Esu SwitchPilot 3 51830 User manual

Instruction manual

1. Edition, January 2021

P/N 00221-24443

From Decoder Firmware 3.0.9

51830 SwitchPilot 3

SwitchPilot 3

SWitch Pilot

2

1. Declaration of Conformity ...................................... 3

2. WEEE-Erklärung ....................................................... 4

3. Important Notes ...................................................... 4

4. Features .................................................................. 5

4.1. General Features...........................................................5

4.2. Technical Data...............................................................5

4.3. Scope of delivery...........................................................5

4.4. Operating modes..........................................................6

4.4.1. Pulse operation..........................................................6

4.4.2. Operating PECO turnout drives .................................7

4.4.3. K83 operation (momentary action mode)...................7

4.4.4. K84 Operation (Bistable continuous operation) ..........8

4.4.5. Alternate flasher mode ..............................................9

4.4.6. Operating mode switch .............................................9

5. Connection to the digital system ......................... 10

5.1. Terminals ....................................................................10

5.2. Power supply by the digital system..............................11

5.3. External power supply ...............................................11

5.4. Wiring the outputs .....................................................12

5.4.1. Solenoid turnout drives............................................12

5.4.2. Daylight signals with incandescent lamps or LEDs ....12

5.4.3. Uncoupling tracks....................................................13

5.5. Wiring the feedback contacts .....................................13

5.6. Connecting the SwitchPilot Extension .........................14

5.6.1. Relay outputs...........................................................14

5.6.2. Motorized turnout drives .........................................14

5.6.3. LGB® Turnout drive .................................................15

5.6.4. Turnout frog polarization .........................................15

6. Configuration with OLED...................................... 16

6.1. Relationship between accessory addresses and turnout

numbers ............................................................................16

6.1.1. Assigning turnout numbers......................................17

6.2. Introduction to the operating structure.......................18

6.3. Address mode for ROCO® command stations ............19

Content

6.4. Configuring outputs ...................................................19

6.5. Setting fade-in and fade-out times..............................20

6.6. Status information ......................................................20

6.6.1. Display software version & track voltage ..................20

6.6.2. Displaying output states...........................................20

6.6.3. Viewing feedback input states .................................21

7. Configuration with LokProgrammer.................... 21

8. Configuration POM (Programming on the Main)22

8.1. Connection to the digital system.................................22

8.2. Reading and writing CVs with POM ..........................22

9. Configuration with the programming track........ 23

9.1. Connection to the digital system.................................23

9.2. Read & Write CVs .......................................................23

10. Learning turnout numbers from command station ...23

11. RailCom® ............................................................. 24

11.1. RailCom® Configuration ........................................24

11.2. Turnout status feedback with the ECoS.....................24

12. Reset to factory default (decoder reset)............ 25

12.1. With the programming button..................................25

12.2. With DCC systems ....................................................25

12.3. With the display........................................................25

14. Support ................................................................. 26

16. Solenoid address & turnout numbers ................ 30

17. List of all supported CVs...................................... 32

18. Change history..................................................... 34

19. Warranty certificate............................................. 35

3

Declaration of Conformity

1. Declaration of Conformity

The manufacturer, ESU electronic solutions ulm GmbH & Co. KG,

Edisonallee 29, D-89231 Neu-Ulm, hereby declares under its sole

responsibility that the product

Product name: SwitchPilot 3

Type: 51830

complies with all relevant provisions of the Electromagnetic Com-

patibility Directive (2004/108/EC). The following harmonised stan-

dards have been applied:

EN 55014-1:2006 + A1:2009: Electromagnetic compatibility -

Requirements for household appliances, power tools and similar

electrical appliances - Part 1: Interference emission

EN 55014-2:1997 + A1:2001 + A2:2008: Electromagnetic compa-

tibility - Requirements for household appliances, power tools and

similar electrical appliances - Part 2: Immunity.

Copyright 1998 - 2021 by ESU electronic solutions ulm GmbH & Co KG. Irrtum, Änderungen die dem technischen Fortschritt dienen, Liefermöglichkeiten und alle sonstigen

Rechte vorbehalten. Elektrische und mechanische Maßangaben sowie Abbildungen ohne Gewähr. Jede Haftung für Schäden und Folgeschäden durch nicht bestimmungs-

gemäßen Gebrauch, Nichtbeachtung dieser Anleitung, eigenmächtige Umbauten u. ä. ist ausgeschlossen. Nicht geeignet für Kinder unter 14 Jahren. Bei unsachgemäßem

Gebrauch besteht Verletzungsgefahr.

Märklin® und mfx® sind eingetragene Warenzeichen der Firma Gebr. Märklin® und Cie. GmbH, Göppingen. RailCom® ist ein eingetragenes Warenzeichen der Firma

Lenz® Elektronik GmbH, Gießen.

Alle anderen Warenzeichen sind Eigentum ihrer jeweiligen Rechteinhaber.

ESU electronic solutions ulm GmbH & Co. KG entwickelt entsprechend seiner Politik die Produkte ständig weiter. ESU behält sich deshalb das Recht vor, ohne vorherige

Ankündigung an jedem der in der Dokumentation beschriebenen Produkte Änderungen und Verbesserungen vorzunehmen.

Vervielfältigungen und Reproduktionen dieser Dokumentation in jeglicher Form bedürfen der vorherigen schriftlichen Genehmigung durch ESU.

4

WEEE Declaration Features

2. WEEE-Erklärung

Disposal of old electrical and electronic equipment (valid in the

European Union and other European countries with separate coll-

ection system).

This symbol on the product of the packaging or in

the documentation means that this product must

not be treated as household waste. Instead, this pro-

duct is to be taken to the appropriate disposal point

for recycling electrical and electronic equipment. If

the product is disposed of correctly, you help to pre-

vent negative environmental influences and damage to health that

could be caused by improper disposal. Recycling material will pre-

serve our natural resources. For more information about recycling

this product, please contact your local citizens‘ office, household

waste collection service or the store where you purchased this

product.

3. Important Notes

Congratulations on your purchase of an ESU SwitchPilot 3 deco-

der. This manual wants to introduce you step by step to the possi-

bilities of the decoder. Therefore, a request:

Please carefully work through this manual prior to commissioning.

Although all SwitchPilot decoders are very robust, a wrong con-

nection could destroy the device. If in doubt, avoid „expensive”

experiments.

•The SwitchPilot is intended exclusively for use with electric model

railway layouts. It may only be operated with the components de-

scribed in this manual. Any use other than that described in this

manual is not permitted.

•All connection work may only be carried out when the operating

voltage is switched off.

•The power supply units must be protected in such a way that in

the event of a short circuit, there is no risk of a cable fire. Use only

commercially available model train transformers manufactured ac-

cording to the VDE/EN standards, bearing the CE mark.

•Never operate the SwitchPilot unattended. The SwitchPilot is not

a (children’s) toy.

•Follow the principles of this manual when connecting the external

components. The use of other circuits may cause damage to the

decoder.

•The SwitchPilot is not waterproof: outdoor use is not intended and

is done at your own risk.

•Do not attempt to open your SwitchPilot module. Improper treat-

ment can destroy it.

5

Features

4. Features

ESU SwitchPilot 3 decoders are optimized for stationary use on

your model train layout and can switch conventional solenoid

turnout drives, daylight signals, magnetic uncouplers, incande-

scent lamps (bulbs) or other stationary electric loads.

4.1. General Features

The SwitchPilot 3 has 8 transistor outputs for switching up to 4

solenoid accessories (e.g.: turnouts) or 8 other electric loads such

as uncoupling tracks or incandescent lamps. Each output can be

individually programmed for the purpose of use and is electroni-

cally protected against overload and short circuit.

The SwitchPilot 3 can receive its power directly from the digital

system or an external DC or AC power supply.

SwitchPilot 3 supports multi-protocol operation and can be used

with central units supporting the Märklin® Motorola® system

(e.g.: 6021, Central Station® or Mobile Station®) as well as DCC

enabled command stations. Configuration can be carried out on

the main (POM – Programming on the Main) and the program-

ming track. Thanks to RailCom®, CVs can also be read out.

Operation with the Roco® Lokmaus 2 is not possible: The Lok-

maus 2 sends only DCC locomotive commands instead of the re-

quired accessory commands.

If desired, a SwitchPilot 3 can transmit feedback reporting the

turnout status directly to the ECoS command station via Rail-

Com®.

For simplifying the rather cumbersome configuration of accessory

decoders, the SwitchPilot 3 has an innovative operating concept

consisting of a 4-line, illuminated OLED display and three input

buttons. All settings can be checked directly on the decoder at

any time with the help of the display and changed, if so desired.

„Programming” with the help of your command station is not

required. It cannot get any easier.

4.2. Technical Data

SwitchPilot 3

Input voltage 12V - 20V DC power supply

12V - 16V AC power supply

Digital track voltage

Outputs 8 Transistor outputs

Maximum load 1.5A each (2.5A for

100msec) arranged in 4 groups as a pair

Short-circuit and overload-protected

Output power Complete module 2A (2.5A for 100msec)

Feedback inputs 8 inputs for turnout status.

Query via RailCom® with ECoS possible

Operating modes DCC „Accessory Decoder” with Rail-

Com® (addressing according to RCN-213

or ROCO®). Turnout numbers 1 - 2048.

Märklin® Motorola®. Turnout numbers

1 - 256. K83 and K84 operating modes.

Configuration 0.91” OLED display with 3 buttons

Dimensions 86mm x 86mm x 25mm

4.3. Scope of delivery

The SwitchPilot 3 is supplied with 5 detachable terminal blocks (1x

4-pole for the track connection, 4x 5-pole for the outputs) as well

as this operating manual. Under part number 51800.SP.01 a pack

of replacement terminal blocks is available from ESU.

6

4.4. Operating modes

The SwitchPilot 3 has a total of 8 transistor outputs, which are

grouped in 4 output pairs 1 to 4. Each output pair contains two

outputs (Out A and Out B) and can be configured individually to

suit the desired application. The following operating modes are

possible:

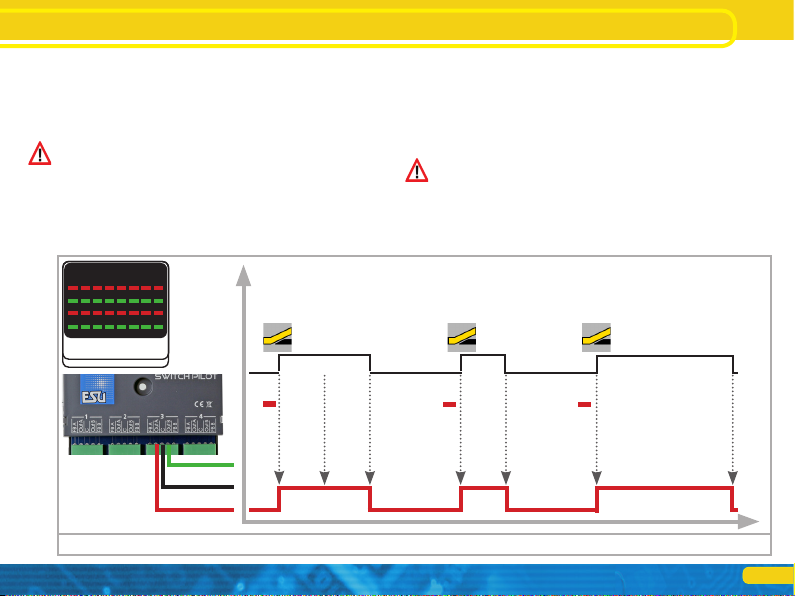

4.4.1. Pulse operation

If the output is configured for pulse operation, the output is swit-

ched on as soon as an appropriate command is received. At the

same time, a timer automatically turns off the output as soon as a

predetermined time (pulse time) saved in the decoder has elapsed,

even if the button (on the command station or control panel) has

been released beforehand. If the button is pressed longer than the

Operating modes

pre-determined pulse time, the output will still be switched off.

Limiting the switch-on time prevents accessories to blow.

Optionally, the output can also be slowly dimmed up and dimmed

down (so-called „zoom” for incandescent lamp simulation).

The pulse operation is the default setting of the SwitchPilot 3 and

is ideal for controlling solenoid turnout drives.

Some DCC command stations (e.g.: by Lenz) repeat the power

command in a fixed rhythm until the button is released. With each

power-on command received, the SwitchPilot 3 resets the stop-

watch. This is shown in Fig. 1.

Figure 1: Pulse operation

keyboard

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

time

on

off

1

RED

ON

1

RED

OFF

1

(RED

ON)

(Lenz)

Impulse-Time

1

RED

ON

1

RED

OFF

Impulse-Time

1

RED

ON

1

RED

OFF

Impulse-Time

7

4.4.2. Operating PECO turnout drives

The PECO mode corresponds to the afore mentioned pulse ope-

ration with the exception that to increase the peak current the

overcurrent protection of the output pair is switched off and the

pulse time is fixed to a relatively short time span. This short current

surge is used to optimally control the PECO drives.

Incorrect wiring or a short circuit at an output in PECO mode can

destroy the SwitchPilot 3 decoder!

4.4.3. K83 operation (momentary action mode)

In K83 mode, the output remains active until the button on the

command station or control panel is released. This operating

mode is suitable for turnout drives with end position shutdown

or for uncoupling tracks.

Optionally, the output can also be slowly dimmed up and dimmed

down (so-called „zoom” for incandescent lamp simulation).

K83 operation may cause problems with older DCC command sta-

tions, because they do not transmit the required „Off” command

(e.g.: older Lenz command stations).

Figure 2: K83 operation (momentary action mode)

keyboard

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

time

on

off

1

RED

ON

1

RED

OFF

1

(RED

ON)

(Lenz) 1

RED

ON

1

RED

OFF

1

RED

ON

1

RED

OFF

Operating modes

8

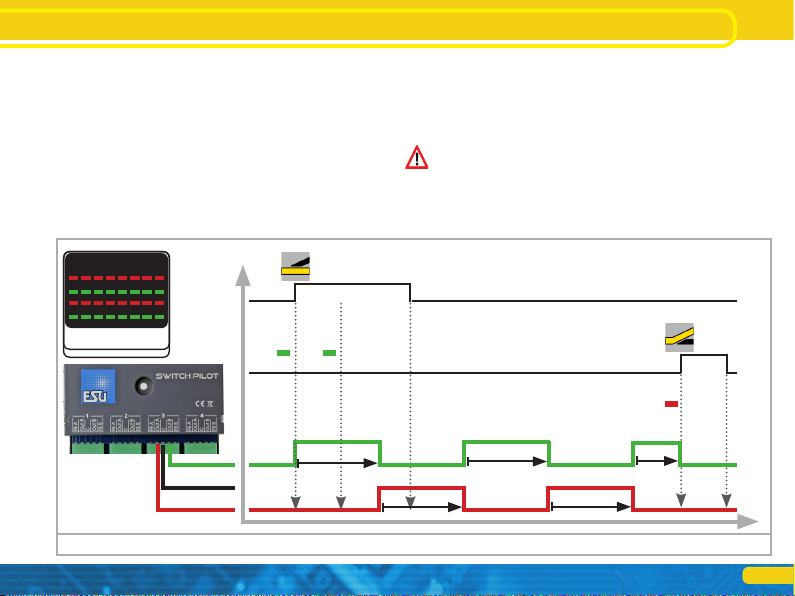

4.4.4. K84 Operation (Bistable continuous operation)

In K84 mode, the two outputs are alternately switched on and

off: When pressing the first button (red) on the command station,

the Output Out A is turned on. It remains active until pressing the

assigned button (green) activates the output Out B of the same

output group. Out A and Out B behave like a change-over switch.

Optionally, the output can also be slowly dimmed up and dimmed

down (so-called „zoom” for incandescent lamp simulation).

The K84 operation is well suited for lighting applications or two-

aspect daylight signals.

The logic of this mode of operation corresponds to the Märklin®

k84 decoder.

Figure 3: K84 operation (Bistable continuous operation)

keyboard

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

time

on

off

1

RED

ON

1

RED

OFF

1

(RED

ON)

(Lenz)

1

GREEN

ON

1

(GREEN

ON)

(Lenz)

1

GREEN

OFF

1

RED

ON

Operating modes

9

4.4.5. Alternate flasher mode

In this mode, the outputs Out A and Out B of an output pair are

switched on alternately with an adjustable flashing frequency. The

alternate flasher is started with the command „Straight/Green” of

the assigned button and stopped again with the command „Di-

verging/Red”.

Optionally, the output can also be slowly dimmed up and dimmed

down (so-called „zoom” for incandescent lamp simulation).

The alternating flasher operation is ideal for illuminating St.

Andrew´s crosses at level crossings.

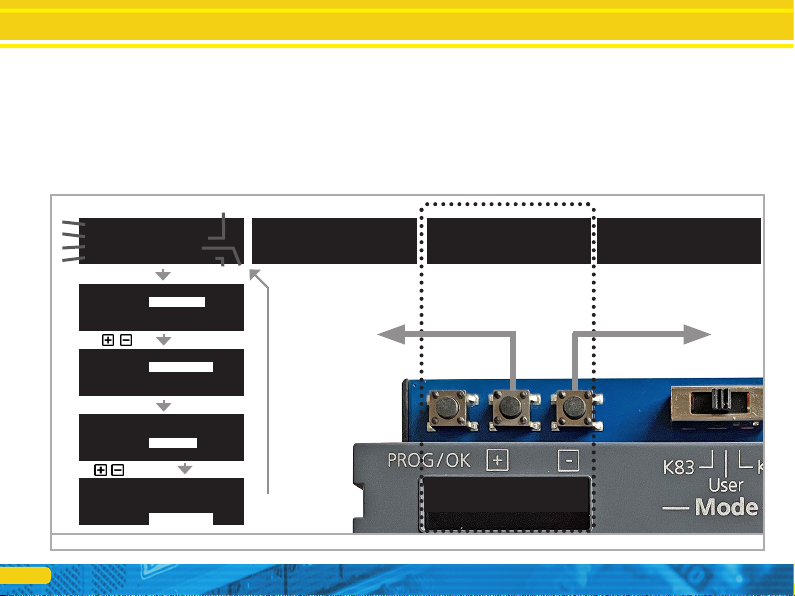

4.4.6. Operating mode switch

With the decoder´s mode switch, you can quickly switch all output

pairs simultaneously to the „k83” or „k84” mode, regardless of

how they might be configured.

Only in the center position „USER” (default setting ex works) the

outputs will behave as programmed in the decoder configuration.

Any configured „zoom” effects are ignored when the mode

switch forces the decoder hard into k83 or k84 mode.

Figure 4: Alternate flasher mode

keyboard

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

time

on

off

1

RED

ON

1

RED

OFF

1

GREEN

ON

1

(GREEN

ON)

(Lenz)

1

GREEN

OFF

Flash-Time

Flash-Time

Flash-Time

Flash-Time

Stop

Operating modes

10

5. Connection to the digital system

We recommend that you first configure the SwitchPilot 3 decoder

completely and then install it on the layout.

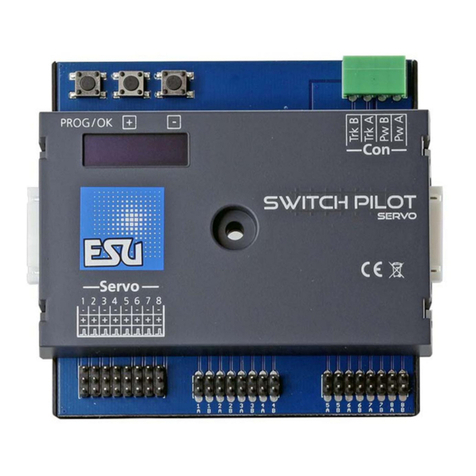

5.1. Terminals

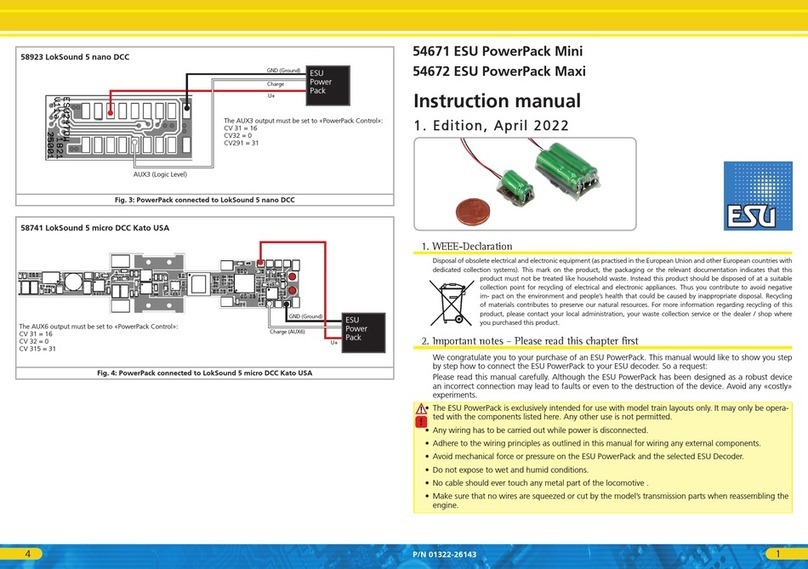

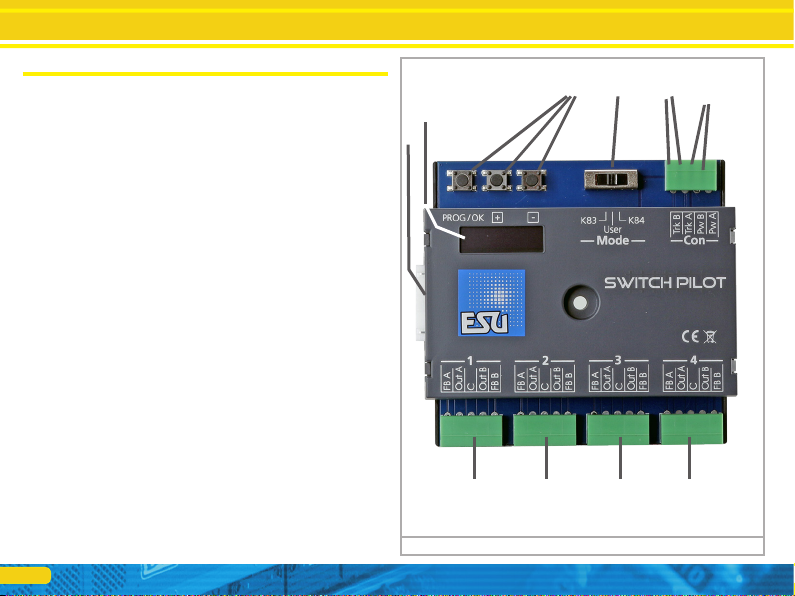

Fig. 5 shows the SwitchPilot 3 with all terminals.

a) Turnouts, daylight signals, uncouplers and similar electric loads

shall be connected to the terminals labelled 1 to 4 for the out-

put pairs 1 to 4. The respective terminals FB A and FB B are

required for providing feedback from the turnout drive to the

SwitchPilot 3.

b) The power supply of the SwitchPilot 3 including all connected

loads is realized vie the Terminals Pw A and Pw B. You can eit-

her use the track voltage or use an external power supply. We

recommend an external power supply, particularly for larger

layouts, because then the energy for powering the drives does

not add to the load for the command station or booster.

c) Connect the Terminals Trk A and Trk B to the track output of

the command station (or booster) that controls the SwitchPilot

3.

d) As described in chapter 4.4.6., the outputs can be configured

simultaneously with the operating mode switch.

e) Input unit. The three buttons PROG/OK as well as (+) and (-)

serve to configure the decoder, as explained in chapter 6.

f) The display shows all settings of the decoder including turnout

address and status of the outputs. After a few seconds, the

screen saver displays the supply voltage.

g) Extension socket for the SwitchPilot Extension relay module.

Figure 5: Terminals of the SwitchPilot 3

Connection to the digital system

g)

f)

e) d) c) b)

a) a) a) a)

11

Connection to the digital system

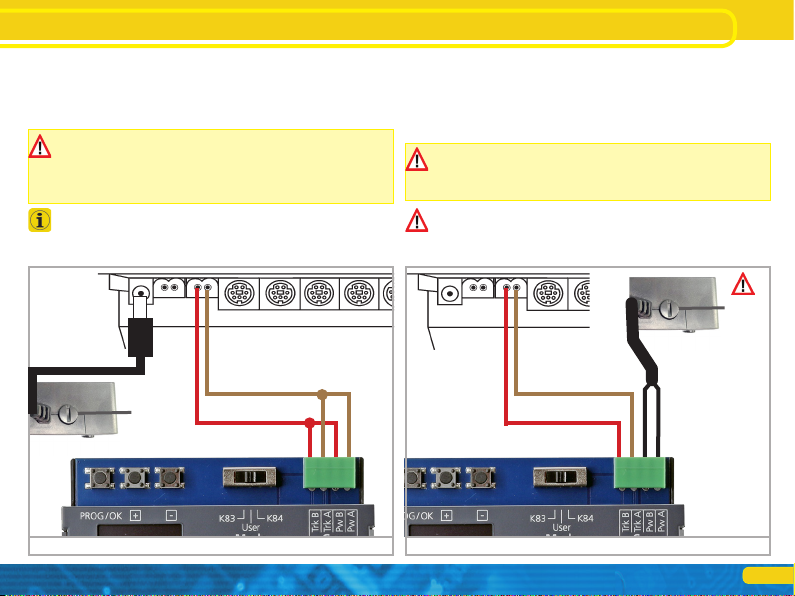

5.2. Power supply by the digital system

For smaller layouts with only a few electric loads turned on at the

same time, the SwitchPilot 3 can be supplied directly from the

command station or booster. The terminals Pw A and Pw B are

connected parallel to the terminals Trk A and Trk B.

If accessories (e.g.: Märklin® K track) do not switch at all or only

respond with little power, check the track voltage and increase

it, if necessary. The SwitchPilot 3 can display the supply voltage

as described in chapter 6.8.1. If the voltage cannot be increased,

please use an external power supply.

This wiring scheme must be used if you want to configure the

SwitchPilot 3 on the programming track of your command station.

For more information, see Chapter 9.

5.3. External power supply

For larger layouts with many electric loads, we recommend the

use of an external power supply. DC and AC power supplies are

suitable with the specifications described in chapter 4.2. We re-

commend the use of a stabilized DC power supply with at least

18V DC at least 3A output power (e.g.: ESU part number 50119).

For switching Märklin® K track drives a minimum of 18V is

required. Keep this in mind when choosing the transformer!

The SwitchPilot 3 can display the supply voltage as described

in chapter 6.8.1.

This type of wiring cannot be used for programming on the pro-

gramming track. In this case, a temporary connection must be

established as shown in chapter 5.2.

B 0

Main track exit

min. 18V

B 0

Main track exit

min. 18V

Stabilized DC

power supply

recommended

Figure 6: Supply from the digital system Figure 7: Separate (external) power supply

12

Wiring the outputs

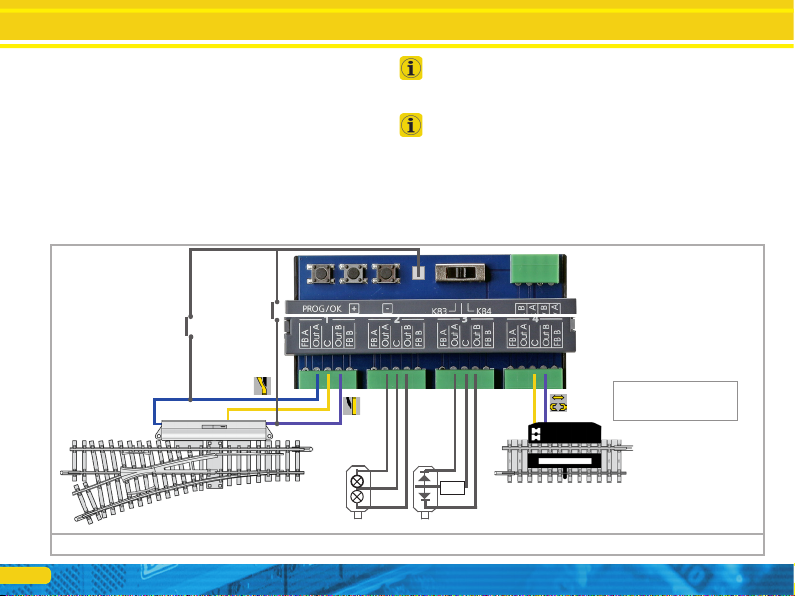

5.4. Wiring the outputs

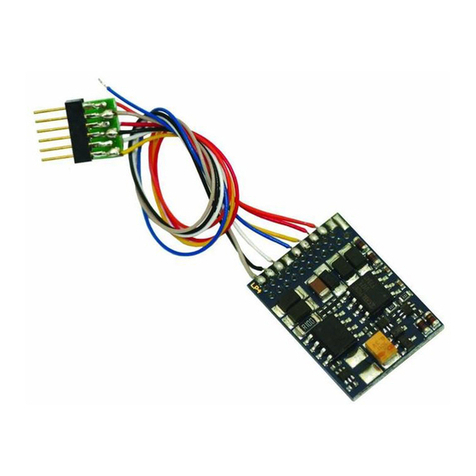

5.4.1. Solenoid turnout drives

You may use any of the commercially available solenoid turnout

drives from the well-known manufacturers with the SwitchPilot 3.

Figure 8 shows the wiring of a turnout at output 1.

a) The common wire from the two coils is connected to terminal

C.

b) Terminal Out A is connected to the wire for the diverging route.

c) Terminal Out B is connected to the wire for the straight route.

Should the turnout not be aligned as you intended after pressing

the respective button on your command station respectively con-

trol panel (diverging and straight route are reversed), please swap

the wires at terminals Out A and Out B.

The power consumption of PECO switch drives is so high that the

PECO operating mode must be set.

5.4.2. Daylight signals with incandescent lamps or LEDs

If you are using daylight signals with incandescent lamps (bulbs)

or LEDs (light-emitting diodes), the corresponding output must be

configured in the K84 mode (Bistable continuous operation).

Incandescent lamps, as shown in Figure 8, Output 2, may be di-

rectly connected to the SwitchPilot 3.

Figure 8: Wiring the outputs

R

For uncouplers:

K83 operation (momentary

operation) to adjust.

Example for output 4:

OUTPUT 4

MODE :K83

Time :Permanent

Zoom :Disabled

Triggering also by

Button possible.

13

Wiring the outputs

If, on the other hand, signals or lighting with LEDs are used (as

shown in Figure 8, Output 3), a series resistor must be used to

limit the current. The resistance value depends to a large extent

on the type of LED used, so no precise statement is possible here.

Values between 1 kOhm and 10 kOhm are common. If in doubt,

start with a higher value.

The terminal C of the output is the „+” pole. Therefore, the catho-

de of the LED must be connected to the terminals Out A or Out B.

5.4.3. Uncoupling tracks

The momentary action mode is suitable for uncoupling tracks, as

the coil will be active only until the button is released. The wiring

is as shown in Fig. 8, Terminal 4. You can use either Terminal Out A

or Out B, depending on whether you want to activate the uncoup-

ler with the „diverging” or „straight” turnout button.

b)

or

a)

Figure 9: Connection of the turnout feedback

5.5. Wiring the feedback contacts

The SwitchPilot 3 can report the actual turnout status to the ESU

ECoS command station via RailCom®. For this purpose, however,

the turnout must have appropriate mechanical feedback contacts.

Figure 9 illustrates the scenario.

a) Connection of a turnout drive with limit stop contacts. Con-

nect terminals Out A to FB A and Out B to FB B.

b) Connection to drives with separate feedback contacts: Here

you wire the two feedback contacts to the terminals FB A and

FB B respectively, and the common wire of the feedback to

terminal C.

You will find more information on turnout feedback to the ESU

ECoS via RailCom® in chapter 11.

14

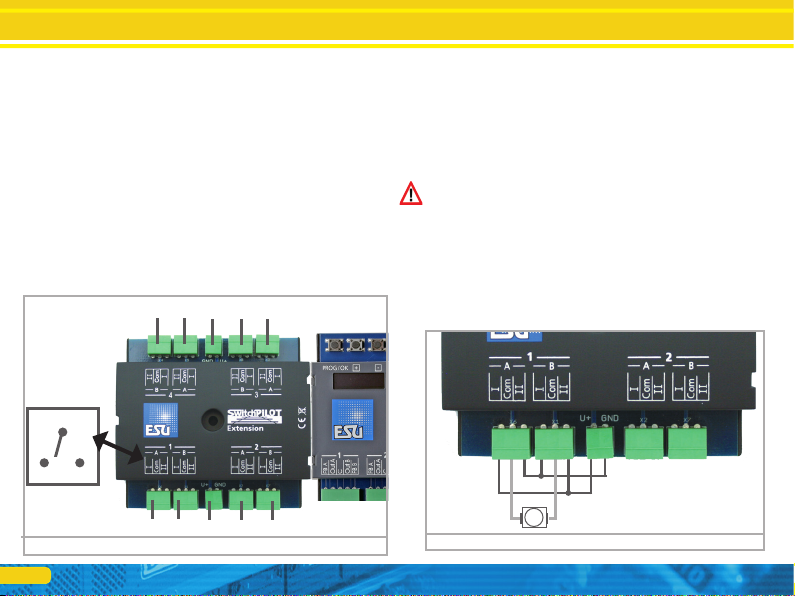

5.6. Connecting the SwitchPilot Extension

The SwitchPilot Extension module is docked sideways to the

SwitchPilot 3; press the extension module with the 8-pin plugs

against the SwitchPilot 3 until the retaining clips of the plugs snap

in. The internal electronics and relay coils of the SwitchPilot Exten-

sion module are powered by the SwitchPilot 3.

5.6.1. Relay outputs

Fig. 10 shows the connections:

a) The outputs 1 to 4 are connected to relay outputs A and B,

which are activated jointly (2x change-over contacts, bistable).

Each relay output corresponds to the corresponding transistor

output of the SwitchPilot 3. If the output Out A of the Switch-

Pilot 3 is active, the terminals Iand COM of the relay output

are also active. If the output Out B on the SwitchPilot 3 is

active, terminals II and COM are also active.

b) Terminals for ground and „U+” (rectified track voltage, sup-

plied by SwitchPilot 3) for powering DC turnout motors.

5.6.2. Motorized turnout drives

Motorized turnout drives can be controlled with the help of the

SwitchPilot Extension module. Reversing the operating voltage of

the electric motor changes the direction of rotation of the mo-

tor, thereby moving the turnout from one position (status) to the

other.

Use only turnout drives with limit stop contacts to prevent the

motor from burning through, because the relay outputs of the

SwitchPilot Extension module are continuously active.

The wiring of the motorized turnout drive is shown in Fig. 11.

Please note the maximum supply voltage values specified in the

instructions for your drive. The Extension module always delivers

the full voltage that is provided to the SwitchPilot 3.

Figure 10: SwitchPilot with mounted SwitchPilot Extension

a) a) b) a) a)

a) a) b) a) a)

III

Com

Figure 11: Motorized point machine with SwitchPilot Extension

M

Wiring the outputs

15

5.6.4. Turnout frog polarization

Mit dem SwitchPilot Exension Modul können sehr einfach Wei-

chen-Herzstücke polarisiert werden.

Wiring the outputs

5.6.3. LGB® Turnout drive

The wiring is as shown in Fig. 12. Unless reprogrammed, the mo-

tors are supplied with electricity for approx. 520 msec and are then

switched off to prevent overheating of the drive.

Figure 12: LGB®Turnout drive Figure 13: Polarization with SwitchPilot Extension

16

Each SwitchPilot 3 can be assigned such a 4-series group: this is

the so-called accessory address.

The accessory address is stored internally in CV 1 and CV 9. The

calculation of the turnout numbers from the values saved in the

two CVs is regulated in the RCN-213 standard.

The table in chapter 16 lists turnout numbers and corresponding

accessory addresses. Only the first 256 turnouts are available

when operating with Motorola® central units.

It is not possible to assign turnout numbers outside the group-of-4

limits to a SwitchPilot 3. For example. it would not be possible to

assign turnout numbers 4, 5, 6 and 7, as these go beyond the limit

of the accessory address groups. Please keep this in mind when

assigning turnout numbers.

Due to a weakness in the DCC standard prior to the creation of

the RCN-213, some command stations (especially ROCO® Multi-

maus or Z21) calculate the turnout numbers differently. In this case

please take note of chapter 6.3.

Configuration with OLED

6. Configuration with OLED

The programming of accessory decoders was usually very cum-

bersome in the past. CV programming with the help of the hand-

held throttle often failed due to the missing programming modes

(e.g.: only very few command stations and/or throttles respectively

central units support „POM for accessory decoders”) or forgotten

addresses of decoders installed on the layout. Even assigning the

decoder address presented many model railway enthusiasts with

major obstacles. Reading the currently assigned decoder address is

also quite cumbersome and causes a lot of displeasure.

To avoid such problems, the SwitchPilot 3 is the first accessory

decoder on the market working with an innovative operating con-

cept. It consists of an illuminated multi-line OLED display and a

3-button input unit. This allows programming all (!) settings of

the SwitchPilot 3 in plain text directly on the decoder, without the

need of external programming devices or cumbersome CV pro-

gramming. In addition, the display shows the currently assigned

turnout numbers at any time and can even accurately display the

supply voltage (respectively track voltage). A screen saver prevents

the OLED display from burning in.

6.1. Relationship between accessory addresses and turnout

numbers

For addressing the outputs of the SwitchPilot 3 decoder with the

command station, so-called turnout numbers must be assigned to

them. The number of turnout numbers is limited and depends on

the digital system:

Motorola®: Turnout numbers 0001 bis 0256

DCC: Turnout numbers 0001 bis 2048

(ROCO command stations 0001 to 2040).

The turnout numbers are arranged into four groups. The first

group comprises turnout numbers 1,2,3,4, the second group the

turnout numbers 5,6,7,8, the third group the turnout numbers

9,10,11,12, and so forth.

17

Assigning turnout numbers

6.1.1. Assigning turnout numbers

Ex works, the 4 double outputs of the SwitchPilot 3 respond to

turnout numbers 0001 to 0004. The turnout numbers can be ea-

sily changed directly on the SwitchPilot 3.

a) Check whether the display shows the screen saver (lettering

„SP” and the supply voltage):

b) In this case, press the „PROG/OK” button only (!) briefly. Now

the SwitchPilot 3 should display its current turnout numbers

directly in plain text:

c) Press the „PROG/OK” button. The turnout numbers should

now flash (inverse).

d) Press the button (+) or (-) to select the desired turnout num-

bers. The currently selected turnout numbers are displayed

flashing.

e) Press the „PROG/OK” button again to confirm the turnout

numbers. The indicator no longer flashes.

Finished! Without programming or cumbersome handling on the

handheld throttle or command station.

SP»17.3V

ADDRESS

Switch 1-4: 0001-0004

ADDRESS

Switch 1-4: 0001-0004

ADDRESS

Switch 1-4: 0009-0012

18

OUTPUT1

Mode : AltFlash

Time : 1720 ms

Zoom : Disabled

Introduction to the operating structure

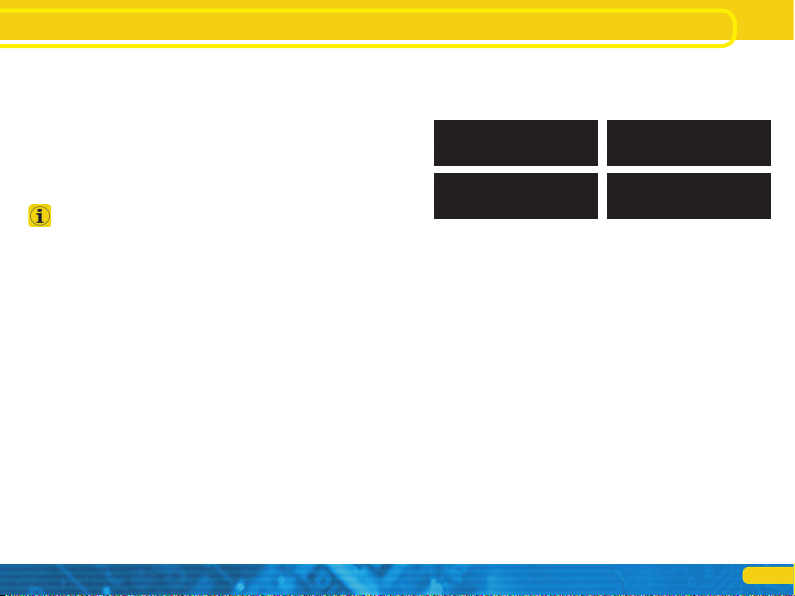

6.2. Introduction to the operating structure

The configuration with the aid of the OLED display and the 3-but-

ton input unit enables you to set all parameters of the SwitchPilot

3 decoder.

All properties are arranged in so-called „panels”. A panel fills in

all four lines of the display. The first line displays the name of the

panel, and rows two to four display a maximum of three different

setting options. With the help of the „+” and „-” buttons you can

scroll between the individual panels.

a) Name of the panel

b) Name of setting option 1

c) Value of the setting option 1

d) Name of setting option 2

e) Value of the setting option 2

f) Name of the setting option 3

g) Value of the setting option 3

Figure 14: Control elements of the SwitchPilot 3

ADDRESS

Switch 1-4: 0001-0004

ADDRESS

Switch 1-4: 0001-0004

ADDRESS MODE

Mode : RCN-213

OUTPUT STATE

1 2 3 4

CMD ........

PHY ........

OUTPUT1

Mode : Impulse

Time : 520 ms

Zoom : Disabled

a)

c)

a)

b)

d)

f)

e)

g)

OUTPUT1

Mode : Impulse

Time : 520 ms

Zoom : Disabled

PROG/OK

OUTPUT1

Mode : AltFlash

Time : 1720 ms

Zoom : Disabled

PROG/OK

OUTPUT1

Mode : AltFlash

Time : 1720ms

Zoom : Disabled

PROG/OK

PROG/OK

19

•If you want to change a setting option of the currently selected

panel, press the PROG/OK button once. The setting option 1 of

the screen will now flash as a sign that it can be changed.

•For changing the respective setting

use the (+) and (-) buttons. Press the button until the display shows

the desired value. The decoder immediately applies the changes so

you can see immediately what is happening.

•Confirm your entry with PROG/OK. After that, the next setting

option will flash as a sign that it can now be changed.

If you do not want to change a setting option, but only want to

proceed to the next one, just press the PROG/OK button. Then

the current value is not changed.

•After you have changed the last of the three setting options re-

spectively confirmed them by pressing PROG/OK, nothing will

flash. You are now back in the display mode of the panel and can

now either make changes to other setting options of the panel

by pressing PROG/OK again or select another panel with the (+)

and (-) buttons.

For a list of all possible panels and their setting options, see Chap-

ter 15.

6.3. Address mode for ROCO® command stations

As already mentioned in Chapter 6.1, ROCO® command stations

(specially the multiMaus, but also the Z21 in the standard setting)

use a different computation method to calculate the turnout num-

bers from the accessory addresses. Set the decoder to “ROCO” to

ensure that the SwitchPilot 3 handles instructions from ROCO®

command stations correctly.

To do this, select „Mode” in the „ADDRESS MODE” panel, and

then select the calculation method „ROCO”.

Introduction to the operating structure

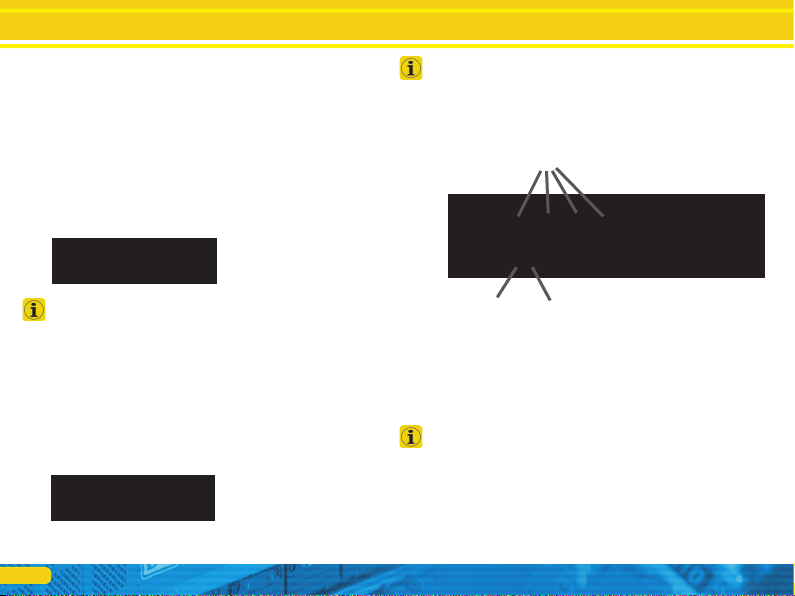

6.4. Configuring outputs

Each output can be configured individually. For this purpose, the

panels „OUTPUT 1” to „OUTPUT 4” are provided.

You can use the “Mode” option to set the desired output mode:

•“Pulse” configures pulse operation according to chapter 4.4.1.

•“PECO” configures PECO operating mode according to chapter

4.4.2.

•“K83” configures momentary action mode according to chapter

4.4.3.

•“K84” configures bistable continuous operation according to

chapter 4.4.4.

•“Alt Flash” configures the alternating flasher operation according

to chapter 4.4.5.

The meaning of the „Time” option depends on the selected out-

put mode:

•In pulse mode, it is determined here how long the output remains

switched on.

•In alternating flasher mode, you specify how fast the two outputs

should flash.

•In all other modes, „Time” has no meaning and cannot be chan-

ged respectively is set to „Permanent”.

OUTPUT1

Mode : Impulse

Time : 520 ms

Zoom : Disabled

OUTPUT2

Mode : PECO

Time : Permanent

Zoom : Disabled

OUTPUT3

Mode : K83

Time : Permanent

Zoom : Disabled

OUTPUT4

Mode : Alt-Flash

Time : 1170ms

Zoom : Enabled

20

Configuration

For particularly realistic fade-in and fade-out effects, you can add

a „zoom” function to each output, if so desired

•“Enabled” enables the pair to fade-in and fade-out

•“Disabled” turns off the fade-in and fade-out feature of the out-

put pair.

6.5. Setting fade-in and fade-out times

Here you can choose the time during which the outputs should

be dimmed up or down if the „Zoom” option is active at the cor-

responding output.

The time can be set from 0 msec to 4160 msec. The value „0

msec” turns off this feature for all outputs.

Do not choose exceedingly long durations. Especially in alternating

flasher mode, you should make sure that the flashing frequency is

selected significantly longer than the fade-in and fade-out times.

6.6. Status information

The SwitchPilot 3 can display extensive status and diagnostic in-

formation, which can be particularly helpful, especially for wiring

and troubleshooting.

6.6.1. Display software version & track voltage

The „Information” panel displays both the hardware („HW”) as

well as the software („SW”) version of the decoder. The supply

voltage („Voltage”) of the outputs is also displayed.

FADEIN & FADEOUT

Time : 260ms

If the SwitchPilot 3 is powered directly by the command station,

„Voltage” displays the digital track voltage, otherwise the voltage

of the connected power supply.

6.6.2. Displaying output states

Important information about the output state is provided by the

„Output State” panel

a) Number of the output

b) Output terminal „Out A” active

c) Output terminal „Out B” active

The PHY line indicates for each output 1 to 4 whether it is current-

ly active. As soon as the state changes (e.g.: when an alternate

flasher is active or because an output is switched off by the timer),

this is displayed in real time.

If the fade-in and fade-out feature is active for an output, the

output is immediately displayed as active, even if it is still fading-

in or -out.

The line CMD shows the latest command received for each output

1 to 4: A bar to the left directly below the number indicates that

the command „Red” was received from the command station, a

bar to the right of it indicates that the last command was „Green”.

If no valid command has been detected, only dots are displayed.

The SwitchPilot 3 saves the most recently detected commands so

that the last operating state is restored after a power interruption.

INFORMATION

HW : 3.0

FW : 3.0.9

Voltage : 17.3V

OUTPUT STATE

1 2 3 4

CMD .».»»..»

PHY .».....»

a)

b) c)

Table of contents

Other Esu Media Converter manuals

Esu

Esu LokPilot Standard User manual

Esu

Esu SwitchPilot User manual

Esu

Esu LokPilot V3.0 User manual

Esu

Esu LokPilot 52600 User manual

Esu

Esu L.Net converter User manual

Esu

Esu LokSound 5 DCC User manual

Esu

Esu LokSound micro V4.0 User manual

Esu

Esu SwitchPilot 3 User manual

Esu

Esu 51801 User manual

Esu

Esu SignalPilot 51840 User manual