Table of contents

1. Overview......................................................................................................................................6

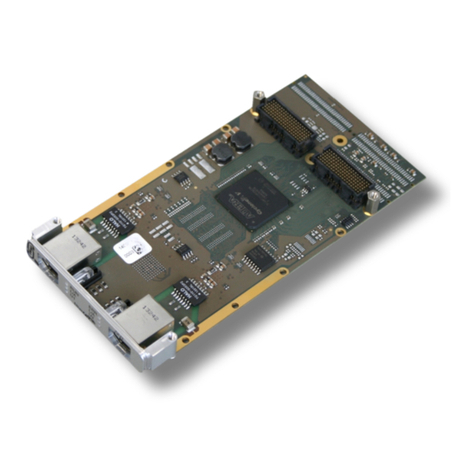

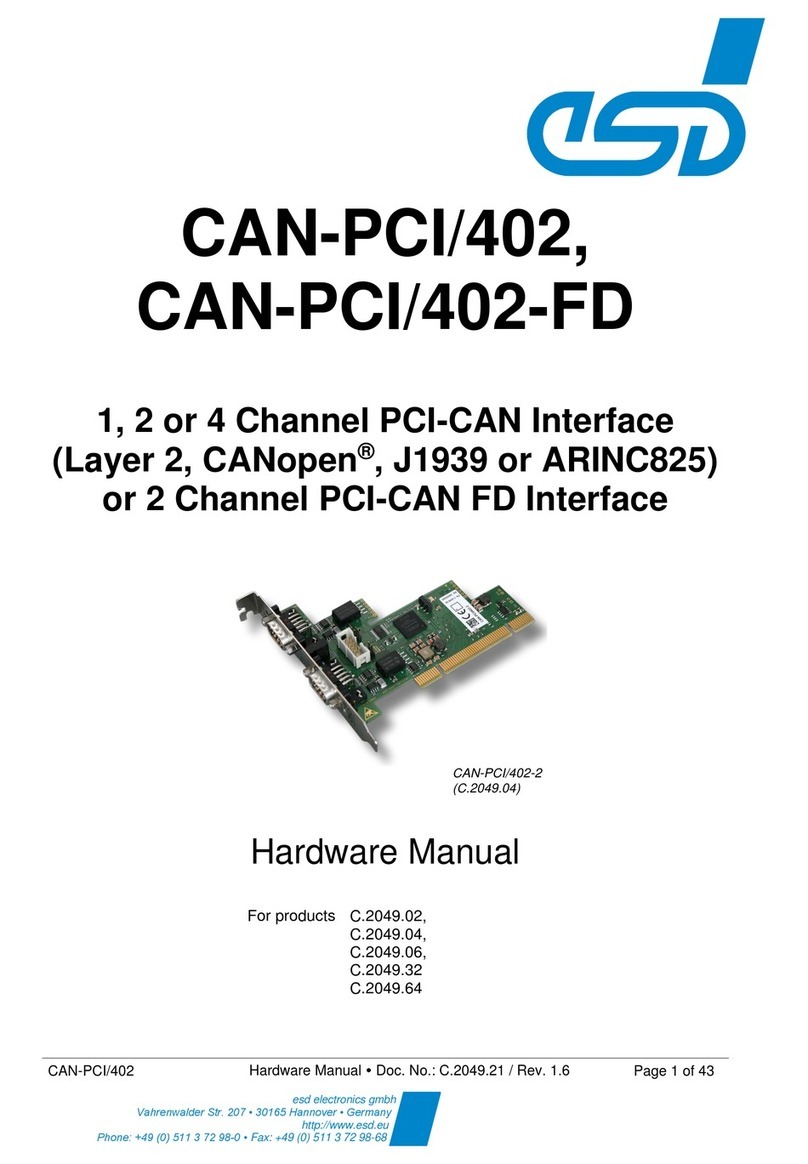

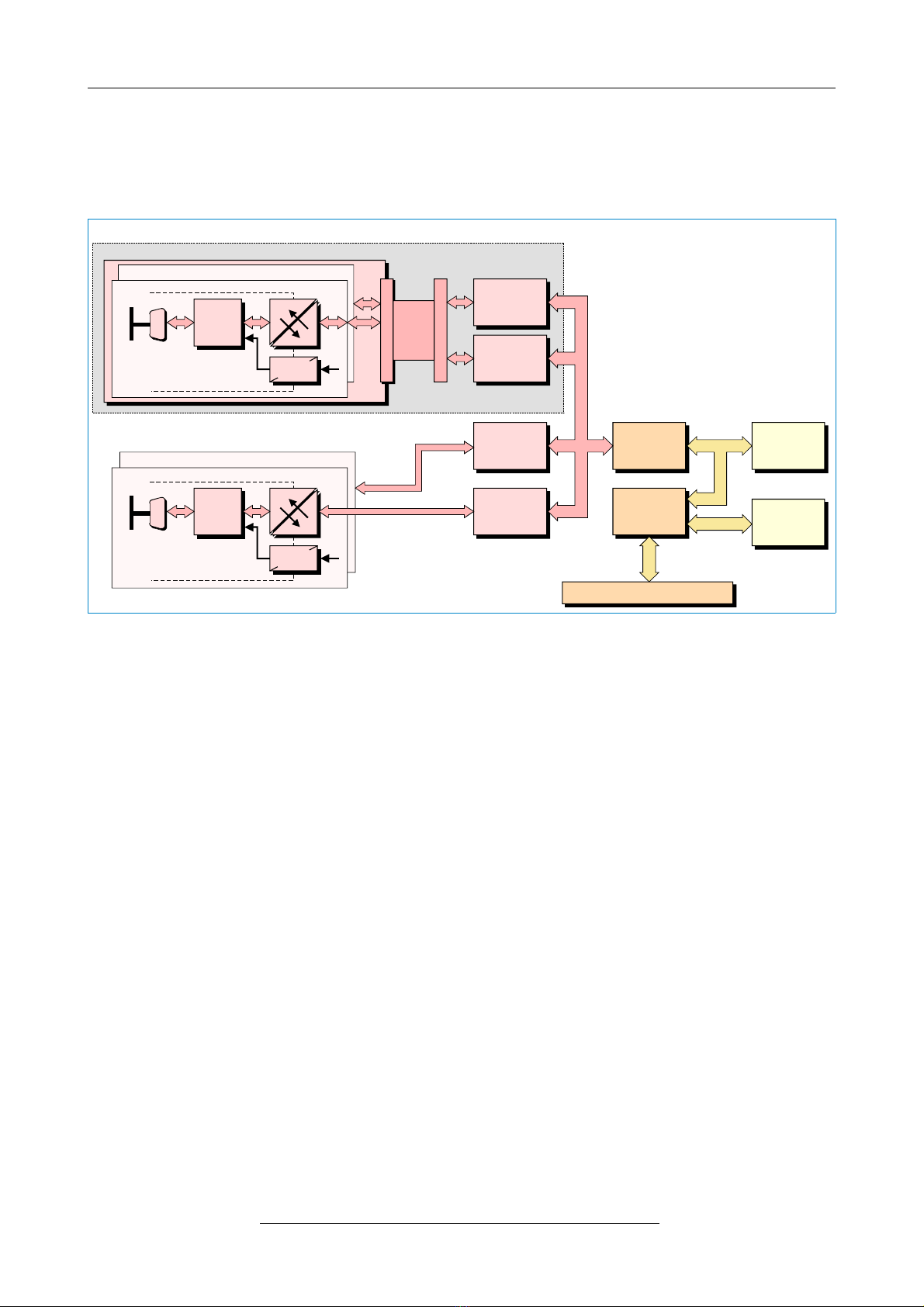

1.1 Module Description................................................................................................................6

2. Hardware Installation....................................................................................................................7

2.1 Procedure..............................................................................................................................7

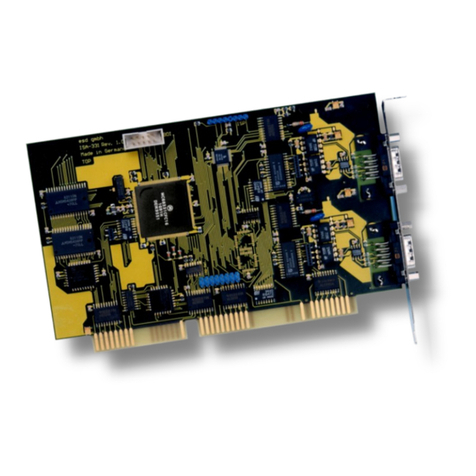

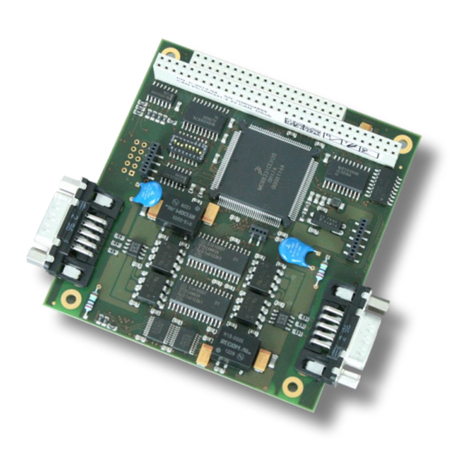

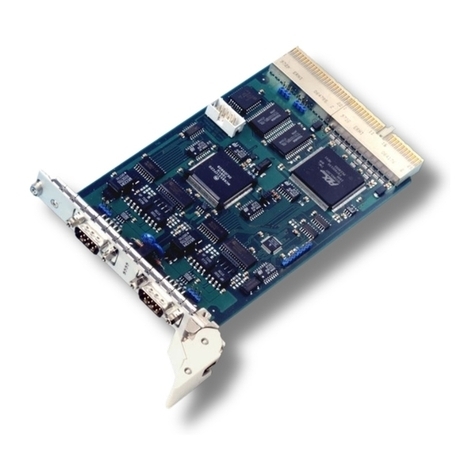

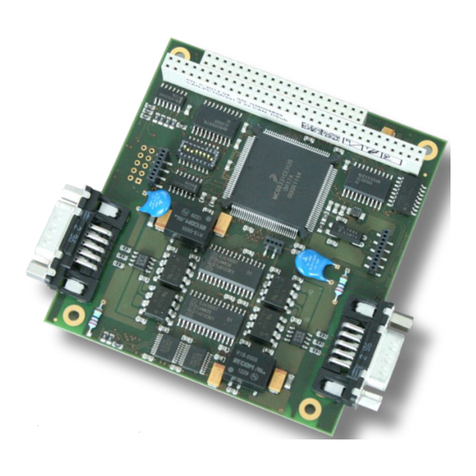

2.2 PCB View with Connectors....................................................................................................9

2.3 LEDs and Connectors in the Slot Cover...............................................................................10

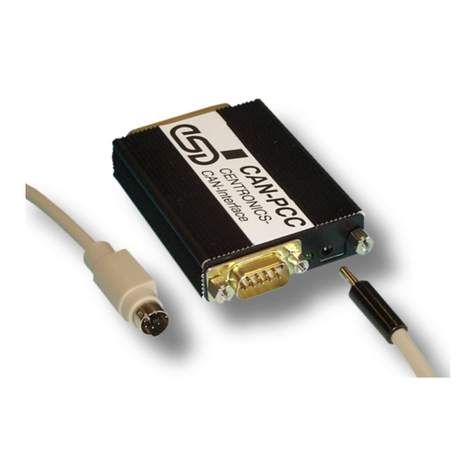

2.4 CAN-PCI/405-4 Version with 4 CAN Interfaces....................................................................11

3. Technical Data............................................................................................................................12

3.1 General Technical Data........................................................................................................12

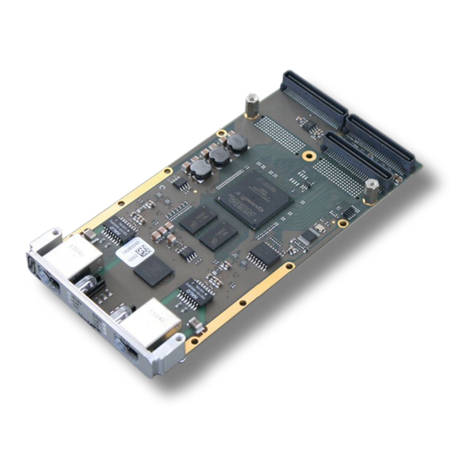

3.2 Microprocessor and Memory................................................................................................12

3.3 PCI Bus................................................................................................................................13

3.4 CAN Interface......................................................................................................................13

3.5 Software Support.................................................................................................................14

4. Connector Assignments..............................................................................................................15

4.1 CAN Interface at DSUB9 Connector....................................................................................15

4.2 Connection to Adapter Board (CAN-PCI/405-4 only)...........................................................16

5. Correctly Wiring Electrically Isolated CAN Networks..................................................................17

5.1 Light Industrial Environment (Single Twisted Pair Cable).....................................................17

5.1.1 General Rules.............................................................................................................17

5.1.2 Cabling........................................................................................................................18

5.1.3 Termination..................................................................................................................18

5.2 Heavy Industrial Environment (Double Twisted Pair Cable).................................................19

5.2.1 General Rules.............................................................................................................19

5.2.2 Device Cabling............................................................................................................20

5.2.3 Termination..................................................................................................................20

5.3 Electrical Grounding.............................................................................................................21

5.4 Bus Length...........................................................................................................................21

5.5 Examples for CAN Cables...................................................................................................22

5.5.1 Cable for Light Industrial Environment Applications (Two-Wire)..................................22

5.5.2 Cable for Heavy Industrial Environment Applications (Four-Wire)...............................22

6. CAN Troubleshooting Guide.......................................................................................................23

6.1 Termination..........................................................................................................................23

6.2 Electrical Grounding.............................................................................................................24

6.3 Short Circuit in CAN Wiring..................................................................................................24

6.4 CAN_H/CAN_L-Voltage ......................................................................................................24

6.5 CAN Transceiver Resistance Test .......................................................................................25

7. Declaration of Conformity...........................................................................................................26

8. Order Information.......................................................................................................................27

CAN-PCI/405 Hardware Manual • Doc. No. C.2023.21 / Rev. 1.3 Page 5 of 28