Esu SwitchPilot User manual

2

Contents

1. Declaration of conformity1. Declaration of conformity

1. Declaration of conformity1. Declaration of conformity

1. Declaration of conformity ....................................................................................

....................................................................................

.......................................... 33

33

3

2. WEEE declaration2. WEEE declaration

2. WEEE declaration2. WEEE declaration

2. WEEE declaration ..............................................................................................................

..............................................................................................................

....................................................... 33

33

3

3. Important notes – Please r3. Important notes – Please r

3. Important notes – Please r3. Important notes – Please r

3. Important notes – Please read this chapter firstead this chapter first

ead this chapter firstead this chapter first

ead this chapter first ....................

....................

.......... 44

44

4

4. How this manual will help you4. How this manual will help you

4. How this manual will help you4. How this manual will help you

4. How this manual will help you ......................................................................

......................................................................

................................... 44

44

4

5. Intr5. Intr

5. Intr5. Intr

5. Introduction – The SwitchPilot familyoduction – The SwitchPilot family

oduction – The SwitchPilot familyoduction – The SwitchPilot family

oduction – The SwitchPilot family ..................................................

..................................................

......................... 55

55

5

5.1. Members of the SwitchPilot family ............................... 5

5.1.1. SwitchPilot Decoder at a glance ................................ 5

5.1.2. SwitchPilot ................................................................ 5

5.1.3. SwitchPilot Servo ....................................................... 6

5.1.4. SwitchPilot Extension ................................................ 6

5.2. Features ....................................................................... 6

5.2.1. Operational modes ................................................... 6

5.2.1.1. k83 mode .............................................................. 6

5.2.1.2. k84 mode .............................................................. 7

5.2.1.3. User mode ............................................................. 7

5.2.2. Transistor outputs ...................................................... 7

5.2.3. Servo outputs ............................................................ 7

5.2.4. Relay outputs ............................................................ 8

5.2.5. Feedback signal input ............................................... 8

5.2.6. Switching input ......................................................... 8

6. Connecting to the digital system6. Connecting to the digital system

6. Connecting to the digital system6. Connecting to the digital system

6. Connecting to the digital system ................................................................

................................................................

................................ 88

88

8

6.1. Terminals of the SwitchPilot ......................................... 8

6.2. Terminals of the SwitchPilot Extension ......................... 9

6.3. Terminals of the SwitchPilot Servo ............................. 10

6.4. Power supply from the digital system ......................... 11

6.5 Separate power supply ............................................... 11

6.6. Wiring of the SwitchPilot Extension ........................... 11

6.7. Wiring of the transistor outputs ................................. 12

6.7.1. Connecting double-coil solenoids ........................... 12

6.7.2. Wiring of daylight signals and light bulbs or LEDs ..... 13

6.7.3. Wiring of a motor drive .......................................... 13

6.8. Wiring of a servo ....................................................... 14

6.9. Wiring of feedback contacts ...................................... 14

6.10. Polarizing electric frogs ............................................ 15

7. Decoder settings (pr7. Decoder settings (pr

7. Decoder settings (pr7. Decoder settings (pr

7. Decoder settings (programming)ogramming)

ogramming)ogramming)

ogramming) ............................................................

............................................................

.............................. 1515

1515

15

7.1. Changeable decoder features .................................... 15

7.1.1. Configuration Variables (CVs) ................................. 15

7.1.1.1. Standardization regarding NMRA......................... 15

7.1.1.2. Bits and bytes ....................................................... 16

7.2. Programming with DCC systems ................................ 16

7.2.1. Programming on the main track ............................. 16

7.2.2. Programming on the programming track ................ 16

7.2.2.1. Connecting to the programming track ................. 17

7.3. Programming with Märklin® central stations ............. 17

7.4. Programming with the ESU LokProgramer ................. 18

8. Addr8. Addr

8. Addr8. Addr

8. Address settings

ess settings

ess settingsess settings

ess settings ..............................................................................................................

..............................................................................................................

....................................................... 1818

1818

18

8.1. Turnout numbers ........................................................ 18

8.2. Decoder addresses ..................................................... 18

8.2.1. Schedule of turnout numbers and addresses .......... 18

8.3. Factory settings .......................................................... 20

8.4.

Programming addresses with the programming button ....

20

8.4.1. First address for outputs 1 – 4 ................................. 20

8.4.2. Second address for outputs 5 – 6 ............................ 20

9. Featur9. Featur

9. Featur9. Featur

9. Features of transitor outputses of transitor outputs

es of transitor outputses of transitor outputs

es of transitor outputs ........................................................................

........................................................................

.................................... 2121

2121

21

9.1. Configuration for impulse output (k83) ..................... 21

9.2. Configuration for preset pulse time ........................... 21

9.3. Configuration for PECO turnout motors ..................... 21

9.4. Configuration for alternate blinking mode ................ 21

9.5. Configuration for variable (k84) ................................. 21

9.6. Configuration for „zoom“effect for impulse output .. 21

10. Featur10. Featur

10. Featur10. Featur

10. Features of servo outputses of servo outputs

es of servo outputses of servo outputs

es of servo outputs ..............................................................................

..............................................................................

....................................... 2121

2121

21

10.1. Configuration of servo end position „A“ ................. 21

10.2. Configuration of servo end position „B“ ................. 21

3

1. Declaration of conformity

We, ESU electronic solutions ulm GmbH & Co KG, Industriestrasse

5, D-89081 Ulm, declare in sole responsibility that the products

to which this declaration refers, namely

SwitchPilot, SwitchPilot Extension, SwitchPilot ServoSwitchPilot, SwitchPilot Extension, SwitchPilot Servo

SwitchPilot, SwitchPilot Extension, SwitchPilot ServoSwitchPilot, SwitchPilot Extension, SwitchPilot Servo

SwitchPilot, SwitchPilot Extension, SwitchPilot Servo

are in compliance with the following standards:

EN 71 1-3: 1988 / 6: 1994 – EN 50088: 1996 – EN 55014, part 1

+ part 2: 1993

EN 61000-3-2: 1995 – EN 60742: 1995 – EN 61558-2-7: 1998

according to the directive 88 / 378 / EWG – 89 / 336 / EWG – 73

/ 23 / EWG

2. WEEE declaration

Disposal of obsolete electrical and electronic equipment (as

practiced in the European Union and other European countries

with dedicated collection systems).

This mark on the product, the packaging or the relevant

documentation indicates that this product must not be treated

like household waste. Instead this product should

be disposed of at a suitable collection point for

recycling of electrical and electronic appliances.

Thus you contribute to avoid negative impact on

the environment and people’s health that could be

caused by inappropriate disposal. Recycling of

materials contributes to preserve our natural

resources. For more information regarding recycling of this

product, please contact your local administration, your waste

collection service or the dealer / shop where you purchased this

product.

10.3. Configuration of servo speed ................................... 22

10.4. Configuration of servo outputs with input unit ........... 22

11. RailCom®11. RailCom®

11. RailCom®11. RailCom®

11. RailCom® ............................................................................................................................

............................................................................................................................

.............................................................. 2323

2323

23

11.1. Activating RailCom® ............................................... 23

11.2. Reading of CVs with RailCom® and ESU ECoS ........ 23

11.2. Feedback of turnout position with ECoS .................. 24

12. Dir12. Dir

12. Dir12. Dir

12. Direct switching with push button inputsect switching with push button inputs

ect switching with push button inputsect switching with push button inputs

ect switching with push button inputs ..............................

..............................

............... 2525

2525

25

13. Options for SwitchPilot Extension13. Options for SwitchPilot Extension

13. Options for SwitchPilot Extension13. Options for SwitchPilot Extension

13. Options for SwitchPilot Extension ......................................................

......................................................

........................... 2525

2525

25

13.1. Switching point ........................................................ 25

13.2. Allocation of relays .................................................. 25

14. Decoder r14. Decoder r

14. Decoder r14. Decoder r

14. Decoder reseteset

eseteset

eset ..................................................................................................................

..................................................................................................................

......................................................... 2626

2626

26

14.1. With DCC systems ................................................... 26

14.2. With the programming button ................................. 26

14.3. With the ESU LokProgramer ..................................... 26

15. Support and assistance15. Support and assistance

15. Support and assistance15. Support and assistance

15. Support and assistance ....................................................................................

....................................................................................

.......................................... 26

26

2626

26

16. T16. T

16. T16. T

16. T

echnical Dataechnical Data

echnical Dataechnical Data

echnical Data ................................................................................................................

................................................................................................................

........................................................ 2727

2727

27

16.1. Technical data of SwitchPilot .................................... 27

16.2. Technical data of SwitchPilot Servo .......................... 27

16.3. 0Technical data of SwitchPilot Extension .................. 27

17. List of all CVs17. List of all CVs

17. List of all CVs17. List of all CVs

17. List of all CVs ..................................................................................................................

..................................................................................................................

......................................................... 2828

2828

28

18. W18. W

18. W18. W

18. Warrantyarranty

arrantyarranty

arranty ................................................................................................................................

................................................................................................................................

................................................................ 3131

3131

31

4

Important notes

3. Important notes – Please read this chapter first

We congratulate you on your purchase of an ESU Switch Pilot

decoder. This manual will guide you step by step through the

features of SwitchPilot respectively SwichPilot Extension.

Important warning:

Please read this manual carefully. Although the SwitchPilot has

been designed as a robust device an incorrect connection may

lead to faults or even to the destruction of the device. Avoid any

“costly” experiments.

•The Switch Pilot is exclusively intended for use with model train

layouts only. It may only be operated with the components listed

here. Any other use is not permitted.

•Any wiring has to be carried out while power is disconnected.

•Any power supply must be protected by a fuse or circuit breaker

to avoid any potential hazards such as burning cables in case of

a short circuit. Only use transformers specifically designed for

model trains that bear the VDE/EN marks.

•Never operate the SwitchPilot unattended. The SwitchPilot is

not a (children’s) toy.

•Adhere to the wiring principles as outlined in this manual for

wiring any external components. Other circuitry may cause

damage to the SwitchPilot.

•SwitchPilot is not water proof. It is not intended for outside

use. If you use this product for exterior applications you do so

at your own risk.

•Do not attempt to open your SwitchPilot module. Improper

treatment may cause damage or destruction.

4. How this manual will help you

This manual was divided into a few chapters, which will gradually

show you how to operate the products 51800,51801 and 51802.

Chapter 5 includes an overview of the features of the single

SwitchPilot decoders.

In chapter 7 we deal with the connection of your layout.

If you wish to adjust the factory settings of your decoder

individually, just do so. In chapter 7 - 11, you will find detailed

explanations about which settings are possible and how you can

change them.

Statements about technical data can be found in chapter 16 as

well as a list of all CVs assisted, if necessary.

Unless indicated otherwise, all statements exclusively refer to

members of the SwitchPilot family. In case a decoder should not

work with a special function, this will be mentioned explicitly.

5. Introduction – The SwitchPilot family

Copyright 1998 - 2007 by ESU electronic solutions ulm GmbH & Co KG.

Electrical characteristics and dimensions are subject to change without prior

notice. All rights reserved. ESU may not be held responsible for any damage

or consequential loss or damage caused by inappropriate use of the product,

abnormal operating conditions, unauthorized modifications to the product,

etc. Not suitable for children under 14 years of age. Inappropriate use may

result in injury due to sharp points and edges.

Märklin® is a registered trademark of the company Gebr. Märklin® und

Cie. GmbH, Göppingen. All other trademarks are owned by the respective

rights holder.

Due to our politics, ESU electronic solutions ulm GmbH & Co. KG keeps on

developing our products steadily. Thus ESU reserves the right to carry out

any kind of improvement or changes to the product without any

anouncement. A reproduction or duplication of this documentation has to

be allowed by ESU.

5

5.1. Members of the SwitchPilot family

The ESU SwitchPilot decoders are especially optimized for

stationary operation on your layout. Not matter if you wish to

activate turnouts, signals, magnetic un-couplers, light bulbs and

other stationary loads or even if you prefer a „state of the art

servo motor: One of the SwitchPilot decoders will be quite useful

for you, for sure.

The SwitchPilot decoders can be supplied with power either from

the digital system or from an external AC- or DC-power source.

Due to an installed full bridge rectification and backup memory

you can do without any additional „power modules“.

All SwitchPilots are multi protocol capable and therefore can

either be operated with command stations as per the Märklin®-

Motorola® system (e.g.: 6021, Central Station®) or with DCC

compliant command stations.

SwitchPilot Decoders are able to control all current DCC

programming modes and can be set up either on the main track

or the programming track. Thanks to RailCom® it is also possible

to read out data on the main track. Some of the SwitchPilot

decoders can be easily set up via a three-button, LED input unit.

SwitchPilot decoders are shipped in a robust body and stand out

due to their excellent price-performance ratio.

Introduction - The SwitchPilot family

5.1.1. SwitchPilot overview

SwitchPilot SwitchPilot Servo

DCC mode Ok Ok

Motorola mode Ok Ok

DCC programming Ok Ok

4 double transistor outputs per 1.5A -

2 servo outputs Ok -

4 servo outputs - Ok

Feedback input Ok -

RailCom® Ok Ok

Input unit - Ok

5.1.2. SwitchPilot

The SwitchPilot is a universal decoder for users who mainly have

double-solenoid motors installed, but would like to test the servo

technology.

Hence the SwitchPilot has four outputs (1-4) for switching of up

to 4 double-solenoid accessories (e.g. switches) or 8 accessories

like uncouplers or light functions.

Each output can be programed individually for continuous or

pulsed output with variable pulse duration or blinking.

Thus it is possible to connect light bulbs or LEDs without any

additional relays. Automatic fading assures prototypical run-up

and shut-down of signal lamps.

In addition two commercially available RC-servos for hobby

applications may be wired directly to the SwitchPilot. Their speed

and end position can be adapted as required.

Due to the integral DCC RailCom® - transmitter it is possible to

provide status feed back of the accessory to the command station.

For instance an ESU ECoS command station can then display the

manually activated change of status.

Of course the transistor outputs of SwitchPilot are electronically

protected against overload and short circuit.

6

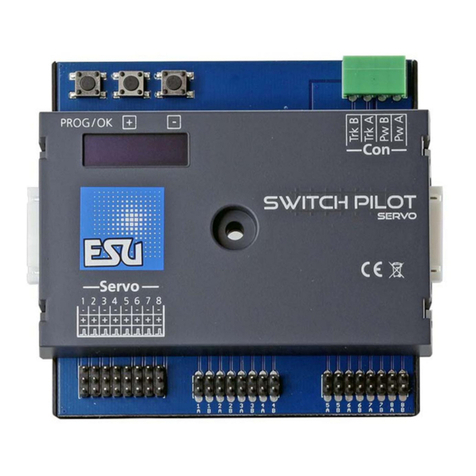

5.1.3. SwitchPilot Servo

The SwitchPilot Servo is a masterpiece among accessory decoders:

it was specifically developed for controlling up to four remote-

controlled servo motors. The SwitchPilot Servo activates these

actuators very precisely and thus is able to control not only

switches, but also other slow motion sequences.

The SwitchPilot Servo has a built-in „Power-on-Pulse-Suppressi-

on“ feature to eliminate or reduce the „twitching“ of the RC

servo when current is being applied. The SwitchPilot Servo can

also be used without a digital control unit. For this, eight push

buttons can be connected to directly control the servo motor.

Thanks to the input unit of three buttons on the decoder, the

servo state as well as speed can be set up pretty easily.

You are using servos and are asking yourself which SwitchPilot

should you use? If you are only controlling turnouts and light

signals the SwitchPilot is the right decoder for you. If you would

like to control railroad crossings or any other devices that might

require slow motion, you should definitely use the SwitchPilot

Servo.

5.1.4. SwitchPilot Extension

For operating motor drives for turnouts or for the polarization of

the frogs you require a relay with potential free contacts. For this

purpose each SwitchPilot can be connected to a SwitchPilot Ex-

tension which can be plugged into the side of the SwitchPilot

and receive its power from it.

Each SwitchPilot Extension module has 4 by 2 relay outputs that

are operated in parallel to the corresponding outputs of the

SwitchPilot. This corresponds to the established k84-solution.

SwitchPilot Servo

5.2. Features

5.2.1. Operational modes

All SwitchPilots are multi protocol capable and therefore can

either be operated with command stations as per the Märklin®-

Motorola® system (e.g.: 6021, Central Station®) or with DCC

compliant command stations. For this SwitchPilot decoders must

be contacted with solenoid accessory addresses. Therefore,

operation with the Lokmaus 2 is not possible. The Lokmaus 2

does not send DCC commands to solenoid devices.

SwitchPilot

The SwitchPilot has a switch to select different operating modes.

Thus you can easily set the desired mode. Therefore

“programming” is not necessary for most standard applications.

This switch only operates the four transistor output pairs 1 to 4.

The servo outputs are not affected.

The operating mode switch is only for the use with Motorola

control units to enable compatibility with Marklin controllers. If

the SwitchPilot is used with the DCC protocol the operating mode

switch needs to stay at the middle position (factory default).

5.2.1.1. k83 mode

SwitchPilot

When you push the slide into the k83 position then the outputs

1 to 4 will be switched to pulse operation regardless of the

programed settings. The SwitchPilot behaves exactly like a

Märklin® k83. Use this mode whenever you want to operate

conventional solenoid drives.

7

5.2.1.2. k84 mode

SwitchPilot

In the k84-mode the outputs 1 to 4 will be set to variable

regardless of any pre-programed settings. The SwitchPilot behaves

exactly like a Märklin® k84.

Use this mode to operate LEDs or light bulbs and whenever you

do not require any specific programming.

All consumer loads are directly electrified by the SwitchPilot. You

must not connect any external voltage!

5.2.1.3. User mode

SwitchPilot

The user mode is switched on by setting the switch for selecting

the operating mode into the centre position. Only in this mode

the outputs 1 to 4 will behave according to the software controlled

settings.

This is the correct use to DCC format, k83 and k84-Modus are

only meant for Motorola® command stations.

5.2.2. Transistor outputs

SwitchPilot

The SwitchPilot has a total of 8 transistor outputs that are grouped

in four pairs 1 to 4. Each pair has two outputs, OutA and OutB.

there are also two separate servo outputs.

The transistor outputs can be set to continuous, to pulsed power

or to alternating blinking.

Pulsed output:

If the output is set to pulse operation it will be activated as soon

as a command is received. At the same time a timer starts

counting: the “on-time” (duration of pulse) is determined by a

pre-programed value. The output cannot be active for longer or

shorter than this value. Should you let go of the button before

the end of the first pulse then the output remains active until the

pre-determined time has been reached. If you press the button

longer than the pre-determined pulse duration then the output

is switched off even though the button is still pressed.

The limitation of the pulse duration helps avoid damage to

solenoids.

The pulse duration can be set in such a way that the outputs are

active as long as the button on the control panel is pressed. This

operating mode is compatible with Märklin® k83 decoders.

Variable:

Pressing the appropriate button on the control panel (e.g.: “red”

for Märklin® central units or „+“ for Lenz Digital Plus®) switches

on the first output Out A. It remains on until the corresponding

button for output Out B is activated. Out A and Out B work like

a change over switch.

Logically this operating mode complies with the Märklin® k84

decoder. From every output EITHER Out A OR Out B is active.

Both cannot be switched at the same time!

Alternating blinker:

In this mode the terminals Out A und Out B of an output will be

activated alternately. This is quite useful for the blinking red lights

at level crossings amongst others.

The “on-time” can be set in the same fashion as the pulse

duration.

Subject to the pulse duration and also in continuous mode it

may happen that several outputs are on at the same time. Please

note that the total current of all connected loads must not exceed

the total permitted load of the decoder, namely 3.0 A.

5.2.3. Servo outputs

SwitchPilot SwitchPilot Servo

RC-servos can be connected to both SwitchPilot decoders.

Compared to gear motors, servos are intelligent actuators with

integrated intelligence which can move to the self-desired position

and can also hold this state. In doing so, they force a different

angle and speed. Will leverage against a force out, it controls

the servo with all force against the angle constantly striving itj

8

should have to keep.

The nominal position will be set by a pulse line (orange on

Graupner ® servos, otherwise white). A constant voltage (4.8 V

- 6V) completes the interface.

On the pulse line the servo expects in a time interval of 20 –

25ms a positive impulse with a length between 1.0ms and 2.0ms.

The length of the pulse is directly proportional to the desired

target position.

If the servo does not receive a signal, the motor gets no power,

so it follows the mechanical forces on the lever.

Servos are available in various designs and sizes. They differ also

in the gear box and actuator angle. There are, for example, servos

to make wind sail adjustment, which makes several revolutions.

ESU offers with the servo motor (51803) a very small servo drive.

This includes all the necessary parts for the switches or turnouts

and you don’t need to search for all these small parts.

Never try to turn the actuator of a servo by hand. The gears

of the servo can be destroyed.

5.2.4. Relay outputs

SwitchPilot Extension

Outputs 1 through 4 each offer a relay output A and B which are

switched together (DPDT, bi-stable). Each relay output

corresponds with the transistor output of the SwitchPilot or the

servo output of the SwitchPilot Servo: If output A is active (or

servo setting A is reached) the terminals I and Com of the relay

output are connected. Is output B on the SwitchPilot active (or

servo setting B is reached) the terminals II and Com are connected.

5.2.5. Feedback inputs

SwitchPilot

Through RailCom® the SwitchPilot can send the current turnout

position back to the digital control unit. For this the turnout needs

to have the corresponding feedback contacts which must be

connected to feedback contact input FB A and/or FB A. (see Figure

7.7 for details)

5.2.6. Push Button Inputs

SwitchPilot Servo

The SwitchPilot Servo can also be used without a digital system.

The setting of servos 1 through 4 can be set with external push

buttons. These could be toggle switches or push buttons known

from the famous analog switch boards. (See Figure 13 for more

details)

6. Connection to the digital system

We recommend setting all parameters of the SwitchPilot prior

to installing the unit on your layout.

6.1. Connecting elements of the SwitchPilot

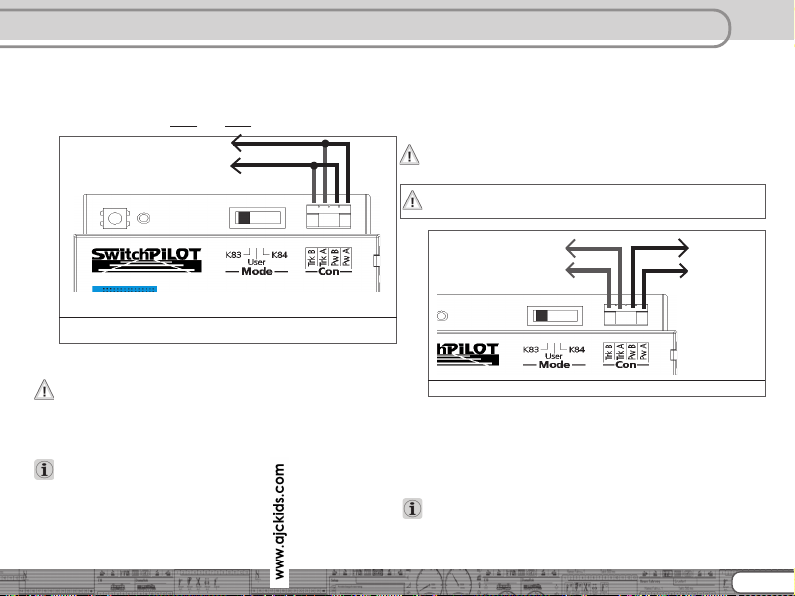

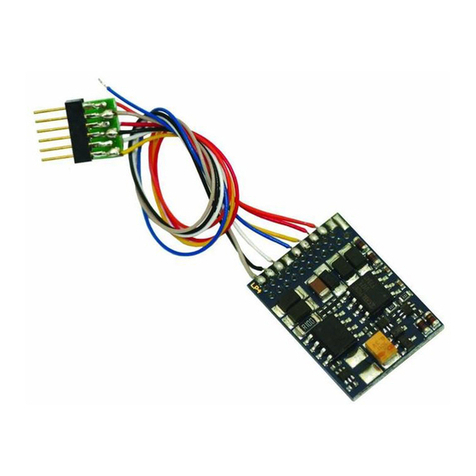

Figure 1 on the right shows the SwitchPilot and SwitchPilot Extension.

Figure 1 shows the SwitchPilot together with the optional

SwitchPilot Extension module.

a) Wire turnouts, signals, un-couplers or similar devices to the

terminals of the (transistor) outputs 1 to 4. The terminals FB A

and FB B are used for status feedback of the device.

b) This multi-pin connector serves to wire two commercially

available RC-Servos (e. g.: Graupner®, Futaba® or ESU) and

represents the outputs 5 and 6 of the SwitchPilot.

Relay outputs

9

c) The power supply for the SwitchPilot and all the devices

connected to it are wired to the terminals Pw A und Pw B.

Both AC- and DC power supplies as well as the digital track

voltage can be used.

d) The screw terminals Trk A and Trk B connect the SwitchPilot

with the power output of a command station (e.g. booster

output) transmitting the digital commands.

e) The switch controlling the operating modes allows you to select

any of the supported modes such as k83, user mode and k84-

mode (also compare with chapter 5.2.1).

f) The LED in conjunction with the

g) programming button helps you to set the digital address of

the SwitchPilot. This process is described in chapter 8.

h) The extension socket / plug connect the SwitchPilot and the

SwitchPilot Extension mechanically and electrically.

z) Decoder ground (optional) – needed for turnout operation

when using the SwitchPilot without a digital control unit.

6.2. Connecting elements of the SwitchPilot Extension

Figure 1 on the left shows the SwitchPilot Extension module

i) The outputs marked 1 to 4 offer one relay output A and B that

can be switched together. Each relay output corresponds with

the respective output of the SwitchPilot: If the output Out A

of the SwitchPilot is active the terminal 1 and COM of the

relay output are also active. If the output Out B of the

SwitchPilot is active then the terminals 2 and COM are

electrically connected. Unlike the transistor outputs the relay

outputs always work as variables.

j) Terminal with ground and voltage power (U+) DC for the use

of DC turnout motors like the Tortoise motor.

Figure 1: SwitchPilot connected with SwitchPilot Extension

a) a) a) a)b)

c)

e)

f)g) d)

i)i)i)i)

i)i)i)i) h)

j)

j) z)

III

Com

10

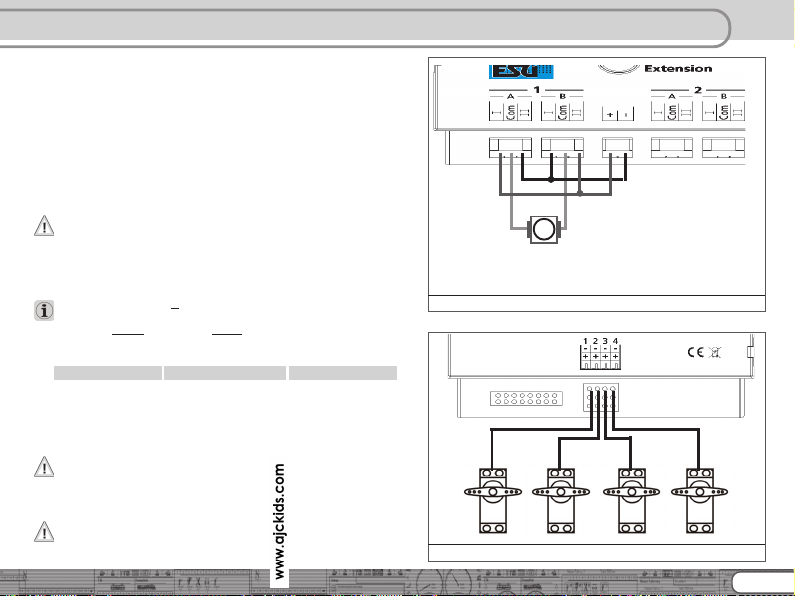

6.3. Connecting elements of the SwitchPilot Extension

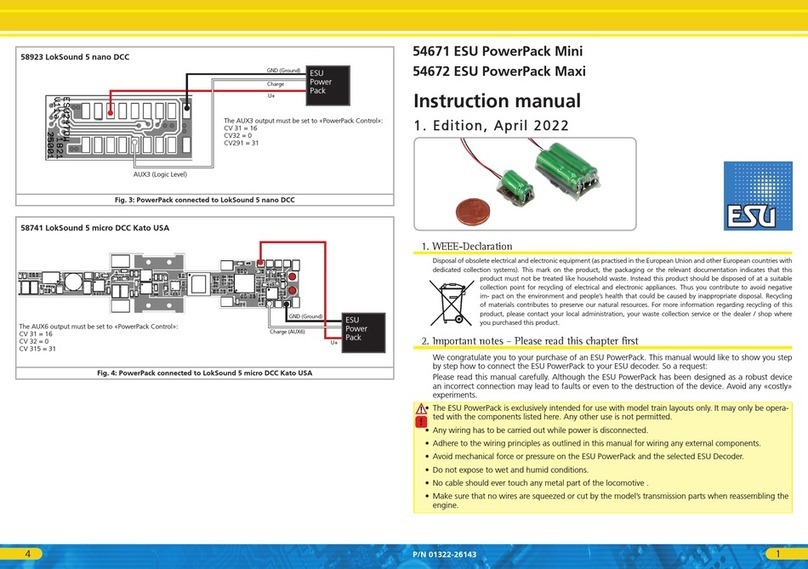

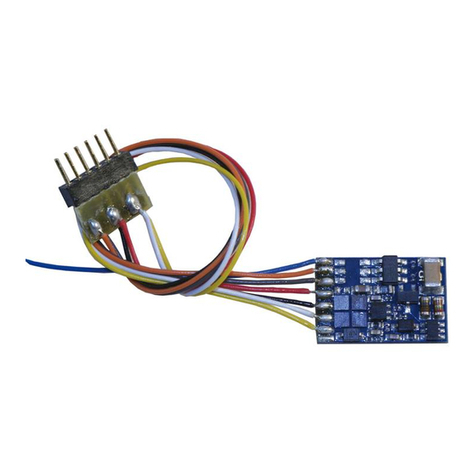

Figure 2 shows the SwitchPilot Servo with its optional SwitchPilot

Extension module.

c) The power supply for the SwitchPilot and all the devices

connected to it are wired to the terminals Pw A und Pw B.

Both AC- and DC power supplies as well as the digital track

voltage can be used.

d) The screw terminals Trk A and Trk B connect the SwitchPilot

with the power output of a command station (e.g. booster

output) transmitting the digital commands.

f) The LED in conjunction with the

g) programming button helps you to set the digital address of

the SwitchPilot. This process is described in chapter 8. In

addition, using the programming button or

k) Input unit with a „+“ and „-“ buttons and monitor LEDs 1)

directly Servo end positions „A“ and „B“ and the rotation

speed set.

l) Monitor LEDs. During the setup of Servo end position and

rotational speed on the input unit actively and show what

servo is being edited. For more information about programming

with the input unit, see section 10.4.

m) This pin block serves to connect up to 8 external push buttons

or toggle switches to operate the servo positions directly

without digital control unit. Chapter 12 gives details.

n) This pin block serves to connect four RC servo motors (eg

ESU, Graupner®, Futaba®, etc.) and forms the outputs 1-4 of

the SwitchPilot servo.

h) Extension connector (female / male): Here is the connection

between SwitchPilot Servo and SwitchPilot Extension unit.

Connecting elements of SwitchPilot Servo

Figure 2: SwitchPilot connected with SwitchPilot Extension

m) n)

c)

l)

f)

g) d)

i)i)i)i)

i)i)i)i) h)

j)

j) k)

11

6.4. Power supply from the digital system

For smaller layouts with only a few devices to be switched

simultaneously the power supply of the digital system may be

used.

The screw terminals Pw A and Pw B are wired in parallel to the

terminal Trk A and Trk B.

Depending on the used solenoid devices the digital control unit

might not be able to supply enough current for a safe operation.

In this case an external transformer which can supply enough

current for these solenoid devices needs to be connected to the

Depending on the used solenoid devices the digital control unit

might not be able to supply enough current for a safe operation.

In this case an external transformer which can supply enough

current for these solenoid devices needs to be connected to the

SwitchPilot (see 6.5). When using certain solenoid devices (i.e.

Märklin® K track turnouts or PECO® motors) you should consider

an external supply of powerSwitchPilot (see 6.5).

6.5 Separate power supply

For larger layouts with many devices controlled by SwitchPilots

and simultaneously active we recommend to utilise a separate

power supply; in this manner the power for switching the devices

is not drawn from the track and thus reduces the load on the

digital system.

Only use commercially available equipment designed for model

trains and also take note of the maximum voltage as stated in

chapter 16 in order to avoid any potential damage.

This way of connecting cannot be used for programming on

the programming track, compare chapter 7.2.2.1

6.6. Wiring the SwitchPilot Extension

The SwitchPilot Extension module is connected by inserting it

into the multi-pin connectors on the side of the SwitchPilot; push

until the retaining clips make positive contact.

Please also refer to figure 1.

The internal logic and relays of the SwitchPilot Extension module

receive power from the SwitchPilot.

Figure 3: SwitchPilot uses digital system for power supply

Connect to track output of

a digital system

Figure 4: separate power supply for SwitchPilot

connect to track output

of digital system

connect to

transformer

12

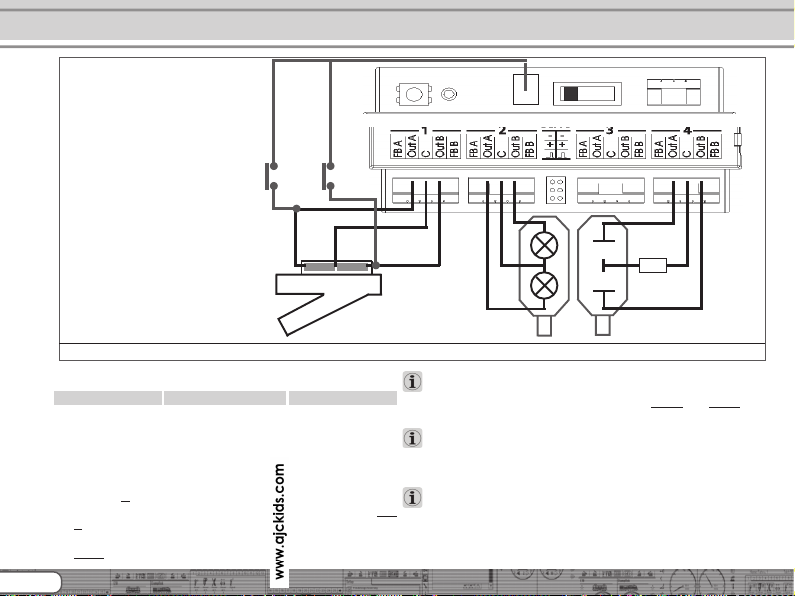

6.7. Wiring of transistor outputs

SwitchPilot

6.7.1. Connecting double-coil solenoids

You may use all commercially available double-coil solenoid drives

by all major manufacturers with SwitchPilot. Figure 4 shows how

to wire output 1:

a) The common wire of the solenoid is wired to screw

terminal C.

b) The wire leading to the first coil is connected to terminal Out

A.

c) The wire leading to the second coil is connected to terminal

Out B.

Should the aspect shown on your control panel not be as desired

(in other words: if straight and diverging route are exchanged)

simply swap the wires between terminals Out A and Out B.

SwitchPilot can also handle PECO® turnouts. However, their

current consumption is so high that you must adjust the overload

setting of the SwitchPilot. Please refer to chapter 9.3. for details.

As shown in Figure 5 the double-coil turnouts can be switched

with two optional push buttons without a digital command. The

needed ground solder pad is not available on all SwitchPilot

surfaces.

How to wire transistor outputs

Figure 5: Connection to transistor outputs 1 - 4

R

a)

b) c)

Activation through

button is possible

(Ground solder pad is

not available on all

models).

13

6.7.2. Wiring daylight signals and light bulbs or LEDs

If you use daylight signals with incandescent lamps (light bulbs)

or LEDs you must set the corresponding output to continuous

mode.

If the signal has incandescent lamps as shown for output 2 in

figure 5 you may wire the lamps directly to the terminals of the

SwitchPilot.

In order to limit the current for signals with LEDs a resistor must

be wired in series with the LEDs. This is shown for output 4 in

figure 5.

Please check if your signal already has a built-in resistor. Applying

power without this resistor will destroy the LEDs immediately!

If there is no resistor in place you must wire this resistor marked

“R” in series to the LEDs. Subject to the supply voltage and the

desired brightness of the signal the resistor should have a rating

of about 1 kohm to 2.2 kohm.

The screw terminal C of each output has positive potential.

Therefore the cathode of the LEDs must be connected to the

terminals Out A respectively Out B.

6.7.3. Wiring a motor drive

SwitchPilot Extension

The SwitchPilot can operate motor drives for turnouts with the

help of the SwitchPilot Extension. The direction of the motor is

reversed by changing the polarity of the voltage on the motor

terminals thus changing the position of the turnout or the aspect

of a semaphore signal.

Only use motor drives with limit stop contacts to avoid overheating

or a burnout of the motor. The relay outputs of the SwitchPilot

Extension always connect the supply voltage to the load.

A motor drive is wired as shown in figure 6. It will be energized

by the SwitchPilot.

Please take note of the permitted maximum supply voltage of

your motor drive as stated in its manual.

Figure 6: Motor drive used with SwitchPilot Extension

M

+

-

Figure 7: Servo connection

14

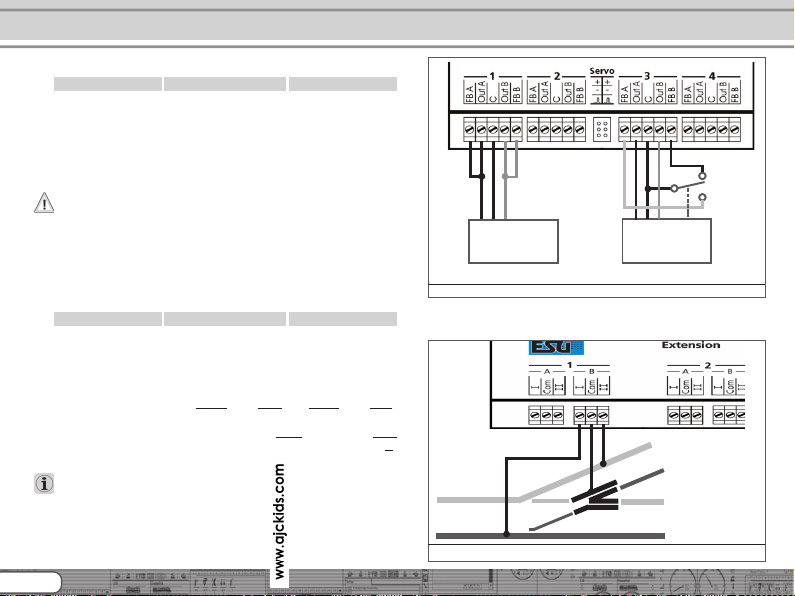

6.8. Wiring a servo

SwitchPilot SwitchPilot Servo

All commercially available RC-servos for hobby applications may

be used. They must have a three-pole terminal and operate on a

positive pulse. The SwitchPilot (Servo) provides 5V to the servo.

Figure 7 on page 13 shows the usual connection.

Simply insert the wire from the servo into the appropriate socket

of the SwitchPilot (Servo). Generally the white or orange wire is

used for the pulsed outputs of the servo.

Please refer to the wiring diagrams on the housing of the

SwitchPilot. Incorrect connections may destroy either the servo

or the SwitchPilot!

The servo outputs can be configured individually as you can see

in chapter 10.

6.9. Wiring feedback contacts

SwitchPilot

The SwitchPilot can report the actual aspect or position of the

turnout to the command station via RailCom®. The turnout must

have some extra contacts for this. Figure 6 on page 9 illustrates

this situation:

a) Connecting a motor of a turnout with limit stop contacts.

Connect the terminals Out A with FB A and Out B with FB B.

b) Connecting a motor with separate feedback contacts: connect

the feedback contacts with terminal FB A respectively FB B

and the common wire of the feedback contacts to terminal C.

How the status (feedback) is displayed depends on your command

station. The ESU ECoS®-command station can display the status

on the turnout control panel with software 1.1.0 and higher.

Further information about feedback of switches via RailCom®

can be found in chapter 11.

Wiring a servo

Figure 8: Wiring feedback of switches

a) b)

Figure 9: Polarizing electric frogs with SwitchPilot Extension

or

15

6.10. Polarizing electric frogs

SwitchPilot Extension

You may polarize (supply power of the correct polarity) to the

electro-frog of your turnout (compare figure 9).

If you would like to use a servo with your turnout it is most often

necessary to choose the exact timing in such a way that the relays

only switches when the servo is positioned in the middle between

setting A and B. This way shorts are being prevented. See Chapter

13 for more details.

7. Decoder settings (programming)

Chapter 7 is about changing the settings of the SwitchPilot

decoder. In case you are not familiar with the CVs please take

some time to read through the sometimes very complex

explanations.

After an introduction into the world of parameters in Chapter

7.1, Chapter 7.2 explains how to change the parameters with

different DCC control units.

Chapters 8 through 11 explain which parameters influence the

behavior of the SwitchPilot decoder.

7.1. Changeable decoder settings

Certain capabilities of the SwitchPilot decoder like the amount

of function outputs or the maximum current load are physically

limited through hardware and are not changeable. However, there

are still plenty of possibilities to change the behavior of the

SwitchPilot decoder through software changes.

For each individual parameter there are one or more storage

locations within the decoder in which numbers or letters can be

stored. You can think of these storage locations as index cards

which are kept in a large file cabinet. In order to find the indivi-

dual index cards each one has a number or description with the

property of the card, e.g. „Loco Address“ or „Maximum Speed“.

Now imagine that those cards can be written on with a pencil;

changes are always possible through erasing and writing. Not all

„cards“ can be written on. Certain pieces of information like the

manufacturer identification for ESU are hardcoded.

The content of these storage locations can be chosen by you and

is being read and considered by the decoder. You can fill the

storage locations with any value through a procedure that is also

known as programming.

7.1.1. Configuration Variables (CV)

All SwitchPilot decoders follow the CV concept which was

developed in the United States. The name CV (Configuration

Variable) is derived from the fact that the memory cells being

described above are not only variable but can also configure the

behavior of the decoder.

7.1.1.1. Standardization

The NMRA (National Model Railroad Association) has specified

which CV controls what function in a decoder. The DCC norm

describes the CVs with numbers whereby the most important

ones are given. Thereby the handling of CVs is simplified for the

user since decoders of many manufacturers follow this

standardization and the learned handling of CVs can be applied

everywhere. Within the DCC CV concept number values between

0 and 255 can be written into CVs. Each CV consists of exactly

one number. While the position (CV number) has been

predetermined the actual range of values can vary. Not all CVs

need to accept values between 0 and 255. Allowed values for

the SwitchPilot decoder are shown in the list in Chapter 16.

Decoder settings (programming)

16

7.1.1.2. Bits and Bytes

Most CVs contain numerical values: CV 8 for example contains

the manufacturer’s identification. This one can range from 1 to

255. Other CVs can be understood as a collection point of diffe-

rent switches which together control different functions (most

often turning on or off). Good examples are CVs 28 and 29: The

intended value for this CV needs to be calculated. This value

depends on the desired parameter. Take a look at the table in

Chapter 17 and its description for CV34: First decide which option

needs to be turned on or off. In the value column are two numbers

for each option. If the option is turned off the value is set 0,

otherwise a number between 1 and 8. Add those two numerical

values for this specific option and you will get the value which

needs to be written into the CV.

Example:

Assuming you would like to activate the SwitchPilot’s „zoom“

function on outputs 1 and 3, the value of CV 34 needs to be set

5 ( 1 + 0 + 4 + 0 = 5 ).

7.2. Programming with DCC systems

SwitchPilot decoders understand all programming methods of

the NMRA, so in addition to the programming track modes (Direct

Mode, Register Mode, Page Mode) also the main track

programming „POM“ (programming on the main).

With POM you can comfortably program your decoder without

having take your locomotive off the track. For this the central

unit must contact the decoder with its specific address, for

example: „Decoder 10, write value 1 into CV 3“. The decoder

address must be known. The reading of CV values is not possible

in this case.

It is possible to read out CVs on the main track with RailCom®.

More information can be found in chapter 11.

Programming

CV values can be read and set on the programming track – a

suitable DCC system provided. Furthermore you can program

decoders on the programming track without knowing the decoder

address since the central unit uses commands like „Write value

1 to CV3!“ Each decoder that receives this command will also

execute it.

ESU counts the bits from 0 to 7 as specified in the DCC norm

while some manufacturers (e.g. Lenz) count the bits from 1 to 8.

Please keep this in mind when programming our decoders with

such systems.

7.2.1. Programming on the main track

The SwitchPilot can remain installed on your layout during the

programming. In order for the main track programming to work

your digital system must also understand „Programming on the

Main: (POM) for solenoid devices. In addition you must know

the decoder address of your SwitchPilot decoder.

Please make sure to carefully read Chapter 8 so you understand

the difference between turnout number and decoder address.

Thanks to the built-in RailCom® technology, ECoS owners with

firmware 1.1.0 or later can program the SwitchPilot while it is

installed on the layout. More can be find in chapter 11.

7.2.2. Programming on the programming track

For programming specific parameters of the decoder outputs the

SwitchPilot has to be programed on the programming track. This

is most practical prior to installation on the layout.

17

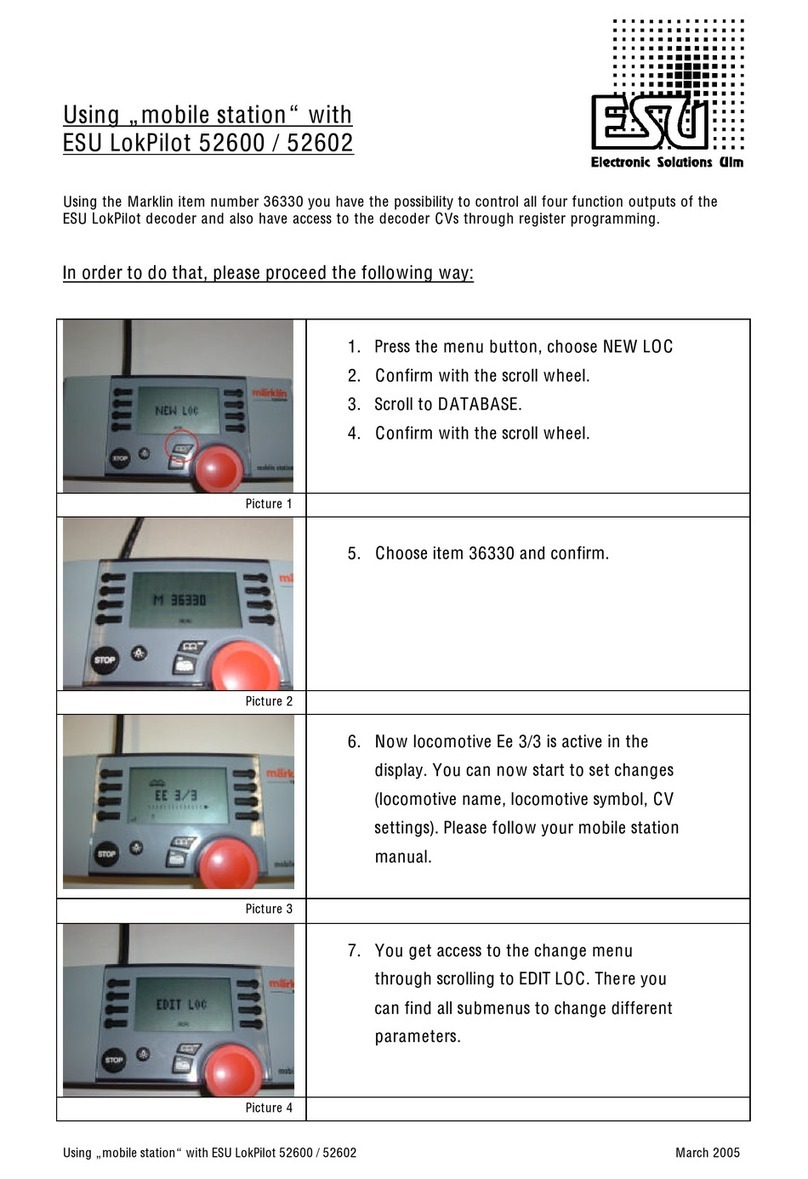

7.2.2.1. Connecting to the programming track

SwitchPilot

For programming please connect the SwitchPilot as shown in

figure 10 to your digital system. In this instance the power must

be supplied from the command station.

The SwitchPilot “understands” all relevant DCC programming

modes. It is best to program it in DCC Direct Mode.

In order to be able to read out any data you must connect a load

to output 1 Out A that draws more than 60 mA, for instance a

light bulb or a 180 Ohm / 1 Watt resistor.

SwitchPilot Servo

For programming please connect the SwitchPilot as shown in

figure 11 to your digital system. In this instance the power must

be supplied from the command station.

The SwitchPilot Servo “understands” all relevant DCC

programming modes. It is best to program it in DCC Direct Mode.

A load resistance with 180 ohm is already built in.

The reading of CVs should function with all DCC conformal

central units and was tested with ESU ECoS, Bachmann® Dyna-

mis ProBox®, Uhlenbrock® Intellibox® and Lenz® Digital Plus

V3®. Unfortunately, Digitrax® units do not supply enough current

on the programming output, ZIMO® units sometimes report an

over current. Therefore, use the main track programming 7.2.1.

7.3. Programming with Märklin® central stations

A direct programming possibility with a Marklin central unit (e.g

6021, Mobile Station®, Central Station®) is not possible due to

the missing DCC format. However, the most important properties

can still be changed.

SwitchPilot

The desired turnout numbers can be set directly with buttons.

Chapter 8.4 has more information. By means of the operating

mode switch you can chose between k83 or k84 mode (find

more 5.2.1).

SwitchPilot Servo

The desired turnout numbers can be set directly with buttons.

Chapter 8.4 has more information. The end positions and speeds

of all servos can be changed with the help of the input unit. See

Chapter 10.4.

For all options we recommend the use of the ESU Lokprogramer.

connect to programming

track output of digital system

Figure 11: SwitchPilot Servo connection to programming track

Figure 10: SwitchPilot connection to programming track

connect to programming

track output of digital system

180 Ohm

Always switch off servo

while programming!

18

7.4. Programming with the ESU LokProgramer

Owners of the ESU LokProgramer device are able to set up the

SwitchPilot decoders very comfortably. Please always use the latest

computer software. It can be downloaded from our website

without any charge.

8. Address settings

The numbers of the outputs of the SwitchPilot can be assigned

freely – within limits. Unfortunately, the DCC norm is not

comprehendible that easily so therefore we would like to explain

it here in detail and also have you very thoroughly work through

Chapter 8 in case you are not yet familiar with it.

8.1. Turnout numbers

The outputs of the SwitchPilot are numbered:

The SwitchPilot offers a total of 6 outputs:

Outputs 1 through 4 are double transistor outputs, outputs 5

through 6 are servo outputs.

All available turnouts are numbered in all DCC or Märklin® digi-

tal systems. The number of available turnout numbers is limited:

Motorola®: Turnout numbers 1 – 256

DCC: Turnout numbers 1 – 2040 Servo outputs:

In DCC or Märklin® Digital systems the available turnouts are

numbered. The number of available choices are limited numbers:

Motorola®: Turnout numbers 1 - 256

DCC: Turnout numbers 1 - 2040

All turnout numbers are summarized by addresses. Turnouts 1 –

4 form the first address, turnouts 5 – 8 the second one, etc.

In order to function properly each SwitchPilot must know the

address that is assigned to it.

Programming

SwitchPilot

Since the SwitchPilot has a total of six outputs two addresses

can be assigned to it: address 1 is responsible for the transistor

outputs 1 – 4, address 2 is for the servo outputs 5 – 6.

This logic means that the outputs (and therefore the turnout

numbers) of the SwitchPilot always start at the beginning of an

address on one hand, and that all outputs stay together in one

block on the other hand.

8.2. Decoder address

The desired address is divided internally and put into CV 1 and

CV 9. Please never mix up decoder address and the turnout

number resulting from it. Most digital systems (incl. the ECoS)

show the turnout numbers instead of the decoder addresses on

the control panels.

SwitchPilot

The second turnout address for the servo outputs 5 - 6 of the

SwitchPilot is stored in CV 35 and CV 36.

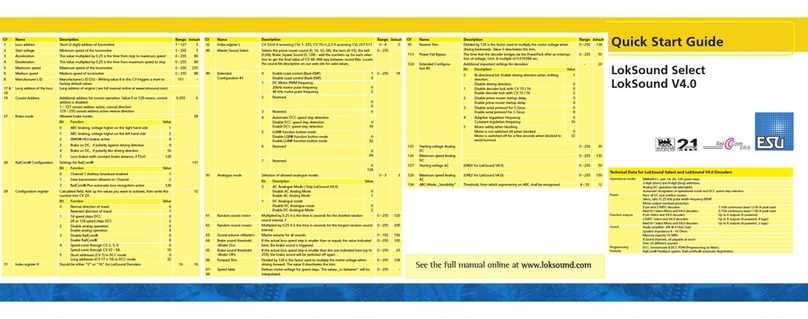

8.2.1. Schedule of turnout numbers and addresses

The relation between turnout numbers and turnout addresses is

explained in Figure 12 on page 19: The desired turnout numbers

are derived from the chosen turnout address. Only the first 256

turnouts are accessible when using Motorola® central units.

It is not possible to assign turnout numbers above the limit of 4

to a SwitchPilot. For example, it would not be possible to assign

turnout numbers 4, 5, 6, or 7 to a SwitchPilot servo since those

are above the address limit. Please keep this in mind when

numbering your turnouts.

The table only shows the first 552 turnout numbers. 2040 turnouts

are possible in DCC operation. A complete table can be found

on our web site.

19

TT

TT

Turur

urur

urnout numbernout number

nout numbernout number

nout number AddrAddr

AddrAddr

Addressess

essess

ess CV1CV1

CV1CV1

CV1 CV9CV9

CV9CV9

CV9

1234 1 10

5678 2 20

9101112 3 3 0

13 14 15 16 4 4 0

17 18 19 20 5 5 0

21 22 23 24 6 6 0

25 26 27 28 7 7 0

29 30 31 32 8 8 0

33 34 35 36 9 9 0

37 38 39 40 10 10 0

41 42 43 44 11 11 0

45 46 47 48 12 12 0

49 50 51 52 13 13 0

53 54 55 56 14 14 0

57 58 59 60 15 15 0

61 62 63 64 16 16 0

65 66 67 68 17 17 0

69 70 71 72 18 18 0

73 74 75 76 19 19 0

77 78 79 80 20 20 0

81 82 83 84 21 21 0

85 86 87 88 22 22 0

89 90 91 92 23 23 0

93 94 95 96 24 24 0

97 98 99 100 25 25 0

101 102 103 104 26 26 0

105 106 107 108 27 27 0

109 110 111 112 28 28 0

113 114 115 116 29 29 0

117 118 119 120 30 30 0

121 122 123 124 31 31 0

125 126 127 128 32 32 0

129 130 131 132 33 33 0

133 134 135 136 34 34 0

137 138 139 140 35 35 0

141 142 143 144 36 36 0

145 146 147 148 37 37 0

149 150 151 152 38 38 0

153 154 155 156 39 39 0

157 158 159 160 40 40 0

161 162 163 164 41 41 0

165 166 167 168 42 42 0

169 170 171 172 43 43 0

173 174 175 176 44 44 0

177 178 179 180 45 45 0

181 182 183 184 46 46 0

TT

TT

Turur

urur

urnout numbernout number

nout numbernout number

nout number AddrAddr

AddrAddr

Addressess

essess

ess CV1CV1

CV1CV1

CV1 CV9CV9

CV9CV9

CV9

185 186 187 188 47 47 0

189 190 191 192 48 48 0

193 194 195 196 49 49 0

197 198 199 200 50 50 0

201 202 203 204 51 51 0

205 206 207 208 52 52 0

209 210 211 212 53 53 0

213 214 215 216 54 54 0

217 218 219 220 55 55 0

221 222 223 224 56 56 0

225 226 227 228 57 57 0

229 230 231 232 58 58 0

233 234 235 236 59 59 0

237 238 239 240 60 60 0

241 242 243 244 61 61 0

245 246 247 248 62 62 0

249 250 251 252 63 63 0

253 254 255 256 64 0 1

257 258 259 260 65 1 1

261 262 263 264 66 2 1

265 266 267 268 67 3 1

269 270 271 272 68 4 1

273 274 275 276 69 5 1

277 278 279 280 70 6 1

281 282 283 284 71 7 1

285 286 287 288 72 8 1

289 290 291 292 73 9 1

293 294 295 296 74 10 1

297 298 299 300 75 11 1

301 302 303 304 76 12 1

305 306 307 308 77 13 1

309 310 311 312 78 14 1

313 314 315 316 79 15 1

317 318 319 320 80 16 1

321 322 323 324 81 17 1

325 326 327 328 82 18 1

329 330 331 332 83 19 1

333 334 335 336 84 20 1

337 338 339 340 85 21 1

341 342 343 344 86 22 1

345 346 347 348 87 23 1

349 350 351 352 88 24 1

353 354 355 356 89 25 1

357 358 359 360 90 26 1

361 362 363 364 91 27 1

365 366 367 368 92 28 1

TT

TT

Turur

urur

urnout numbernout number

nout numbernout number

nout number AddrAddr

AddrAddr

Addressess

essess

ess CV1CV1

CV1CV1

CV1 CV9CV9

CV9CV9

CV9

369 370 371 372 93 29 1

373 374 375 376 94 30 1

377 378 379 380 95 31 1

381 382 383 384 96 32 1

385 386 387 388 97 33 1

389 390 391 392 98 34 1

393 394 395 396 99 35 1

397 398 399 400 100 36 1

401 402 403 404 101 37 1

405 406 407 408 102 38 1

409 410 411 412 103 39 1

413 414 415 416 104 40 1

417 418 419 420 105 41 1

421 422 423 424 106 42 1

425 426 427 428 107 43 1

429 430 431 432 108 44 1

433 434 435 436 109 45 1

437 438 439 440 110 46 1

441 442 443 444 111 47 1

445 446 447 448 112 48 1

449 450 451 452 113 49 1

453 454 455 456 114 50 1

457 458 459 460 115 51 1

461 462 463 464 116 52 1

465 466 467 468 117 53 1

469 470 471 472 118 54 1

473 474 475 476 119 55 1

477 478 479 480 120 56 1

481 482 483 484 121 57 1

485 486 487 488 122 58 1

489 490 491 492 123 59 1

493 494 495 496 124 60 1

497 498 499 500 125 61 1

501 502 503 504 126 62 1

505 506 507 508 127 63 1

509 510 511 512 128 0 2

513 514 515 516 129 1 2

517 518 519 520 130 2 2

521 522 523 524 131 3 2

525 526 527 528 132 4 2

529 530 531 532 133 5 2

533 534 535 536 134 6 2

537 538 539 540 135 7 2

541 542 543 544 136 8 2

545 546 547 548 137 9 2

549 550 551 552 138 10 2

Figure 12: Turnout number, adresses & CVs of the first 552 turnouts

20

8.3. Factory settings

SwitchPilot

The four transistor outputs 1 to 4 react ex works to the turnout

numbers 1 to 4 with all outputs set to single pulse mode with

520 msec pulse duration. Address „1“ belonges to the

SwitchPilot.

The servo outputs 5 – 6 are deactivated ex works. There is no

second address to be allocated.

SwitchPilot Servo

The four servo outputs 1 to 4 react ex works to the turnout

numbers 1 to 4 and require 3.75 sec for a full movement with

both end positions being about 50% of the possible distance of

the starting point. Address „1“ belonges to the SwitchPilot

Servo.

8.4. Programming addresses with the programming button

You may program the addresses with the help of the programming

button without any complicated procedure on the programming

track. We recommend to proceed as follows:

You must use this method if you work with a Märklin® Motorola®

central unit (6021, Central Station®) or if you want to change

the addresses of the turnouts after installation of the decoder on

your layout.

8.4.1. First address for outputs 1 – 4

SwitchPilot SwitchPilot Servo

1. Select the turnout number on your digital system that you

want to assign to the first output of your SwitchPilot. Proceed

as per the instructions of your handheld throttle or your

command station as if you wanted to switch the respective

turnout (for ECoS users: refer to chapter 13 in the ECoS manual).

2. Turn on the power supply of your layout.

3. Press the programming button and hold it long enough until

(after about two seconds) the LED blinks as follows: short,

pause, short, pause, and so on.

4. You may now release the button, the decoder is in learning

mode.

5. Now switch the turnout you have selected in step 1 on your

handheld controller or your command station. It is immaterial

whether you switch from “straight” to “diverging route” or

vice versa.

6. Once the decoder has “understood” the address it will confirm

this by lighting up the LED for one second.

7. Then the SwitchPilot goes back to the normal operating mode

and the LED extinguishes.

Should you have programed another turnout instead of the first

one of the group of four the correct group will be automatically

detected and programed.

8.4.2. Second address for outputs 5 - 6

SwitchPilot

The second address is used for the (servo) outputs 5 and 6. Always

select turnout numbers at the beginning of a group of four, e.g.:

1 and 2, 5 and 6, 9 and 10, 13 and 14, etc.

1. Select the turnout number with your digital system that you would

like to assign to output 5 (first servo) of the SwitchPilot. Proceed

as per the instructions of your handheld controller or your

command station as if you wanted to switch this particular turn-

out (ECoS users please also refer to chapter 13 in the manual).

2. Turn on the power for your layout.

3. Press the programming button and hold it down until (after about

four seconds) the LED blinks as follows: short, short, pause, short,

short, pause, and so on.

4. Then you may release the button; the decoder is now in learning mode.

5. Switch the turnout you have selected in step 1 with your hand

held or the command station. It is immaterial if you switch from

“straight” to “diverging route” or vice versa.

6. If the decoder has “understood” the address it confirms this by

the LED lighting up for about one second.

7. The SwitchPilot then goes back to the normal operating mode

and the LED extinguishes.

Programming

This manual suits for next models

5

Table of contents

Other Esu Media Converter manuals

Esu

Esu LokSound micro V4.0 User manual

Esu

Esu LokPilot mfx User manual

Esu

Esu LokPilot V4.0 User manual

Esu

Esu 51801 User manual

Esu

Esu L.Net converter User manual

Esu

Esu LokPilot V3.0 User manual

Esu

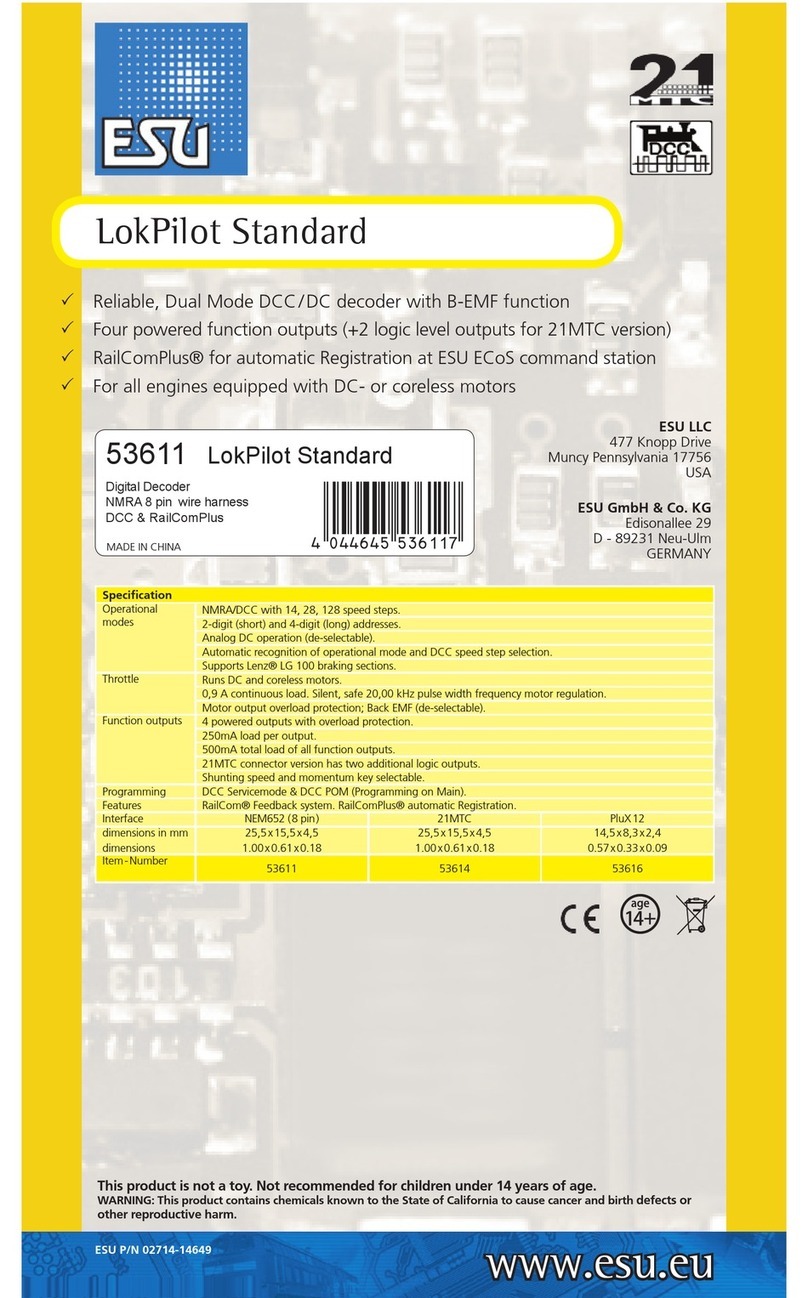

Esu LokPilot Standard User manual

Esu

Esu SwitchPilot 3 51830 User manual

Esu

Esu LokSound V3.0 User manual

Esu

Esu LokPilot V2.0 User manual