Esu LokPilot Standard User manual

www.esu.eu

LokPilot Standard

ESU P/N 02714-14649

P Reliable, Dual Mode DCC / DC decoder with B-EMF function

P Four powered function outputs (+2 logic level outputs for 21MTC version)

P RailComPlus® for automatic Registration at ESU ECoS command station

P For all engines equipped with DC- or coreless motors

ESU LLC

477 Knopp Drive

Muncy Pennsylvania 17756

USA

ESU GmbH & Co. KG

Edisonallee 29

D - 89231 Neu-Ulm

GERMANY

53611 LokPilot Standard

Digital Decoder

NMRA 8 pin wire harness

DCC & RailComPlus 4AOEGOP*fdgbbh+

MADE IN CHINA

Specification

Operational

modes

NMRA/DCC with 14, 28, 128 speed steps.

2-digit (short) and 4-digit (long) addresses.

Analog DC operation (de-selectable).

Automatic recognition of operational mode and DCC speed step selection.

Supports Lenz® LG 100 braking sections.

Throttle Runs DC and coreless motors.

0,9 A continuous load. Silent, safe 20,00 kHz pulse width frequency motor regulation.

Motor output overload protection; Back EMF (de-selectable).

Function outputs 4 powered outputs with overload protection.

250mA load per output.

500mA total load of all function outputs.

21MTC connector version has two additional logic outputs.

Shunting speed and momentum key selectable.

Programming DCC Servicemode & DCC POM (Programming on Main).

Features RailCom® Feedback system. RailComPlus® automatic Registration.

Interface NEM652 (8 pin) 21MTC PluX12

dimensions in mm

dimensions

25,5x 15,5 x4,5

1.00x 0.61 x0.18

25,5x 15,5 x4,5

1.00x 0.61 x0.18

14,5x 8,3 x2,4

0.57x 0.33 x0.09

Item- Number 53611 53614 53616

This product is not a toy. Not recommended for children under 14 years of age.

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

Warnings

•Do not expose to wet and humid conditions and

Avoid mechanical force or pressure on the decoder

•Do not remove the heat shrink sleeve.

•Never solder on the circuit board, extend cables if

necessary.

•Never wrap the decoder in insulation tape, since this

may cause overheating.

•Any wiring has to be carried out while power is dis-

connected.

•Make sure that neither the decoder nor any blank

wire ends may come into contact with the engine

chassis (risk of short circuit).

•Never operate the LokPilot unattended. The LokPi-

lot is not a (children’s) toy

Requirements for Installation

The locomotive must be in perfect operating condi-

tion prior to the conversion: Only a locomotive with

faultless mechanical properties and smooth running

characteristics in analogue mode is worth converting

to digital. Check and replace all wear and tear parts

such as motor brushes, wheel contacts, light bulbs

etc., if necessary.

Installing the Decoder

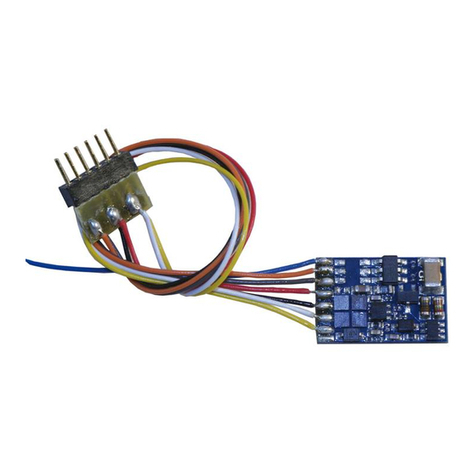

Locomotives with 8-pin NEM 652 interface

Some LokPilot Standard decoders are supplied with

an 8-pin interface as per NEM 652 (refer to Fig 1).

Remove the dummy plug from the socket and keep

it for later use. Insert the plug of the decoder in such

a way that pin 1 of the plug (this is the side with

the red / orange wires) sits next to the corner of the

socketthatisusuallymarkedwith*,+,•.Makesure

that the pins are straight and do not tilt when inser-

ting the plug.

Abb. 1: LokPilot Standard with NEM652 interface

AUX2 --

Right motor terminal --

Right track terminal --

Rear light --

Common (+pole) --

AUX1 --

Head light --

Left track terminal --

Left motor terminal --

Pin Description Color

1 Right motor terminal orange

2 Rear light yellow

3 Output AUX1 green

4 Left track terminal black

5 Left motor terminal gray

6 Head light white

7 Common (+pole) blue

8 Right track terminal red

5 4

1

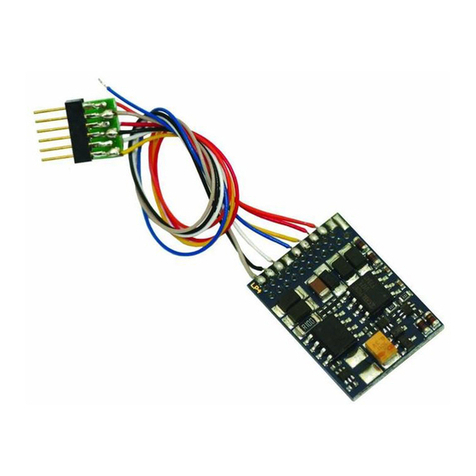

Abb. 2: LokPilot Standard with 21MTC interface

n.c. 1

n.c. 2

n.c. 3

AUX4 4

n.c. 5

n.c. 6

Rear light 7

Head light 8

n.c. 9

n.c. 10

Index pin 11

22 Right track

21 Left track

20 GND

19 Right motor

18 Left motor

17 n.c.

16 Common (+)

15 AUX1

14 AUX2

13 AUX3

12 VCC

How to connect the decoder: Insert the decoder with

connector towards top

(e.g. Atlas, Intermoun-

tain, Bowser, Märklin®)

Insert the decoder with

connector towards

bottom (e.g. Brawa®)

Locomotive PCB

(Side view)

Locomotive PCB

(Side view)

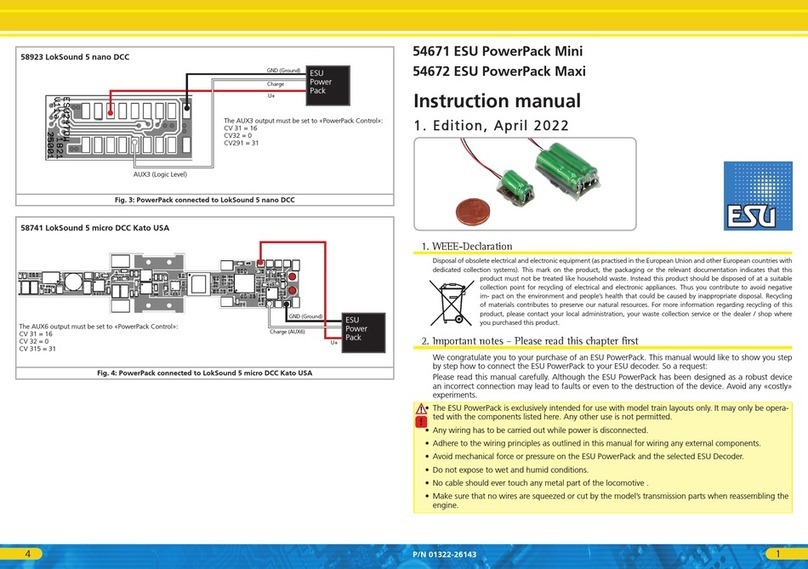

Locomotives with PluX12 interface

The LokPilot Standard supplied with a PluX12 inter-

face (fig. 3) ist designed for locomotives in gauge TT.

Decoders fitted with PluX12 connector also will fit

into locomotives with PluX16 or PluX22 interface.

Consider the correct seating of the decoder: One

position of the multi-pin plug of the decoder has no

pin (index pin). This position should be marked in the

locomotive.

Abb. 3: LokPilot Standard with PluX12 interface

Head light 7

Common (+) 9

Index pin 11

Rear light 13

- 15

- 17

8 Motor +

10 Motor -

12 Right track

14 Left track

16 AUX1

18 AUX2

Locomotives without interface

Firstly, please cut all wires installed in the locomotive.

Take special care to remove any connections to the

chassis (ground): the motor leads must be positively

potential-free, in other words they may not have any

contact to the chassis or body or the wheels and

wheel contacts. Figure 4 shows all connections.

Function outputs

You can wire all kind of load to the function outputs.

Please make sure that the load does not exceed

the permitted maximum current and there are no

short circuits. The outputs of the LokPilot have pro-

tection but if an external voltage is applied, the

outputs may suffer damage or destruction.

Only install bulbs rated 16V or higher and with a no-

minal current draw, that does not exceed 50 mA or

use suitable smoke generators such as Seuthe No.

11. If you like to use LEDs, a resistor with a rating

between 470 Ohms and 2.2 kOhms need to be wi-

red in series. Running the LED without resistor will

lead to their immediate destruction!

Only the decoders with 21MTC interface have two

additional outputs besides the 4 standard outputs,

namely AUX3 and AUX4. Since they are pure „logic-

outputs“, it is not possible to connect any external

loads directly. External power transistors are requi-

red. Connect AUX3 and AUX4 via the 21MTC inter-

face; there are equal to the other outputs. ESU offers

an appropriate adapater board (art.no. 51968) with

transistors.

Locomotives with 21MTC interface

Some LokPilot Standard decoders are equipped with

an 21MTC interface (fig. 2) You can insert the deco-

der in two ways: either the pins are put through the

decoder; the socket of the decoder remains visible

after installation (mounting on top) or the decoder

is inserted in such a way that the pins go straight

into the socket. Once the decoder sits in the socket,

the socket is hidden from view. Which of the two

mounting positions is the correct one depends solely

on the locomotive. The position of the marker-pin is

the crucial indicator. Plug the decoder into the socket

in such a way that the locomotive interface corre-

sponds with the decoder. Do not apply too much

pressure when inserting the plug. The decoder must

go in without force.

DCC Operation

The LokPilot Standard works with any DCC system..

Remove any capacitors that are wired into the track

feeders (e.g. ROCO® feeder track). This could impair

the functionality of the decoder.

The address is set to 03 with 28 speed steps.

F1 switches output AUX1

F2 switches output AUX2

F3 switches the switching mode on and off

F4 switches the acceleration an deceleration on /off

F5 switches output AUX3 (if applicable)

F6 switches output AUX4 (if applicable)

DC Operation

The LokPilot Standard are set ex factory to operate

on conventional DC layouts as well. No settings are

needed to be done.

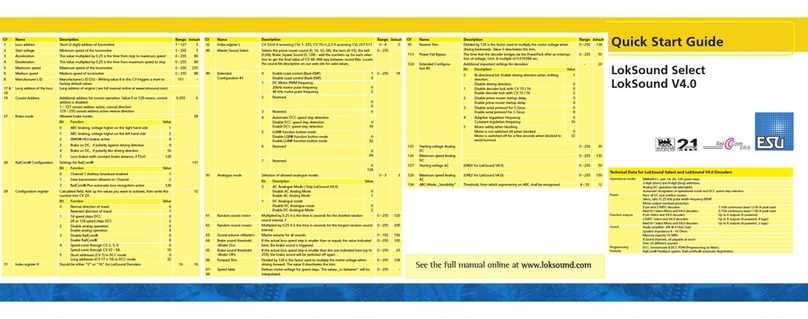

Decoder Settings (Programming)

A list of all CV parameters ist given later. These can

be changes using any DCC command station. LokPi-

lot decoders support all NMRA programming modes

as there are the programming track modes (Direct

Mode, Register Mode, Paged Mode) and the mode

for the main („POM“, „Programming on the Main“).

With RailCom® you can read CV values on the main.

RailComPlus®

Using RailComPlus®, the decoder will be automa-

itcelly recognized by a compatible command station.

You can disable this feature by deleting Bit 7 of CV

28.

Function Outputs

Each function output can be set to a certain effect.

For each physical output one CV (CV113 - CV118,

refer table page 4) is provided to define both their

behaviour (Mode) and the brightness. Please write

the following values into the corresponding CVs to

enable the following effects:

Name Description Brighness Mode

Light Normal light 0- 15 + 0

Blink light

Phase I

Output is blinking with

defined frequency

0- 15 + 16

Blink light

Phase II

like above, but the light is

blinking alternating

0- 15 + 32

Strobe Strobe light 0- 15 + 48

firebox Flickering light of a fire box

or braking lights

0- 15 + 80

Zoom Light that fades in / out 0- 15 + 112

Marslight Mars light 0- 15 + 128

Gyra light Gyra light 0- 15 + 144

Ditch light Ditch light phase I 0- 15 + 208

Ditch light Ditch light phase II 0- 15 + 244

Flash rate for blinking lights

You can also set the flash rate for all lighting effects

globally. All effects will flash or strobe at the same

rate. The desired value should be stored in CV 112.

Function Mapping

All function outputs may be assigned to the available

function buttons. Your dcc throttle may not have all

function button. Each function button is linked to a

CV in which any number of events ma be combined.

The number you enter defines the behaviour of the

output. Some functions are directional. For F0 For-

ward, it is CV33, for F0 Reverse it is CV34 and so on.

Example: Writing the value 8 into CV36 defines that

output AUX2 will listen to Function Button F2.

The following table shows the different possible

combinations and also the ex-factory settings (hown

in bold numbers):

CV Funktion LV LR AUX

1

AUX

2

AUX

3

AUX

4

Shun-

ting Acc/Dec

33 F0 Forward 124816 32 64 128

34 F0 Reverse 124 8 16 32 64 128

35 F1 Forward 1 2 4816 32 64 128

36 F2 124816 32 64 128

37 F3 1 2 4 8 16 32 64 128

38 F4 Forward 1 2 4 8 16 32 64 128

39 F5 Forward 1 2 4 8 16 32 64 128

40 F6 Forward 1 2 4 8 16 32 64 128

41 F7 Forward 1 2 4 8 16 32 64 128

42 F8 1 2 4 8 16 32 64 128

43 F9 1 2 4 8 16 32 64 128

44 F10 1 2 4 8 16 32 64 128

45 F11 1 2 4 8 16 32 64 128

46 F12 1 2 4 8 16 32 64 128

47 F1 Reverse 1 2 4816 32 64 128

129 F13 1 2 4 8 16 32 64 128

130 F14 1 2 4 8 16 32 64 128

131 F15 1 2 4 8 16 32 64 128

132 F16 1 2 4 8 16 32 64 128

133 F17 1 2 4 8 16 32 64 128

134 F18 1 2 4 8 16 32 64 128

135 F4 Reverse 1 2 4 8 16 32 64 128

136 F5 Reverse 1 2 4 8 16 32 64 128

137 F6 Reverse 1 2 4 8 16 32 64 128

138 F7 Reverse 1 2 4 8 16 32 64 128

Refering to the table, locate the intersection of

•The row of the desired function button and

•The column for the desired function output.

There you can find the value that you have to enter

into the appropriate CV. If one function button has

to control more outputs, simply add the numbers

and write the result into the CV (33 - 138).

Abb. 4: Wiring diagram for LokPilot Standard (wiring example)

violet

orange

red

yellow

blue

green

white

black

grey

R

housing

violet

AUX2

green

AUX1

yellow

Rear

light

white

Head

light

black orange grey

CV 8 Function Description

90 Normal default Refer to table page 3

91 Tillig Diesel- and

Electric engines

F0 = Front white / Rear Red

directional

F1 = No Rear Red lights,

directional

F2 = Switching light

92 Tillig Diesel- und E-

Loks mit Fernlicht

F0 = Front white / Rear Red,

directional

F1 = Additional High beam light

F2 = No Rear Red lights,

directional

F3 = Switching light

(but no High beam lights)

CV Name Description Range Value

1Locomotive address Adress of engine 1 - 127 3

2Start voltage Sets the minimum speed of the engine 1 - 64 3

3Accceleration This value multiplied by 0.25 is the time from stop to maximum speed 0 - 255 16

4Deceleration This value multiplied by 0.25 is the time from maximum speed to stop 0 - 255 12

5Maximum speed Maximum speed of the engine 0 - 64 64

6Medium speed Medium speed of the engine 0 - 64 22

8Manufacturer ID Manufacturer´s ID ESU - Writing value 8 in this CV triggers a reset 151 -

17/ 18 Extended address Long address of the engine 128- 9999 192

19 Consist Address Additional address for consist operation. Value 0 or 128 disables the

consist address

1 – 127 Consist address, normal direction

129 – 255 Consist address, reverse direction

0-255 0

27 Brake mode Allowed brake modes 24

Bit Function Value

3Brake on DC, if polarity against driving direction 8

4Brake on DC, if polarity like driving direction 16

28 RailCom® Configuration Settings for RailCom® (Set value to 0 to disable an option) 131

Bit Function Value

0Channel 1 Broadcast enabled 1

1Data transmission allowed on channel 2 2

7RailComPlus® automatic loco recognition enabled 128

29 Configuration register This CV contains important information to setup your decoder 12

Bit Function Value

0Reverse Direction of travel 1

128 or 128 speed steps instead of 14 speed steps 2

2Enable analogue operation 4

3Enable RailCom® 8

4Speed curve through CV 67 - 94 (instead of CV 2,5,6) 16

5Long addresses (CV 17+18) instead basic address (CV 1) 32

33-47 Function mapping Assignment of function outputs to the function buttons. Part #1 0 - 255 -

49 Extended Configuration Further settings of the decoder (set value to 0 to disable an option) 0 - 255 17

Bit Function Value

0Enable B-EMF function 1

4Enable automatic DCC speed step detection 16

53 Control Reference

voltage

Defines the Back EMF voltage, which the motor should generate at

maximum speed. If the engine does not reach maximum speed, reduce

this parameter.

0 - 255 140

54 Load control parameter

«K»

«K»-component of the internal PI-controller. Defines the effect of load

control. The higher the value, the stronger the effect of Back EMF

0 - 255 50

55 Load control parameter

«I»

«I»-component of the internal PI-controller. Defines the momentum

(inertia) of the motor. The higher the momentum of the motor (large

flywheel or bigger motor diameter), the higher this value has to be set.

0 - 255 100

67-94 Speed table Defines motor voltage for speed steps. 0 - 255 -

112 Blinking frequency Blinking frequency for light effects. A multiple of 0.065536 Seconds. 1 - 255 16

113 Head light configuration Defines brightness and mode of output Head light 0 - 255 15

114 Rear light configuration Defines brightness and mode of output Rear light 0 - 255 15

115 AUX1 configuration Defines brightness and mode of output AUX1 0 - 255 15

116 AUX2 configuration Defines brightness and mode of output AUX2 0 - 255 15

117 AUX3 (21MTC) config. Defines brightness and mode of output AUX3 (21MTC only) 0 - 255 15

118 AUX4 (21MTC) config. Defines brightness and mode of output AUX4 (21MTC only) 0 - 255 15

129-

136

Function mapping Assignment of function outputs to the function buttons. Part #2 0 - 255 -

Decoder Reset

You can reset the decoder to the default settings

at any time.

Enter the value 08 into CV 08.

Function outputs for Tillig locomotives

There are specific default settings for the function

mapping stored in the decoder in order to make the

usage easier for some Tillig TT scale engines. To ena-

ble them, you need to write a certain value into CV

8. The following settins do exist:

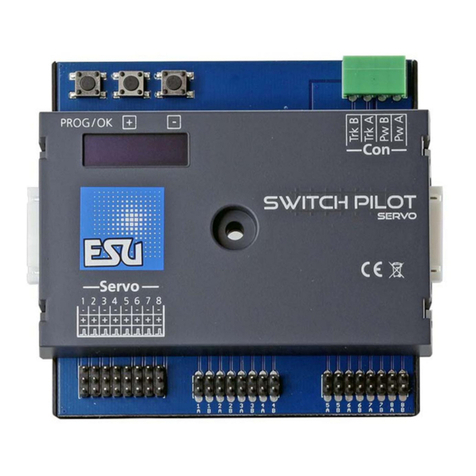

Other Esu Media Converter manuals

Esu

Esu PowerPack Mini User manual

Esu

Esu LokPilot V4.0 User manual

Esu

Esu SwitchPilot 3 User manual

Esu

Esu 51801 User manual

Esu

Esu SwitchPilot User manual

Esu

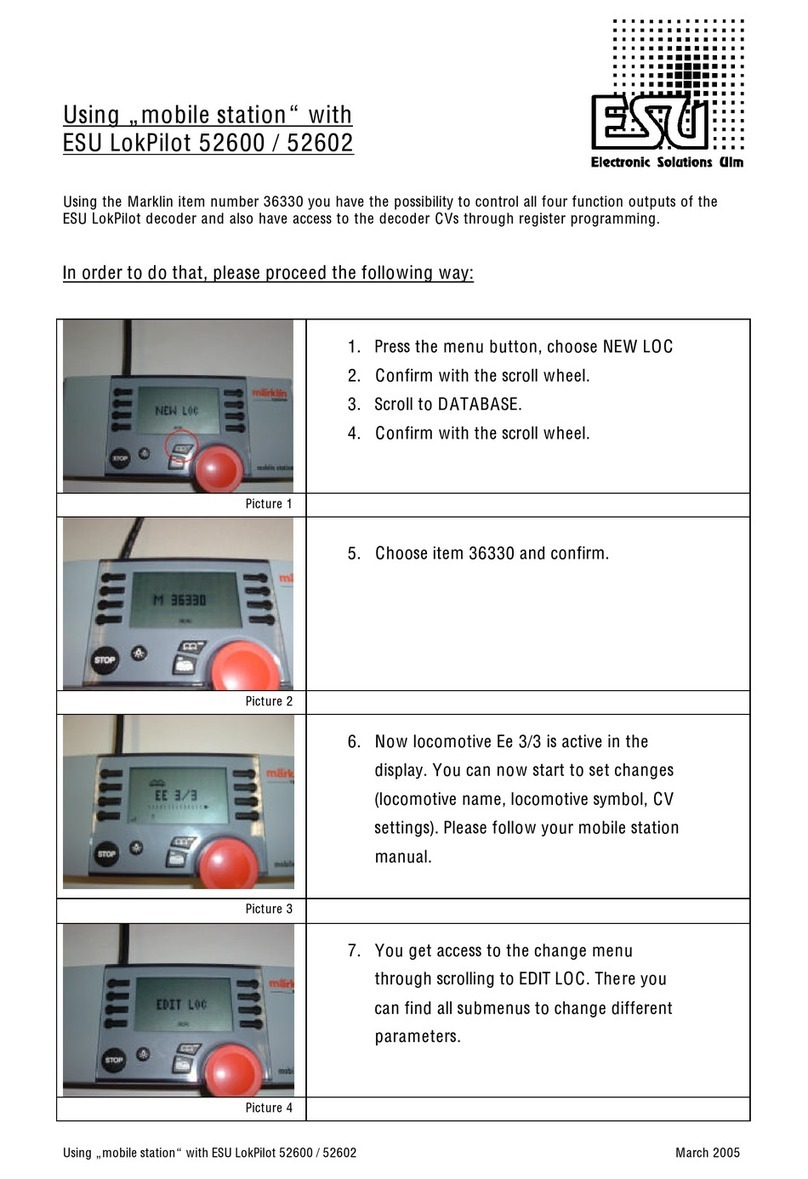

Esu LokPilot 52600 User manual

Esu

Esu LokPilot mfx User manual

Esu

Esu L.Net converter User manual

Esu

Esu LokSound 5 User manual

Esu

Esu LokSound User manual