4user manual LokSound / LokSoundXL V3, 1st edition, 07/2004

2. Characteristics of the LokSound decodersCharacteristics of the LokSound decoders

Characteristics of the LokSound decodersCharacteristics of the LokSound decoders

Characteristics of the LokSound decoders

The LokSound decoder is a universal electronic module

for installation in model engines of most common

scales. We recommend LokSound for all engines in TT,

HO gauge as well as smaller engines in O gauge.

LokSoundXL is best suited for larger scales such as O,

I, II and G gauge. ESU LokSound decoders

revolutionize any model train layout. They intelligently

combine a sophisticated digital decoder and a digital

sound module. With LokSound you can run your

engine with load control and many auxiliary functions

while enjoying the original sound of the prototype.

Its unique features provide flexibility and safety in

operation that you have come to expect from a state-

of-the-art decoder. Even future standards are no

problem for LokSound: its flash technology allows

adaptation to the latest developments.

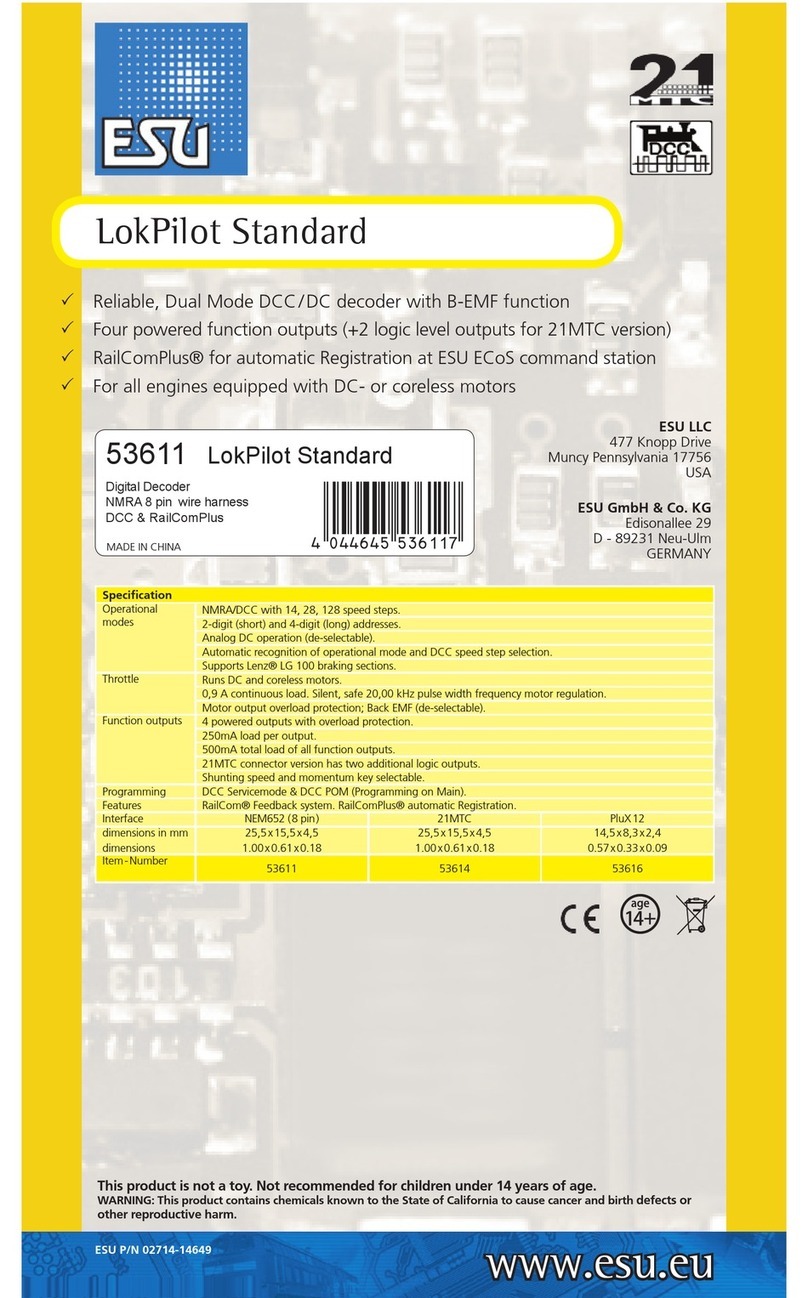

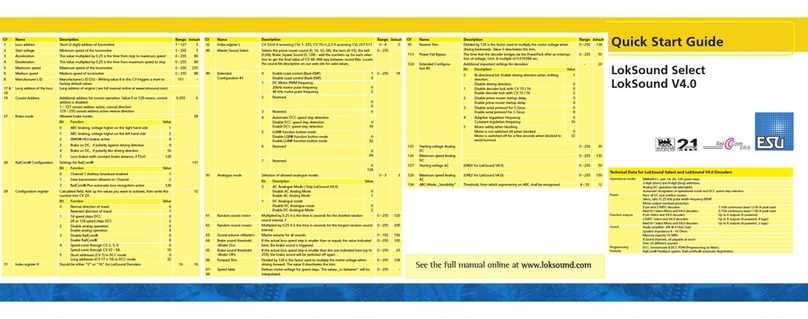

Multi-protocol operation: LokSound decoders und-

erstand both, the commonly used Märklin® /

Motorola® – format and the NMRA / DCC - system.

Thus LokSound may be used with almost all currently

available digital command control systems. Amongst

others LokSound was tested with:

• Arnold Digital® (DCC system)

• Lenz Digital Plus®

• ROCO® digital is cool®

• Märklin® 6021

• Uhlenbrock® Intellibox (DCC+ Motorola® system)

• ZIMO MX-1 (DCC-Betrieb)

• Fleischmann® Twin-Center

• LGB MZS Steuerung

Automatic change between all four operating modes

during operation (AC analogue, DC analogue, DCC

digital, Märklin® digital)

Universal motor connection: All types of motors

commonly used for model trains may be connected

to LokSound:

• DC motors (e.g. Bühler, Mabuchi)

• Coreless motors (e.g. Faulhaber, Maxxon)

• Alternating current

High motor pulse frequency: The pulse frequency of

32 kHz (!) assures absolutely smooth running. Thus

the motor runs silently and without any whine, heat

generation is minimized and lifetime is prolonged. Even

coreless motors may be operated with LokSound

decoders without any problem.

Characteristics of the LokSound decodersCharacteristics of the LokSound decoders

Characteristics of the LokSound decodersCharacteristics of the LokSound decoders

Characteristics of the LokSound decoders

Motor control: LokSound offers fourth generation

load control. It may be adapted to suit each individual

motor and can be switched off. Suitable for DC motors

and coreless motors. Therefor your engine will always

travel at the selected speed, no matter how large the

load is or whether the engine is traveling up or down

gradients.

4 function outputs: In addition to the two lighting

outputs, two more function outputs are available:

switch on a smoke generator or the interior lighting

or activate a digital coupler by pressing a button!

Lighting effects and individually dimmable lamps help

to make your models even more prototypical and you

will have lots of fun.

Brake sections: LokSound decoders recognize (and

respond to) the most common brake systems: besides

the Lenz brake generator, the Märklin® brake track

is also supported.

Circuit protection: the motor output and all function

outputs are protected against short circuit.

Please make sure that the total current does not

exceed the maximum permitted current for the

function outputs and avoid short circuits

between the outputs: LokSound circuits are

protected, but an external voltage at the terminals

of a function output may destroy the circuitry.

Analogue operation: LokSound decoders may be

operated on AC- and DC layouts without any problems.

Easy programming: Even with Märklin® 6021 all

functions may be changed comfortably without

opening the engine.

A digital, four-tone sound module with unique

characteristics:

Prototype sounds: sounds of prototype engines were

sampled using high fidelity microphones and recorded

digitally on the flash memory module. Thus your

engines sound exactly like the prototype!

With four independent channels your engine sounds

even more realistic since you can simultaneously add

3 sound effects to the running sound. Pumps, power

switches and squealing brakes can all be heard at the

same time. The exhaust chuffs of steam engines vary

with the revs of the drivers and the load. Now you

can really hear your engine work. Diesel engines can

now simulate the reduced revs of the diesel while the

engine is coasting. The running sound and the sound