3

7.2.2. Motorola® mode.....................................................26

7.2.2.1. 28 Speed Steps.....................................................26

7.2.2.2. Extended Motorola® address range......................26

7.2.3. Selectrix® mode ......................................................27

7.2.4. M4 mode.................................................................27

7.3. Analogue mode..........................................................27

7.3.1. Analogue DC operation ...........................................27

7.3.2. Analogue AC operation ...........................................28

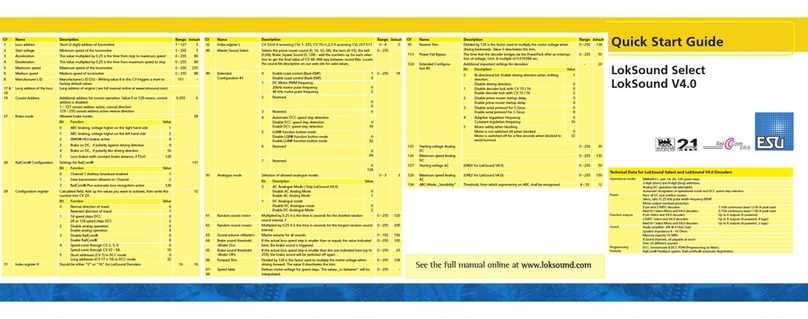

8. Decoder Settings (Programming) ........................ 28

8.1. Adjustable Properties of Decoders ..............................28

8.1.1. M4 configuration range...........................................29

8.1.2. M4, the mfx® compatible protocol by ESU ..............29

8.1.1. Configuration Variables (CVs) ..................................30

8.1.1.1. Standardisation in the NMRA................................30

8.1.1.2. Bits and Bytes .......................................................30

8.2. Programming with popular digital systems..................30

8.2.1. Programming with DCC Systems .............................31

8.2.2. Programming with the ESU ECoS.............................31

8.2.3. Programming with Märklin® 6021 ..........................31

8.2.3.1. Changing to the Programming Mode ...................32

8.2.3.2. Short Mode ..........................................................32

8.2.3.3. Long Mode...........................................................32

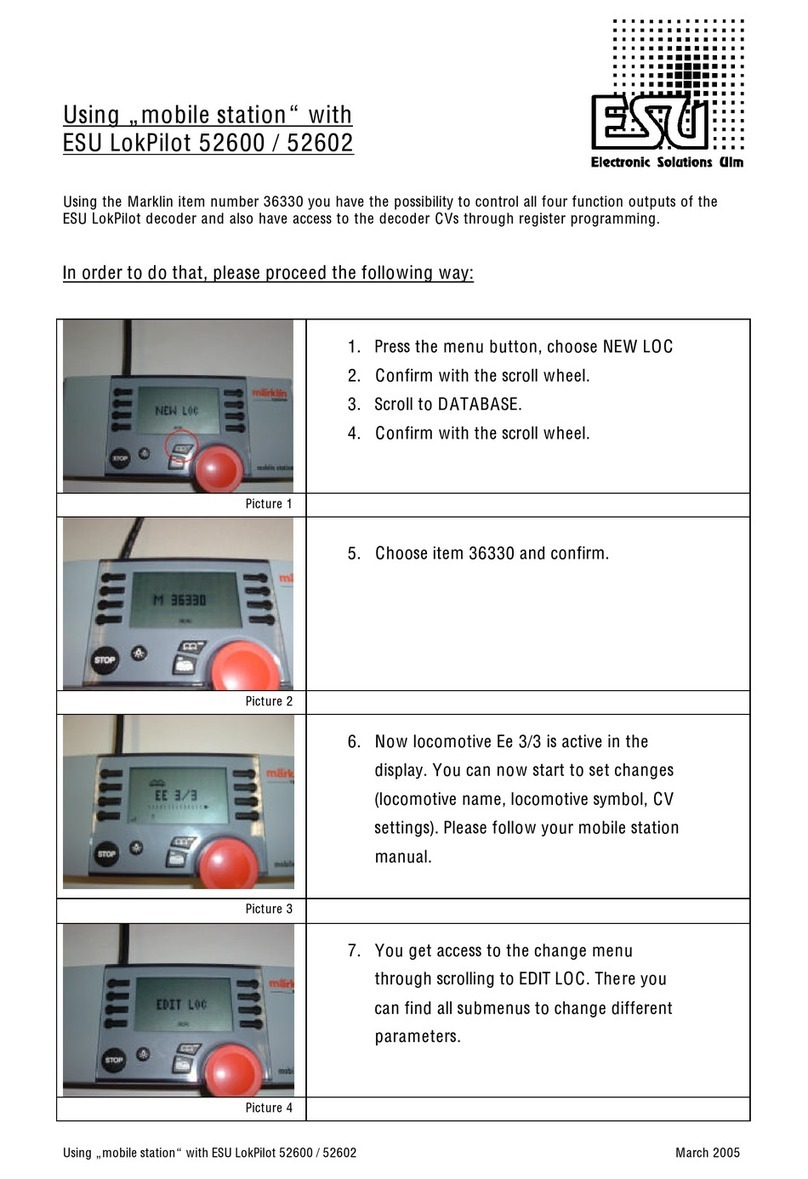

8.2.4. Programming with the Märklin® Mobile Station®...33

8.2.5. Programming with the Märklin® Central Station .....33

8.2.6. Programming with the ESU LokProgrammer ............34

8.2.7. Programming with the ROCO® Multimaus ............34

8.2.8. Programming with the ROCO® LokMaus II..............35

9. Address Settings .................................................... 36

9.1. Short Addresses in DCC mode ....................................36

9.2. Long Addresses in DCC mode.....................................36

9.3. Motorola® address.....................................................36

9.3.1. Consecutive addresses for more functions ...............36

9.4. Addresses in M4 mode ...............................................37

9.5. Turning off data protocols not needed........................37

10. Adapting the Driving Characteristics ................. 38

10.1. Acceleration and deceleration...................................38

10.1.1. Switching acceleration / deceleration .....................38

10.1.2. Shunting mode......................................................38

10.2. Starting Voltage, Maximum and Medium Speed .......38

10.3. Speed Curve ............................................................39

10.4. Changing between operating modes .......................39

10.4.1. Changing from Digital to Analogue DC ................39

10.4.2. Changing from Digital to Analogue AC ................40

10.4.3. Changing from Analogue to Digital (Directional Bit) 40

10.4.4. Changing from Digital to Digital ...........................40

10.4.5. Changing modes with analogue mode turned off. . 40

10.5. Brake sectors ............................................................41

10.5.1. DC brake mode .....................................................41

10.5.2. Märklin® brake mode............................................41

10.5.3. Selectrix® Diode Brake Sector................................41

10.5.4. Lenz® ABC brake mode ........................................41

10.5.4.1. ABC “slow approach” section ............................42

10.5.4.2. ABC detection threshold.....................................42

10.6. Constant brake distance ..........................................42

10.6.1. Linear braking distance ..........................................43

10.6.2. Constant Linear Braking Distance...........................43

10.6.3. Push-pull trains ......................................................43

10.6.4. Braking at speed step 0..........................................43

10.7. Settings for analogue operation................................43

10.7.1. DC analogue operation..........................................43

10.7.2. AC analogue operation..........................................44

10.8. Motor brake .............................................................44

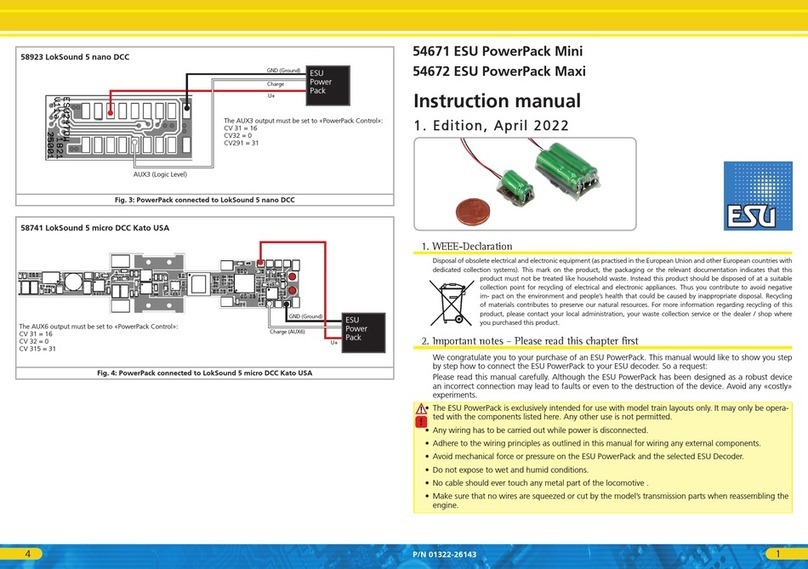

10.9. Configure the PowerPack „Switch off“ time .............44

11. Motor Control ...................................................... 45

11.1. Adjusting load compensation....................................45

11.1.1. Parameter for frequently used motors....................45

11.1.2. Adjustments for other motors / „Fine Tuning“ .......45

11.1.2.1. Parameter „K“....................................................45

11.1.2.2. Parameter „I“ .....................................................45

11.1.2.3. Reference voltage ...............................................46

11.1.2.4. Parameter “K slow”............................................46

11.1.2.5. Parameter „I slow“ .............................................46

Content