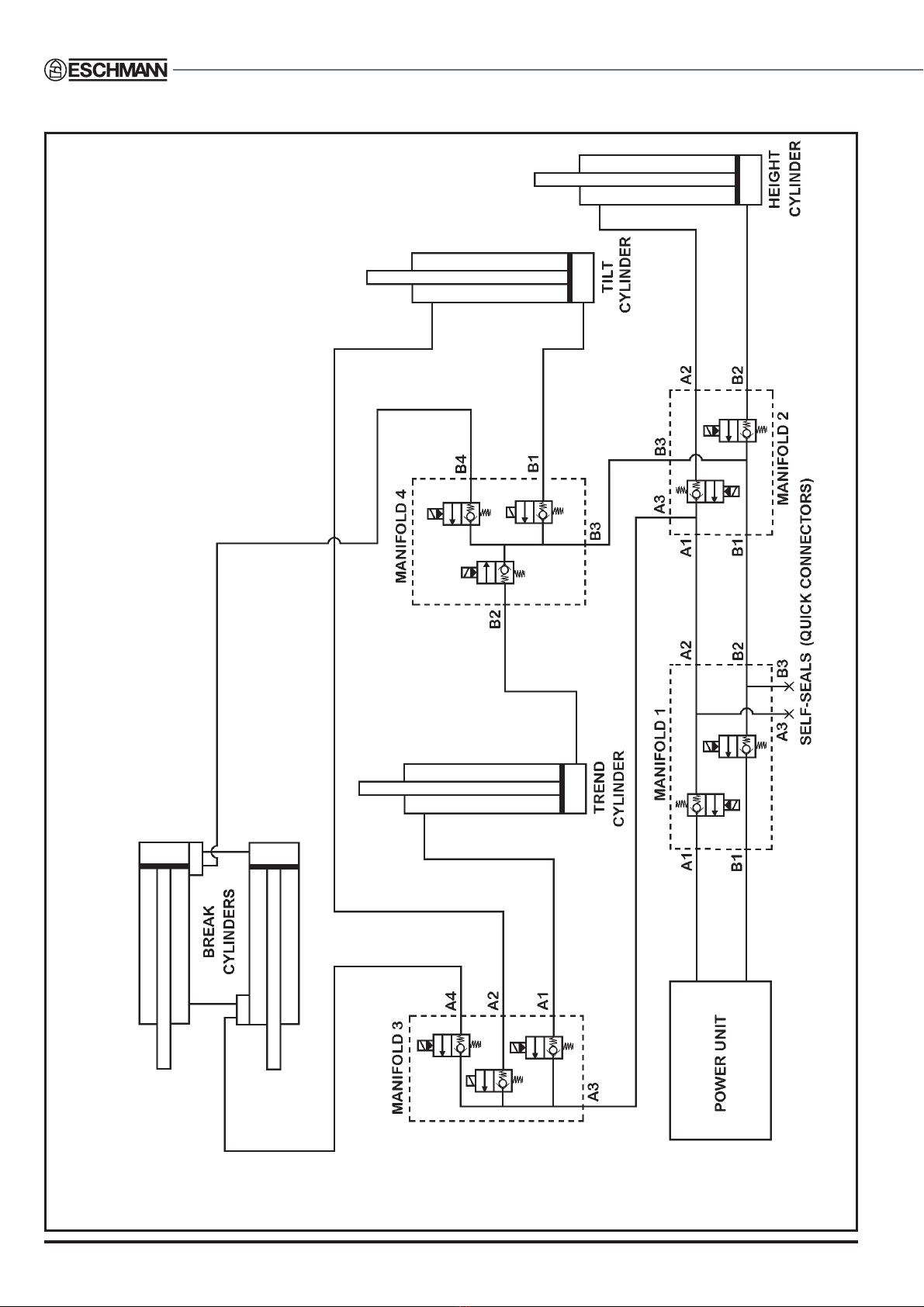

Fig. 9 Hydraulic system - Schematic diagram

T-SM14g 17/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

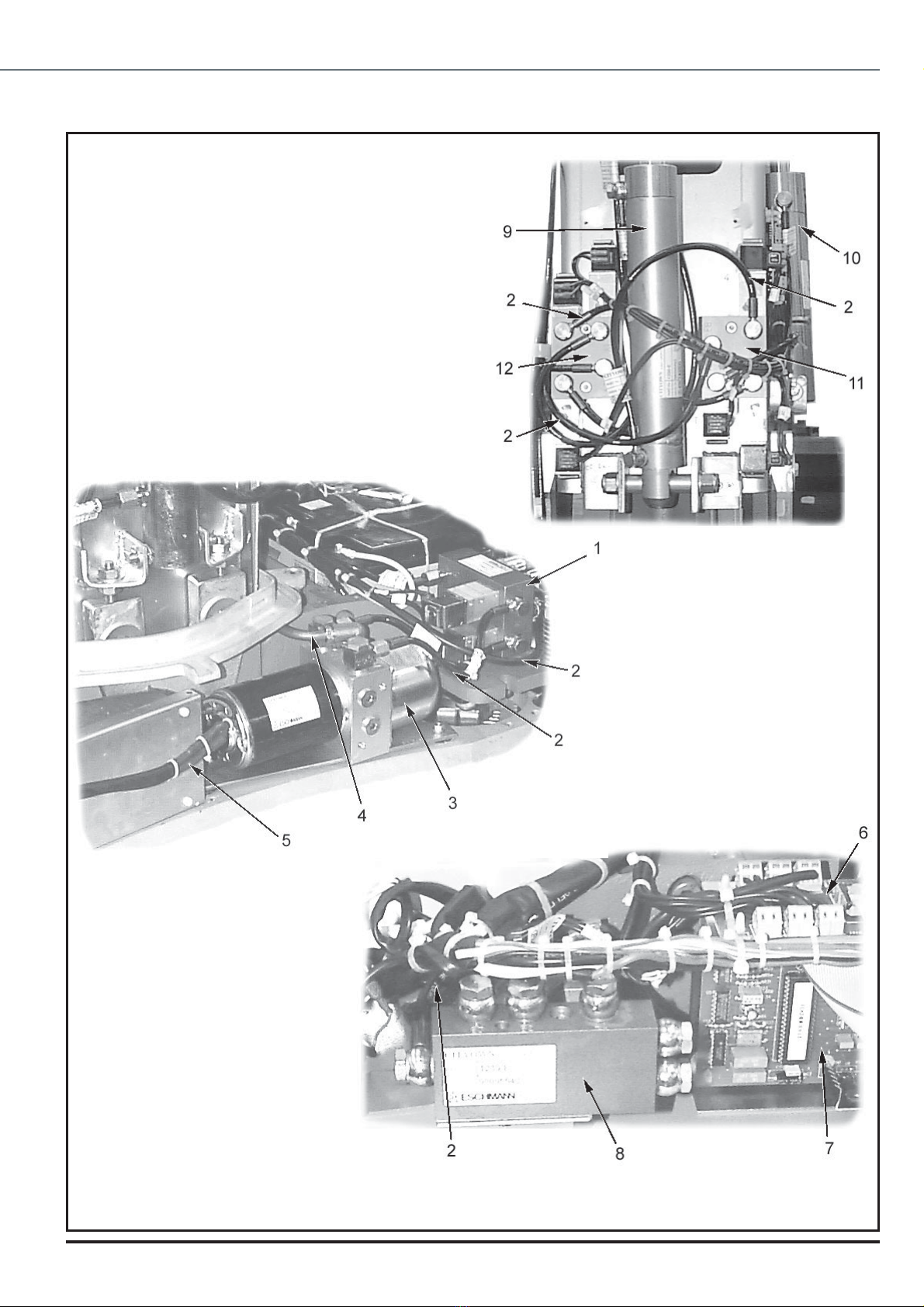

6. MAINTENANCE

1 Manifold1

2 Hydraulic connections

3 Power unit

4 Feed from reservoir

5 Power unit electrical lead

6 Base distribution board

7 Base control board

8 Manifold 2

9 Trendelenburgcylinder

10 Tilt cylinder

11 Manifold 4

12 Manifold 3

Fig. 10 Hydraulic system - main components

For break cylinders see Fig.18

and for height cylinder see Fig.22.

The lateral tilt cylinder is also

shown in greater detail in Fig.19.

Note: Hydraulic cylinder rams are

retractedwhenthe tabletopispositioned

as follows, but care must be taken when

movingthetableintothispositiontoavoid

damage, sections will be very close to

the floor :

Minimum height and onto castors.

Maximum extension achievable at the

minimum height set above.

Maximumtilt achievablewith tableatthe

minimumheightand extension setabove

(tilt table such that the right hand side is

lowered when viewed from short trunk

endoftable).

18/44 T-SM14g

Access to fuses

6.14 The high current 30A mains fuse is fitted in the

table base standby panel (item 4, Fig. 4).The three other

fuses for the operation table are fitted on the main PCB

(item 3, Fig.11) in the base of the table. To get to them

remove the base covers as described in section 6.26.The

installationofthe base coversis described insection6.27.

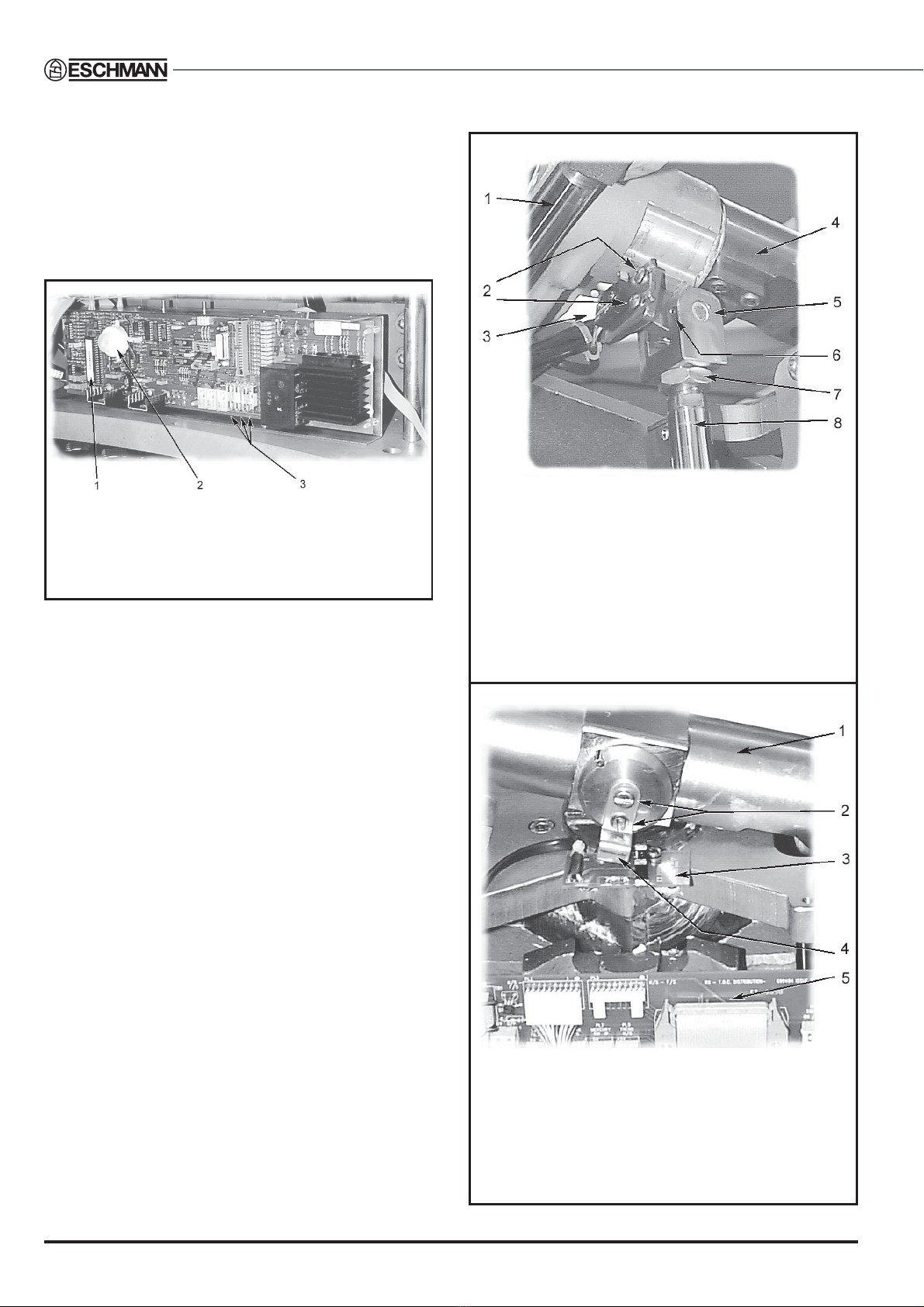

1 Programmed microcontroller

2 Beeper

3 Fuses

Fig. 11 Main control board

Hand control

6.15 The factory sealed hand control requires no

maintenance.If a faultissuspectedin thehandcontrol first

test all table functions using a hand control known to be

fault free. If a fault is confirmed with the hand control the

complete assembly (including lead and plug) should be

replaced (see Fig.31 for details of hand control function).

After maintenance

6.16 After maintenance on the operation table, always

check all functions (section 6.17) and lower the table fully.

FUNCTIONAL CHECKS

General

6.17 The following functional checks should be carried

out after maintenance of the operation table, or after

rectification of any faults:

i Refer to ManualT-IM33 issue‘d’or later, and check

the state of batteries using the hand control, codes

01 and 02 should not be displayed. If they are the

table batteries need recharging.

ii Using the hand control, check that all table

movements agree with theTechnical Data.

iii Using the foot control unit (optional accessory),

check that the table movements are correct for

Trendelenburg,ReverseTrendelenburg, and Height.

iv Usehandcontroltocheckoperationofthe‘auto level’

function.

6. MAINTENANCE

1 Breakcylinder

2 Microswitch adjusting screws

3 Trendelenburgmicroswitch

4Yoke

5 Pivot pin

6 Pivot pin set screw

7 Tilt cylinder ram lock nut

8 Tilt cylinder ram

Fig. 12 Trendelenburg microswitch

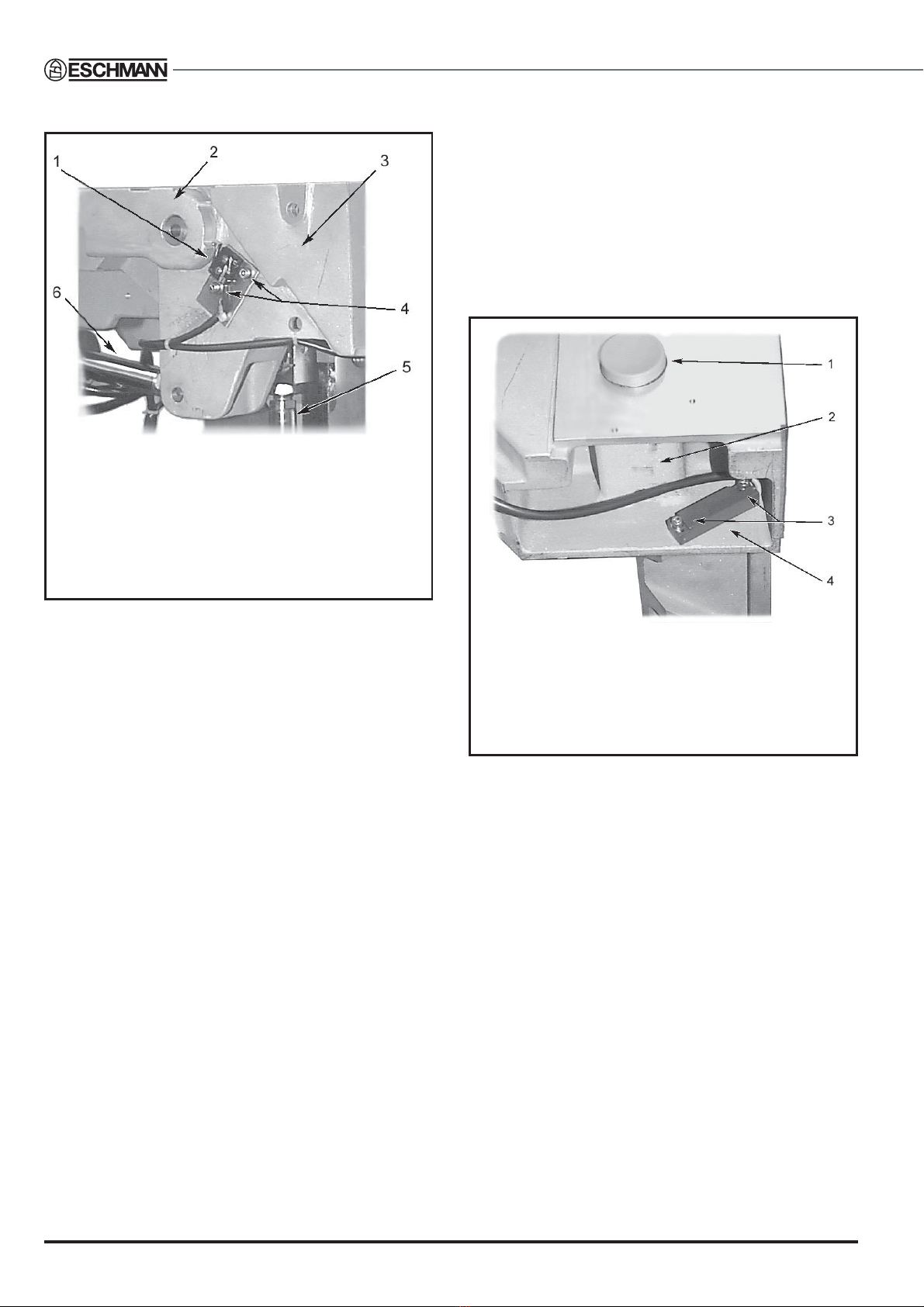

1Yoke

2 Adjusting screws

3 Lateral tilt opto board

4 Lateral tilt opto flag

5 Top of column distribution board

Fig. 13 Lateral tilt opto detail

T-SM14g 19/44

RX600RX600

RX600RX600

RX600

OPERATION TABLE

HYDRAULIC SYSTEM

CAUTION

Scrupulous cleanliness is essential to prevent

contamination of the fluid in the hydraulic

system.

Notes:

1 Use only Eschmann RX hydraulic oil, Part

No.699408, which is obtainable from Eschmann

Equipment or their accredited agents.Replace cap

on oil container after use.

2 When replacing hydraulic components all Banjo

fittingsmustbe tightenedto atorquesettingbetween

19 and 21 Nm.

3 The hydraulic system schematic diagram is shown

inFig.9 withthemain components illustratedin Fig.

10. Individual cylinders are also shown in the

‘RemovalandInstallation’section laterinthemanual.

General

6.18 Ifthetablecannotbeplacedintothe castorposition

using the hand control, it may be necessary to manually

raise the table base. To raise the table base, proceed as

follows:

i Remove table base covers, see section 6.26

ii Locate the jacking nut at each corner of the table

base (see Fig.26, item 1) and wind the nuts down

evenly to raise the table base.

Topping-up the hydraulic reservoir

6.19 Top-up the hydraulic reservoir as follows:

i Set table to an appropriate height and remove base

covers as described in section 6.26.

ii Release the central column cover and remove the

upstand as described in section 6.30.

iii Retract all cylinder rams before filling reservoir so

thatthe trueoillevel canbeestablished(seeNote in

Fig.10).Overfilling could damage the reservoir.

iv Remove the filler cap from the hydraulic reservoir

andfill the reservoirwith EschmannRX hydraulicoil

until oil level is 13 mm below the filler hole of the

reservoir.

v Refit the filler cap on reservoir.

vi Refit the central column cover and upstand as

described in section 6.31.

vii Refit the base covers as described in section 6.27.

ADJUSTMENTS

Trendelenburg (Trend) microswitch

6.20 Tocheckandadjust theTrendelenburgmicroswitch

(item 3, Fig.12) proceed as follows:

i Ensure the table is on a level surface.

ii Using the hand control, move the table top to the

maximumTrendelenburgposition.

iii Onthe handcontrol,pressthe‘autolevel’buttonand

wait until the table top stops when level.

iv Using an inclinometer (on section radiopaque top

notthemattress), checktheangle of theshorttrunk

section in the horizontal plane.

v If the angle is more than one degree out in either

direction adjust the Trendelenburg microswitch as

necessary, by releasing the adjusting screws

(item 2, Fig.12) and moving the microswitch in the

appropriatedirection,retightentheadjustingscrews.

vi Repeat steps‘ii-v’until the short trunk section stops

level.

Lateral tilt opto

6.21 Tocheck andadjustthelateraltiltoptoflag(item 4,

Fig.13) proceed as follows:

i Ensure the table is on a level surface.

ii Using the hand control, tilt the table top to the

maximum lateral tilt position (left or right).

iii Onthe handcontrol,pressthe‘autolevel’buttonand

wait until the table top stops when level.

iv Using an inclinometer (on section radiopaque top

notthemattress), checktheangle of thetable top in

the lateral plane.

v If the angle is more than one degree out in either

directionadjust theflag (item4,Fig.13)for thelateral

tilt opto by releasing the adjusting screws (item 2,

Fig.13) and moving the flag in the appropriate

direction, retighten adjusting screws.

vi Repeat steps‘ii-v’until the table stops level.

Break microswitch

6.22 Tocheck andadjust thebreak microswitch (item 1,

Fig.14) proceed as follows:

i Ensure the table is on a level floor.

ii On the hand control, press the break (extension)

buttonandmovethetabletop tothe maximumbreak

(extension)position.

iii Onthe handcontrol,pressthe‘autolevel’buttonand

wait until the table top stops when level.

6. MAINTENANCE

20/44 T-SM14g

1 Breakmicroswitch

2 Long trunk assembly

3 Short trunk assembly

4 Adjusting screws

5 Tilt cylinder ram

6 Break cylinder ram

Fig. 14 Break microswitch

iv Using an inclinometer (on section radiopaque top

notthemattress), checkthat the short trunksection

is level, if it is not adjust the Trendelenburg

microswitch as detailed in section 6.20.

v Using an inclinometer (on section radiopaque top

not the mattress), check the angle of the long trunk

section.

vi If the angle is more than one degree out in either

direction adjust the break microswitch by releasing

the adjusting screws (items 4, Fig.14) and moving

themicroswitchintheappropriatedirection, retighten

the adjusting screws.

vii Repeat steps‘ii-vi’until the long trunk section stops

level.

Level tilt switch

6.23 To adjust the level tilt switch (item 4, Fig.15)

proceed as follows:

i Ensure the table is on a level floor.

ii Onthe handcontrol,pressthe‘auto level’buttonand

wait until the table top stops when level (check the

long and short truck sections are level in both

directions and adjust if required as detailed in

sections 6.20 to 6.22).

6. MAINTENANCE

iii On the hand control, press patient right orientation

button (button 2, Fig.31).

iv Onthehand control,press theTrendelenburgbutton

(button 3, Fig.31) and move the table top to the

maximum reverseTrendelenburg position.

v Using an inclinometer (on the radiopaque top not

the mattress of the short trunk section), check the

angle of the table top. The angle should be 35

degrees.

1 Push button

2 Short trunk assembly

3 Adjusting screws

4 Level tilt switch

Fig. 15 Level tilt switch

vi On the hand control, press the break (extension)

button(button 5, Fig.31)andcheckfor movement of

the long trunk section of the table top.If movement

occurs, adjust the level tilt switch by releasing the

adjusting screws (item 3, Fig.15) and moving the

level tilt switch in the appropriate direction to stop

anymovement ofthelongtrunk sectionwith thetable

top in the reverseTrendelenburg position.

vii Afteradjustingthe leveltilt switch repeat actions(iv)

(v) and (vi) until there is no movement of the long

trunksection inthemaximumTrendelenburgposition.

Table of contents

Other eschmann Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual